In-situ conversion processing (ICP) of shale oil underground at the depth ranging from 300 m to 3 000 m is a physical and chemical process caused by using horizontal drilling and electric heating technology, which converts heavy oil, bitumen and various organic matter into light oil and gas in a large scale, which can be called “underground refinery”. ICP has several advantages as in CO2 capture, recoverable resource potential and the quality of hydrocarbon output. Based on the geothermal evolution mechanism of organic materials established by Tissot et al., this study reveals that in the nonmarine organic-rich shale sequence, the amount of liquid hydrocarbon maintaining in the shale is as high as 25% in the liquid hydrocarbon window stage (Ro less than 1.0%), and the unconverted organic materials (low mature-immature organic materials) in the shale interval can reach 40% to 100%. The conditions of organic-rich shale suitable for underground in-situ conversion of shale oil should be satisfied in the following aspects, TOC higher than 6%, Ro ranging between 0.5% and 1%, concentrated thickness of organic-rich shale greater than 15 meters, burial depth less than 3 000 m, covering area bigger than 50 km2, good sealing condition in both up- and down-contacting sequences and water content smaller than 5%, etc. The shale oil resource in China’s onshore region is huge. It is estimated with this paper that the technical recoverable resource reaches 70-90 billion tons of oil and 60-65 trillion cubic meters of gas. The ICP of shale oil underground is believed to be a fairway to find big oil in the source kitchen in the near future. And it is also believed to be a milestone to keep China long-term stability of oil and gas sufficient supply by putting ICP of shale oil underground into real practice in the future.

Based on the mechanism of hydrocarbon generation and expulsion as well as existing laboratory data, the authors and the research team propose the connotation, applicable conditions, resource potential, and future development prospects of underground in-situ conversion of shale oil. This paper points out that the potential of lucastrine shale oil resources in China is gigantic. The in-situ conversion of shale oil will exert milestone significance for maintaining long-term stability and even make leaping development of China's oil industry once pilot tests are conducted on careful selected target areas and breakthroughs in the industrial exploitation are made.

The security situation of China’ s oil supply is grim, with the discovery of quality oil reserves and the maintenance of stable production both facing challenges: (1) As the proven degree of oil resources in major oil-bearing basins of China keeps increasing, it becomes more challenging to find large reserves with great profits. In the meanwhile, the quality of newly added proven oil reserves is decreasing, with low- and extra-low permeability and tight oil reserves accounting for 65% of the total oil reserves, and low- and extra-low-abundance reserves accounting for 70%[1]. (2) The main oilfields in China face great challenges to maintain stable productions. As water cut increases year by year, the annual comprehensive declining rate reaches 5% to 6%, and the new production capacity can hardly make up for the decline in the output of old oil fields. (3) In the context of medium and low oil prices, the profitability of oil companies remain declining, the break- even oil price becomes higher, and the pressure for efficient production increases. In 2017, the national oil output was 1.92× 108t and the dependence on foreign oil reached 67.4%. Searching for the replacement of petroleum resources to ensure the stability and even enhancement of oil production and thus reducing the dependence on foreign oil has become an urgent need to ensure national energy security.

The innovation of key technologies in the field of engineering technology has enhanced the possibility and reliability of effective development and utilization of unconventional oil and gas resources. The “ shale gas revolution” mainly relied on horizontal wells and stimulated reservoir volume (SRV) fracturing technologies to break down the underground shale gas-bearing formations, thereby establishing numerous seepage channels and thus increasing the output of single wells and realizing the commercial development and utilization of shale gas. The shale gas commercial development and utilization technologies were copied to the development of tight oil, realizing the large-scale development and utilization of tight oil resources. The United States leading “ shale oil and gas revolution” has changed the global energy supply map and also made a major impact on the global geopolitical setup[2, 3, 4, 5, 6, 7]. The horizontal well SRV fracturing technology has basically solved the problems of the large-scale development and utilization of retained hydrocarbon resources in unconventional shale formations at mature to post-mature stages (with Ro of 1.0% to 2.9%). However, pertinent key technologies are still urgently required to develop for the effective development of petroleum resources in shale with low-medium maturity, mainly un-expelled liquid hydrocarbons and unconverted organic matter (these are collectively referred to as shale oil). The in-situ conversion of shale oil is the most promising replacement resource. According to the global shale database, PetroChina Research Institute of Petroleum Exploration and Development estimated that the global technologically recoverable resources of shale oil were about 1.4× 1012 t, nearly 3 times the total conventional oil resources. Relying on the innovations in drilling and recovery technologies, the “ shale oil revolution” in mid-to-low mature shales will be a new revolution in the oil and gas industry, not out of reach but worth expecting.

The development of shale oil in China has roughly gone through three stages. The first is the concurrent prospecting stage of “ conventional oil” in fractured shale reservoirs in the early period. Fractured shale oil reservoirs were discovered in hydrocarbon source formations before 2010, along with the broad scale exploration of oil and gas in Songliao Basin, Bohai Bay Basin, and Jianghan Basin. For example, Well Da 4 drilled in the Da’ an structure in the Jilin exploration area in the southern part of the Songliao Basin tapped an oil production of 2.66 t/d in the shale section of the Qingshankou Fm. Twenty four wells drilled in the Xinbei structure also obtained industrial oil flows with a cumulative production of more than 30 000 tons in the shales of the Qingshankou Fm., the Yaojia Fm., and the Nen 1 Member. Additionally, 6 wells such as the Well Ying 12 drilled in the Gulong Depression in the northern Daqing exploration area had attained industrial oil flows in the shale section of the Qingshankou Fm. However, as the overall reserves and production scale of fractured shale reservoirs were limited, petroleum resource evaluation was difficult to conduct and the progress of shale oil development was slow. The second stage is the main exploration stage of "tight oil" with SRV fracturing of vertical wells and horizontal wells. Inspired by the “ shale oil and gas revolution” , Changqing, Daqing, Shengli, Dagang, and other oilfields have continuously researched key technologies such as prediction and evaluation of “ sweet-spot area (segment)” , cost reduction and production improving technologies in drilling and well completion, development technologies for petroleum in porous interbeds of mature to high-mature shale and sandstone since 2010, and have made new progress in multiple strata. For example, Well Kongnan 9 and Guan 1608 drilled in the Cangdong Sag of the Bohai Bay Basin obtained high-yield industrial oil flows in the shale section of Member 2 of Kongdian Fm. Two recently completed horizontal wells (Guandong 1701H and Guandong 1702H) with great hydrocarbon show had a drilling rate of shale oil layer in the horizontal section of as high as 96%. Eight wells, including Well Ning 148 in the Ordos Basin tapped industrial oil flow from the shale section of the Upper Triassic Chang 7 Member, and 2 wells (including Well Songyeyou 1) drilled in the Gulong Sag of the Songliao Basin obtained industrial oil flow from the oil shale of the Qing I Member. In addition, 8 vertical wells and 4 horizontal wells in the Jiyang Depression had got industrial oil flow or good petroleum shows in the test production. The inter-salt shale section of the Qianjiang Fm. in the Jianghan Basin tested good oil and gas shows. Practically, the interbedded shale oil remain great resource potential, but problems still exist such as low single-well production and premature production stabilization technologies. The third stage is the exploration stage of “ artificial oil” based on in-situ heating conversion of oil shale. Oil shale refers to shale strata rich in liquid oil and unconverted organic matter at a buried depth of less than or equal to 300 m. The process of ground extraction of oil shale, commonly known as “ artificial oil” , already existed in the period of Japanese aggression against China in the 1940s. New explorations on the ground transformation of oil shale have been made recently. The exploration of in-situ conversion technology and on-site pilot tests have been carried out on the oil shale of the Qingshankou Fm. in the Songliao Basin since 2015. The lower-limit of total organic carbon (TOC) abundance required for in-situ conversion of oil shale has been determined through international cooperation, drilling core analysis and field tests. A small amount of artificial oil has been obtained in field tests by fracturing combustion, chemical retorting, critical water, and other methods. In addition, the PetroChina Research Institute of Petroleum Exploration and Development and Shell Oil Company have cooperated for several years in succession to perform potential and feasibility study on in-situ heating conversion of shale oil. The cooperation targets primarily on the organic-rich shale of the Chang 7 Member of the Upper Triassic Yanchang Fm. in the Ordos Basin with low to moderate maturity (Ro< 1.0%). Based on the analysis of sealed coring samples from two newly completed wells and core thermal simulation experiments, a test production scheme has been preliminarily designed and proposed. Hopefully, the technical test of in-situ conversion for oil shale will enter the implementation stage soon.

On the whole, many large international oil companies such as Shell, Exxon Mobil and Total have attached great importance to the development and utilization of oil shale resources. They have long been committed to the research and development and field tests of in-situ conversion technology for oil shale (Ro< 0.5%)[8]. At present, Shell’ s in-situ conversion process (ICP) is the most mature[9]. According to the connotations of in-situ conversion technology of various oil companies, horizontal wells with short well spacing (appr. 6-20 m), precise borehole trajectory controlling technology, heating pipe, automatic temperature controlling technology and heating modes are the cores of the in-situ conversion technology. Based on the statistical studies on more than 10 companies over the world, there are three main types of heating modes for in-situ conversion (Table 1).

| Table 1 Basic conditions of heating modes for in-situ conversion of oil shale. |

Shell has committed to the research and development (R& D) of oil shale in-situ heating conversion technology, with more than 20 years of history in indoor and field test. It has invested approximately $3 billion in R& D, and its ICP technology maturity has exceeded 80%. Technical problems such as heating technology and key equipment have basically been solved. To date, Shell has conducted field tests in 38 well groups in Colorado, Alberta, Jordan, and other regions by using their own technologies, which have basically fulfilled industrial application conditions. In particular, Shell succeeded in the pilot test of oil shale in-situ conversion in the South Mahogany test area of the Green River shale in the United States from 2003 to 2005. Vertical well patterns were used in this pilot test, and two production wells and 16 heating wells were designed. The vertical depth of the wells was 93 m and the thickness of the heating section was 38 m. The heating process was set as slow heating and the cumulative heating time was 15 months, with cumulative oil production of 256 t barrels, and the calibrated recovery rate of 62%. The field pilot test verified that the new heater manufacturing process was mature, the production process was proper, and the technology was feasible. The core equipment of shale oil in-situ conversion technology is the heating pipes. At present, foreign researchers have successfully developed ultra-long heating pipes with a length of more than 4 000 m and an average life cycle of more than 5 years. These pipes are able to maintain an underground constant temperature of 600-800 ° C. Compared with the early ground in-situ conversion technology, the present technology differs evidently in core technology, exploitation depth, oil production rate, investment return, and development and utilization potential. In addition, underground in-situ conversion technology has advantages in pollutant discharge control and surface environmental protection.

In China, we have also paid great importance to the development and utilization of oil shale and low-moderate mature shale oil resources. Research on in-situ conversion technology has also achieved new progress. (1) In 2005, Jilin Province cooperated with Shell and established a joint venture company to carry out the feasibility study on in-situ conversion process of oil shale, and drilled three oil shale wells in Shulan, Dunhua, Songyuan. However, drilling core analysis revealed that the oil saturation and net-formation ratio in oil shale layers in Jilin Province were below the lower limits for the in-situ conversion standards of Shell, so Shell eventually gave up the cooperation. (2) In 2014, Zhongcheng Company conducted a pilot test of “ in-situ conversion of oil shale and chemical distillation” on the shale of the Qingshankou Fm. in Fuyu-Changchunling of Jilin Province. The oil production was 5.20 tons at the initial stage of test and 8.86 tons during the middle stage of test. (3) In 2015, Jilin University cooperated with Israel to carry out an oil shale in-situ conversion pilot test based on near-critical water (NCW) method and produced a small amount of crude oil. (4) Since 2013, the PetroChina Research Institute of Petroleum Exploration and Development has cooperated with Shell to conduct basic research on the Permian shale of the Lucaogou Fm. in the Junggar Basin and the organic-rich shale of Chang 7 Member of the Yanchang Fm. in the Ordos Basin. After nearly 5 years of research, underground “ horizontal well electric heating upgrading” efficient conversion technology has been proposed on the basis of the original technology to develop and utilize the shale oil resources, according to the characteristics of China’ s continental moderate and low-mature organic-rich shale. The technology is applicable to shale oil enrichment areas with buried depth of 300 m to 3 000 m, and is expected to greatly expand the potential of the development and utilization of shale oil resources.

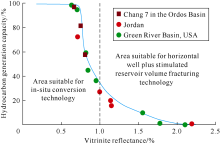

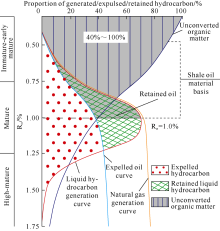

The resource potential of in-situ conversion of shale oil depends mainly on the hydrocarbon generation potential of the unconverted organic matter in the shale formation and the amount of retained hydrocarbons that have generated but not yet expelled. Obviously, the shale with low to moderate maturity and high organic abundance is the ideal object for in-situ conversion. Hydrocarbon generation modeling experiments of Type I and Type II organic matter of nonmarine shale shows (Fig. 1) that when Ro reaches 0.5%, the conversion potential of organic matter remains about 90% of the original hydrocarbon generation potential; when Ro reaches 1.0%, the proportion of conversion potential dramatically declines to about 35%, and the amount of retained hydrocarbon peaks, accounting for 25% of the total hydrocarbon generated. Therefore, in addition to the abundance of organic matter in shale, Ro is also a key factor affecting the in-situ conversion potential of shale oil. A comparative analysis shows that the potential for hydrocarbon generation and conversion of organic matter in shale decreases with the increase of Ro overall in China, the U.S. and Jordan (Fig. 2). With the increase of thermal evolution, the organic matter in shale is gradually converted into hydrocarbons, and the retained hydrocarbon volume shows a trend of initial increase followed by a later decrease. When Ro is in the range of 0.5% to1.0%, the amount of retained liquid hydrocarbons is maximum and the organic matter that has not yet been converted accounts for a relatively large proportion, rendering this stage the best maturity window of in-situ shale conversion. The proportion of liquid hydrocarbons retained in the shale in the window are as high as 25%, and that of unconverted organic matter is as high as 40% to 90% (Fig. 1).

| Fig. 1. Hydrocarbon generation/expulsion/retention model of shale (modified based on the Tissot model). |

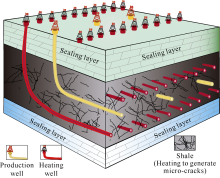

The existing research, experiment and on-site pilot tests show that in-situ heating is the best choice for the scale development and utilization of shale oil. The in-situ conversion of shale oil can be regarded as an “ underground refinery” . It is a physical and chemical process, in which the horizontal well electric heating upgrading technology is used to constantly heat the organic-rich shale intervals with the buried depth of 300 m to 3 000 m, converting various types of organic matter to light fractions. In the process, organic matter such as heavy oil and bitumen can be converted into light oil and natural gas extensively, and pollutants such as coke and CO2 will remain underground, which is beneficial to environmental protection. In theory, there are mainly two dynamic evolution processes to achieve the goals of hydrocarbon generation, supercharging, reservoir-forming, pressure maintenance and oil recovery enhancement in the heat injection with electric heater to the underground shale layer: (1) Heat accumulation, hydrocarbon generation and pressurization process. At the beginning of the heating phase, the temperature in the shale section slowly increases and the formation pressure increases correspondently because of thermal expansion. Light hydrocarbon gas and oil begin to be produced when the temperature continues to rise to a certain level (about 280 ° C) [10]. As the temperature further rises, the gas-oil ratio rises and the fluid flow capacity in the shale section increases significantly. The oil and gas flow production capacity is already achieved at this point. (2) Reservoir-forming, temperature and pressure keeping and mobility increase process. During the later period of heating, the temperature peaks (about 330 ° C)[10]. The shale section has undergone delamination due to thermal effect, and the book-like interlayer micro-cracks have been formed massively, allowing wide scale storage and transport of hydrocarbons (Fig. 3), and the gas-oil ratio further increases. The generated gas contains a large amount of C3S and C4S (excellent solvents), which combines with natural gas and light oil produced by high-temperature pyrolysis to reduce the viscosity and enhance the mobility of the liquid hydrocarbons. This way, the shale section is fully equipped with the ability to store oil and gas on a large scale and allow oil and gas to flow. The continuous heating enables a relatively constant temperature, continuous generation of oil and gas, and an increase in gas-oil ratio. In this way, the formation pressure can be maintained, and the oil and gas production process can continue until the hydrocarbon generation process is terminated. A very high recovery ratio can be achieved in the in-situ heating and conversion of the entire shale section.

Therefore, in-situ heating and conversion of shale oil can enable the shift from the “ ground refinery” model with high energy consumption and high pollution to high-quality clean “ underground refinery” model, to realize clean and efficient development and utilization of shale oil.

In-situ conversion of shale oil mainly has three technical advantages. First, the in-situ conversion process can enable the clean production of shale oil. With no hydraulic fracturing, no tailing waste, no air pollution and basically no groundwater pollution, and small land occupation, this technology can minimize the damage to the ecological environment caused by the recovery process. Second, in-situ conversion can enable a high recovery degree of oil and gas resources. During the in-situ conversion process, an overpressure fluid system and a micro-fracture system will be created, which will increase the seepage channel, driving force and high-efficiency discharge capacity of the shale formation, and can achieve a fairly high crude oil recovery rate. The ultimate recovery rate can reach 60%-70%. Third, the oil obtained through the in-situ heating and conversion is of good quality. Under the high-temperature underground conditions, the unconverted organic matter in the shale formation is degraded by artificial heating to form light oil and natural gas; the heavy oil and asphalt remaining in the shale form low-carbon hydrocarbons through thermal cracking, with viscosity significantly reduced.

After years of research and field tests, shale oil suitable for in-situ conversion must meet the following five conditions: Firstly, the organic matter abundance in the shale concentrated section should be high, with the average TOC of greater than 6%, and the bigger the better. In addition, good kerogen type is desirable, and Type I and II 1 kerogen has higher ability to produce liquid hydrocarbons. Secondly, the shale concentrated section should be generally greater than 15m thick and greater than 0.8 in net shale-formation ratio. Thirdly, the shale should be moderate in thermal maturity, with Ro of generally 0.5% to 1.0%. Fourthly, the shale interval should be moderate in buried depth and distribution area, with a buried depth of less than 3 000 m, and a continuous distribution area of greater than 50 km2. Fifthly, the target interval of the shale should have a good top and bottom sealing conditions. The shielding layer should be greater than 2 m thick with no faults, and the formation should be less than 5% in water cut, with no active water.

After nearly 60 years of exploration and development practices, most easily discoverable and high quality oil and gas reservoirs on the land in China have already been found and have been put into development for decades. The undiscovered conventional oil and gas resources still account for a considerable proportion, but most of them are distributed in the blind area of interpretation of existing theory, technology and data and can only be found after better understanding, new technological innovation and higher research precision are reached, which takes time.

The evolution of sedimentary basins and geological conditions determine that China is a country with relatively abundant unconventional oil and gas resources, and the unconventional oil and gas resources are lower in exploration degree. As long as we adhere to technological innovation and management innovation, unconventional oil and gas resources will play an important role in maintaining sustainable and healthy development of China’ s oil and gas industry. There is a large amount of retained liquid hydrocarbons and unconverted organic matter in shale formations, which is a major reserves replacement area to the development and utilization of unconventional oil resources. If the commercial development and utilization of shale oil by in-situ conversion can be realized, the significant progress from “ seeking oil at structural highs” to seeking oil deep down depressions” to “ seeking oil from the source kitchen” will be made[11, 12, 13]. This will be a “ dream trip” for the oil seekers. The resulting theoretical and technological innovations in the oil industry will bring about a major change in China’ s oil and gas supply security.

The liquid petroleum existing in the shale layer is difficult to flow due to the poor permeability of the shale itself (porosity < 3%; permeability < 1× 10-9 μ m2), and the movable oil saturation is extremely low, so it is difficult to realize commercial development and utilization of the oil with conventional technology. In-situ conversion technology can further pyrolyze the retained hydrocarbons in shale into light oil and natural gas, and also enable the unconverted organic matter to degrade into oil and gas. Therefore, the electric heating in-situ conversion technology is the “ ace” technology for the scale development and utilization of shale oil profitably.

Based on laboratory data and available geological data, the authors think that China’ s continental shale oil resources are quite abundant, with technically recoverable oil resources of approximately (700-900)× 108t, which is 3 to 4 times the total amount of technically recoverable resources of conventional oil in China. They are mainly distributed in three major depression basins, Ordos, Songliao and Junggar, which are also the major areas for China’ s oil and gas production. According to the existing shale oil and gas yield data, combined with numerical simulation results, it is predicted that at the oil price of USD (377-409)/m3 (USD (60-65)/bbl), the economic recoverable resources of shale oil in China are approximately (200-250)× 108t, equal to the technically recoverable resources of conventional oil in China; and the technically recoverable resources of shale gas are approximately (60-65)× 1012 m3, which is three times the conventional natural gas resources in China[14]. The technically recoverable resources of shale oil in the three major basins, Ordos, Songliao and Junggar are approximately (570-680)× 108t (Table 2), accounting for more than 80% of the total technically recoverable resources of onshore shale oil.

| Table 2 Key geological parameters of shale in the Ordos, Songliao and Junggar Basins. |

The shale oil mentioned in this paper refers to the oil and multiple kinds of organic matter existing in organic-rich shale beds of low-moderate maturity (Ro< 1.0%) at a burial depth greater than 300 m, including petroleum hydrocarbon, bitumen, and unconverted organic matter already formed underground. In contrast, tight oil refers to the oil accumulated in the tight sandstone and tight carbonate strata interlayered with source rocks.

The differences between shale oil and tight oil mainly include three aspects: (1) The difference in the hydrocarbons. Shale oil includes various kinds of converted hydrocarbons and unconverted organic matters, which belongs “ self-generation and self-accumulation” within the source kitchen; while tight oil is the oil generated and expelled from nearby source rocks, and should be described as “ exotic generation and self-accumulation” . (2) The difference in natural reservoir permeability. Shale oil reservoirs are very low in porosity and permeability (porosity < 3% and permeability < 1× 10-9 μ m2); while tight oil reservoirs are better in porosity and permeability, with porosity > 6% and mostly above 10%, but with very low permeability of < 1× 10-3 μ m2 in general. (3) Nonmarine shale beds usually have high plasticity and low brittle mineral content, and it is difficult for the shale beds to form effective artificial flow channels by fracturing. Therefore, the initial production of single well is low after stimulation and so is the cumulative oil production of single well, making it impossible to realize large-scale commercial development.

The shale oil and tight oil referred to by the U.S. is different from the shale oil mentioned in this paper. The shale oil referred to by the U.S. is in fact the tight oil mentioned in this paper. Besides, U.S.’ s shale oil (tight oil) is mainly produced from marine strata with good continuity, large distribution area, big gross thickness, high oil maturity, and gas-oil ratio (Table 3). Therefore, the initial production and cumulative production of single well are both high. The development of U.S.’ s shale oil (tight oil) mainly employs horizontal well and multi-stage hydraulic fracturing, which are suitable for the development of China’ s continental tight oil but not for that of shale oil.

| Table 3 Comparison of geological characteristics and development technology between China and America’ s shale oil. |

4.3.1. In-situ conversion of shale oil in the Chang 7 of the Yanchang Formation of the Ordos Basin is the most realistic

According to the site selection criteria for in-situ conversion of shale oil, the shale in the Chang 7 Member of the Yanchang Fm. in the Ordos Basin meets the standards.

(1) The continuous thickness of organic-rich shale is large. According to the research, the shale in the Chang 7 with organic abundance over 6% is 16 m thick on average, with 60 m thick at most. The shale has a distribution area of about 3× 104km2, and the shale section more than 20 m thick takes 50%, with an area of about 1.8× 104km2. The horizontal distribution of the shale section is continuous and stable[15, 16].

(2) The organic matter is high in abundance and good in type. The shale in the Chang 7 is featured with high TOC contents (5%-38%, 13.8% on average), type-I and II1 kerogen, and higher hydrogen index (HI) (with the maximum of 750 mg/g). According to the HI values, the Chang 7 can be roughly divided into three areas. With similar maturity (Ro is about 0.8%), the HI values are the highest in the northwest area, with an average value of 550 mg/g, and the lowest in the central area, with an average value of 350 mg/g. The southwest area is characterized with moderate HI values, with an average value of 450 mg/g.

(3) The contents of retained hydrocarbon are high. The oil content in the Chang 7 shale is one of the key parameters for evaluating in-situ conversion potential of shale, and accurate data can be obtained through sealed coring. Taking Well Le 85, a recently completed sealed coring well, for example, Ro of the Chang 7 shale is 0.8%, and site measurement indicated relatively high free gas content, with the maximum value of 1.7 m3/t and average of 1.0m3/t; oil content of shale was between 8.80 and 26.77 mg/g, with an average value of 18.70 mg/g, among which light component content before the C16- was 5.54 mg/g on an average, taking 31.4% of total oil content (Fig. 4).

(4) The residual hydrocarbon generation potential of shale is great. The shale with TOC above 6% has hydrocarbon generation potential between 27.53 and 132.23 mg/g, on average 63.88 mg/g (Fig. 4).

(5) The Chang 7 shale has low water saturation and water cut, and no active water. First, the fracturing oil test results of 7 wells targeting at the shale intervals of the Chang 7 showed that none of them produced water; second, the analysis results of sealed coring samples showed that the shale samples had water saturation of less than 10% and water cut of less than 0.3% in general (Fig. 4). This feature can help reduce energy consumption and improve heat utilization ratio during the heating process of in-situ conversion.

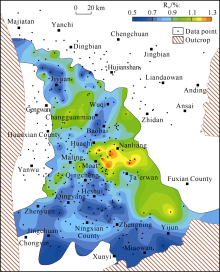

(6) The shale is moderated in thermal maturity. The shale of the Chang 7 Member has a wide range of thermal maturity, with Ro between 0.5% and 1.3%. However, the area with Ro less than 1.0% covering about 90% of the total distribution area of shale (Fig. 5). Therefore, its in-situ conversion potential is high.

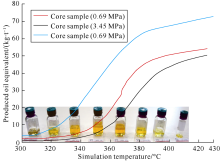

(7) Thermal simulation experiment results show that the in-situ conversion potential of the Chang 7 shale is high. Two groups of thermal simulation experiments were conducted in the in-situ conversion laboratory of Royal Dutch Shell, and the core sample used in the experiment had TOC of 23.7%, Ro of 0.82% and HI of 347 mg/g. The simulation results show that, the oil production of one ton of shale is 36 kg and gas production is 22.5 m3. The outcrop sample used in this experiment had a TOC of 24.7%, Ro of 0.51% and HI of 405 mg/g. The simulation results show that, the production of one ton of shale is 52 kg and gas production is 26 m3. The simulation results showed that the oil generated was all light oil (Fig. 6). Based on the thermal simulation experiment results of geological samples, we completed the resource potential evaluation of in-situ conversion of medium-low maturity shale in the Chang 7 of the Ordos Basin, which indicated that the technically recoverable resources of oil by underground in-situ conversion in the Chang 7of the Basin are approximately (400-450)× 108 t and that of natural gas are about (30-35) × 1012 m3. When oil price is USD (377-409)/m3(USD (60-65)/bbl), the economically recoverable resources are approximately (150-180) × 108t, which is basically 4-5 times technically recoverable resources of conventional oil in this basin, with huge potential.

The in-situ conversion pilot test carried out by Royal Dutch Shell on the shale in the Colorado-Green River succeeded. This verifies that the manufacturing technique of heater for underground in-situ conversion is mature, and that the work flow is complete and technology is feasible. It also proves that the laboratory parameters are rational and can be apply to resource prediction. The nitrogen content, Ro, lower water cut, no active water, and ground infrastructure conditions of the Chang 7 shale excel those of the shale in the Colorado-Green River (Table 4). Therefore, we have reasons to believe that the in-situ conversion conditions of the Chang 7 in the Ordos Basin are better than those of the Green River.

| Table 4 Comparison of main characteristics between the Chang 73 Sub-member shale in the Ordos Basin and shale in the Colorado-Green River. |

4.3.2. Basin conditions and potential of Nen 1 shale oil in the Songliao Basin

Two sets of source rocks, i.e. the Qingshankou Fm. and the Nenjiang Fm. in the Cretaceous system, are developed in the Songliao Basin, in which the Qingshankou Fm. shale is the main source rock for the world-class large placanticline oilfield of Daqing. The comparisons between these two source rocks showed that the Qingshankou Fm. source rocks have an average TOC of 3.8% and Ro of 0.8%-1.4%, while the Nenjiang Fm. have an average TOC of 4.5%, Ro of below 0.8% in general. With lower maturity and higher TOC contents, Nenjiang Fm. possesses greater in-situ conversion potential of shale oil.

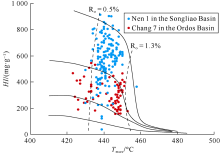

Shale of Member 1 of the Nenjiang Fm. in the Songliao Basin has a burial depth of less than1400 m and distribution area of about 2.5× 104km2. The shale concentrated section with TOC> 6% is 8-12 m thick. The shale has TOC values of 7% on average, a distribution area of about 2× 104km2 and Ro between 0.4% and 0.8%. Comparing the shales in the Nen 1 of the Songliao Basin with the Chang 7 in the Ordos Basin, we realized that the HI values of the former is 1.73 times as high as that of the latter (Fig. 7), and the in-situ conversion potential of Nen 1 shale is worth noticing.

| Fig. 7. Shale HI comparison between the Nen 1 in the Songliao Basin and the Chang 7 in the Ordos Basin. (HI— Hydrogen index; Tmax— Thermal decomposition peak temperature) |

In-situ conversion potential of Nen 1 shale was evaluated by using the thermal simulation results of the Chang 7 shale in the Ordos Basin, and the technically recoverable resources of the Nen 1 shale in the Songliao Basin are (120-150) × 108t for oil, and (9-10) × 1012m3for natural gas. It is predicted that at the oil price of USD (377-409)/m3 (USD (60-65)/bbl), the economic recoverable resources of shale oil in China are approximately (200-250)× 108t.

Shale oil is probably the next “ revolutionary” in the petroleum industry. To realize breakthroughs in shale oil commercial development in China is of great significance for both improving China’ s capability of crude oil self-sufficiency and leading the future development of world’ s petroleum industry.

(1) Technical breakthroughs in underground in-situ conversion of shale oil will effectively liberate the development and utilization of shale oil resources with great potential, and thus guarantee the long-term stable and even increasing production of domestic crude oil. If technical and economic breakthroughs can be made through a period of technical problem solving and pilot test preparation, China’ s annual crude oil production through in-situ conversion of shale oil is expected to exceed 200 million tons and the stable production period will exceed 50 years. By then, China’ s external dependence on crude oil will be reduced from the present 65%-70% to below 50%, which will greatly improve the energy security of our country.

(2) The breakthrough of shale oil exploitation is of high scientific and technological significance, which can help solve the difficulties in large-scale recovery of low-grade oil reserves. Shale oil is the most challenging type of petroleum resources for development and utilization, and breakthroughs in bottleneck technologies can provide referential technical methods for the large-scale development of oil in extra-low permeability and even tight reservoirs, and high-viscosity oil. So far, the underground in-situ conversion of shale oil has attracted wide attention from international peers. China will play an important role in changing world’ s petroleum supply pattern if we can take the lead in the large-scale development and utilization of shale oil.

According to the evolutional mechanism of hydrocarbon generation and expulsion, only a small portion of liquid and gaseous hydrocarbons can be thermally matured and physically expelled from the shale matrix, leaving quite a large amount of organic matter, including generated liquid hydrocarbons, heavy hydrocarbons stayed after hydrocarbon expulsion, bitumen, and unconverted immature organic matter retained in shale. If underground in-situ conversion can be technically realized, it is just like building many underground refineries which can continuously supply high-quality oil and gas up to the surface while leaving the pollutants underground, thus realizing the harmonious development of resource recovery and environmental protection. This is exactly the true essence advocated in this paper.

Shale suitable for underground in-situ conversion should meet the following conditions: (1) be organic rich in the concentrated shale zone (with a TOC more than 6%, the higher the better), and excellent in organic matter type (with type-I and II1 the best); (2) have Ro between 0.5% and 1.0%; (3) be greater than 15 m in thickness; (4) be less than 3000 m in burial depth and more than 50 km2 in area; (5) have good sealing of the roof and floor beds; and (6) have water cut less than 5%.

China’ s in-situ conversion resources of shale oil are mainly distributed in the nonmarine shale beds in the Ordos Basin, the Songliao Basin, and the Junggar Basin. Preliminary evaluation suggests that the technically recoverable oil resources using underground in-situ conversion are approximately (700-900)× 108t, and the economically recoverable resources are about (200-250) × 108t when the oil price is USD (377-409)/m3 (USD (60-65)/bbl), which is equivalent to the total technically recoverable resources of conventional oil. The technically recoverable resources of natural gas are approximately (60-65)× 1012m3, which is three times of China’ s total conventional gas resources. Among them, the in-situ conversion of shale oil in the Chang 7 of the Yanchang Fm. of the Ordos Basin is the most realistic.

Promoting the initiative industrial tests of underground in-situ conversion of shale oil in China and realizing commercial breakthroughs is of revolutionary strategic significance for stabilizing and increasing oil production and technical upgrading in China. The state government shall actively pay attention to and provide expenditure supports for related researches and pilot tests.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|