Through detailed analyses of the distribution characteristics of organic-rich shale, appearance features of high-quality shale, microscopic characteristics of shale reservoir rocks, fracability, and the relationship between preservation conditions and shale gas enrichment in Upper Ordovician Wufeng Formation-Lower Silurian Longmaxi Formation in Sichuan Basin, theoretical understandings and specific suggestions with respect to the exploration and development of shale gas in China are summarized and proposed respectively. Important geological understandings in the exploration and development of shale gas of the Wufeng Formation-Longmaxi Formation in the Sichuan Basin can be summarized into the following aspects: depositional environment and depositional process control the distribution of organic-rich shale; high quality shale in “sweet spot segments” are commonly characterized by high content of organic carbon, high brittleness, high porosity and gas content; organic pores are important storage space for the enrichment of shale gas; preservation conditions are the key factor for the geological evaluation of shale gas in structurally complex regions; shale gas can be considered as “artificial gas reservoirs” and the fracability assessment is essential for high-production; nanoscale storage space and the mode of occurrence control the special seepage characteristics of shale gas. The following suggestions are proposed for the development of China’s shale gas industry: (1) focus more on fundamental research to achieve new breakthrough in the geological theory of shale gas; (2) emphasize exploration practices to have all-round discoveries in multiple strata; (3) study the regularities of development and production to establish new models of shale gas development; (4) think creatively to invent new technologies to tackle key problems; (5) explore the management innovation to create new mechanisms in shale gas development.

The successful exploration and development of unconventional resources represented by shale gas is a huge step forward in the global oil and gas industry in terms of theoretical and technological innovation. The successful development of shale gas has broken through the lower limit of conventional reservoir and the traditional concept of trap accumulation, and reinvested the geological theory of petroleum and gas with new connotations[1, 2]. It has expanded the exploration and development types and the amount of hydrocarbon resources, and overturned theories known as “ peak oil” and “ oil depletion” . Massive application of innovative technologies represented by multistage fracturing of horizontal wells has upgraded the technology of energy industry[1]. Through shale gas revolution, America’ s external dependence on oil and gas has been declining continuously. Global energy structure has also been altered significantly. As China’ s economy is stepping into high-quality development and the environmental protection is upgraded, there is a rapid growth in China’ s demand for hydrocarbon resources, particularly for natural gas. Therefore, the exploration and development of shale gas is of great significance for ensuring China’ s energy security, reforming the energy structure, and promoting technological progress in China’ s oil and gas industry. China has attached great importance to the utilization of unconventional natural gas, such as shale gas. The top-level design and supporting polices have been made for the development of shale gas industry. Since the initiation of China’ s shale gas exploration in 2009, the commercialized shale gas development in marine shale of the Wufeng-Longmaxi Formation made China one of a few countries which have realized industrial shale gas exploitation. In this study, the important geological understandings and successful practical experiences from the recent ten years’ exploration and development of shale gas in the Wufeng-Longmaxi Formation are summarized, and suggestions for the future development of China’ s shale gas industry are presented.

China has discovered natural gas flow in mud shale while carrying out exploration and development of conventional hydrocarbons in the Sichuan and Ordos Basins since the 1960s. In 1966, Well Wei-5 obtained a daily gas production of 2.46× 104 m3 in the Lower Cambrian Qiongzhusi Formation. Well Yang 63 tested a daily gas production of 3 500 m3 from the Upper Ordovician-Lower Silurian Longmaxi Formation after acidification[3]. Chinese researchers[4, 5, 6] started to pay close attention to shale gas resources since the 1980s. Starting from 2000, research groups from the Strategic Consulting Center of Oil and Gas Resources of the former Ministry of Land and Resources, China University of Geosciences (Beijing), Sinopec, and PetroChina etc. initiated the investigation on geological conditions of shale gas and the evaluation of resource potential through reviews on old data and outcrop studies based on their understandings of the geology theory and technology of shale gas development in United States. In 2009, the former Ministry of Land and Resources initiated the project “ Evaluation of shale gas resource potential and selection of favorable zones in important regions of China” , and drilled the first well, Yuye 1[3], to evaluate the shale gas resource potential in Pengshui Town, Chongqing. In 2011, the former Ministry of Land and Resources organized national-wide investigation of shale gas resource potential and selection of favorable zones, and announced to the public, on March 1st, 2012, that the amount of geological resources of shale gas in China were up to 134.42× 1012 m3, and the amount of recoverable shale gas resources were 25.08× 1012 m3. In March, 2011, the Chinese Academy of Engineering started the strategic research on the exploration and development of China’ s unconventional natural gas and concluded that the recoverable amount of shale gas resources in China were 10.50× 1012 m3, and proposed the trend and the roadmap for the development and exploitation of shale gas in China[7].

In 2009, major oil companies represented by PetroChina and Sinopec initiated shale gas exploration. In 2010, a vertical well, Well Wei 201, drilled by PetroChina in Weiyuan region in the south of Sichuan obtained shale gas flow from the Lower Silurian Longmaxi Formation by fracturing[2, 3, 8]. In April 2012, Well Ning 201-H1 in Changning region obtained a daily shale gas production of 15× 104 m3 from the Wufeng Formation and the Longmaxi Formation[8, 9], marking China’ s breakthrough in commercial shale gas exploration. In November of the same year, Well Jiaoye 1HF drilled by Sinopec in Jiaoshiba region in the southeast of Sichuan obtained a daily shale gas production of 20.3× 104 m3 from the Wufeng Formation and the Longmaxi Formation[10]. In the year 2014, Sinopec submitted the first time proved shale gas reserves of 106.75 billion m3. By the end of 2017, Fulin shale gas field had cumulative reserves of over 600 billion m3, shale gas production capacity of 10 billion m3, and annual gas production of 6.04 billion m3. Besides, Sinopec has made breakthroughs in shale gas exploration in the Wufeng-Longmaxi Formation in the Weiyuan, Rongchang and Dingshan areas, and in the Lower Cambrian Qiongzhusi Formation in Jingyan-Jianwei area in the Sichuan Basin. At the same time, Sinopec has made new discoveries in the continental shale of the Jurassic Ziliujing Formation in the Fulin, Yuanba and Jiannan areas, and in the Xujiahe Formation in western Sichuan area of the Sichuan Basin[11]. Meanwhile, PetroChina has built commercialized shale gas development areas in Weiyuan, Changning and Shaotong in Chuannan region[12], discovered proved shale gas reserves of more than 300 billion m3 cumulatively, and had a shale gas production of 3 billion m3 in 2017. The Yanchang Petroleum Group drilled tens of wells in the continental shale of the Chang 7 Member, Yanchang Formation, and obtained shale gas flows[13]. China Geological Survey carried out shale gas geological survey in non-hydrocarbon exploration areas in South China and North China and made new discoveries in the Lower Cambrian and Silurian in Yichang region[14]. Energy corporations such as China Huaneng, China Huadian and Shenhua joined the shale gas exploration actively and made progresses. By the end of 2016, 2D seismic lines of 24 760 km, 3D seismic data of 4013 square kilometers and 1161 wells[15] had been completed in total for China’ s shale gas exploration and development. Four commercialized shale gas development areas have been built up in Fulin, Weiyuan, Changning and Shaotong in the Sichuan Basin, with both shale gas reserves and production rate growing rapidly. By the end of 2017, the proved shale gas reserves in China have approached about 1 trillion m3, and the shale gas production increased from 25 million m3 in 2012 to more than 9 billion m3, heralding a promising prospect of shale gas exploration and development in China.

Through the practices of exploration and development, Chinese researchers[10, 16, 17, 18, 19, 20, 21, 22] proposed “ two-element enrichment rule” for marine shale gas in regions with complex structures, and enrichment models of “ structure type sweet spot” and “ continuous type sweet spot” . The procedure of selection and evaluation of favorable zones and targets has been improved to a mature level. Preliminary technologies such as gas reservoir characterization, production capacity evaluation and optimization of development parameters have been established. Techniques such as fast drilling of horizontal wells, pumping bridge plug and clustered perforation for multistage fracturing, simultaneous fracturing and chain fracturing are now under mature application, allowing massive development of shallow-sea facies shale gas above the depth of 3500 m. The well factory operating mode in mountainous areas has been worked out, significantly improving the operation efficiency and shortening the drilling and operation cycle by 30% than single well per wellsite. The associated cleaner production technical system represented by cyclic utilization and innocuous disposal of waste residue, waste liquid and waste gas has been developed. In the development of key fracturing equipment, fracturing truck of style 3000 with independent intellectual property rights has been designed and produced, and research and development system, testing and manufacturing system, and the application standard of domestic high power fracturing machine set have been established. Fracturing equipment such as open hole packers and bridge plugs have been developed independently and realized industrialized massive production. Taking the Fuling shale gas field as an example, hundreds of technical standard and norms have been set up, 39 national patents have been authorized, among which 12 are invention patents. China has gained worldwide recognition and attracted great attention in global shale gas industry. In the Fifth World Shale Oil and Gas Summit in 2014, Chinese enterprise received the international pioneering award in shale oil and gas development. In 2018, the project “ High Efficiency Exploration and Development of Large Marine Shale Gas Field in Fuling” won the first prize of the national scientific and technological progress.

The exploration and development of shale gas is different from that of conventional oil and gas. Multistage fracturing of horizontal wells must be adopted to reform the tight shale reservoir rocks rich in nano-scale pores to get commercial shale gas. Shale gas reservoirs are characterized by good continuity and self-generation and self-storage. In North America, geological evaluation system focusing on shale quality mainly includes two aspect of evaluation. The first aspect is the evaluation on gas-bearing property, including TOC, types of organic matter, maturity, porosity, thickness of organic-rich shale, and gas content, etc. The second aspect is fracability, which has become an important factor of evaluation because of its close relationship with shale gas production. Chinese geologists’ understanding on shale gas has been grown gradually. At the early stage, the focus is on shale quality evaluation based on experiences from North America. Through practices of exploration, it is found that the preservation condition is the key factor for marine shale gas enrichment in China’ s structurally complicated regions. Chinese geologists have gradually recognized that the sedimentary environment, preservation, and fracturing are the fundamentals for shale gas enrichment and high production. Through nearly ten years of persistent research, Chinese researchers have made major progress in the understanding on major factors controlling gas enrichment and high production of marine shale represented by the Wufeng-Longmaxi Formation.

Exploration and development of shale gas in North America and China suggest that the precondition for high-production of marine shale gas is that organic-rich (TOC> 2%) shale has to be continuously developed. Therefore, the distribution of organic-rich shale is considered as an important factor for shale gas evaluation. At the early stage, Chinese geologists put a lot of effort into the study on the distribution and development of source rocks. Liang Digang[23, 24] investigated the distribution characteristics, geochemical features, formation environment and the controlling factors of the Paleozoic marine source rocks in South China, confirmed the development of four sets of marine source rocks, Lower Cambrian, Upper Ordovician-Lower Silurian, Lower Permian and Upper Permian, of seven favorable depositional facies, classified these seven favorable depositional facies into three models, and systematically analyzed the temporal and spacial distribution of important parameters of the source rocks, such as TOC and Ro. These results provided important references for the selection of favorable marine shale gas areas of Wufeng-Longmaxi Formation and for the discovery of the Fuling shale gas field.

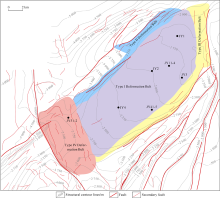

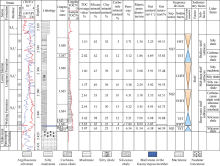

As the exploration and development of shale gas advances, based on the differentiation of graptolite zones by Xu Chen and Junxuan Fan[25, 26, 27], many scholars[28, 29, 30, 31, 32, 33, 34, 35] carried out detailed sequence-stratigraphic division and stratigraphic correlation of Wufeng Formation-Longmaxi Formation. Research and production units of Sinopec divided the lower member of the Wufeng-Longmaxi Formation into nine layers (Fig. 1). Organic-rich shale (TOC> 2%) is distributed from No. ① to No. ⑤ layer. This set of organic-rich shale is characterized by stable stratigraphic position and wide distribution. No. ① to No. ③ layers have been selected as sweet spot intervals, representing a set of high-quality shale with TOC of more than 3%, which is part of the two transgressive systems tracts under rapid rise of global sea level in the end of the Late Ordovician and the beginning of the Early Silurian in the restricted deep-water shelf related reducing environment. A thin-layer of shell limestone of Guanyinqiao Member occurs locally on the top of Wufeng Formation, representing low water level deposits during the expansion of Antarctic ice sheet and the drop of global sea level. Affected by the submarine uplifts in Chuanzhong, Qianzhong and Yichang, the two-phase deposits of transgressive systems tracts at the bottom of the Wufeng-Longmaxi Formation had several depocenters (Figs. 2 and 3).

| Fig. 1. Profile characteristics of typical wells in Jiaoshiba (Testing results are represented by average values). |

| Fig. 2. Map showing the thickness distribution of high-quality shale of the SQ1 transgressive systems tract of the Upper Ordovician Wufeng Formation in the Sichuan Basin and the surroundings. |

Compared with other thin-layers, the No. ① to No. ③ thin layers of the sweet spot intervals of the Wufeng-Longmaxi Formation have the following characteristics (Fig. 1).

2.2.1. High organic carbon content

The No. ① to No. ③ thin layers have an organic carbon content of more than 4% in general, lower than 2% locally, and an average organic carbon content of more than 3%. Sta- tistical analysis of organic matter of the No. ① to No. ③ thin layers in the Jiaoshiba, Yongchuan and Weiyuan areas reveals that about 70% to 80% of maceral compositions are non-animal debris such as phytoplankton, acritarchs, bacteriaand solid bitumen, whereas about 20% to 30% is animal debris, among which more than 90% is graptolites, and the rest is chitinozoa. For shale layers with TOC content of less than 2%, about 47% to 67% of the maceral components of organic matter are animal debris (mainly graptolites and chitinozoa), whereas about 24% to 53%[36, 37] of organic matter is non-animal debris. Foreign researchers have confirmed that phytoplankton, acritarchs and bacteria contain a lot of aliphatic structures, leading to high hydrocarbon potential[38, 39, 40].

2.2.2. High silica content

The average silica content of the No. ① to No. ③ thin layers is about 60%. Numerous siliceous radiolarian and sponge spicule are developed along the bedding plane. The content of siliceous radiolarian can be as high as 30%. Biogenic quartz associated with skeletons of siliceous radiolarian and siliceous sponge spicule makes up about 67% to 90% of the total silica. The average silica content of the other thin shale layers is about 42% to 53%, with detrital quartz as the major component[17, 18, 19].

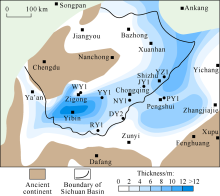

2.2.3. High porosity

The average porosity of the No. ① to No. ③ thin layers is larger than 5%, with the average diameter of matrix pores larger than 7 nanometers. More than 50% of the total porosity is organic porosity. The CT scan of black siliceous shale with TOC content of about 5.89% in the No. ① thin layer (Fig. 4a) reveals that the major storage space is organic porosity. The pore size is about 30 nanometers. Pores are well-connected, and the porosity is 5.06%.

| Fig. 4. Black siliceous shale with TOC of 5.89% (a) and silty shale with TOC of 1.27% (b) CT scanning. |

The No. ⑥ to No. ⑨ thin shale layers with an average TOC content of less than 2% have a porosity of less than 4% and average diameter of matrix pores of about 1.34 to 2.29 nanometers. The CT scan of a silty shale sample with TOC of about 1.27% from the No. ⑥ thin layer shows that the storage space is composed of mostly inorganic pores[41], with few organic matter pores and poor pore connectivity, and the porosity is 2.44%.

2.2.4. High gas content

The No. ① to No. ③ thin shale layers of the Wufeng Formation-Longmaxi Formation have an average gas content of more than 6 m3/t and gas saturation of about 67-77%, which are much higher than those of the shale with TOC content of less than 2%.

The sweet spot intervals, No. ① to No. ③ thin layers of high quality shale have high organic content, organic matter dominated by algae and acritarchs with hydrogen-rich lipid structures characterized by high hydrocarbon potential and good gas-bearing property. The high porosity provides storage space for the enrichment of shale gas, while the high brittleness lays a good foundation for fracturing.

As the nanometer-scale testing technology advances, the research on reservoir rocks is deepening and more elaborate. Large amounts of nanometer-scale pores have been found in the organic matter of shale, which provides the theoretical basis for the integrated source and storage characteristic of organic-rich shale.

Recently, the exploration and development practices of shale gas in the Wufeng-Longmaxi Formation[42] suggest that the shale porosity is closely related to gas content of shale and well production, so it is considered an important factor for the evaluation of shale gas enrichment and high productivity. According to the type of matrix, researchers usually divide the shale pores into organic pores, brittle minerals pores and clay minerals pores[43, 44, 45, 46]. Through examination and statistical analysis of pore types and characterization of pore structures, the following understanding has been reached.

2.3.1. Organic pores can be original and secondary, and the latter can be heterogeneous

Studies on organic pores in shale of different types and different maturities[36, 37, 47] show that organic pores can be divided into two types. The first type of pore is original organic pore, which is associated with the internal structure of organisms, such as the pores in the fiber structure of higher plant, pores between algae cells and pores in the honeycomb structure of animal skeleton. The other type of pore is formed during the thermal evolution of organic matter, including organic pores in kerogens and solid bitumen. The secondary organic pores are often heterogeneous. In the shale of the Wufeng- Longmaxi Formation, the organic pores are largely concentrated in solid bitumen and hydrogen-rich lipid organic matter. The organic-rich shale of the Wufeng-Longmaxi Formation is in the dry gas evolution phase (with Ro about 2.2%-3.06%, on average 2.5%). In the process of thermal evolution, the shale experienced oil generation of organic matter, cracking of oil to gas, gas generation by kerogen directly and cracking of bitumen to gas. Such a process reflects the “ multi-element” hydrocarbon supply at micro-scale.

2.3.2. Formation of organic pores controlled by thermal evolution, and the development of organic pores dependent on the physical properties of organic matter

Both domestic and foreign researchers[48, 49, 50, 51, 52, 53, 54] have carried out many experiments and simulations with the aim to understand the evolution of organic pores in the course of thermal evolution, and proposed that organic pores increase and then decrease as the maturity of organic matter increases. Studies on organic-rich shale in the Tertiary of the East China, the Triassic in the Ordos Basin, the Jurassic, Silurian, and Cambrian in the Sichuan Basin have confirmed this rule. Most of the researchers[51, 52, 53, 54, 55, 56] hold that organic pores do not develop when Ro is lower than 0.7, and organic pores start to form and increase when Ro reaches 1.2% or higher; when Ro is higher than 2%, organic pores start to decrease. Some researchers[57] proposed that when Ro is between 2.2%-2.7%, secondary cracking can occur, causing the increase of organic pores, and when Ro is more than 2.7%, the organic pores start to decrease. Research on the organic-rich shale of the Lower Cambrian Niutitang Formation suggests that as the maturity increases, organic matter can be carbonized, the organic pores collapse or are filled, causing the decrease in porosity, and increase in electric conductivity[55].

The variation of the amount of organic pores as documented above is associated with the intrinsic physical properties of organic matter. Compared with brittle minerals such as quartz, organic matter, with lower density and light mass, is plastic materials with lower resistance to compression. As the maturity of organic matter increases, organic pores form and provide storage space for hydrocarbon. At the same time, as the amount of organic pores increases, organic matter becomes more fragile and less resistant to compression. When the pores are filled with gas, the pore pressure increases and balances the overburden pressure, so that the organic pores can be preserved. When gas in the organic pores dissipates, pore pressure decreases and the organic pores collapse, causing decrease of organic pores. Therefore, it is not difficult to explain why the amount of organic pores firstly increases and then decreases as the maturity increases. Similarly, the shale with overly high organic matter content has less organic pores (TOC> 10%), and in regions with poor preservation conditions, the proportion of organic pores are relatively lower[56]. Nevertheless, further observations and studies are needed for confirming the explanation presented above.

2.3.3. The development degree of organic pores is positively correlated with the gas bearing property of shale and the well production

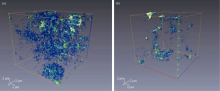

Research shows that shale porosity and specific surface area of pores and pore volume have significant impact on gas bearing property of shale[11, 12, 13, 14, 15, 16, 17, 18]. Statistics on shale porosity, gas bearing property and production per well of different deformation belts in the Jiaoshiba anticline in the Fulin shale gas field (Fig. 5) reveal that in the typeⅠ deformation belt at the core of the Jiaoshiba anticline, the shale has log porosity of more than 4.6% and average gas content of over 6 m3/t, and the wells have an average open flow capacity of more than 0.5 million m3 per day. In comparison, in the type Ⅳ deformation belt in the Wujiang faulted anticline belt, the shale has an average log porosity of 2.9% and gas content of 5 m3/t, and the wells there have an average open flow capacity of less than 0.1 million m3 per day. This suggests that shale with high porosity have higher gas content and single well production.

The development degree of organic pores is positively correlated with the gas bearing property of shale, single well production and recoverable reserves. In the Jiaoshiba area, the lower member of the Wufeng-Longmaxi Formation can be divided into ①-⑨ nine thin layers, and the nine thin layers are grouped into two gas-bearing intervals, the lower interval composed of ①-⑤ and the upper interval composed of ⑥-⑨. From the bottom to top, the proportion of organic pores decreases, while the amount of clay mineral pores increases. The lower gas bearing interval[57] has an average content of organic carbon of about 3.39%, average porosity of 4.31% to 7.8%, mostly organic pores (accounting for more than 50% of the total pores). The upper gas-bearing interval has lower organic carbon content of 1.5% on average, a porosity range from 3.38% to 5.12%, and largely inorganic pores and micro cracks, where the organic pores make up 30.4% to 35.4% of the total pore volume[57]. Compared with the development wells in the lower gas-bearing layers, the appraisal wells in the upper gas-bearing layers have relatively lower production, rapid pressure decline, and lower predicted recoverable reserves per well.

For shale reservoirs with the same TOC, the development degree of organic pores is positively correlated with the single well production. Well Dingye 1 in the Dingshan area is a low production well with normal pressure coefficient at the wellhead[59]. Compared with the high production well in the Jiaoshiba area with high pressure coefficient, the lower gas-bearing layers in Well Dingye 1 has an average TOC of 3.4%, similar to that in Jiaoshiba area; average porosity of 3.03%, lower than that of Jiaoshiba area, and the pores are dominated by inorganic pores, and the organic pores account for 10-40% of the total pore volume, which is much lower than that of the Jiaoshiba area (50%).

Pressure coefficient of gas reservoir is an important parameter in evaluating favorable zones and targets of shale gas. The exploration and development of shale gas in North America and China have confirmed that the pressure coefficient of shale gas reservoirs in high production zones is commonly higher than 1.2[16, 17, 18, 19, 20, 21, 22]. Pressure coefficient is also a comprehensive indicator to judge the preservation conditions. Overpressure commonly indicates good preservation conditions. Because the geophysical prediction of pressure coefficient of shale gas reservoir is still in the exploratory stage, geological analysis and evaluation of the preservation conditions has become an important research subject in shale gas potential evaluation. The preservation conditions of shale gas can be influenced by a number of geological factors, including the sealing capacity of shale, roof/floor conditions, reformation time and intensity of tectonic movements[16, 17, 18, 19, 20, 60].

2.4.1. Sealing capacity of shale and roof/floor condition

Shale reservoirs are characterized by high porosity and low permeability. Under tectonic stress, the physical properties of shale and bedding planes control the development of fractures, which can influence the storage capacity and preservation of shale gas. For example, cores from several wells drilled in the Pingqiao anticline of the Fulin shale gas field show that under tectonic compression, a fracture-damage zone developed in the lower member of the Wufeng Formation, causing lower gas content. This is closely related to the high brittleness of the Wufeng Formation.

The roof and floor of a shale layer refer to the overlying and underlying layers in direct contact with the shale layer. The contact relationship and the breakthrough pressure of the roof and floor are crucial to the preservation of shale gas. Chinese researchers[16, 17, 18, 19, 20, 22] have found that the carbonized shale at the bottom of Lower Cambrian has high content of organic carbon. But gas testing results reveal that its gas content is much lower than the middle and upper shale. This is related to the weathering crust dolomite of the Dengying Formation functioning as the floor of the Lower Cambrian which has no sealing capacity. Good sealing capacity of the roof and floor of the shale layer is an important factor controlling the enrichment and high-production of shale gas in the Wufeng-Longmaxi Formation.

2.4.2. The effect of tectonic burial, tectonic uplift, faulting and fracturing

As the burial depth increases, the temperature and pressure also increase, the clay minerals in shale dehydrate, meanwhile, and the organic matter generates oil and gas with increase of maturity, leading to overpressure[61, 62]. Overpressure is beneficial for the preservation of organic pores, which provide storage space for shale gas enrichment. However, overpressure is also a challenge to the sealing capacity of mud shale and the roof/floor condition. If the breakthrough pressure of them is not high enough, shale gas will dissipate.

Tri-axial mechanical experiments[17, 20, 58, 63]on the mud shale samples from the Longmaxi Formation in Well Jiaoye 2 suggest that when the shale is uplifted from the depth of 3 000 m to 1 000-1 500 m, and the confining pressure drops from 50 MPa to about 15 MPa, the shale would turn from plastic to brittle[58, 63], micro-fractures would open, and the porosity and permeability of shale would increase significantly, and the storage capacity of shale would enhance, but the preservation conditions would turn worse. Under tectonic uplifting, the uplift magnitude, stages and duration of the uplift can all affect the preservation conditions of shale gas.

In the Jiaoshiba area, analysis of the cores sampled from the roof and floor layers reveals that the cores sampled far from faults have few hydrocarbon inclusions; whereas cores sampled near faults have rich fractures and large amounts of hydrocarbon inclusions, suggesting that faults and fractures damaged the sealing capacity of shale. At the same time, exploration and development experiences show[60] that whether the fault is open or not has a strong effect on shale gas production of well. The Jiaoshiba block is a NE trending box anticline, there develops a northwest trending Wujiang fault zone in the southwest of the anticline, which is a thrust belt formed under multiple-stage compression and thrusting with the Silurian strata as the detachment layer, with a damages zones composed of faults of various hierarchies extending to the surface. When drilling near the damage zone, horizontal wells often have circulation loss, low pressure coefficient and low well production. The fault zone can influence the production of wells within the distance of 5 to 6 kilometers. In contrast, the fault located in the west wing of the Jiaoshiba anticline is closed below the surface with good sealing capacity, so the production of wells located on two sides of the fault are not affected (Fig. 5). The fault developed in the eastern wing of the Pingqiao anticline is not open. The horizontal wells drilled nearby have high productions.

The effect of tectonics on shale gas enrichment and high production can be two-sided. On one hand, it can improve the storage capacity of shale. On the other hand, tectonics can damage the sealing capacity of shale and the shale gas can dissipate.

Tight in nature, shale reservoirs must be fractured at massive scale to get commercial gas flow. Therefore, fracability assessment is an important research subject for geological research of shale gas. Exploration and development of shale gas stresses the importance of integrated exploration and development engineering, the core of which is to integrate geological understanding with drilling and fracturing design, aiming at having optimal results of engineering operation and high production. Nowadays, in China, research on fracability involves mainly study on mineral composition and mechanical properties of rocks. Recent development of Funling shale gas field suggest that factors such as structural configuration, burial depth of strata, early-formed fractures, all have significant impact on fracturing effect in shale[60, 64]. The authors think that the research and assessment of fracability include the following contents.

2.5.1. Fracability assessment of mud shale layers and selection of layers for drilling horizontal wells

After the discovery of Well Jiaoye 1, researchers carried out detailed stratigraphic division and achieved the identification and characterization of layers for drilling horizontal wells. Based upon this work, statistics on the layers horizontal well drilled through, fracturing result and single well production indicate that different thin layers are different in breakdown pressure, sensitivity to proppant concentration in fracturing, and pump off pressure[41, 42]. Statistics suggest that for horizontal drilling, the longer the well drills through the layer, the higher the productivity of the well will be[64, 65, 66, 67, 68].

When selecting the layer for drilling a horizontal well, firstly, the position of layer with high TOC in the mud shale interval should be located. Detailed stratigraphic division of the shale interval with high TOC content can be carried out based on lithology, TOC content, gas content and rock mechanical properties. Through laboratory simulation and on-site testing, the layers with the best fracability and the highest possible production should be selected for the placement of the horizontal interval. In some cases, the layer selected for horizontal interval placement can vary in the same stratum if the gas content and lithology changes. In the production building area of the Pingqiao anticline, the layer for drilling horizontal interval was adjusted because the natural fractures and gas content vary in the Wufeng Formation.

2.5.2. Detailed structural analysis and selection of horizontal well trajectory and fracturing stages

Exploration and development practices[64] suggest that burial depth, structural configuration, distribution of earlier fractures, and present stress state can all influence the effects of staged fracturing of horizontal wells. From the structural configuration, anticlines commonly have tensile stress, whereas synclines commonly have compressive stress, so it is more difficult to carry out hydraulic fracturing operation in synclines than in anticlines. Because the stress varies in the core part, the hinge zone, and the wings of anticlines, the effects of fracturing and well production vary.

Detailed structural interpretation is the key to the design of trajectory and staged fracturing of horizontal wells. Firstly, the present-day stress orientation should be confirmed, so that the orientation of horizontal wells can be determined. Secondly, the development characteristics of early-formed fractures should be identified by using methods of curvature, coherence and ant-body attributes. Thirdly, based on accurate characterization of structure burial depth, structural features and development characteristics of fractures on the plane, the trajectory of horizontal wells can be designed. Fourthly, after the drilling of a horizontal well, layers the horizontal well passes through should be identified, the fracture zones and faults the horizontal well drilled through and faults and fractures near the well should be characterized by using well logging, well testing and seismic data. Relevant engineering personnel can design staged fracturing based on the information.

Combined analysis of mercury intrusion-nitrogen adsorption of the samples from Well Jiaoye 1 shows that the shale reservoir has mostly nano-scale pores of micro-medium sizes and few big nanopores, with pore diameters generally less than 20 nanometers. Shale gas occurs in several states, including free state, adsorbed state and dissolved state. The free gas to adsorbed gas ratio is 6:4 in general. Compared with the production characteristics of conventional natural gas wells which are characterized by linear relationship between pressure and cumulative production, shale gas wells have linearly relationship between high pressure and cumulative production, and nonlinear relationship between low pressure and cumulative production. In general, the flow of shale gas involves the following processes: desorption of absorbed gas from the surface of organic matter (which can be described by the Langmuir model); the desorbed gas entering pores, the gas in matrix pores flowing into fracture systems through diffusion flow and slip flow (which can be described by Knudsen equation); the gas in the fractures flowing into the wellbore (which can be described by Darcy’ s flow). Under the temperature and pressure conditions (82 ° C and 37.7 MPa) of the Fulin shale gas field, Darcy flow occurs in pores and fractures larger than 100 nanometers, slip flow occurs in pores of 20 to 100 nanometers, slip flow and transition flow occur in nanopores of 1 to 20 nanometers. Diffusion occurs in pores smaller than 1 nanometer under low pressure.

Compared with the widely distributed marine shale gas in North America, mud shale of marine facies, transitional facies and continental facies of various types are developed in China.

3.1.1. Marine shale gas

Taking the Upper Ordovician-Lower Silurian Wufeng Formation-Longmaxi Formation and Lower Cambrian Qiongzhusi Formation as examples, these two sets of organic-rich shale strata have similar depositional environment, thickness, lithology, mineral composition, content of organic matter, and types of organic matter with the marine shale strata in North America.

Marine shale strata in North America were formed in craton basins and foreland basins, with large-scale stable base and relatively simpler history of tectonic movement. The Chinese landmass, as a composite continent, consists of multiple small continental blocks, such as Sino-Korea, Yangtze, Tarim, etc., and orogenic belts, so it is characterized by unstable base and strong tectonic movements. For instance, the lower part of the Sichuan Basin is a Paleozoic craton basin, and the upper part is superimposed with Mesosoic and Cenozoic foreland basins. The Cambrian and Silurian shale strata therein have experienced Caledonian, Hercynian, Yanshannian, and Himalayan tectonic movements. After the deep burial at 6 000 to 10 000 m in late Yanshannian, these two sets of shale strata experienced compression and tectonic uplift in Yanshannian and Himalayan. Not surprisingly, the geological conditions of marine shale gas in China differ widely from those in North America in two aspects.

(1) High degree of evolution. The thermal evolution of marine shale strata in North American regions follows the burial trend of present-day basins. From shallow to deep, the shale strata transit from premature to highly or over-mature, and contain oil, condensate oil, wet gas and dry gas, which is universal in all shale gas basins of North America. Thermal evolution of shale and the distribution of areas of different thermal evolution degrees are important study subjects of shale oil and gas research in North America. In the Sichuan Basin, Cambrian and Silurian shale are both in the dry gas generation window. There is no corresponding relationship between the present-day degree of thermal evolution and the current burial depth. The Wufeng Formation-Longmaxi Formation has Ro values between 1.5% and 3.5%, with an average of 2.5%. The Lower Cambrian Qiongzhusi Formation in Sichuan and Southern China has an average Ro of 3.5%, but lower Ro from 2.0% to 2.5% in the Central Sichuan ancient uplift and its surrounding area.

(2) Strong heterogeneity of shale gas accumulation. The shale gas basins in North America are simple in architecture, so shale gas favorable areas are often distributed continuously. In contrast, under multiphase tectonic movements, the organic-rich shale in China, for example, Wufeng-Longmaxi Formation in the Sichuan Basin, has been reformed by faults and folds of different orientations and ages and cut into multiple structural blocks. Because different blocks are different in fracture development degree, fault nature, tectonic-burial history and present-day burial depth, the Wufeng-Longmaxi Formation shale in them are different in gas content, pressure coefficient and single well production after fracturing. In the north Guizhou region out of the Sichuan Basin, the Wufeng- Longmaxi Formation in the anticline region is exposed to the surface, shale gas is mostly enriched and distributed in isolated syncline areas with normal pressure and low production per well. In the Sichuan Basin, high-quality shale in the Jiaoshiba anticline of Fuling Gas Field, influenced by tectonization like faults, differs clearly in gas content and single well production in different zones[60] (Fig. 5).

3.1.2. Transitional and continental shale gas

The oil and gas industry in China was initiated from continental facies. The widely developed source rocks of continental and transitional facies were once the main concern in the early research and assessment of shale gas. Gas testing of vertical wells and horizontals wells drilled in the eastern part of the Ordos Basin, in Yuanba, Fulin and Jiannan areas of the Sichuan Basin shows many wells are low and unstable in production. Compared with marine shale in North America, shale of continental and transitional facies is characterized by variations in shale quality.

Shale of transitional facies often interbeds with coal and sandstone. The organic-rich shale layer has small thickness and rapid lateral change. The shale layers of transitional facies and coal strata mainly contain mixed-type and humic-type organic matter, and are characterized by high content of brittle minerals, and large proportion of water sensitive minerals in clay minerals. For instance, the fifth member of the Xujiahe Formation in western Sichuan has a quartz content of 33.2% to 52.9%, feldspar content of 3.0% to 20.9%, water sensitive minerals, illite/smectite, make up 12.7% to 22.0%, and Kaolinite makes up 11.0% to 38.0% of the clay minerals.

Continental shale strata are mainly distributed in the lacustrine deposits in the Mesozoic-Cenozoic basins in East China. With low degree of thermal evolution, they are mainly in the phase of oil generation, but in the center of the basin or areas deep buried, they may already enter into gas generation phase. For instance, in the Jiyang Depression of Bohai Bay Basin, the Paleogene organic-rich shale in gas generation window has a burial depth of more than 4 000 m. The continental mud shale is characterized by strong stratigraphic rhythmicity and frequent changes in lithology. Their TOC content is often positively correlated with the content of clay minerals. Similar to shale of transitional facies, their clay minerals have higher proportion of illite/smectite, so they are strongly water sensitive.

Because of the high content of water sensitive minerals in shale layers of continental and transitional facies, large-scale hydraulic fracturing often doesn’ t have ideal results. New engineering technologies and associated equipment systems suitable for shale of continental facies and marine-continental transitional facies need to be developed.

Through ten years of exploration and development, Chinese scholars’ understandings on shale gas, particularly marine shale gas advance significantly. Under thermal evolution, organic matter starts to generate hydrocarbon and forms nano- scale and micro-scale organic pores when reaching certain degree of maturity, providing storage space for methane molecules. Because of the high porosity and low permeability of shale, the shale gas reservoir is characterized by source rock-reservoir-cap in one. In the later period of structural reformation, particularly the tectonic uplifting, the stress state of shale varies, the amount of micro fractures increases, improving porosity and permeability. In this case, methane molecules in the nano-scale pores start to migrate, adjust and finally dissipate. Under the effects of tectonic compression, extension, uplifting, deep burial, and faulting, the shale gas accumulates in strong heterogeneity in the end. Shale gas reservoirs are man-made reservoirs, which must be fractured to get commercial production, so the effect of fracturing determines the well production. Meanwhile, the shale gas reservoir is of marginal benefits, the best tradeoff between operation cost and well production is essential for the profitable development of shale gas. In the process of exploration and development of shale gas in China, we have come up with the integrated evaluation idea of evaluating “ geological sweet spot” , “ engineering sweet spot” , and “ economic sweet spot” at the same time.

3.2.1. Evaluation of “ geological sweet spot”

The aim of the evaluation of “ geological sweet spot” is to understand the spatial distribution of the most enriched shale gas. Through the research on depositional facies and organic geochemistry, the variation pattern of TOC, mineral composition and of porosity of the shale formation can be understood. Based on these studies, organic-rich shale intervals with certain continuous thickness, high TOC, high porosity, high gas content can be selected as “ geological sweet spot intervals” . Meanwhile, areas where sweet intervals are thick, high in quality and good in preservation conditions can be selected as “ geological sweet areas”

3.2.2. Evaluation of “ engineering sweet spot”

The goal of “ engineering sweet spot” evaluation is to select the best layers and positions in the “ geological sweet interval” and “ geological sweet area” for horizontal well fracturing, so that best fracturing results can be reached, realizing high production per well. Firstly, favorable areas for fracturing are selected from the geological sweet areas. Secondly, fracability assessment is carried out to find out the layer for horizontal well drilling with the best fracturing effect in the geological sweet interval. Thirdly, according to the present-day stress orientation, and results of detailed structural interpretation and fracture prediction, the orientation, length of the horizontal interval and trajectory control points of the horizontal well can be optimized. Fourthly, after the completion of a horizontal well, based on the layers the horizontal well drilled through and fracability of the horizontal interval, the locations for staged fracturing and fracturing parameters of all stages are determined.

3.2.3. Evaluation of “ economic sweet spot”

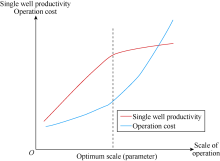

The objective of the evaluation of “ economic sweet spot” is to make technical policy of development through economic evaluation of operation parameters, to maximize the benefit of shale gas development. Theoretically, under the same geological conditions, the length of horizontal interval and scale of fracturing are proportional with well production. In practice, limited by operation capability, increase in the length of horizontal interval and the scale of fracturing can add cost and difficulty of operation. Therefore, the operation costs of horizontal intervals of different lengths and scales of fracturing and single well production need to be compared to get the best development policy (Fig. 6). In the Jiaoshiba region, experiments on horizontal intervals of 1 000 m, 1 500 m and 2 000 m show that the production of well with 1 500 m long horizontal interval is much higher than that with 1 000 m long horizontal interval. Limited by the engineering operation capability, the well with 2 000 m long horizontal interval increases largely in operation cost, meanwhile, because of the drop of completion quality, the production of this well is even lower than that of the well with 1 500 m long horizontal interval. Therefore, the length of the horizontal interval for development wells was determined to be 1 500 m. Through statistics on fracturing fluid volume and sand dosage per stage and well production, the best fracturing fluid volume and amount of sand added were determined.

| Fig. 6. Schematic map showing the relationship between the scale of engineering operation production per well and operation cost. |

The successful exploration and development of shale gas are dependent on the collaborative research across different disciplines, integrated geological-engineering-economic evaluation and integrated implementation of exploration and development engineering.

3.3.1. Great resource prospects and numerous challenges

The former Ministry of Land and Resources carried out multiple rounds of evaluation on the resource potential of China’ s shale gas, and concluded that the recoverable resources of shale gas were 10 to 32 trillion m3, the recoverable resources of marine shale gas were 8.2 to 13 trillion m3. The estimates of the recoverable resources of shale gas of transitional facies and continental facies differ widely. Although Chinese researchers have different views on the resource potential of shale gas in China, the basic consensus is that the recoverable shale gas resources are abundant.

Through ten years of endeavor, shale gas industry in China has gained a solid start. Scaled commercial development of the Wufeng-Longmaxi Formation above the depth of 3 500 m in the Sichuan Basin has been achieved. The rapid development of shale gas industry is facing with numerous challenges. Marine shale strata in China are universally old-aged. The favorable areas of marine shale gas are distributed mostly more than 3 500 m deep in the Sichuan and Tarim basins. The organic-rich shale formations are widely distributed in south China. But affected by multiphase tectonic movements, they often have normal pressure coefficients and poor preservation conditions. For example, the Wufeng-Longmaxi Formation, in the Sichuan Basin, its favorable areas less than 3 500 m deep and between 3 500 m and 4 500 m deep are more than 3500 square kilometers and 2 000 square kilometers respectively, with amount of resources of more than 2.6× 1012 m3and 10× 1012m3 respectively[68, 69]. Outside of the Sichuan Basin, in the remaining syncline areas in the north Guizhou region, the resources of shale gas are about 2 to 8 trillion m3. Shale gas resource in deep strata with normal pressure is difficult to develop profitably with the current engineering technology. Though shale gas flow has been obtained in some wells from the Cambrian, Permian shale of marine, continental, and transitional facies, actual breakthrough in commercial development has not been achieved. The production regularities, development technologies and policies remain to be explored. In China, 67% of shale gas favorable areas are located in hills and mountain regions with fragile ecology, so the requirements on environmental protection are high, plus the lack of natural gas networks, making the profitable development of shale gas more challenging.

3.3.2. Recommendations for developing shale gas industry

(1) Srengthen fundamental research to achieve new breakthrough on the geological theory of shale gas. In terms of the sedimentary research, the distribution characteristics of organic-rich shale of the Longmaxi-Wufeng Formation have made significant progress. Distribution pattern of other organic rich formations in Cambrian marine facies, transitional facies and continental facies needs deeper investigation. Regarding the storage mechanism of shale reservoirs, preliminary understanding have been gained in the development of organic pores under thermal evolution and the relationship between the enrichment of shale gas and organic pores. However, the current conclusions are drawn mainly through observation and statistical analysis, the intrinsic mechanism remains to be explored. Regarding the enrichment characteristics of shale gas, enrichment rules of shale gas in normally pressured deep marine strata, and continental and transitional strata need to be examined further. Fracability study of mud shale is weak in the fundamental research of both geology and engineering of shale gas. Further study requires the integration of geology and engineering related disciplines, and the establishment of research direction of multiple disciplines. Evaluation system and standard should be built for the economic evaluation of shale gas.

(2) Reinforce exploration practices to have all-round discoveries in multiple strata. As the exploration in the Silurian strata of the Sichuan basin advances, new discoveries in Cambrian and Permian strata are under expectation. Recently, in the Jingyan-Jianwei area at the west margin of the Changning-Mianyang tensional trough [70, 71] , Well Jinshi 1 and Jinye 1 drilled have proved the Changning-Mianyang tensional trough is the favorable area for Lower Cambrian organic-rich shale[72]. Well Jinye 1 tested a daily gas production of 59.5 thousand m3 from the Lower Cambrian Qiongzhusi Formation, showing good exploration prospects. Two organic-rich shale zones have been confirmed in the Permian strata recently. The cores sampled from Well Dongyeshen 1 contain dark mud shale with higher gas content. Through systematic research on sweet intervals and layers for horizontal wells, breakthroughs in Cambrian and Permian strata are expected. At the same time, fundamental research in the Yichang and Guizhong regions should be paid more attention to, so that discoveries in new areas of marine shale can be obtained. Shale gas flows have been acquired in transitional and continental facies in the Daanzhai Member, Dongyuemiao Member in the Jurassic Ziliujing Formation in the Sichuan Basin, in the Triassic Yanchang Formation and the Carboniferous Shanxi Formation in the Ordos Basin, in the Lower Cretacious Yingcheng Formation in the Lishu Sag in the northeastern China. Referring to the exploration idea of marine shale, sweet spot intervals and areas in shale, mud limestone and coal strata need to be sorted out by strengthening research.

(3) Study the regularities of development and production, to establish new models of shale gas development. Further studies on dynamic analysis of development wells should be promoted. The development and production systems for shale of different types and pressure coefficients should be established. New development models for man- made gas reservoirs are to be established. Lessons should be drawn from the three-dimensional development model established in North America. Three dimensional development in upper and lower gas-bearing intervals of the Wufeng-Longmaxi Formation, in the Cambrian, Silurian, Permian and Jurassic strata in the Sichuan Basin remains to be explored.

(4) Think creatively to invent new technologies to tackle key problems. In terms of geophysical technology, “ sweet spot” prediction techniques, such as prediction of formation pressure and fracture, sealing capability of faults, and identification of high TOC content should be tackled. More research on fracturing technologies for deep strata and low-cost fracturing in normally pressured regions should be carried out. In light of the high content of clay minerals and strong water-sensitivity of continental and transitional shale strata, new fracturing technologies such as supercritical carbon dioxide fracturing and the associated equipment system should be further studied. Development of information and digital technologies should be stepped up. Researchers abroad hold that efficient utilization of information and digital technology can improve the production efficiency significantly, reduce about 20% of the capital expenditure, and lower the management cost of the upstream by about 3% to 5%. At the same time, tracking the cutting edge technology such as nano-technology, graphene, quantum and man-made intelligence is important, so that subversive technology can be developed.

(5) Explore management innovation to form new mechanisms in shale gas development. While oil companies are utilizing new technologies to improve efficiency and lower operation cost, more focus should be put on optimizing engineering design and management workflow. The market mechanism should be utilized efficiently, the management on contractors and supply chains should be improved, so that the cost can be reduced in every aspect. The cooperation and development mechanism of investors can be established at the country level. Experiences can be shared and communicated, trials of new technologies and application mechanisms should be encouraged. Security, environmental protection management and surveillance mechanism should be improved so that the environment for rapid growth of shale gas industry can be created.

Since the initiation of China’ s shale gas exploration in 2009, the commercialized shale gas development in marine shale of the Wufeng-Longmaxi Formation has been realized, making China one of the few countries that have developed shale gas in industrial scale.

After nearly ten years of persistent research, major progress has been made in the understanding on major factors controlling gas enrichment and high production of marine shale represented by the successful development of the Wufeng-Longmaxi Formation. The development of shale gas of the Wufeng Formation-Longmaxi Formation in the Sichuan Basin, which can be summarized into the following aspects: depositional environment and depositional process control the distribution of organic-rich shale; high quality shale layers in “ sweet spot intervals” are commonly characterized by high content of organic carbon, high brittleness, high porosity and gas content; organic pores are important storage space for the enrichment of shale gas; preservation condition is the key factor in the geological evaluation of shale gas in structurally complex regions; shale gas reservoirs can be considered as “ man-made gas reservoirs” and fracability assessment is essential for high- production; nanoscale storage space and the occurrence state of shale gas make seepage characteristics of shale gas special.

The successful exploration and development of shale gas are dependent on the collaborative research across different disciplines, the integrated geological-engineering-economic evaluation and the integrated implementation of exploration and development engineering.

China’ s shale gas industry has great resource potentials and numerous challenges. We recommend the following for the rapid development of China’ s shale gas industry: (1) strengthen fundamental research to achieve new breakthrough in the geological theory of shale gas; (2) reinforce exploration practices to get all-round discoveries in multiple strata; (3) study the regularities of development and production to establish new models of shale gas development; (4) think creatively to invent new technologies to tackle key problems; (5) explore management innovation to create new mechanisms in shale gas development.

The authors thank HU Zongquan, FENG Dongjun, YI Jizheng, WANG Feng and DENG Shang for their help in this study.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|

| [47] |

|

| [48] |

|

| [49] |

|

| [50] |

|

| [51] |

|

| [52] |

|

| [53] |

|

| [54] |

|

| [55] |

|

| [56] |

|

| [57] |

|

| [58] |

|

| [59] |

|

| [60] |

|

| [61] |

|

| [62] |

|

| [63] |

|

| [64] |

|

| [65] |

|

| [66] |

|

| [67] |

|

| [68] |

|

| [69] |

|

| [70] |

|

| [71] |

|

| [72] |

|