Carbonate reservoirs in China have the characteristics of diversified accumulation pattern, complex structure and varying reservoir conditions. Concerning these characteristics, this article tracks the technical breakthroughs and related practices since the 1950s, summarizes the developed theory and technologies of carbonate reservoir development, analyzes their adaptability and problems, and proposes their development trend. The following theory and technologies have come into being: (1) carbonate reservoir formation mechanisms and compound flow mechanisms in complex medium; (2) reservoir identification and description technologies based on geophysics and discrete fracture-vuggy modeling method; (3) well testing analysis technology and numerical simulation method of coupling free flow and porous media flow; (4) enhanced oil recovery techniques for nitrogen single well huff and puff, and water flooding development techniques with well pattern design in spatial structure, changed intensity water injection, water plugging and channel blocking as the core; (5) drilling and completion techniques, acid fracturing techniques and its production increasing techniques. To realize the efficient development of carbonate oil and gas reservoirs, researches in four aspects need to be done: (1) complex reservoir description technology with higher accuracy; (2) various enhanced oil recovery techniques; (3) improving the drilling method and acid fracturing method for ultra-deep carbonate reservoir and significantly cutting engineering cost; (4) strengthening the technological integration of information, big data, cloud computation, and artificial intelligence in oilfield development to realize the smart development of oilfield.

Carbonate reservoirs take an important position in the global petroleum resources. According to the statistics of IHS, the carbonate hydrocarbon resources account for about 70% of the global oil gas resources, and the proved recoverable reserves for about 50% of the global total, the production for about 60% of the global total. Widely distributed in the North America, Middle East, Central Asia and other areas, carbonate reservoirs mainly include organic reef, grain beech, dolomite and weathering crust types. Usually big in scale and shallow in burial depth of less than 3 000 m, they concentrate dominantly in the Jurassic, Cretaceous and Neogene, and are mostly pore type. The development design of most carbonate reservoirs aboard is based on continuum theory; and in the drilling completion and engineering processes, a series of technologies, such as complex well, have been developed to improve the production and enhanced oil recovery (EOR) of carbonate reservoirs.

China also has rich oil and gas resources in carbonate reservoirs. According to the dynamic evaluation on nationwide hydrocarbon in 2015, the geologic oil and gas resources amount to 340× 108 t and 24.3× 1012 m3, accounting for 27.0% and 26.9% of the total oil and gas resources respectively. Recently, with the development on giant carbonate oil gas fields, such as Tahe Oilfield, Puguang Gas Field, and Anyue Gas Field, the production of natural gas and crude oil grow rapidly, becoming an important domain for the E& D and reserve production growth in China.

Compared with the carbonate reservoirs in the other countries, the carbonate reservoirs in China are characterized by ancient geologic age, deep burial, multistage reformation by tectonic movements; and the oil reservoirs are mainly fracture-porous and fracture-cave types, while gas reservoirs are mainly porous reef beach dolomite, bringing about more difficulties to the development. After study and exploration of several generations of researchers, new progress has been made in genetic mechanism of different reservoirs, fluid compound flow mechanism and characterization etc., meanwhile some key techniques have been developed, such as ultra-deep geophysical description, discrete geology modelling, ultra-deep complex well, deep large-scale reservoir stimulation, water flooding and gas flooding EOR etc.[1, 2, 3, 4], which have improved and enriched the carbonate reservoir development theory and technology system.

In this paper, the development status of theories and engineering technologies for the three types of carbonate reservoirs (pore, fracture-pore, fracture-cave) are reviewed, the challenges of carbonate reservoir development are clarified, the next-step technical development direction is pointed out, and the solving approaches to the challenges are put forward, to guide the deepening of carbonate reservoir development theories and technologies.

The large-scale development of carbonate oil and gas field in China began since the 1950s, and has mainly undergone three stages, namely, the first stage from 1950 to 1975 with the emphasis on the reef beach reservoirs in the Sichuan Basin, the second stage from 1975 to 1996 with the emphasis on the pre-Tertiary fractured buried-hill reservoirs represented by Renqiu Oilfield, the third stage of karst belt fracture-cave reservoirs represented by Tahe Oilfield from 1990 to 2018 and deep natural gas reservoirs represented by the Puguang, Yuanba and Anyue gas fields from 2003 to 2018, with a history of nearly 70 years.

By the end of 2015, the cumulative proved carbonate oil and gas reserves in China were 29.34× 108 t and 3.37× 1012 m3[5] respectively, and mainly distributed in the Tarim, Sichuan, Bohai Bay, Ordos and Pearl River Mouth basins. The oil resource mainly occurs in the Tarim, Bohai Bay and Pearl River Mouth basins, while the natural gas mainly occurs in the Sichuan, Ordos and Tarim basins[6, 7, 8].

The occurrence horizons span from the Sinian to Triassic, dominantly Paleozoic. The oil is found largely in the Ordovician and pre-Sinian; and the natural gas in the Permian, Triassic, Cambrian and Sinian.

The carbonate reservoirs in China are characterized by “ diverse accumulation models, complex structures, and different reservoirs” .

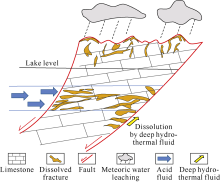

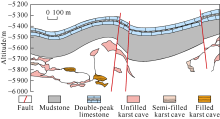

(1) Complex geologic conditions. No matter the Ordovician fracture-cave oil reservoirs in the Tarim Basin, the reef beach gas reservoirs in the Sichuan Basin, or the pre-Tertiary buried-hill hydrocarbon reservoirs in the Bohai Bay Basin, they are all buried deeply in the Paleozoic, usually at 5 000-7 000 m, and experienced multistage tectonic movements and karst superimposed reformation, including old source and old reservoir pools (Fig. 1), new source and old reservoir pools, and new source and new reservoir pools, exhibiting extremely complicated geologic conditions.

| Fig. 1. Section of fracture-cave reservoirs with old source and old reservoirs in the Tahe Oilfield. |

(2) Multiple types and strong heterogeneity of reservoirs. The carbonate oil reservoirs onshore China are mainly limestone, and the gas reservoirs are mainly dolomite; and the reservoir space comprises of pores, fractures and caves, resulting in large reservoir physical property distribution difference, strong heterogeneity and poor physical property, with the porosity of generally 2%-6%, yet matrix porosity generally less than 2%. Carbonate reservoirs abroad are mostly porous type with good physical property, for example, the carbonate reservoirs in the Middle East are mostly 8%-25% in porosity[9].

(3) Diverse types and complex distribution of fluid. The carbonate oil and gas reservoirs in China have multiple reservoir forming stages, and different reservoir forming stages have different oil and gas phase states, leading to different properties and complex distribution of fluids, so the reservoirs could contain light oil, heavy oil, dry gas, condensate gas, or acid gas with high H2S and CO2 contents. Meanwhile, the oil, gas and water relationship is also very complicated, for example, each fracture-cave unit in the Tahe Oilfield constitutes an independent oil-water system; there are 9 gas-water systems in the Feixianguan Formation gas pool and 13 gas-water systems in the Changxing Formation gas pool in the Longgang Gas Field, where most wells are characterized by “ one well, one horizon and one system” [10].

The carbonate reservoirs in China are diverse in reservoir space type, the gas pools are mostly porous type, oil pools mostly fracture-porous and karst fracture-cave types. The fluid flows in multiple forms, mainly free flow in large caves and fractures, and seepage in small scale space, thus the reservoir differ widely in development characteristics, generally:

(1) High initial production and rapid decline. The carbonate reservoir space comprises of pores, caves and fractures with great scale difference. For oil wells, in the initial development stage, the oil and gas in free flow state in the large fractures and caves is firstly produced, resulting in high yield. However, along with the decrease of pressure, some fractures close, and oil and gas flow slow in small scale space such as intergranular pores, inter-crystalline pores and micro-fractures, thus the production declines rapidly. The gas well production is similar to oil well production, initially they are produced at stable production at the expense of pressure drop, but this period is short, and the production declines quickly when entering into the pressure maintaining and production drop period.

(2) Great influence on the production by ubiquitous edge-bottom water. For the fracture-porous and karst fracture-cave oil reservoirs, the edge-bottom water can quickly invade along the fractures, causing quick rise of water cut in the oil well or even water flooding, oil production decline and low recovery rate. For example, in the Tahe Oilfield, the fracture-cave bodies mostly connect with bottom water directly[11], so during the development about 20% producers are shut in because of violent water flooding. Similarly, the edge-bottom water invasion causes water production in gas wells, leading to rapid decline of gas production and decrease of gas recovery rate. Among 42 Carboniferous gas pools in Eastern Sichuan, 36 gas pools produce water, accounting for 86%, and the water invasion reduces the recovery rate by about 2%-8%[12]. The carbonate gas reservoirs in China have an average recovery rate of 42.3%, lower than the tight sandstone gas reservoirs (about 50% on average), therefore the control on edge-bottom water invasion is a key link in the development of this type of gas reservoir.

(3) Easy channeling and low recovery rate of oil reservoirs by water flooding. The injected water is easy to dash along fractures, leading to drop in the swept volume and displacement efficiency on one hand, more complicated residual oil distribution and higher difficulty in enhancing recovery because of the separation and shielding effect of the injected water on the other hand. The recovery rate of 25 major carbonate oil reservoirs in China averages only 14.4%.

Compared with the porous carbonate reservoirs continuously distributing in the Middle East and North America, the carbonate reservoirs in China have more complex geologic conditions and development characteristics, so they face three special problems.

(1) Difficult precise description of the reservoir body. On one hand, reformed by multistage tectonic movements, the carbonate reservoirs present multiple media types and complicated genetic mechanism, with distribution pattern difficult to recognize; on the other hand, the reservoirs are deeply buried, diverse in fracture-cave relationship and filling type, and different greatly in horizontal and vertical distribution, making them difficult to identify. Complicated in reflection behavior, low in signal-to-noise ratio and imaging precision[13, 14, 15, 16], carbonate reservoirs of super-deep burial are difficult to be identified and described by the geophysical technologies.

(2) Difficulty in development index prediction. The fluid flow in fracture-porous and karst fracture-cave reservoirs is a kind of coupled flow composed of seepage in the porous media, high velocity flow in the fracture media and free flow in vuggy media, thus the experiment and simulation based on the porous media seepage theory cannot effectively describe the characteristics of this compound flow, and it is difficult to accurately predict the development rule and dynamic indexes of this kind of reservoir.

(3) Low effective utilization rate of reserve and recovery rate. The carbonate reservoirs are discrete in distribution, different greatly in horizontal and vertical directions, extremely heterogeneous, complicated in oil, gas and water relationship, and greatly different in single well production, so it is difficult to deploy rational well pattern, leading to low effective utilization rate of reserves. Meanwhile, due to the existence of large-scale fractures, the edge-bottom water and injected water are likely to channel, resulting in small swept volume, rapid production decline and low recovery rate.

In view of the special problems encountered in carbonate reservoir development, after 70 years of persistent research, the theoretical systems on carbonate reservoir genetic mechanism and fluid flow mechanisms etc., and technical series including reservoir description, geologic modelling, drilling completion, reservoir stimulation, and EOR etc. have been developed.

There are three types of carbonate reservoirs in China, pore, fracture-pore, and karst-cave. The pore type reservoirs are mainly distributed in the Sichuan Basin, and largely reef beach facies; the fracture-pore type reservoirs are mostly found in the pre-Tertiary fault rift basins in eastern China, and are largely buried hill; the karst-cave reservoirs are largely distributed in the Tarim and Ordos basins, and mainly weathering crust and unconformity. Different types of reservoirs have different genetic mechanisms.

2.1.1. Pre-Tertiary fracture-pore type buried hill reservoirs

The pre-Tertiary fault rift basins in the eastern China have buried hill oil reservoirs universally, where the strata settled again and then were covered by the Cenozoic sediments after the tectonic movements and weathering erosion, and the prominent blocks are the buried hills.

The buried hills in the Bohai Bay Basin occur mostly in the Paleozoic, and experienced 3 stages of structural evolution: in the Indosinian epoch the sinistral extrusion orogeny creating folds; in the Yanshan epoch the sinistral shear tension giving rise to faulted block buried hill; in the Himalayan epoch buried hill finalized under the background of dextral shear tension.

The buried hill reservoir space comes from three origins: (1) The shaping of buried hill is associated with a lot of faults and fractures. (2) The weathering leaching and underground water effect expand and connect the original fractures and pores, and produce many dissolved caves. (3) The acid fluid generated from different source rocks and the thermal fluid in the Himalayan epoch reforms the limestone and dolomite inside the buried hills (Fig. 2).

2.1.2. Karst-cave reservoirs in the Tarim Basin

The karst fracture-cave reservoir space comprises of fractures, caves and pores, with rich large caves and fractures. In the Tarim and Ordos basins, there are many Paleozoic karst fracture-cave reservoirs resulted from the multistage karstification and later burial reformation, mainly including weathering karst and fault dissolving karst.

The weathering karst is controlled by the geomorphologic unit and karst belt, and can be vertically divided into four zones, epi-karst, vertical percolation, runoff dissolution and undercurrent dissolution, among which the runoff dissolution zone is most developed[17]; on the plane, it can be divided into four 2nd-order topographic units, namely, the karst terrace, karst gentle slope, karst slope and karst intermontane basin, which can be further divided into eight 3rd-order geomorphologic units, including peak cluster low, karst hill low and hill peak low, etc, among which peak cluster low and hill peak low are most developed[18].

The fault dissolving karst refers to the karstification around the fault zone to develop the prospective reservoir belt, where the fault zone and structure deformational zone match well with the karst. According to the distribution shape, this kind of karst can be classified into stripe, sandwich pancake and tablet types[19].

The two kinds of karst reservoirs both occur in the Tarim Basin, with the weathering karst spreading widely, and the fault dissolving karst appears in stripe.

2.1.3. Reef-beach pore reservoirs

The pore type carbonate reservoirs, mostly grain limestone and dolomite, are mainly distributed in the Sichuan Basin and of grain beach and organic reef facies.

A great majority of the grain beaches and organic reefs developed in the high energy belt of platform margin; under the control of structural paleo-uplift, the hydrodynamic condition there was strong, which facilitated the grain reef beach deposition in the platform marginal high and its periphery. The paleo-high around the large intra-platform low could also develop reservoirs of grain beach facies. For example, the grain beach of Longwangmiao Formation in the eastern Sichuan was controlled by the sea level fluctuations, vertically showing superimposition of multiple thin beach bodies (small thickness of single beach body), with dark fine sediments of deep water environment in the lower part and grain beach composed of grain dolomite and grain limestone in the upper part[20].

The reservoir of reef beach facies is prone to dolomitization, which is conducive to the development of reservoir space. This kind of reservoir is controlled by three factors: the sedimentation-diagenetic environment controls reservoir scale and early pore development; the coupling of structure and fluid controls the fractures and dissolution; and the mutual action between the rock and fluid controls the pore preservation. For example, the lower part of Changxing Formation organic reef reservoir in the Sichuan Basin is point reef sediments on the background of carbonate gentle slope, depositing during the process of long quick sea level rise, the reef body is small, and the reservoirs are thin and poor in physical property; in contrast, the upper part is platform margin facies of gentle slope when the transgression transited to regression; thus the reef body is large, and the reservoir is thick and good in physical property. With structural fractures hardly filled in the diagenesis period, the Changxing Formation reservoirs are higher in permeability[15].

The fluid flow mechanism in the carbonate reservoirs, especially the fracture-pore and karst fracture-cave types, has been always the hot research topic at home and abroad. In the 1950s, Bruce G H et al.[21] established the mathematical model of single medium, that solved the characterization problem of flow mechanism of fluid in the multi-pore continuous media. Warren et al.[22] proposed the mathematical model of double medium in the 1970s and discrete fracture network model in the 1990s, which solved the characterization of flow mechanism of fluid in the fracture-pore reservoir. The dual media model assumes the reservoir fracture as network and the bedrock is separated into individual groups by the fractures, for this type of reservoir, the matrix has large porosity and small permeability, while the fractures have small porosity and large permeability. The matrix and fractures form relatively independent hydrodynamic systems with fluid exchange. The mathematical model of dual media and discrete fracture network lay foundation for the numerical simulation and well testing technologies.

In one flow unit of the karst fracture-cave reservoir, there are both free flow in the large caves and fractures, and seepage flow in small scale reservoir space, thus the fluid flow is a kind of compound flow and characterized by: (1) The free flow is nonlinear with inertial force in the caves and large fractures. (2) There exists abrupt change in flow speed at the interface between the free and seepage flow. (3) At the interface between the cave and fracture (or well), turbulent current is apparent, showing a complicated streaming condition. (4) In the cave under low flow velocity, the oil, gas and water show quick gravitational differentiation, and there exists distinctive interfaces between the oil, gas and water. (5) During production, fractures and pore caves have strong compressibility, and the fractures are likely to close.

The Tahe Oilfield is the largest karst fracture-cave reservoir in the world, the fluid flow mechanism in this kind of reservoir is a publicly known problem. After more than ten years of research, on the basis of indoor physical modeling experiment, Chinese researchers established the mathematical model of pore-cave-fracture complex media[23]. In this model, the caves and large fractures are treated as discrete media separately, in which the fluid flow follows the Navier-Stokes fluid dynamics rule, yet the small scale caves, fractures and pores are taken as continuous media to set up the Darcy equation and mass balance equations based on triple continuous media; and the interface equation[24] is adopted to realize the coupling of free and seepage flows, and the two-phase interface equation system consists of normal velocity continuity equation, normal stress continuity equation, and tangential stress condition equation.

Normal velocity continuity equation:

${{\left[ \mathbf{u} \right]}_{{{\Omega }_{\text{ff}}}}}\cdot \mathbf{n}={{\left[ {{\mathbf{u}}_{\text{w}}}+{{\mathbf{u}}_{\text{n}}} \right]}_{{{\Omega }_{\text{pm}}}}}\cdot \mathbf{n}\text{=}{{\left[ \mathbf{u} \right]}_{{{\Omega }_{\text{pm}}}}}\cdot \mathbf{n}$ (1)

Normal stress continuity equation:

$n\cdot {{\left[ pI-a\mu \left( \nabla {{u}_{\text{f}}}+\nabla {{u}_{\text{f}}}^{\text{T}} \right) \right]}_{{{\Omega }_{\text{ff}}}}}\cdot n=$

$\frac{1-\Phi }{2}{{\left[ {{p}_{\text{n}}} \right]}_{{{\Omega }_{\text{pm}}}}}+\frac{1+\Phi }{2}{{\left[ {{p}_{\text{w}}} \right]}_{{{\Omega }_{\text{pm}}}}}\text{ }$ (2)

Tangential stress condition equation:

${{\tau }_{i}}\cdot {{\left\{ {{u}_{l}}+b\frac{\sqrt{{{K}_{\text{r}}}\left( {{S}_{\text{w}}} \right)K}}{\alpha \left( {{S}_{\text{w}}} \right){{\mu }_{l}}}{{\left[ \mu \left( \nabla {{u}_{\text{f}}}+\nabla {{u}_{\text{f}}}^{\text{T}} \right) \right]}_{l}} \right\}}_{{{\Omega }_{\text{ff}}}}}\cdot \mathbf{n}=0$

$(i=1, 2, \cdots , d-1)$ (3)

After years of persistent research, Chinese researchers have made great progress in the description of reservoir shape, scale, pore-cave-fracture relationship, filling characteristics and oiliness, developed several series of technologies, including geophysical identification, description and geologic modelling, enhancing the precision of carbonate reservoir description greatly.

3.1.1. Geophysical identification

Centering on improving seismic imaging precision, technologies on the petrophysical experiment, diffraction wave separation and reverse time-depth migration high precision imaging, and detection and identification of reservoir space by scales have been developed.

(1) In the aspect of petrophysical experiment: Full-scale, high precision, automatic forward modelling technology was developed. The carbonate reservoir space comprises of caves, pores and fractures, resulting in complicated wave field. This forward modelling equipment can realize the fitting of wave field responses for different reservoir media, and complete high speed automatic seismic survey for indoor large-scale fluctuating model. With this model, the minimum controllable scale of cave is reduced from 1 mm to 0.1 mm, and the modeling depth can reach 6 500 m.

(2) In the aspect of imaging technology: With the reverse time-depth migration, the energy of the cave-fracture bodies can be enhanced by 20%, effectively improving the imaging precision. The diffractive wave separation fracture-cave imaging method with high computation speed, can obtain the direct image of fracture-cave bodies under the disturbing background of weathering crust reflection, which is particularly effective in improving the identification precision of small cave-fracture bodies, with the identified number of fractures and caves increasing by 20%. By using the two methods jointly, the imaging precision of fracture-cave bodies can be enhanced by 100%.

(3) Reservoir identification: Detection technologies for various scales of fractures and caves have been established[25, 26], seismic reflector structure analysis and strong amplitude cluster method are used to detect large-scale caves, and seismic geometric attributes are applied to detect large-scale fracture belts; meanwhile based on the ancient landform, a kind of inversion method is worked out to count the petrophysical Bias’ s probabilistic physical parameters constrained by lithofacies, realizing characterization of the cave scale, porosity and filling parameters of different combinations of fracture and cave bodies.

(4) Gas-bearing property prediction: for the reservoirs of reef beach facies, the abnormal value in seismic data volume of the target formation is employed to predict the gas bearing property[27], which has achieved good results. Guided by the results of gas-bearing prediction, 100% of new wells drilled in the Puguang Gas Field encountered high quality reservoir.

3.1.2. Geologic modelling

In the 1980s, the technical problems of deterministic and stochastic modeling were developed, solving the geostatistical modelling problem of continuous porous reservoir and greatly improving the description precision of the clastic rock and pore type carbonate rock. At the beginning of the 21st century, the discrete fracture modelling method was advanced[28, 29], ending the description problem of the fracture-porous reservoir; in line with karst fracture-cave oil reservoirs represented by Tahe, the discrete fracture-cave modelling method was set up[30, 31, 32, 33], finishing off the geologic modelling problem of com-posite media oil reservoirs of karst fracture-cave type.

Karst fracture-cave reservoir bodies differ widely in scale. The large caves can be up to thousands of meters in diameter, and the large fractures and caves, with distinctive geophysical features, can be identified and described by geophysical methods; in contrast, the small fractures, caves and dissolved pores can be only identified by core observation and logging analysis. The fracture and cave modelling should consider different scales and precisions. In order to improve the modelling precision, the reservoir space in carbonate reservoirs can be divided into matrix pores, fractures, dissolved pores and caves, and large karst caves according to the reservoir space shape. Meanwhile, to facilitate identification of reservoir space and fluid flow description, the carbonate reservoir bodies classification and grading standard[34] is set up (Table 1).

| Table 1 Classification and grading standard for carbonate reservoir bodies. |

In discrete fracture-cave modelling, constrained by the ancient landform, karst development model and fault development pattern, the discrete distribution models are built by class and grade: the large karst caves, small karst caves, dissolved pores and caves, large, medium and small scale fractures are modeled by seismic identification method, multiple-point geostatistical stochastic modelling method, sequential Gauss stochastic simulation method, seismic identification deterministic modeling, ant body tracking and target-based stochastic simulation respectively[34]. The equivalent assignment fusion method is used to construct the multi-scale fracture and cave distribution model. The shape, scale, relation and filling of fractures and caves and reservoir physical property are described in detail to clarify the geologic reserves and distribution of different reservoirs. According to the geologic model, wells were deployed, with drilling coincidence rate increasing from the 71.1% to 92.7%, greatly improving the reserve producing rate.

From the perspective of fluid flow type, the fluid flow in carbonate reservoirs, especially karst fracture-cave reservoir, is flowing in composite media, which cannot be effectively modeled and predicted by the conventional numerical simulation methods based on continuous media and seepage theory, hindering the prediction of development rule and optimization of development design. In view of this characteristic, the coupling numerical simulation and well testing analysis technology were developed.

3.2.1. Numerical simulation for free-seepage flow coupling

The mathematical models coupling free and seepage flows in numerical simulation can be divided into two types: (1) The control equations are built based on equation of cave free flow, and the seepage in the dissolved pores is treated as the source sink term, which has high calculation precision for multiphase flow in the karst cave and is applicable for the precise mechanism research of fracture-cave combination. (2) The control equations are built based on the Darcy’ s law of percolation, and the free flow in the cave or fracture is processed through embedding[23, 35, 36], for the small scale fracture, pore and cave zones, the single, double or triple media zoning simulation is adopted according to the distribution. This method is mainly used for simulation of large-scale reservoir.

The model calculation uses the limit volume method to carry out numerical discretion on each partial differential control equation and solution of the model adopts the algorithm of the improved constraint pressure residual preprocessing combined with the algebraic multigrid linear equation.

The karst fracture-cave reservoir numerical method is adopted to predict the oil production index, with a coincidence rate of up to 85.1%[37], which is nearly 100% higher than the coincidence rate of the commercial continuous numerical method.

3.2.2. Fracture-cave reservoir well testing

The well testing surveys the reservoir parameters through the changes in working system and the bottom-hole pressure. The Warren-Root model[22] can simulate the seepage in the fracture-pore carbonate reservoirs, but the karst fracture-cave carbonate reservoir generally has caves, dissolved pores and fractures, so the dual-porosity model can’ t meet the requirements of well testing interpretation of this kind of oil reservoir any more.

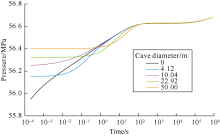

For the karst fracture-cave oil reservoir, two kinds of well testing models were developed: (1) In case of the reservoir media having representative elementary volume of small scale, the equivalent continuous medium numerical model can be used to construct the well testing interpretation method (triple media model). (2) In the case that there are large scale karst caves, the well testing model for the coupling of free flow in large-scale karst cave media and seepage flow in multi-porous media should be used[1].

Besides the traditional well testing interpretation parameters (such as wellbore storage coefficient, skin factor, permeability, crossflow coefficient, and elastic storage ratio etc.), the most important feature of the triple media model and coupling media model is that they can interpret the scale of the karst cave (Fig. 3) as well as the position between the cave and well, fracture width, and density etc., so the physical property and flow parameters of the underground fracture cave reservoirs can be assessed effectively.

Since the well testing period is short, it is impossible to predict the reserves in the fracture-cave bodies far away, the production data analysis and interpretation method has been developed to predict the single well control reserves in three types of reservoir space (karst cave, pore and cave, fracture) and improve the precision of well controlled reserves calculation based on the relation curve between the mass balance time and flow reforming pressure at the quasi steady state.

Carbonate oil and gas reservoirs are deep in burial depth and high in temperature and pressure, and diverse in types; especially, most carbonate gas reservoirs in the Sichuan Basin are sour, posing great challenge to the safe-fast drilling and profitable development. Through research, technologies such as safe-fast drilling and real-time optimization of ultra-deep horizontal well trajectory for high sulfur content gas fields have been worked out. Meanwhile, the sidetrack slimhole drilling completion technology has been developed to solve the old well utilization problem in the Tahe Oilfield.

3.3.1. Safe-fast drilling technology for gas fields with high sulfur content

The Puguang Gas Field contains 15.16% of H2S and 8.64% of CO2, so the drilling there faces not only the problems of blowout, lost circulation, wellbore collapse, bit sticking, inclination and hard rock, but also the possible leakage of toxic H2S gas. In view of these issues, upper non-pay zone gas drilling ROP enhancement, well control for safe drilling, anti-channeling anti-leaking corrosion-resistant latex cement system and positive injection and reverse squeezing etc. completion technologies[27] have been developed. The average penetration rate of gas drilling amounts to 7.49 m/h, that is 3-8 times of the penetration rate of conventional drilling, so the single well drilling cycle is shortened by more than 60 d; the one-time qualified rate of cementation is 100%, and the rate of good quality cementing of the gas zones exceeds 85%.

3.3.2. Real-time optimization of ultra-deep horizontal well trajectory

The bio-reef gas pool of Changxing Formation in the Yuanba Gas Field is buried deep (about 7 000 m), and the high quality reservoir is thin, thus the vertical wells are low in productivity, failing to meet the demand of effective development. The optimum choice for developing this kind of reservoir is to adopt horizontal well, yet for this ultra-deep thin reservoir on the fluctuated structure, it is very difficult to control the horizontal well trajectory. Aiming at this problem, while matching drilling tools, the carbonate rock lithologic interpretation chart and reservoir NMR physical property evaluation standard were set up, forming the quick rock identification while-drilling technology and quick reservoir evaluation while-drilling technology; horizontal well trajectory optimization mode for the ultra-deep band-like small reef gas reservoir has been established to adjust the designed track and promptly increase or decrease the inclination[38, 39]. This technology resulted in 100% drilling success rate, nearly 95% coincidence rate of reservoir prediction, more than 82% penetration rate of reservoir by horizontal wells, and 2-3 times of single well productivity enhancement in Yuanba Gas Field.

3.3.3. Drilling and completion technology for sidetracked slimhole

Due to small fracture-cave body and bottom water flooding, some production wells in the Tahe Oilfield were shut down. In order to make full use of these old wells, the slimhole sidetracking technology has been come up, including the cementing technique through small liner with small clearance and small hole directional drilling method, the restraint drilling liner hanger and nonstandard casing, solving the problems of small casing size, difficult cementation through small liner, and difficult matching of drilling tool for the 2nd drilling section, and satisfying the demand of sidetrack drilling and completion from Φ 177.80 mm casing and Φ 193.70 mm casing[40]. This technology resulted in the overall good quality cementing rate of up to 85% and cost reduction by 50%-70%.

The water flooding is the most economic and effective energy supplementary way. The oil reservoir of Wumishan Formation in the Renqiu Oilfield was put into production in 1975 and started water injection in 1976. The development strategy there was early water injection at the margin bottom and later irregular triangle well pattern. The major problems during water flooding development were sharp water cut rise caused by channeling and quick oil production decline. In the late stage, pressure drop and unstable water injection were taken to control water cut and improve the oil displacement efficiency by water[41].

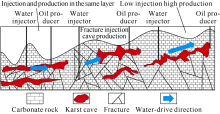

Water flooding was tested first in the karst fracture-cave oil reservoir of the Tahe Oilfield in 2005. During water flooding, water channeling was commonly occurred, causing rapid rise of water cut. To solve these issues, the technologies of spatial well pattern design, intensity-variable water injection and water plugging have been invented, effectively improving the reserve control degree and prohibiting the water channeling.

3.4.1. Spatial injection-production well pattern design

Well pattern deployment is the basis for effective water injection, and its design should match with the reservoir development and distribution. Karst fracture-cave reservoirs vary greatly, thus if areal well pattern is adopted, many non-productivity and low productivity wells would occur, and the control degree on reserves would be low.

In order to solve this issue, the well pattern design was extended from the 2D planar configuration to 3D spatial structure[42] (Fig. 4), and the “ three-factors controlled” spatial well pattern design technology for the karst fracture-cave oil reservoir has been set up: (1) Oil well deployment is dependent on the cave reservoir, oil producers should be deployed according to the reserve scale and order. (2) The deployment of water wells depends on connectivity, in reference to the connectivity appraisal, water wells should be deployed following the principle of “ fracture injection and cave production, low injection and high production, injection and production in the same layer” . (3) Well number should be decided according to reserves, considering the economic factor, the number of injection and production wells should be determined according to the unit reserve scale.

The spatial well pattern design method has improved the water-drive reserve control degree, after implementation, water- drive reserve control degree in the Tahe Oilfield increased by 25%, and the theoretical recovery rate was calculated at 32%.

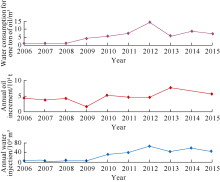

3.4.2. Variable intensity water flooding

In variable intensity water flooding, by changing injection- production intensity, the pressure field is disturbed to remove the fracture separating screening effect, and thus improve water swept area of fracture-pore and karst fracture-cave oil reservoirs. The variable intensity water flooding can take the forms of periodical water injection, impulse water injection, unstable water injection and asynchronous water injection and production etc.

The water injecting optimization model with double targets of recovery rate and economic profit was established and stochastic perturbation algorithm was modified, realizing real- time optimization of injected water flow direction and intensity. After variable intensity water injection was implemented in Block 6 of Tahe Oilfield, the water consumption for one ton of oil reduced from 14.2 m3 to 7.4 m3 (Fig. 5).

3.4.3. Water plugging technology

Karst fracture-cave reservoirs are rich in fractures, water channeling is likely to occur in this kind of reservoir. In general, water channeling comes in three types, edge water, bottom water and injected water, which directly influences the improvement of oilfield production and recovery rate. Therefore, three kinds of water plugging agents have been developed: (1) Ultra-low density curable particle water plugging agent for sealing the channeling bottom water, which has a density between the formation water and crude oil, and is not dispersible. (2) Silicate gel plugging agent with controllable gelling time and high plugging rate for sealing the water channeling in large fractures. (3) Soluble silicate plugging agent with good thermal stability which swells when meeting water and contracts when meeting oil to seal the water channeling in small fractures. Hence, the multi-plug composite water plugging technique has been worked out to enhance water injection swept efficiency[43].

In the Yanling Oilfield of Renqiu, the test of nitrogen injection into reservoir top started in October, 1994 to enhance recovery and ended in October, 1999, with a cumulative gas injection volume of 4 556× 104 m3, failing to reach the anticipated production.

The Tahe Oilfield began to carry out nitrogen huff-and-puff test in Well TK404 in April 2012[44, 45], in the first round, 778 m3 of liquid nitrogen was injected to form gas top to displace the residual oil in the structural high, the periodical oil production was 2 659 t; in the later three rounds, 5 025 m3 of nitrogen and 2 070 m3 of water were injected, and periodical oil production was 3 685 t; cumulatively, 6 674 m3of nitrogen was injected and 6 344 t of oil was produced, with oil producing degree increasing by 1.23%, showing a significant oil increment effect.

Subsequently, gas flooding was promoted across the Tahe Oilfield, by December 2017, there were 163 nitrogen injection wells in the main body of Tahe Oilfield, tapping the reserves of 0.98× 108t, with a cumulative oil increment of 93× 104 t, among which, the cumulative single well oil increment from huff-and-puff was 63.2× 104 t, and the cumulative oil increment from gas flooding was 19.8× 104t. Meanwhile, in the peripheral blocks, the technology covered the geologic reserves of 1.11× 108 t, with a cumulative oil increment of 88.2× 104 t.

The carbonate reservoir stimulation technologies mainly include acidification and acid fracturing etc. After years of exploration, some pertinent technologies have been developed for different types of reservoirs, mainly including large-scale acid fracturing, ultra-deep long-segment horizontal section multistage temporary plugging acidification and large-scale multistage acid fracturing etc.

3.6.1. Large scale acid fracturing

For the karst fracture-cave oil reservoirs in the Tahe Oilfield, 70% of wells need acid fracturing before put into production. Aiming at the problems of quick reaction between the acid and rock, serious leak-off of acid fluid, and short effective dissolved fractures, a high viscosity corrosion inhibitor cross-linking agent with heat resistance of 150 ° C, slow autogenic acid of 12.5% concentration, polymer in-situ variable-viscosity acid, have been developed, and the small span fracture height control acid fracturing and deep-penetrating compound acid fracturing technology[46] have been worked out, realizing controllable fracture height of 40 m and artificial acid etched fracture half-length of more than 145 m. This technology has been applied 42 well-times, with an effective rate of 97.6% and cumulative oil increment of 69.4× 104 t.

3.6.2. Ultra-deep long horizontal section multistage temporary plugging acidification

Horizontal wells in the Yuanba Gas Field are completed with liner or as open hole, thus the middle-rear horizontal section and low permeability segments are difficult to be effectively stimulated. To solve this problem, multistage fiber temporary plugging acidification technique has been developed, by using high temperature gelled acid, high temperature diversion acid and temperature control + acid control degradable organic fiber featuring slow corrosion, moderate speed, small friction, high conductivity, sulfide precipitation resistance at 160 ° C, the diverted acidizing of “ three-stage temporary plugging and alternate injection” can be realized to complete even acid stimulation in the ultra-deep long horizontal section[39].

3.6.3. Large-scale multistage acid fracturing

The reservoirs in the Puguang Gas Field have big thickness, strong heterogeneity and high H2S content. The gelled acid multistage injection + closed fracture acidification has been worked out, which features heat resistance of up to 130 ° C, sulfur resistance, strong slow release, small friction, and strong flowback. By using gelled acid system and high efficient acid soluble temporary plugging agent, the well interval stimulated can reach 500 m long[27]. With this technology, the open flow capacity of Well Puguang 302-2 after acid fracturing amounted to 768.2× 104 m3/d.

China has achieved fruitful results in carbonate reservoir development theory and technical research, which have supported the development of different carbonate reservoirs, such as Renqiu, Tahe, Tazhong, Puguang, Jingbian and Yuanba etc. These theories and technologies cover four aspects: (1) the genetic mechanisms of three kinds of carbonate reservoirs (buried-hill fracture-pore, karst fracture-cave, reef beach pore), and the reservoir identification and description technology cored on geophysical description and discrete fracture-cave modelling method; (2) composite fluid flow mechanism in complex media, free-seepage flow coupling numerical modeling and well testing analysis method, which enrich the carbonate reservoir development theory; (3) water injection cored on spatial well pattern design, variable intensity water injection and water plugging, and single well nitrogen huff- and-puff EOR technology; and (4) complex carbonate reservoir drilling completion and acid fracturing stimulation technology.

The carbonate oil and gas pools in China feature diverse accumulating patterns, complex structure, and great differences in reservoirs, and the current technologies can’ t solve all the problems in carbonate reservoir development. The major challenges in carbonate reservoir development in the future include: (1) The newly discovered reservoirs are buried deeper and more complicated in geology, so more advanced reservoir description technology is needed. For example, the Ordovician carbonate dissolved fracture oil reservoir in the Shunbei Oilfield of Tarim Basin, the average burial depth of the reservoir exceeds 7 000 m, deep faults have more prominent control on the oil accumulation, and the features and distribution of the reservoirs are more difficult to describe. (2) Enhancing recovery: The water flooding development of carbonate reservoirs is affected by heterogeneity, with recovery rate lower than clastic reservoirs, and it is less than 20% in Tahe Oilfield; although nitrogen huff-and-puff has achieved good effect, it is far away from large scale application. (3) Lowering exploration and development costs: deep burial, high temperature high pressure, strong heterogeneity, and great difference of productivity, carbonate reservoirs are high in exploration and development costs, thus cost control is the key for profitable development.

Although the carbonate reservoir development in China has achieved fruitful results, it is still far away from the high efficient development. Research on all development technologies is the key to improving the oilfield development level: (1) The higher precision complex reservoir description technique need to be developed, higher precision reservoir depiction and fluid property identification technology are required as factors affecting reservoir genesis, distribution, and physical property, and the configuration between the fluid and reservoir bodies are more complicated with deeper burial depth. (2) Various EOR technologies need to be developed, mainly including technologies for enhancing water swept degree in the small caves and small fractures and filling pores of buried hill and karst fracture-cave reservoirs and new EOR methods such as scale gas flooding and chemical flooding besides improving existing water injection and gas injection technologies. (3) The ultra-deep carbonate rock drilling and acid fracturing methods need to be improved and developed to not only increase the production but also greatly reduce the engineering cost. (4) The fusion between the information technology, big data technology, cloud computing, artificial intelligence and oilfield development need to be strengthened to realize the overall optimization of the reservoir, wellbore, ground and management systems.

The carbonate hydrocarbon resources account for more than 1/4 in China. The development of this kind of resource was initiated in the 1950s, after persistent research of several generations, a complete development theory and technical system has been established, but it is still far away from the highly efficient development. The technologies such as high precision description of complex carbonate reservoirs, EOR and drilling and completion technologies that can lower costs, in combination with modern artificial intelligence, will dramatically improve the development scale and promote the rapid development of carbonate oil and gas in China.

Nomenclaturea— dimensional equilibrium coefficient of normal stress continuity equation, 10-6;

b— dimensional equilibrium coefficient of tangential stress condition equation, 10-6;

d— geometry dimension;

i— geometry dimension No.;

I— unit vector;

K— permeability, μ m2;

Kr— relative permeability, dimensionless;

n— Interface unit normal vector;

p— pressure, MPa;

S— saturation, %;

u— flow velocity, m/s;

α — interface slip coefficient, dimensionless;

μ — flow viscosity, mPa• s;

τ — interface unit tangential vector;

Φ — fluid phase fraction, dimensionless.

f— free flow;

l— flow property, l = w, n;

n— non-wetting phase;

w— wetting phase;

${{\Omega }_{\text{ff}}}$— free flow region;

${{\Omega }_{\text{pm}}}$— multi-porous media region.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [41] |

|

| [42] |

|

| [43] |

|

| [44] |

|

| [45] |

|

| [46] |

|