To solve the problems facing the economic development of unconventional oil and gas, a new concept and corresponding technology system of reservoir stimulation based on “fracture-controlled reserves” are put forward. The “fracture-controlled reserves” stimulation technology is to realize the three-dimensional producing and economic and efficient development of unconventional hydrocarbon resources by forming a fracture system that well matches “sweet spots” and “non-sweet spots”. The technical route of the stimulation technology is “three optimizations and controls”, that is, control the scope of sand body through optimizing well spacing, control the recoverable reserves through optimizing fracture system, and control the single well production reduction through optimizing energy complement method. The “fracture-controlled reserves” stimulation emphasizes the maximization of the initial stimulation coefficient, the integration of energy replenishment, stimulation and production, and prolonging the re-fracturing cycle or avoiding re-fracturing. It aims at realizing the three-dimensional full producing and efficient development of reservoir in vertical and horizontal directions and achieving the large-scale, sustainable and high profitable development of unconventional oil and gas resources. The stimulation technology was used to perform 20 pilot projects in five typical tight-oil, shale gas blocks in China. The fracturing and producing effects of tight oil improved and the commercial development for shale gas was realized.

Unconventional oil and gas resources are rich in China, with tight gas recoverable resources of more than 9× 1012m3, shale gas recoverable resources of (10-25)× 1012m3 and tight oil total resources of (119.7-124.5)× 108t. The effective development of these unconventional resources can help improve the energy structure[1, 2, 3]. Referring to North America technology mode[4, 5], the breakthrough of initial production in unconventional oil and gas “ sweet spot” has been realized in China by self-developed volume fracturing technology[6, 7, 8, 9, 10]. However, due to the complex geological conditions, strong heterogeneity of physical properties, large differences in fracture geometry after fracturing and insufficient energy in some regions, tight and shale reservoirs in China are difficult to realize stable production and low in recovery degree. The development of unconventional oil and gas still faces four difficulties: the fast decline of production caused by the insufficient formation energy and ineffectiveness of replenishment energy method after fracturing, low yield of “ non-sweet spots” , the difficulty of profitable development because of high single well construction cost and sustained low oil price, and the difficulty of wellbore reconstruction for re-fracturing at low cost due to the large number of scattered and clustered perforations spreading all over the wellbore and staged fracturing tools in the well after the initial fracturing of horizontal wells.

In order to solve the above problems, a new concept of “ fracture-controlled reserves” based stimulation technology and matching technology method system are put forward in this study. Aiming at maximizing oil and gas overall recovery in the reservoirs, this technology stresses on the matching between fractures and reservoirs, maximization of the initial stimulation coefficient and integration of energy replenishment, stimulation and production. Meanwhile, well pattern and fracture system matching with the block and new energy replenishment methods are established to make the single well cumulative production approach the well-controlled target reserves, maximize the reservoir initial stimulation coefficient, extend the re-fracturing cycle or avoid re-fracturing for horizontal wells, and finally achieve the efficient, long-acting producing and scale effective development of inferior and inefficient resources.

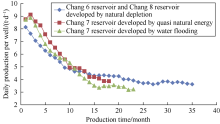

Although the unconventional oil and gas resources are distributed widely in large areas continuously in China, the resources are low in abundance and poor in seepage capability, and thus having almost no natural productivity. At present, the resources are largely developed by depletion after stimulation. Tests of energy replenishment through water flooding were carried out in some tight oil layers, but no obvious effect has been seen. Taking a tight oil well block in Changqing Oilfield as an example, the production decline trend of Chang 7 reservoir developed by water flooding is similar to that of Chang 6 reservoir and Chang 8 reservoir developed by depletion, with the first year production decline rates of all above 40% (Fig. 1) In addition, the first year production decline rates of the tight oil well blocks, such as Santanghu in Tuha Oilfield and Mahu in Xinjiang province, are 50%-70%. Therefore, in the tight oil reservoirs in China, “ sweet spots” are characterized by high early-time production, fast decline, low recovery factor and high cost in general; and “ non-sweet spots” are low in single well production and not able to be developed commercially at all. Numerical simulation results show that because of poor physical properties of tight oil reservoirs, when the artificial fracture density is low, there is a lot of remaining oil left between the fractures after the first time stimulation. However, at present there lacks wellbore reconstruction technology with low cost, and the pipe string of re-fracturing tools is small in size, so refracturing with large displacement, large sand concentration and high fracturing fluid volume is unable to be implemented in horizontal wells. When the fracture density is high, the remaining oil area after the first time of stimulation becomes smaller (Fig. 2). Based on the above reasons, the concept of “ fracture-controlled reserves” stimulation design optimization is proposed in this paper, which means that frac-ture systems matching the “ sweet spot” and “ non-sweet spot” well are to be designed through optimization to realize the three-dimensional producing and economic and efficient development of unconventional hydrocarbon resources.

Taking the whole oil and gas block as research object, “ fracture-controlled reserves” stimulation design optimization aims at maximizing the one time producing degree and producing as much gas and oil in the reservoir as possible. Through optimizing well patterns, drilling trajectories, well completion methods, distribution and shape of fractures, energy replenishment modes and drainage methods, the well pattern, fracture system and displacement system that matches the reservoir in concern will be built to realize the integration of injection and production and ultimately change the seepage field and mobility of oil and gas, which can improve the primary recovery factor and net present value and fulfill scale effective development and all production of oil and gas resources. The key of the technology is to form the fracture system and energy replenishment system matching with the reservoir to realize the reserves producing around the fractures after the first fracturing and the maximum production of crude oil and minimize the amount of remaining oil and gas between fractures and wells.

The conventional volume stimulation technology for reservoirs used currently lays stress on optimization and stimulation of “ sweet spots” on the plane and in vertical direction; while the “ fracture-controlled reserves” stimulation design optimization lays stress on the three-dimensional production of “ sweet spots” and “ non-sweet spots” and maximizing the oil and gas reserves producing degree after first stimulation. Following the technical idea of “ integration of exploration, development and engineering” , a perfect fracture system is built at once through optimizing well pattern, fracture system and energy replenishment mode.

The technical connotation of “ fracture-controlled reserves” stimulation design optimization includes three aspects: the research object is the whole block, covering “ sweet spot” and “ non-sweet spot” ; the objective of the research turns from well controlled reserve estimation[11, 12, 13, 14] and development mode which take wells as the main body to fracture-centered reserves producing mode, in which each fracture presents an individual state depending on the physical properties of its location. It emphasizes the one-off development and production of the reserves, in which the re-fracturing is to recover the permeability of old fractures rather than to create new fractures.

In order to quantify the application effect of the reservoir stimulation technology, the objective function is defined according to the concept of "fracture-controlled reserves" stimulation technology.

$M=\sum\limits_{i=1}^{n}{\sum\limits_{j=1}^{m}{\frac{V_{\text{P, }j}^{{}}(t)}{V_{\text{M, }i}^{{}}}}}$ (1)

$S=\frac{{{V}_{\text{P}}}(t)}{{{V}_{\text{F}}}}$ (2)

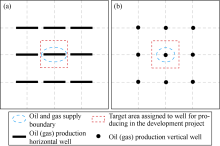

During exploration and/or development, the reservoir is divided into n independent regions and one well is deployed in each region which is defined as well-controlled target area (Fig. 3a, 3b). The oil and gas reserves within the area is the well-controlled target reserves of this well. Dividing a well-controlled target area into m units, and in each unit deploy 1 set of single fractures or a group of interconnected complex fractures. The oil and gas reserves controlled and produced by this group of fractures (network) in the unit is called fracture-controlled target reserves (VF), as shown in Fig. 3c-3f.

| Fig. 3. Application schematic diagram of the “ fracture-controlled reserves” stimulation design optimization of horizontal wells. |

The difference between the well-controlled target reserve and the single well controlled reserve lies in that the latter refers to geological reserves of the oil and gas supply area in the production process of the oil well[15, 16, 17, 18] (Fig. 4), namely, it is the reserves of the actual area which can be controlled by the well; while the well-controlled target reserve proposed in this paper is the “ responsibility field” assigned to a well in the development project. This is the reserve of the area which needs to be developed by the well. The effective control of it depends on physical properties of the reservoir and operational parameters in the process of development.

From the definition, it can be seen that in the case of lower stimulation coefficient (Fig. 3c, 3e), there are a lot of “ blank spaces” in the well-controlled target area of horizontal wells on the plane or between layers vertically, which cannot be effectively developed in the late production and become residual oil and gas areas, making the stimulation coefficient far less than 1. In the case of higher stimulation coefficient (Fig. 3d, 3f), the fractures are wide spread in vertical direction and on the plane, covering almost all the oil and gas area, so the oil and gas resource in the region can be fully produced at the end of well lifecycle, with the stimulation coefficient approaching 1. Meanwhile, when the reservoir-controlled coefficient approaches 1, the “ blank spaces” on the plane or between layers are very small, and the oil and gas can be effectively controlled and produced.

Improving the stimulation coefficient is the key to increasing the ultimate recovery factor in the well-controlled target area of tight reservoir, while improving reservoir-controlled coefficient can raise the ultimate recovery factor of the whole reservoir. The final goal of the “ fracture-controlled reserves” stimulation design optimization is that the stimulation coefficient and reservoir-controlled coefficient after stimulation are close to 1.

In order to realize the goal of “ fracture-controlled reserves” stimulation design optimization, the technical route of “ three optimization and three controlling” is proposed, that is, optimizing well spacing to realize the control of the sand body range, optimizing the fracture system to realize the control of the geological reserves and optimizing the energy replenishment method to realize the control of production decline of single well. The core technical methods include optimization of well spacing in the large platform operation mode, optimization of fracture parameters based on the principle of maximizing the stimulation coefficient and optimization of injection fluid with the goal of supplementing energy and increasing efficiency.

2.1.1. Evaluation of reservoir physical property

Reservoir physical properties are the basis of technology application, and accurate characterization of reservoir physical properties can ensure the rationality of subsequent implementation plan. Therefore, reservoir evaluation and natural fracture system prediction technologies are the important foundation for the “ fracture-controlled reserves” stimulation design optimization technology. The current technical means can make full use of existing exploration and development big data information of unconventional oil and gas resources to obtain geological and well logging parameters such as lithology, physical properties, hydrocarbon source rock, oil-bearing property, brittleness, geo- stress and anisotropy to build the geological physical model reflecting the actual underground conditions and the three dimensional stress field model to finely characterize the reservoir and provide a reliable model for production capacity simulation and fracture propagation simulation.

2.1.2. Evaluation and recognition of fracture system

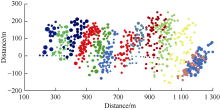

The understanding of fracture geometry is the basis for optimization of the fracturing program. Micro-seismic monitoring (Fig. 5), micro-deformation and tracer techniques are used jointly to analyze the complexity of the fracture system. Based on this, using techniques such as artificial fracture inversion and numerical simulation (Fig. 6), a fracture system model that can reflect the actual underground conditions is established. According to the model, the effectiveness of fracturing is evaluated and oil and gas production performance is predicted and energy replenishment development methods are selected.

| Fig. 5. Micro-seismic monitoring results of LAH well (different colors represent different fracturing stages). |

2.1.3. Design and implementation of the long lateral

The well trajectory is optimized based on high-quality reservoir distribution, and the polycrystalline diamond compact (PDC) drill bit, high-efficiency screw drilling tools, design of “ one trip drilling” and high-quality water-based drilling fluid system are used to reduce wellbore complexity, improve the drilling speed and reduce the cost of drilling. The prediction of combined geologic-engineering “ sweet spots” , horizontal well geo-steering and three- dimensional avoidance of obstacle drilling are adopted to increase drilling ratio of reservoir and achieve “ zero” loss of high-quality reservoir. The length of horizontal section is increased to 2 000-3 000 m according to sand body distribution characteristics in the reservoirs and well site design, which can increase the contact area between horizontal wellbore and reservoir, enhance the oil and gas producing capacity of horizontal section, reduce the drilling cost per unit length, decrease the number of platforms required per unit area and the cost of ground engineering and middle-stream infrastructure construction.

2.1.4. Design of small horizontal well spacing

The horizontal well spacing in several major tight oil and gas blocks in the United States has reduced from 400 m to 100-200 m. Horizontal wells drilled from well pad with a minimum well spacing of 76 m were tested at Barnett, Eagle Ford and Marcellus[19]. At present, the distance between tight oil wells in China is generally 300-800 m, and the well spacing after infill drilling in the tight oil reservoir of Tuha oilfield is 100 m. With the fracture length recognized by the fracture system assessment as the upper limit, the well spacing should be optimized to decrease the “ fracture-controlled” area in the reservoir matrix between two wells, further reduce the seepage distance from the matrix to the fracture within the “ fracture-controlled” area, decrease the area hard to produce between wells, and increase the sweep efficiency. At the same time, the decrease of well spacing lowers the requirement on fracture length in the process of well pad fracturing, which is conducive to the application and control of fracturing technology.

2.2.1. Precise fracture layout technology by “ four-stage control”

The layout of fracture is a systematic project and needs to be controlled from the source. Based on this, the precise fracture layout technology by “ four-stage control” has been proposed, that is, to control the fracture from four key links, including well placement, completion, fracturing and flowback. In the well placement stage, through the design of well spacing, horizontal section length, wellbore direction and well trajectory, the distribution of fracture is controlled to form a fracture system that matches the sand body. In the completion stage, the fracture starting point and number of fractures are optimized by the means of perforation or open hole completion to control the fracture spacing and reserves between fractures. In the design and implementation stage, the quality of fracture is controlled, that is to control the shape of the artificial fractures by optimizing liquid performance, injection displacement, pumping sand process etc., and adjusting fracturing parameters according to micro-seismic monitoring results. In the flow back stage, the flow back rate is controlled by optimizing the soak time and choke size to achieve no sand production in the formation and high conductivity of fractures near wellbore to ensure the stimulation effect and regulate the propped fracture shape.

2.2.2. Technical ideas of design and implementation

Two types of fine fracturing technology have been established: (1) For tight oil reservoirs that are likely to form complex fractures, “ bridge plugs able to be rapidly drilled and clustering perforation” are worked out to divide and reform the reservoir accurately by staged and clustering perforation. (2) Fracturing stimulation method of complex fractures: this method is suitable for brittle reservoirs with rich natural fractures, in which large displacement and temporary plugging diversion etc. are adopted and fracture spacing is optimized to generate complex fracture system; and various types of reservoir stimulation intelligent material systems are added to the end of fracture, inside of fracture and the fracture mouth in reservoirs with different characteristics to change the wettability of the reservoir rock and realize artificial fracture diversion at fixed points.

2.2.3. Low cost staged fracturing technology

In order to further increase the “ fracture-controlled reserves” , the stage interval of staged fracturing is gradually reduced in the development of unconventional oil and gas reservoirs in foreign countries. Taking the Utica Oilfield as an example, the interval between the stages in 2014 was 61-76 m. In March 2016, the stage interval of horizontal well fracturing on the Purple Hayes well pad was 46 m. In June of the same year, the stage interval of horizontal well fracturing on the Wheeler well pad was decreased to 34 m, and the minimum cluster spacing was only 4.5 m[20]. Oil companies also conducted fracturing tests of dense wells spacing and dense fracture spacing in the Permian Basin[21]. As the tight reservoirs have low permeability and high starting pressure, within a certain development period, the well-controlled range is almost equal to the area controlled by the artificial fracture. Indoor physical simulation experiments and field practices of domestic tight oil reservoirs have demonstrated that the tight oil reservoirs in China are difficult to “ break” , and the existing staged horizontal well volume fracturing with bridge plugs and clustering perforation cannot create the ideal complex fracture network (currently, the fracturing stage length of horizontal well commonly used in China is 60-80 m, with 2-3 clusters of perforation in each stage and 10-16 holes in each cluster). In order to increase the density of artificial fractures, control the reservoir reserves and reduce the construction cost at the same time, the extreme limited entry is adopted to reduce the interval between stages (clusters) in foreign countries[22, 23, 24], that is, under the premise of ensuring that each cluster within a stage can be fracked open, the number of clusters in each stage is increased to the maximum, and the total number of holes is used to achieve the control of throttling resistance of each cluster, thereby forming a fracture-controlled matrix unit, greatly increasing producing reserves per unit area, turning the traditional well-controlled reserves mode into the fracture-controlled recoverable reserves mode, and increasing recovery factor.

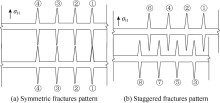

2.2.4. Interdigitating layout of fractures

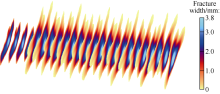

Interdigitating the layout of fractures on two parallel horizontal wells (Fig. 7) can increase the fracture penetration ratio. Besides, making use of the induced stress between the two fractures, the original natural fracture shape can be changed, and secondary fractures can be generated to form complex fracture network structure to increase the complexity of the fractures in the formation and thereby expanding the fracture-controlled area and avoiding the disadvantage of two wells being connected due to the increase of fracture penetration ratio under the condition of symetric fractures pattern.

In the absence of energy replenishment, the primary recovery factors of tight oil reservoirs are just 5%-10% by the elastic energy of the fluid and rock and depletion drive with multi-staged fracturing of horizontal well. The technical methods of effective energy replenishment for tight oil and gas reservoir in foreign countries are still under probing. Based on literature review, field practice and theoretical analysis, 3 ways of energy replenishment have been advanced in this work.

2.3.1. Energy storage by injecting a large amount of fracturing fluid in early stage

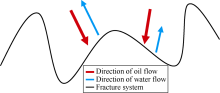

Tight oil reservoirs have the characteristics of low porosity and ultra-low permeability and there is no reservoir connectivity effect between individual wells. That is, the reserves scope controlled by a single well can be regarded as an independent sealed reservoir, which can effectively ensure the formation energy does not leak outside. A large amount of fluid is injected at high speed in the process of reservoir fracturing. On the one hand, this can improve the complexity of artificial fractures, stimulated volume and the specific surface area of fractures and increase the retained time and volume of fracturing fluid, thereby enhancing the effect of energy replenishment. On the other hand, there is heterogeneous pressure system in the artificial fractures of different positions or fracture branches, which can cause the displacement between fractures (Fig. 8). This method can obviously improve the formation energy and accumulative production than huff-and- puff and depletion drive.

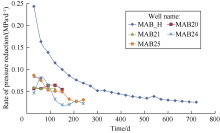

Reservoir numerical simulation results show that for a reservoir with volume of 8× 106 m3, after 1× 104 m3of fracturing fluid is injected rapidly by hydraulic fracturing, the average formation pressure increases by 2.14 MPa. The formation energy is replenished and the production increases accordingly. From the field test it can be seen that in the hydraulic fracturing of the tight oil reservoir in Mahu area, Xinjiang, when the volume of fluid injected in a unit length section increased from 8.5 m3 to 15.0 m3 (the injection fluid volume of the horizontal section of MAB_H well is 8.5 m3/m, and that of the other wells is 15 m3/m), after 300 days, the flow back rate of fracturing fluid decreased from 65% to 20%, and the pressure drop rate decreased by 40%-46% (Fig. 9). Thus it indicates that the injection of a lot of liquid is favorable for enhancing the formation energy.

| Fig. 9. Comparison of pressure reduction rate of "fracture-controlled reserves" stimulation for energy storage effect in the field test. |

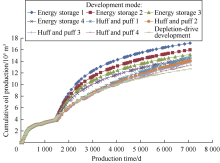

Take a well in Changqing Oilfield as an example to illustrate the method of energy storage by fracturing. In this horizontal well, the oil reservoir buried at 2 288 m deep and is 16.46 m thick with a pressure coefficient of 0.72, matrix permeability of 0.17× 10-3 μ m2, and porosity of 7.9%. The well has an 800 m long horizontal section and is fractured in 10 stages with the stage spacing from 48 to 67 m. The fractures have half-length of 211 m and conductivity of 30 μ m2· cm. Three different schemes were designed and the effects of oil production compared: (1) The depletion drive with no energy supplement. (2) 5 cycles of huff and puff, namely, after 3 years of production, the production well is injected water of 80%, 100%, 120% and 150% of the produced liquid respectively in one month. After 1 month of soaking, it continues to produce for 3 years; then the same volume of water is injected again within one month, and then soaking for one month. Five cycles of injection and production in total are carried out. (3) Injection by energy storage fracturing, that is, the equal amount of active water which is equal to the total amount of water of 5 cycles in the second method, is injected at one time in the process of fracturing. The comparison shows that energy storage fracturing can significantly increase the cumulative production of single well (Fig. 10).

| Fig. 10. Comparison of cumulative production of energy storage fracturing, cyclic huff and puff and depletion-drive development. |

2.3.2. Energy replenishment by multi-cycle water injection in the medium-later stage

After hydraulic fracturing of the tight oil reservoir, the fracturing fluid mainly exists in the fracture network created (or in the matrix near the fractures), as the matrix is low in permeability, the fracturing fluid can’ t get into the matrix effectively within a short period of time. The massive fracturing fluid makes the pressure in the fracture network of the stimulated area increase significantly. However, the pressure inside the matrix rocks cut by the fracture network remains the original formation pressure. Therefore, there is a large amount of residual oil in the matrix rock, and it is necessary to conduct multiple cycles of "injection-shut in-production" to improve the recovery factor in the middle and late stage of development. In the process of shut-in, on the one hand, the pressure can spread from the fracture network to the inside of the matrix rock cut by fractures; on the other hand, due to the effect of gravitational differentiation of oil and water, the fracturing fluid continuously moves to the lower part of the fracture network of the reservoir, while the oil migrate to and gather in the higher part of the fracture network, so oil can be produced at once after shut-in for energy accumulating. The shut-in time is mainly influenced by the interval of the fracture network and matrix permeability. The smaller the fracture interval is, the smaller the needed driving pressure differential is and the shorter the reasonable shut-in time is. The smaller the matrix permeability is, the higher the starting pressure gradient of oil and gas is, and the longer the reasonable shut-in time is.

2.3.3. Energy replenishment technology by reinjecting produced gas in late stage

Gas injection is an effective method to enhance oil recovery[18, 19], which can not only maintain the formation pressure, but also enhance oil displacement efficiency. The miscible gas injected into the formation has cross-flow and mass transfer with fluid in bedrock through gravity drainage, capillary pressure drainage, dispersion diffusion, pressure drainage etc. to produce the large amount of crude oil remaining in the bedrock. It isn’ t difficult to reach miscible flooding by reinjecting the produced gas, and it is cost-effective and environmentally friendly. Due to the strong injection capacity, under the same injection pressure, gas is easier to enter the microscopic pores, so the pressure can be transmitted to the deep end of the reservoir. Thus, the purpose of supplementing energy is achieved and the tight oil remaining in the pore of the reservoir is displaced. According to the results of the core- flooding experiment and the reservoir simulation of the Bakken formation, more primary geological reserves can be produced by gas flooding than water flooding, with the displacement efficiency of 28%-60%[24]. Assuming that the volumetric sweep efficiency is 50%, the ultimate recovery factor would be 14%-30%, and the ultimate recovery factor of the pilot test predicted by the simulation model can reach 23%[22].

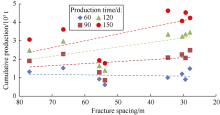

The “ fracture-controlled reserves” stimulation technology has achieved remarkable effect in the development of unconventional oil and gas. In 2017, this concept was applied to the development plan of the Ma131 well block of Xinjiang Oilfield. In this block, the horizontal well spacing was reduced from 400 m to 300 m, and the fracture spacing was decreased from 60-100 m in exploration stage to 30 m in development test stage. As a result, the cumulative production of 150 d increased by nearly 60% (Fig. 11). The average production of 8 test wells at the end of 30 days was 23.5 t/d, which is 1.9 times higher than that in the past, and the recovery factor of the reservoir is expected to increase by more than 2%. In the same year, the pilot test of “ fracture-controlled reserves” stimulation was carried out in Block Ma 56 of Santanghu tight oil reservoir in Tuha oilfield. In this block, the horizontal well spacing was reduced from 400 m to 100 m. The fracture spacing of fractured wells was decreased from 46m to about 12 m, and clusters of each stage were increased from 2 to 5. The pilot test of 5 wells with a total of 47 fracturing stages and 195 perforation clusters was accomplished. Among them, the initial production of Well Ma58-2H was 51.0 t/d, and the average production of the test wells was 25.7 t/d, which is 1.7 times higher than that of the adjacent wells. The recovery factor of the well group is predicted to increase by 0.92%.

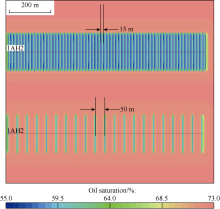

Long horizontal section wells can increase the fracturing scale and effective stimulated reservoir volume. In 2017, the average horizontal section length of shale gas horizontal wells in the Longmaxi Formation of Changning-Weiyuan demonstration area was 1 624 m, and the length of the longest horizontal section was 2 512 m. The average sand quantity added per stage was 1.4 t/m, and the maximum sand quantity added in one stage was 3.1 t/m. The degree of stimulation has been improved by increasing the number of stages, reducing the length of the stage, increasing the number of clusters and decreasing the spacing between the clusters. In 2017, the mean spacing of fracturing clusters of shale horizontal wells in the Longmaxi Formation in Changning-Weiyuan demonstration area was 22.8 m, with the minimum cluster spacing of 15 m among all wells and the maximum clusters of 134 in a single well. The application of the “ fracture-controlled reserves” stimulation design optimization has made the average shale gas production of typical wells increase from 10.2× 104 m3/d (8 wells) in 2014 to 28.8× 104 m3/d (16 wells) in 2017, which effectively supports the commercial-scale development of shale gas.

The “ fracture-controlled reserves” stimulation technology is to form fracture systems matching the “ sweet spots” and “ non-sweet spots” in a high degree by optimization to realize the three-dimensional producing and economic and efficient development of unconventional hydrocarbon resources. With this technology, well patterns matching with the block and the corresponding fracture system are established to make the cumulative production produced by hydraulic fractures of single well close to the well-controlled target reserves, maximize the reservoir initial stimulation coefficient, extend the re-fracturing cycle or avoid re-fracturing for horizontal wells, and finally achieve efficient, long-acting producing and scale effective development of inferior and inefficient resources.

Following the technical route of “ three optimization and three controlling” , the realization approach and core technology system of “ fracture-controlled reserves” stimulation design optimization have been established: by taking the length of fracture (or fracture network) recognized by the fracture system evaluation as the upper limit, considering the mode of fracture layout and optimizing well spacing, the control of sand body scope is realized. Through the idea of “ four-stage control of fracture” for precise fracture layout, the fracture system is optimized to realize the control of the geological reserves. The control of production decline of single well is realized by 3 ways of energy replenishment, namely, injecting a large amount of fracturing fluid in early stage, multi-cycle water injection in the medium-late stage, and reinjecting produced gas in late stage.

“ Fracture-controlled reserves” stimulation design optimization theory and technology has turned the “ development- fracturing” into “ fracturing-development” . In this technology, fractures are more accurately and reasonably laid to achieve the three-dimensional full producing of oil and gas in vertical and horizontal directions and large-scale, sustainable and high profitable development of unconventional oil and gas resources to the full extent. It is of great value to the basic theoretical innovation and technological innovation of petroleum industry.

Nomenclaturei— independent region number in the reservoir;

j— unit number in the well-controlled target area;

M— controlled reservoir coefficient, dimensionless;

m— the number of units in the well-controlled target area;

n— the number of independent regions in the reservoir;

S— stimulation coefficient, dimensionless;

t— time, d;

VP— fracture-controlled production, t;

VM— the well-controlled target reserves, t;

VF— fracture-controlled target reserves, t.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|