Introduction

In recent years, with the rapid development of fire flooding technology in Liaohe and Xinjiang oilfields, how to properly dispose flue gas generated by fire flooding has become a big problem. Affected by strong heterogeneity, water-driving conglomerate light oil reservoirs near the fire flooding pilot area in Xinjiang Oilfield witnessed rapid decline of formation pressure and low recovery, so it is necessary to find feasible technology to improve their oil recovery[1]. If flue gas flooding can be implemented successfully there to improve oil recovery and bury flue gas at the same time, good economic and social benefits would be achieved. Restricted by the property of injected gas, flue gas is poorer in displacement efficiency than CO2. But flue gas flooding saves complex process and high cost for purifying CO2, and can use and bury flue gas at the same time[2,3,4,5,6,7]. Therefore, flue gas flooding technology has a broad application prospect[8,9,10,11,12,13].

In laboratory, long core physical modeling is often used to study oil displacement characteristics and efficiency of gas flooding. Generally, the long core model is composed of multiple cores with 2.5 cm or 3.8 cm in diameter put together[2, 14-16]. Some researchers, e.g. Li Xiangliang[14], Guo Yongwei[15], and Zhang Yanyu[16], have done a lot of studies. But most of the studies focus on sandstone reservoir with even grain size and weak heterogeneity. As conglomerate or fracture-vug carbonate reservoirs with gravels or fractures and vugs amounting to 2-3 cm, strong heterogeneity, and small size core can’t represent the reservoir physical characteristics. Meanwhile, because cores taken from different positions are different in porosity and permeability widely, the experimental results would vary greatly, unable to reflect the real seepage characteristics in reservoir.

Increasing core diameter to 10 cm can reduce the effect of heterogeneity and improve the modeling effect. For example, Cheng Xinfang et al.[17] simulated the water flooding characteristics of an anisotropic reservoir in Daqing oilfield with a core of 10 cm in diameter and 5 cm in length; Fan Jianming et al.[18] examined the influence of pore media on the phase state of CO2 injected into the stratum with full-diameter core; Zhao Lei et al.[19] tested the huff and puff effect of N2 and CO2 for a fracture-vug carbonate reservoir in Tahe oilfield with full-diameter core. However, all the experiments mentioned above utilized a single full-diameter core, and the core length could not meet the requirements of simulating gas displacement characteristics and seepage effect. In particular, few literatures have reported high temperature and pressure gas flooding simulation with full-diameter long core.

At present, a conglomerate reservoir in Xinjiang oilfield at the stage of water flooding has seen rapid formation pressure drop and low recovery degree, so it is urgent to seek out new development method that can effectively enhance recovery for it. In this study, several full diameter cores of 10 cm in diameter were spliced together into a long core model to model reservoir depletion, water flooding, flue gas flooding, and CO2 flooding, to examine the displacement characteristics of all the flooding stages and evaluate development effect of flue gas flooding.

1. Displacement experiment design

1.1. Experimental material

Core. The cores used in the experiment were taken from the objective interval of a specific well in Xinjiang H Oilfield. Cores with relatively little damage were selected to be numbered, trimmed, spliced together into the spliced core (Fig. 1). The length and gas permeability of each core section are shown in Table 1. The total length of the spliced core is 52.3 cm. According to the weighted average of length and permeability, the gas permeability of the spliced core calculated is 44.6×10-3 μm2.

Table 1 Core length and gas permeability.

| Core No. | Length/ cm | Gas permeability/10-3 μm2 | Core No. | Length/ cm | Gas permeability/10-3 μm2 |

|---|---|---|---|---|---|

| 1 | 7.8 | 59.2 | 4 | 12.2 | 36.2 |

| 2 | 10.3 | 56.8 | 5 | 13.2 | 35.6 |

| 3 | 8.8 | 42.3 | Spliced core | 52.3 | 44.6 |

Fig. 1.

Full diameter core and assembling diagram.

The spliced core was saturated with formation water and then crude oil to measure its porosity, oil saturation and water permeability. The measured volume of saturated formation water and the water produced during oil saturation of the spliced core are 649.52 mL, and 384 mL respectively. According to calculation, the average flowing porosity of spliced core, hydrocarbon pore volume (HCPV), and initial oil saturation are 15.82%, 384 mL and 59.12% respectively. In water permeability test, when the flow rate was 0.2 mL/min, thepressure difference stabilized at 0.64 MPa, so the water permeability of the spliced core calculated is 34.7×10-3 μm2 according to Darcy’s law.

Simulated reservoir oil. According to the original PVT data of formation crude oil in Xinjiang H Oilfield, simulated reservoir oil was prepared by mixing wellhead degassed oil with natural gas in the lab. Under the formation temperature of 42°C, the reservoir oil has a saturation pressure of 11.8 MPa, dissolved gas oil ratio of 48 m3/m3, viscosity of 6.38 mPa•s, density of 0.825 6 g/cm3 and volume factor of 1.086 respectively, representing typical black oil.

Saturated water and injected water. The original data shows that the formation water salinity is 16 102 mg/L. while the injected water salinity is 5 265.32 mg/L according to field data. In the process of the experiment, the water saturated the core was formation water, and the water used in water flooding and gas-water alternative flooding was injected water. The main ion contents of them are shown in Table 2.

Table 2 Main mineral ions of the formation water and injected water.

| Water Type | Main ion content/ (mg•L-1) | |||

|---|---|---|---|---|

| $CO_{3}^{2-}$ | HCO3- | Cl- | $SO_{4}^{2-}$ | |

| Formation water | 117.90 | 1 856.30 | 8 290.70 | 232.80 |

| Injected water | 122.71 | 665.46 | 2 659.60 | 80.67 |

| Water Type | Main ion content/(mg•L-1) | Total salinity/ (mg•L-1) | ||

| Ca2+ | Mg2+ | Na++K+ | ||

| Formation water | 268.80 | 113.40 | 5 863.80 | 16 102.00 |

| Injected water | 81.19 | 30.78 | 1 957.64 | 5 265.32 |

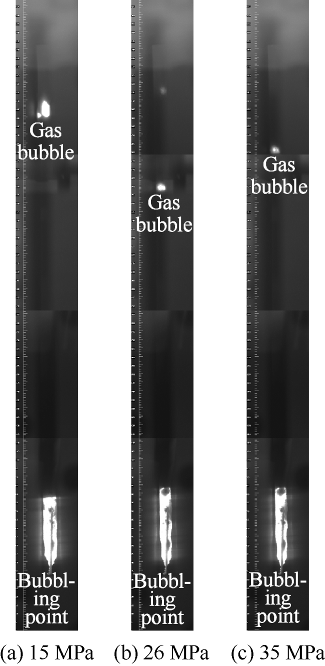

Flue gas generated by fire flooding. It is mainly composed of N2, CO2 and methane, as shown in Table 3. By using high temperature and high pressure rising bubble apparatus, we observed the morphologic change of flue gas bubbles rising in crude oil under the condition of 42 °C, and 15 MPa, 26 MPa and 35 MPa respectively (Fig. 2). The results show that bubbles are clearly visible and don’t completely disappear in the whole process, from which we can conclude that the miscible pressure of flue gas and crude oil is greater than 35 MPa. Therefore, the flue gas flooding should be immiscible displacement under the reservoir conditions.

Table 3 Main components of flue gas.

| Gas component | Mol percent/% | Gas component | Mol percent/% |

|---|---|---|---|

| O2 | 1.300 0 | Propane | 0.141 0 |

| N2 | 76.970 0 | Iso-butane | 0.040 3 |

| CO2 | 15.250 0 | Normal butane | 0.040 2 |

| Methane | 5.920 0 | H2S | 0.060 0 |

| Ethane | 0.281 0 |

Fig. 2.

Flue gas bubbles rising in crude oil.

1.2. Experimental equipment

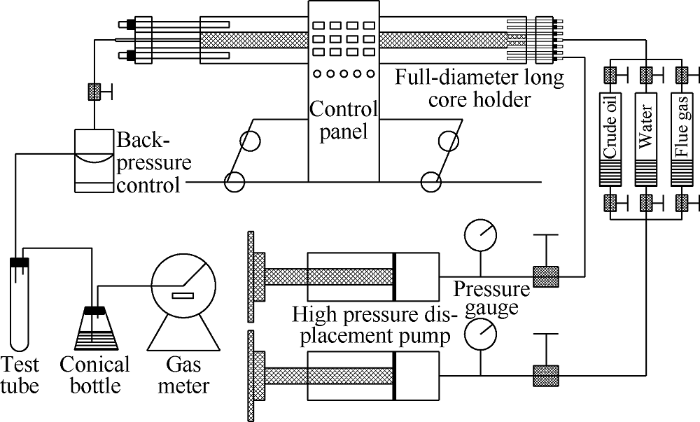

The experiment equipment adopted was a HTHP full diameter long core flooding system developed independently by China. The system has a maximum working pressure of 70 MPa and highest working temperature of 150 °C, and canhold core of up to 2 m long and 10 cm in diameter. The system consists of a full-diameter core holding system, a high-accuracy HTHP displacement pump system, and a back-pressure control and high-accuracy measuring system (Fig. 3). The flooding system ensures temperature stability and equilibrium of the core through multi-point control and measurement of temperature and heating, with temperature error of less than 0.1 °C during the experiment. The combination of high-accuracy back-pressure control system and displacement pump can control pressure error at less than 0.1 MPa and volume error at less than 0.01 mL. The displacement pump can work in constant pressure, constant speed, fixed volume modes etc.

Fig. 3.

Equipment for full diameter long core experiment.

1.3. Experiment scheme

Two different flooding schemes were designed. In scheme 1, the core was first water flooded until oil no longer produced, then displaced by flue gas, and finally by gas and water alternatively. In Scheme 2, the core was displaced by water to the middle stage, and then by flue gas and water alternatively after the pressure increased. The specific details are shown in Table 4.

Table 4 Experiment schemes.

| No. | Experiment content | Scheme 1 | Scheme 2 |

|---|---|---|---|

| 1 | Saturate the core with water, measure pore volume of spliced core | Temperature of 42 °C, Pressure of 15.02 MPa | Temperature of 42 °C, Pressure of 15.02 MPa |

| 2 | Saturate the core with oil to simulate bound water | Temperature of 42 °C, Pressure of 15.02 MPa | Temperature of 42 °C, Pressure of 15.02 MPa |

| 3 | Age the oil saturated core for one month | Temperature of 42 °C, Pressure of 15.15 MPa | Temperature of 42 °C, Pressure of 15.15 MPa |

| 4 | Depletion development | Pressure dropped from 15.15 MPa to 8.11 MPa | Pressure dropped from 15.15 MPa to 8.11 MPa |

| 5 | Water flooding | Outlet pressure kept at 8.22 MPa, stopped until water cut was 100% | Outlet pressure kept at 8.22 MPa, stopped when recovery was 24.79% |

| 6 | Increase pressure by flue gas | Increased pressure to 12 MPa | |

| 7 | Continuous flue gas flooding | Outlet pressure kept at 8.22 MPa, stopped when there was no oil and little liquid produced | |

| 8 | Flue gas-water alternative flooding | At the outlet pressure of 8.22 MPa and injected gas-water ratio of 2∶1, the flooding stopped when only gas was produced, with 5 cycles in total | At the outlet pressure of 12 MPa and injected gas-water ratio of 2:1, the flooding ended when only gas was produced, with 8 cycles in total |

| 9 | Continuous flue gas flooding | At the outlet pressure of 12 MPa, the flooding stopped when only gas was produced with a total injection volume of 7 times HCPV | |

| 10 | Storage | Till pressure increased to 20 MPa | |

| 11 | CO2 flooding | At the outlet pressure of 8.22 MPa, the flooding ended when only gas was produced | |

| 12 | Continuous injection of flue gas | At the outlet pressure of 8.22 MPa, H2S content of produced gas was measured |

1.4. Experiment procedure

First, the numbered cores were assembled in sequence before the displacement experiment, and multi-layer filter paper was added between the cores to minimize the influence of accumulation or uneven distribution of fluid on seepage. Then the experiment equipment was connected with pressure tested at 30 MPa and temperature tested at 42 °C to make sure no leakage. Finally, two groups of experiments were carried out on this basis.According to scheme design, the specific steps of Scheme 1 are:(1) To clean oil and water in the core successively with methanol and petroleum ether until the produced liquid is crystal clear again, then the core was blew dry with nitrogen and vacuumized.(2) At formation temperature of 42 °C and formation pressure of 15.02 MPa, the core is saturated with water and then with oil, and then set aside to age for 1 month.(3) Close the inlet and slowly adjust the back-pressure valve connecting the outlet to 8.11 MPa after multi-stage pressure drop to simulate the depletion drive development process of reservoir.(4) Water flooding is carried out at the outlet pressure of 8.22 MPa and displacement pressure difference of 3 MPa. When the water cut is 100% (oil is no longer produced), the water flooding is ended.(5) At outlet pressure of 8.22 MPa, continuous flue gas flooding is conducted and stopped when only gas with no liquid is produced.(6) At the outlet pressure of 8.22 MPa, flue gas-water alternative flooding (at gas-water ratio of 2:1) is performed and stopped when only gas but no liquid is produced.(7) Close the outlet valve and conduct storage experiment till the system pressure is increased to 20 MPa.(8) Reduce outlet pressure to 8.22 MPa to implement CO2 flooding and stop injecting CO2 when only gas but no liquid is produced.(9) Continuously inject flue gas, conduct intermittent sampling of produced gas 6 times. and measure the content of H2S in the sample to estimate the remaining H2S in the core.The specific steps of Scheme 2 are:(1) Repeat the first three steps of Scheme 1.(2) When the recovery is 24.79%, stop water flooding and adjust the back-pressure valve of outlet to increase the system pressure to 12MPa.(3) Flue gas-water alternative flooding (gas-water ratio of 2:1) is carried out at the outlet pressure of 12 MPa and stopped when only gas but no liquid is produced.(4) The continuous injection of flue gas ends till the total injection is 7 times HCPV.

2. Experiment results

2.1. Flue gas displacement effect

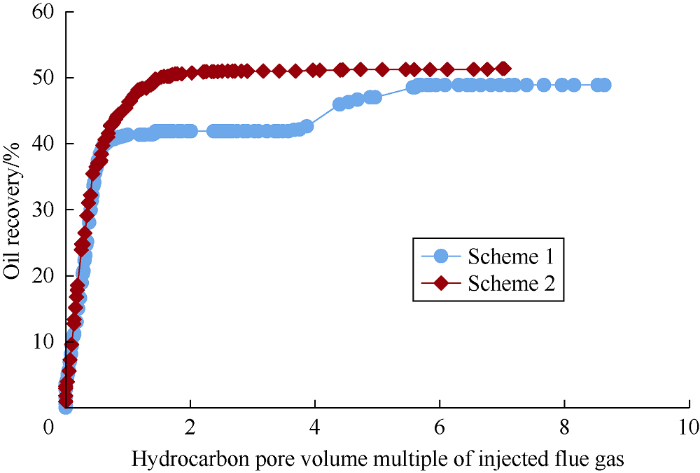

The volumes of injected water, flue gas, and produced fluid (oil, gas, water) at different times were recorded, the experimental data was sorted and a plot was drawn (Fig. 4) in combination with the pore volume of the spliced core and hydrocarbon, initial oil saturation, and the development indexes of different experimental stages were counted at the same time (Table 5).

Fig. 4.

Recovery curves of core flooding.

Table 5 Recovery in different flooding modes.

| No. | Case 1 | Case 2 | ||||

|---|---|---|---|---|---|---|

| Flooding mode | Flooding HCPV multiple | Recovery/% | Flooding mode | Flooding HCPV multiple | Recovery/% | |

| 1 | Depletion | 0 | 3.66 | Depletion | 0 | 3.25 |

| 2 | Water flooding | 1.19 | 41.34 | Water flooding | 0.25 | 24.79 |

| 3 | Continuous gas flooding | 2.38 | 41.89 | Gas-water alternative flooding | 1.67 | 50.21 |

| 4 | Gas-water alternative flooding | 3.09 | 41.89 | Continuous gas flooding | 7.03 | 51.38 |

| 5 | Storage | 3.57 | 41.89 | |||

| 6 | CO2 flooding | 5.60 | 48.52 | |||

| 7 | Continuous gas flooding | 8.63 | 48.89 | |||

Based on the analysis of Fig. 4 and Table 5, the flue gas flooding can effectively enhance recovery, and the increase of recovery differs widely depending on different flooding modes. In this study, Scheme 2 has a better development effect.(1) For the conglomerate spliced core used in the experiment, the recovery of depletion drive is 3.25%-3.66%, and the ultimate recovery of water flooding is 41.34%.(2) For Scheme 1, water flooding followed by continuous flue gas flooding doesn’t work very well, with a recovery increment of only 0.55%. And the final gas-water alternative flooding doesn’t work at all.(3) For Scheme 2, the core was turned to gas-water alternative flooding when the recovery of water flooding was 24.79%, the recovery enhanced significantly, with an ultimate recovery of 50.21%, 8.32% higher than the recovery of gas-water alternative flooding in Scheme 1.(4) In Scheme 2, the recovery reached 50.21% when the total gas-water displacement volume was 1.67 times HCPV, while the recovery was only 41.89% when the total gas-water displacement volume was 2.38 times HCPV in Scheme 1. This shows that Scheme 2 increases the swept volume and improves the development efficiency.(5) After finishing depletion, water flooding, flue gas flooding etc., the recovery can still be improved by 6.63% with continuing CO2 flooding.

2.2. Calculation of flue gas storage capacity

The calculation procedure of flue gas storage capacity:

(1) Based on the calculation method proposed in literatures before[20], apparent critical temperature and apparent critical pressure of flue gas were 158.686 7 and 4.106 2 respectively.

(2) According to Eq.1 and Eq.2[20], the apparent reduced temperature and pressure were calculated.

(3) Gas deviation factor at corresponding temperature and pressure were obtained from a special template.

(4) The storage volume was worked out by Eq.3.

(5) The storage volume was converted into storage capacity (mass).

The storage volume of flue gas in the development process (depletion development, water flooding, gas flooding and gas-water alternative flooding) and the storage capacity of flue gas after the reservoir development can be calculated by the following equation:

The storage volume and capacity of flue gas at different stages can be calculated (Table 6). During the oil displacement process, the volume of flue gas trapped inside the core was 11.899 L. At the late stage after the experiment, the total storage capacity (under 20.15 MPa in pressure) of flue gas was 79.594 g, and the storage capacity of unit pore volume was 0.123 g/cm3, which shows better storage effect of flue gas.

Table 6 Flue gas compressibility factor and storage capacity.

| Outlet pres- sure at storage phase/MPa | PV multiple of injected flue gas | HCPV multiple of injected flue gas | Apparent reduced temperature of gas | Apparent reduced pressure of gas | Gas deviation factor | Flue gas storage volume at storage phase/L | Total storage volume/L | PV multiple of total storage | Total storage capacity/g | Storage capacity per unit pore volume/(g•cm-3) |

|---|---|---|---|---|---|---|---|---|---|---|

| 8.26 | 1.488 | 3.093 | 1.846 | 2.012 | 0.925 | 0 | 11.899 | 19.509 | 14.491 | 0.022 |

| 11.85 | 1.553 | 3.227 | 1.846 | 2.886 | 0.911 | 5.143 | 17.042 | 27.941 | 20.754 | 0.032 |

| 12.96 | 1.612 | 3.349 | 1.846 | 3.156 | 0.908 | 10.233 | 22.132 | 36.288 | 26.954 | 0.041 |

| 13.67 | 1.639 | 3.405 | 1.846 | 3.329 | 0.902 | 12.744 | 24.643 | 40.404 | 30.012 | 0.046 |

| 14.38 | 1.675 | 3.480 | 1.846 | 3.502 | 0.898 | 16.259 | 28.158 | 46.168 | 34.293 | 0.053 |

| 17.12 | 1.805 | 3.750 | 1.846 | 4.140 | 0.903 | 31.173 | 43.072 | 70.620 | 52.456 | 0.081 |

| 20.15 | 1.973 | 4.100 | 1.846 | 4.871 | 0.922 | 53.456 | 65.355 | 107.156 | 79.594 | 0.123 |

2.3. H2S safety evaluation

During the experiment, gas samples were collected several times, and the RAE hydrogen sulfide sampling pump and detection tube system (Type LP-1200) were used to test hydrogen sulfide (Table 7). No hydrogen sulfide was found in any of the gas samples.

Table 7 Hydrogen sulfide content in the gas samples.

| Sample No. | HCPV multiple of displacement (Sampling time) | H2S content/ % | Sample No. | HCPV multiple of displacement (Sampling time) | H2S content/ % |

|---|---|---|---|---|---|

| 1 | Injected gas | 0.06 | 5 | 4.78 | 0 |

| 2 | 1.05 | 0 | 6 | 7.32 | 0 |

| 3 | 2.25 | 0 | 7 | 8.56 | 0 |

| 4 | 2.87 | 0 |

It is inferred from analysis that hydrogen sulfide in injected flue gas can be adsorbed or dissolved by porous media and bound water, which is consistent with the experimental results. In the process of oil displacement, hydrogen sulfide (0.06% mole percent) was completely absorbed by porous media and bound water, thus the harmful gas hydrogen sulfide in flue gas can be safely and effectively buried.

3. Discussion

The experimental results show that flue gas flooding after water flooding can further enhance oil recovery, but the key factor to obtain good development effect is to choose the right timing for gas injection. In Scheme 1, the flue gas is injected at the end of water flooding (41.34% recovery), the recovery increment is limited (only 0.55%), and the development effect is poor. In Scheme 2, the flue gas-water alternative flooding is introduced in the middle stage of water flooding (at recovery of 24.79%). Compared with Scheme 1, the recovery increased by 8.32% (from 41.89% to 50.21%), confirming a better development effect.

Through analysis, the conglomerate reservoir has strong heterogeneity (Fig. 5) and complex connection relationships between the large pore path, small pore path and pore throat. In Scheme 1, after the water flooding, dominant seepage channel was formed inside the core. Therefore, the injected gas or water in flue gas flooding or flue gas-water alternative flooding would flow along the dominant seepage channel that has been formed. As a result, the contact with crude oil was limited, the sweep efficiency was low, and the increment of recovery was small, which means poorer results.

Fig. 5.

Conglomerate core and pore structure.

In Scheme 2, flue gas-water alternative flooding was adopted when the dominant seepage channel of water flooding has not fully formed (at the recovery of 24.79%). At this moment, due to the large flow resistance, the flue gas would move slowly behind the water slug, effectively slowing down the gas channeling, increasing swept volume and enhancing recovery significantly.

In the conglomerate, the largest gravel can reach 3 cm, while the small particles are similar to sandstone particles at around only 0.1 mm, so there is a large difference in particle size. This difference results in wide distribution of pore radius, poor pore sorting and strong heterogeneity of the conglomerate, which means complex seepage characteristics. The seepage and sweep characteristics cannot be truly reflected by traditional displacement devices with small diameter cores (2.5 cm or 3.8 cm). Full-diameter core displacement experiment can avoid blocking of flow channel by large gravels, which is favorable for simulating the real displacement characteristics and seepage characteristics of conglomerate reservoir.

The experiment results also show that after the completion of water and flue gas flooding, injection of CO2 can enhance the recovery further. N2 accounts for 76.97% of flue gas, and it does not exchange components with crude oil. Therefore, most of injected flue gas rapidly advances along the dominant channel formed by water flooding in the early stage, and acts as ineffective circling. CO2 flooding has many advantages[21]. First, it has relatively strong solubility and extracting ability, which means CO2 constantly dissolves in crude oil, thus oil-water interface tension decreases, leading to the reduction of crude oil viscosity. Second, as CO2 dissolves in formation water to carbonize water, water viscosity increases, improving oil-water mobility ratio. Finally, the carbonic water formed by solving CO2 in formation water can react with carbonate cement in rock and improve the permeability of formation. Therefore, although the dominant channel has been formed after water flooding, CO2 can still exchange components with the remaining oil around when flowing in the dominant channel, so some crude oil can be produced.

4. Conclusions

Full-diameter core displacement experiment can avoid blocking of flow channel by large gravels, which is favorable for simulating the real displacement and seepage characteristics of conglomerate reservoir.

The flue gas generated by fire flooding can be used to further improve the recovery of the conglomerate reservoir after water flooding. And the key to achieve better development effect is to choose a reasonable timing, pressure and mode of gas injection.

Given that dominant seepage channel has not yet fully formed at the middle stage of water flooding, turning into flue gas and water alternating flooding at this point after reservoir pressure increase can avoid ineffective circling brought by early flue gas channeling, so this way can significantly enhance the recovery.

During the process of flue gas and water alternating flooding, the reservoir can effectively absorb the harmful hydrogen sulfide in flue gas, making the storage of flue gas safe and effective.

Nomenclature

GOR—produced GOR, cm3/cm3;

i—gas component number;

j—flue gas component number;

m—gas component amount;

M—component molar mass of flue gas, g/mol;

Ms—flue gas storage capacity, g;

n—flue gas component amount;

p—gas pressure, MPa;

p0—atmospheric pressure, MPa;

p1—experiment pressure, Mpa;

pc—critical pressure of a gas component, MPa;

pinj—injection gas pressure during flooding, MPa;

ppc—apparent critical pressure, MPa;

ppr—apparent reduced pressure of the gas, dimensionless;

y—mole percent of a gas component, %;

T—gas temperature, K;

T0—room temperature, K;

T1—experiment temperature, K;

Tc—critical temperature of a gas component, K;

Tpc—apparent critical temperature, K;

Tpr—apparent reduced temperature of the gas, dimensionless;

V—storage volume of flue gas, cm3;

V0—gas volume at p0 and T0, cm3;

V1—gas volume at p1 and T1, cm3;

Vf—storage volume during flue gas flooding, cm3;

Vg,inj—injected gas volume while flooding, cm3;

Vg,pro—produced gas volume at the end of development, cm3;

Vo—produced oil volume at the end of development, cm3;

Z0—gas deviation factor at p0 and T0, dimensionless;

Z1—gas deviation factor at p1 and T1, dimensionless;

Zinj—injected gas deviation factor while flooding, dimensionless.

Reference

Dual alkali solvent system for CO2 capture from flue gas

The application and enlightenment of Carbon Dioxide flooding in United State

The dissolving capacity and volume expansion of n-alkanes due to Carbon Dioxide

Multiphase boundary of C16+ heavy n-alkanes and CO2 systems

Experiments on CO2 foam seepage characteristics in porous media

Flue gas injection for EOR and sequestration: Case study

DOI:10.1016/j.petrol.2017.07.044 URL [Cited within: 1]

Study on the performance of flue gas improving steam huff and puff for super heavy oil reservoir

Flue gas injection for heavy oil recovery

Evaluation of the miscibility and contribution of flue gas to oil recovery under high pressure air injection

Comparative effectiveness of CO2 produced gas, and flue gas for enhanced heavy oil recovery

Physical analogue experiment of CO2, N2 and flue gas stimulation for oil production

Long core physical simulation for CO2 miscible displacement

Experiment on physical modeling of displacement oil with natural gas for long core.

A study on long-core experiment of natural gas driving

Study of whole core water displacement oil experiment

Experiment research of the phase transition of carbon dioxide in the true core of low permeability reservoir.

Research on gas injection puff and huff displacement of full diameter core in fracture-vug carbonate reservoir

Development theory and technology of low permeability reservoirs in China