Introduction

The oil and gas exploration and development in China has been advancing toward deep reservoirs in recent years. With rich oil and gas resource of 32.5 billion tons of oil equivalent and remaining deep resources accounting for 48% of the total remaining resources, deep reservoirs in China have become a major domain for increasing oil and gas production and reserve. They are characterized by great depth, high pressure and high temperature (HPHT), large thickness and strong heterogeneity, etc. For example, a deep gas reservoir in Tarim Basin, the wells in the reservoir have an average depth of 6800 m (8 000 m at maximum), a bottom hole pressure coefficient of 1.53-1.82, bottom hole pressure of over 105 MPa (150 MPa in maximum), and bottom hole temperature of 150-170°C (191 °C at maximum); moreover, the reservoir is up to 300 m thick, leading to long drilling circle and high costs. Meanwhile, the reservoir is tight (with porosity of 5%-11% and permeability of (0.07-1.11) × 10-3 μm2), with low natural productivity, adding difficulty to reservoir stimulation. In recent years, numerous laboratory experiments have been performed to study mechanism of reservoir stimulation, and several new technologies have been applied in oil and gas field[1,2,3,4]. However, there is still no safe and economical technology for stimulation of deep and ultra-deep oil and gas reservoirs. The main difficulties in stimulating deep oil and gas reservoirs are as follows: (1) Large reservoir thickness, uneven distribution of natural fractures and strong vertical heterogeneity make the general stimulation low in producing degree and poor in effect. (2) As the reservoir is characterized by HPHT, staged stimulation with mechanical isolating tools in deep and ultra-deep reservoirs is complicated and risky, the sealing by mechanical tools is easy to fail, and the operation cost is high. (3) The available temporary plugging materials and diverting technology can not satisfy the needs of diverted fracturing in high temperature and high pressure wells, as they are no resistant to high temperature and low in temporary blocking pressure.

To solve these problems, an idea of new multi-stage stimulation based on chemical temporary plugging is proposed in this study, its feasibility is verified through experiments. A series of new degradable temporary plugging and diverting materials with high temperature resistance and high strength with staged stimulation techniques are developed. Eventually, an efficient reservoir stimulation technology based on the chemical method is established, and its results in field application is analysed.

1. High efficiency reservoir stimulation technology

1.1. Technical principles

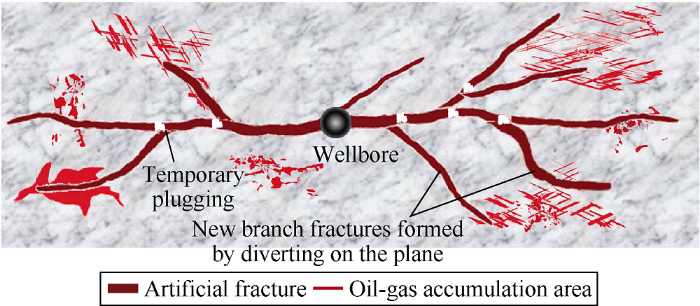

This study proposes a high efficiency stimulation idea of deep and ultra-deep reservoirs with HTHP based on chemical temporary plugging and diverting. The idea includes: plugging agent is injected to seal opened fractures in vertical direction, and more fractures generate along wellbore direction, to realize multi-stage stimulation and enhance the producing degree of reservoir (Fig. 1); similarly in lateral direction, opened fractures are temporarily plugged to force the development of more fracture branches and enlarge stimulated reservoir scope (Fig. 2); after stimulation, the plugging materials can be completely degraded, allowing all the fractures to recover original conductivity. By using the technology to form fracture network, deep and ultra-deep oil and gas reservoir can be stimulated with safety, economy and high efficiency.

Fig. 1.

Multi-stage stimulation with vertical temporary plugging.

Fig. 2.

Fracture network in the lateral direction created by temporary plugging and diverting.

1.2. Modeling experiment of temporary plugging staged fracturing

In order to verify the feasibility of this technique, we did modeling experiments of temporary plugging staged fracturing by large-scale tri-axial fracturing simulation system. The rocks used in the experiment were taken from an outcrop of a deep gas reservoir in Tarim Basin, and cut into samples of 762 mm × 762 mm × 914 mm. A hole was drilled in the center of the rock sample and a steel pipe of 25.4 mm (1 inch) in diameter was put into the hole and bonded with the rock to simulate casing completion. The pipe was slotted in different positions to simulate the perforating holes distributed along wellbore. The structure of the well model is shown in Fig. 3. In the experiment, three-axis stress was loaded according to the strike-slip fault mechanism of a deep gas reservoir in Tarim Basin, i.e. the maximum horizontal principal stress was greater than the vertical stress, and the vertical stress was greater than the minimum horizontal principal stress. The loaded overburden pressure was 10 MPa, the maximum principal stress was 12 MPa, and the minimum principal stress was 5 MPa.

Fig. 3.

Schematic of experimental well.

Experimental procedure is as follows:

(1) To inject fracturing fluid to create and make the 1st fracture extend sufficiently.

(2) To inject crosslinked fracturing fluid mixed with chemical plugging agent to plug the 1st fracture temporarily. Then to inject base fracturing fluid (no crosslinked) by switching pipeline after temporary plugging agent is injected. In the process, the injecting pressure is observed closely, a quick rise of injecting pressure indicates the 1st fracture is successfully plugged, base fracturing fluid will be injected into wellbore continuously to open the 2nd fracture.

(3) If the pressure does not increase, repeat step 2 until temporary plugging is successful.

(4) The acoustic monitoring technology was used during the whole experimental process to monitor real-time fracture initiation and expansion.

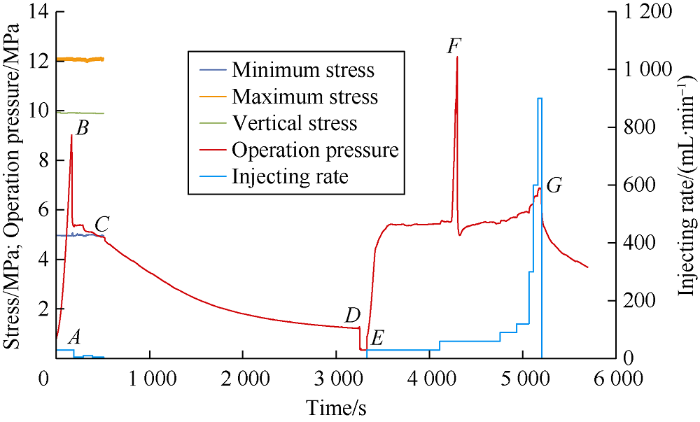

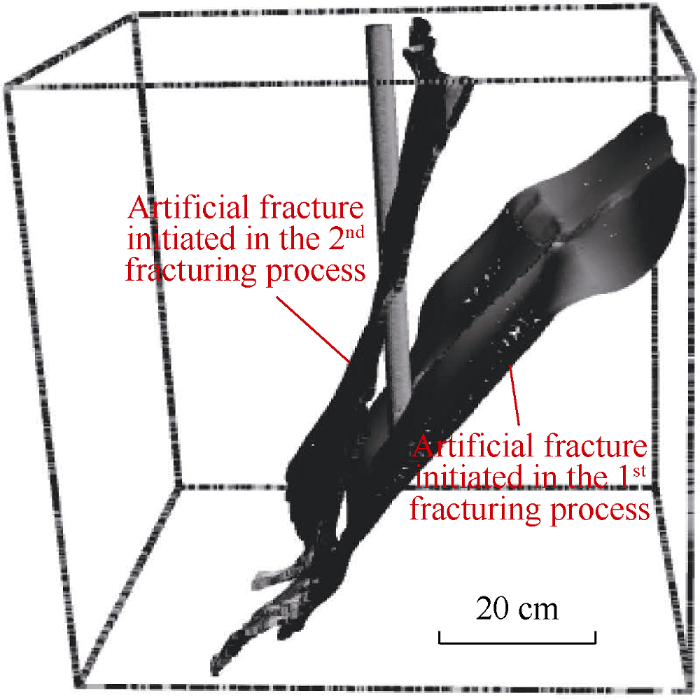

The pressure curve during the experiment is shown in Fig. 4. AD section of the curve represents the first fracturing process, AB is the stage of forming fracture, in which injecting pressure rose sharply to the fracture pressure (point B), and then dropped rapidly after the 1st fracture was created. BC section represents the injection of the fracturing fluid at low rate to extend the fracture for a certain distance. Pressure drawdown (CD section) was tested to obtain leak-off parameters and closing pressure of 1st fracture. DE section represents the injection stage of temporary plugging agent. EF section represents the 2nd fracturing process. It can be seen that the pressure increased rapidly after the injection of temporary plugging agent and switched to fracturing fluid injection, indicating the success of temporary plugging, meanwhile, the 2nd fracture was also created. FG section represents the extension stage of the 2nd fracture. The injecting rate was increased gradually during this stage to make the 2nd fracture extend fully, which can facilitate the identification of fractures generated after the experiment. The curve after G point represents pressure drawdown test. After the experiment was completed, rock sample was cut open along the direction of the minimum principal stress (Fig. 5), and the internal structure of the rock sample was reconstructed by laser scanning (Fig. 6), which indicated that two fractures were generated in the experiment. The result confirms the feasibility of multi-stage fracturing with the temporary plugging. In order to distinguish the opening sequence of different fractures, tracers with different colors were added to the fracturing fluid before and after the temporary plugging. According to tracer distribution, the lower slotted section was firstly fractured, and then the upper slotted section was opened.

Fig. 4.

Pressure curve during the experiment during temporary staged fracturing.

Fig. 5.

Rock sample profile after the experiment.

Fig. 6.

Laser scanning reconstruction of two fractures after experiment.

1.3. Development and evaluation of high temperature resistance, high strength and degradable temperay plugging materials

1.3.1. A series of temporary plugging materials with high temperature resistance and high strength

For reservoir stimulation based on chemical plugging and diverting in deep and ultra-deep wells, the key lies in the development of high temperature resistance and high strength temporary plugging materials. Meanwhile, in order to ensure the recovery of conductivity after fracturing, the plugging material must be completely degraded to avoid damage to the formation and fractures. The existent temporary plugging materials generally have defects like low temperature and pressure resistance. For example, the wax ball plugging agent[5] has a temperature resistance of 30-43 °C and pressure resistance of only 3-5 MPa; oil soluble temporary plugging agents have low temperature resistance[6,7] and cannot be used in gas reservoir; water soluble plugging agents[8,9,10] dissolve fast at high temperature, so it is difficult for them to form effective temporary plugging; plugging fluid system based on foam[11,12,13] has limited plugging strength, high friction, complex preparing process, so it is difficult to use them in deep wells; gelled acid[14,15] and viscoelastic surfactant acid[16] is poor in temperature resistance and cannot be applied in high temperature deep wells. Therefore, it is necessary to develop new plugging materials suitable for stimulation in high temperature and high pressure deep wells.

Temporary plugging requests the materials can block the reservoir or fractures with the ability to be removed automatically. Therefore, the new plugging material should be degradable and can automatically degrade and disappear in a period in the sense of thermodynamics and dynamics[17], and the degradation products should not cause damage to reservoir and environment. Biodegradable materials derived from renewable resources and environment-friendly, have been developed rapidly in recent years. At present, the commonly used biodegradable materials include polylactic acid (PLA), polyglycolic acid (PGA), poly butylenes succinate (PBS) etc.[18,19] However, the PLA isn’t high enough in mechanical strength, the PGA degrades too fast, the PBS is too slow in degradation rate and poor in mechanical properties, so the materials above cannot be applied in high temperature and high pressure environment. Because ester bonds are easy to hydrolyze with no need of enzyme, and the degradation process has low environmental requirements, material based on polyester is good candidate of chemical plugging and diverting material. In order to improve the thermal stability of biodegradable polyester materials, a new type of biodegradable polyester materials was synthesized with prepolymers such as PLA, PGA and PBS. By changing the proportion of each raw material, the degradation temperature of the materials could be adjusted to meet the degradation requirements of different well bottom temperatures. In order to improve the mechanical properties of the materials, chain extenders containing the active epoxy group were added in the synthesis process to increase the molecular weight of the materials. Meanwhile, nano-silica materials were added to further improve the mechanical strength of the materials. Finally, a series of high temperature resistance, high strength and fully degradable nano-ester plugging materials has been developed, by balancing the mechanical strength and degradation degree of the material. Compared with traditional biodegradable materials, the degradable materials developed in this study have higher temperature resistance and mechanical strength by adjusting the molecular structure and adding nanomaterials. In order to meet different requirements of staged temporary plugging and diverting, the plugging materials are manufactured into balls (more than 3 mm in diameter), larger particles (1-3 mm in diameter), small particles (about 1 mm in diameter), powder (0.15-0.25 mm in diameter (60-100 mesh)) and plugging tablets, as shown in Fig. 7. Among them, the plugging ball, large particles and small particles are used to temporarily block the perforation in the fractured section, forcing the fracturing fluid to enter the layers without fracture and to realize multi-stage fracturing along wellbore. Small particles and powder materials are used to temporarily block opened fractures, forcing them to divert into multi-branch fractures, and expanding the scope of fracturing on the plane.

Fig. 7.

Degradable temporary plugging materials with high temperature resistance and high strength.

1.3.2. Evaluation of pressure bearing and degradation performance of the material

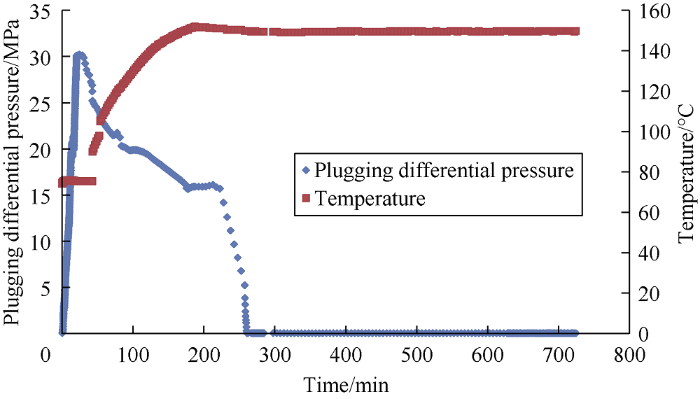

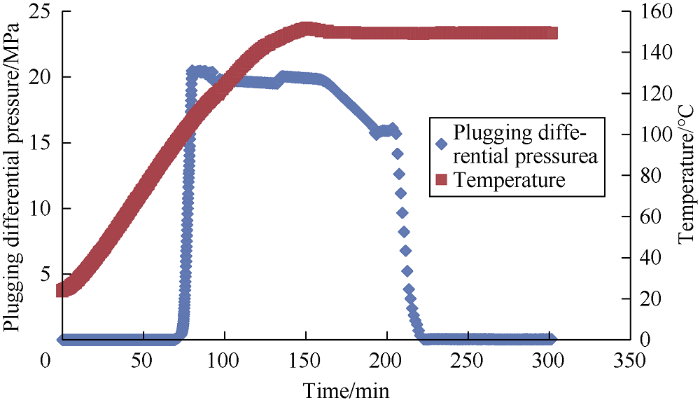

The experiment modeled the temporary plugging process of perforations in large field was conducted to test the pressure bearing capacity of the plugging material. Simulated ball seat and fracturing pump were used in the experiment to test the plugging strength of the plugging ball. The results (Table 1) show that the temporary plugging ball could bear pressure of 50-70 MPa, and has deformation rate of less than 1.5% after experiment. At the same time, laboratory temporary plugging strength tests with high temperature were also performed. The results show that the plugging pressure of plugging ball can be more than 30 MPa at 150 °C (Fig. 8). Plugging pressure of powder and big/small particles can be above 20 MPa (Fig. 9). All of the plugging materials have excellent plugging performance (with effective plugging pressure of generally around 20 MPa).

Table 1 Results of pressure bearing test of plugging ball.

| Plugging ball No. | Maximum pressure/ MPa | Eternal diameter before test/ mm | External diameter after test/ mm | Deformation rate/ % |

|---|---|---|---|---|

| 1 | 52.20 | 11.90 | 11.88 | 0.17 |

| 2 | 70.00 | 8.48 | 8.48 | 0 |

| 3 | 55.40 | 11.88 | 11.70 | 1.50 |

Fig. 8.

Results of pressure bearing test of plugging ball in laboratory.

Fig. 9.

Results of pressure bearing test of plugging particles and powders in laboratory.

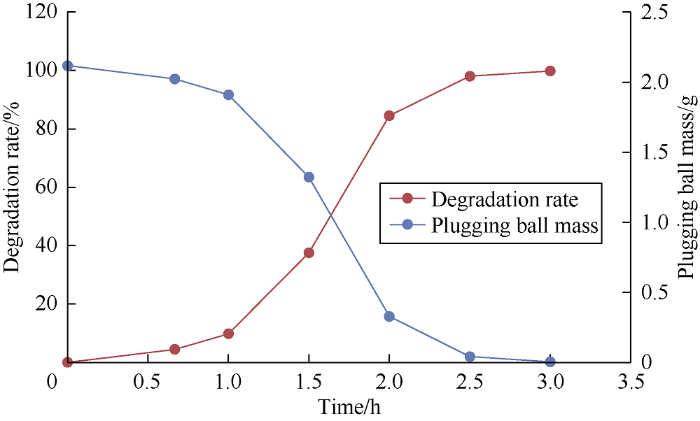

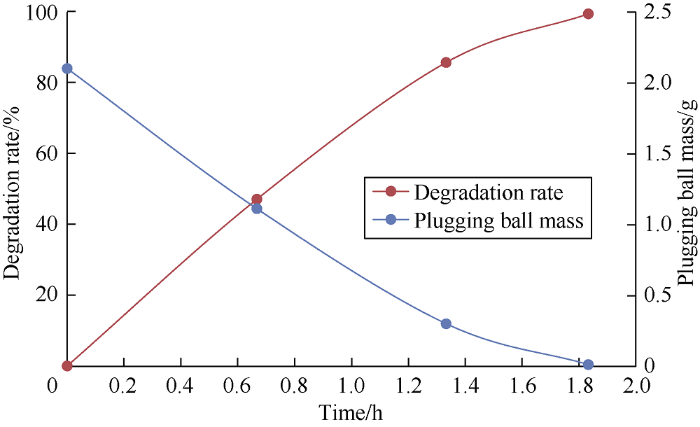

The results of degradation tests show that all the plugging materials can be completely degraded at high temperature. At 150 °C, plugging material can be completely degraded in water after about 2.5 h (Fig. 10). Acid can accelerate the degradation of plugging ball or particles. At 150 °C, plugging ball can be degraded completely after about 2 hours in acid (Fig. 11). The final degradation rates of all materials are more than 99%, and the degradation products can be completely dissolved in fracturing fluid without compatibility problems. The nanomaterials in the degradation products can easily flow back with the fracturing fluid due to the small dosage (less than 0.5%) and small size, and thus will not cause pollution to the formation and fractures.

Fig. 10.

Degradation curve of plugging material in water (150°C).

Fig. 11.

Degradation curve of plugging material in 15 wt% HCl (150 °C).

1.4. Technological process

1.4.1. Temporary plugging and multi-stage fracturing in vertical direction

For wells completed by casing with long reservoir interval, clustering perforation should be performed according to logging interpretation. Then general fracturing of the whole well should be done first. Fractures would be initiated firstly in weak layers with more natural fractures during the first fracturing process, making fluid absorbing ability of these layers increase. After that, plugging balls and big/small plugging particles will be injected into wellbore, which will be carried into the perforations in the layers with opened fractures. Big/small particles would bridge inside the perforations and plugging balls would stuck at the mouth of perforation to prevent fracturing fluid from flowing into the opened fractures, forcing fracturing fluid to enter other layers which are not fractured. Repeat this process to realize multi-stage fracturing vertically (Fig. 1). After fracturing, the plugging materials will be completely degraded at high temperature, allowing oil and gas to flow back through artificial fractures. Furthermore, the wellbore integrity will be remained, not causing troubles to subsequent downhole operations.

1.4.2. Temporary plugging and diverting process inside fractures in horizontal direction

Fig. 2 shows the process of temporary plugging and diverted fracturing on the plane inside fractures. A fracture is broken open in the formation first, and more fracturing fluid is injected at large pumping rate to keep the fracture open. Then plugging materials (small particles, powders and fibers) are added into the fracturing fluid, which will take them into the opened fracture. Due to the roughness of the inner wall of the fracture, small particles will be stopped and accumulated during the migration, and bridge plugging will be generated. At the same time, the powders and fibers inside the fracture will fill into the pores of small particle skeleton, forming a high- strength plugging barrier, preventing the fracturing fluid from flowing into the opened fracture. At this point, the fluid pressure inside the fracture will rise rapidly. When the pressure exceeds the tensile strength of the existing fracture wall, branch fractures will be generated at a new position. The process of plugging, pressure-rising and cracking will repeat at different positions of the main fractures and even in the branch fractures, turning the original single fracture into a complex fracture with multiple branches, and greatly expanding the scope of stimulation on the plane. After the stimulation, all the plugging materials accumulated in the fractures will be completely degraded at high temperature and will not cause damage to the formation and fractures.

2. Field application

2.1. Overall situation of field application

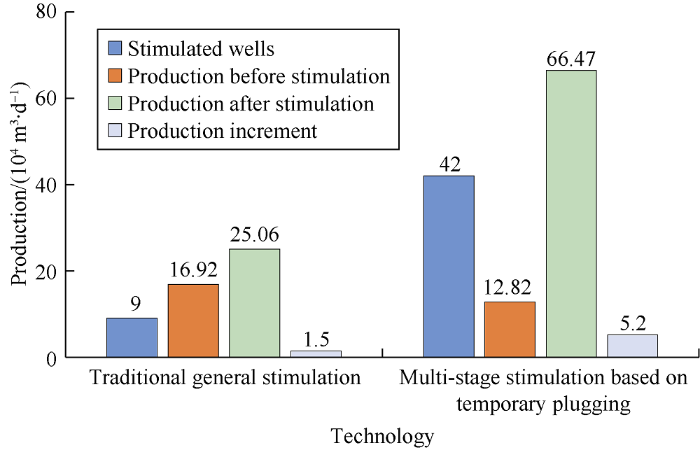

This technology has been successfully applied in 211 wells of 10 deep oil and gas fields across China. The maximum well depth and temperature among them were 7780 m and 191 °C respectively. And the treatment has an effective rate of 95.6% with success rate of 100%. According to statistic results of fracturing conducted in one block of Tarim Basin (Fig. 12), average production of wells stimulated with the new technology is 3.5 times of wells stimulated with traditional technology. This technology achieves the goal of isolating vertically and diverting within fractures in deep and ultra-deep wells. It can save huge cost of high temperature and high pressure resistance mechanical sealing tools, avoid the risks that may occur when using mechanical isolating tools for multi-stage stimulation, and provides new technical support for safe and economic stimulation in HPHT deep and ultra-deep reservoirs.

Fig. 12.

Comparison of stimulation results.

2.2. Representative example

KS-XX is a producing well in Tarim Basin, with designed depth of 7 095 m, and its target layer is Cretaceous Bashijiqi Formation. Bottom-hole temperature and formation pressure are 172 °C and 122 MPa respectively. The pay zone spanning 92 m (6 968-7 060 m), was divided into 8 perforation sections.

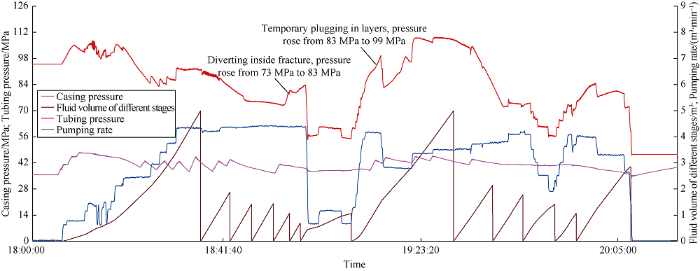

A 2-stage stimulation was designed for this well because the pay zone is thin. After the first fracture was generated, 1 mm plugging particles and powder were injected into the opened fracture to conduct plugging inside the and diverting, expand the scope of stimulation. Surface injection pressure increased from 73 MPa to 83 MPa when the plugging particles and powder reached well bottom, diverting pressure reached 10 MPa inside the fracture indicating the success of diverted fracturing. When the first stage treatment was completed, 8 mm plugging balls, 3 mm particles and 1 mm particles were injected into wellbore together, to plug the perforations of layers with fractures. Surface injection pressure rose from 83 MPa to 99 MPa when corresponding perforations were plugged, indicating 16 MPa of plugging pressure was obtained to initiate new fractures in different sections (Fig. 13). Before stimulation, the tubing pressure and gas production of this well were 91.7 MPa and 154 769 m3/d. After stimulation, the tubing pressure and gas production increased to 92.34 MPa and 651356 m3/d respectively, demonstrating good fracturing effect.

Fig. 13.

Fracturing curve of Well KS-XX.

3. Conclusions

In light of the characteristics of deep reservoirs in China, a high efficiency reservoir fracturing technology based on chemical temporary plugging has been proposed for deep reservoirs. This technology achieves the goal of multi-stage fracturing and diverting within fractures, enhancing the reservoir stimulated volume. The technical feasibility and effectiveness have been proved both in field and laboratory. A series of high temperature resistance, high strength and degradable nano- ester plugging material has been developed by adding nano materials and modifying molecular structure, solving the problem of strength and degradation degree balance of chemical plugging materials. Furthermore, vertical plugging in layers and lateral plugging and diverting technological processes have been worked out to effectively stimulate deep reservoirs. This technology can avoid the risks that may occur during application of mechanical isolating tools and save large amount of costs of fracturing operations in deep reservoirs with high temperature and high pressure. This technology has been successfully applied in 211 wells of 10 deep oil and gas fields in China with obvious stimulation effect. This technology provides a new way for safe and economic stimulation of deep and ultra-deep oil and gas reservoirs.

Reference

Segmented reconstruction technique of high-temperature deep heterogeneous carbonate horizontal well

Deep strata geologic structure and tight conglomerate gas exploration in Songliao Basin, East China

Acid fracturing in high temperature deep layer carbonate reservoir

Efficient development strategies for large ultra-deep structural gas fields in China

DOI:10.1016/S1876-3804(18)30010-7 URL [Cited within: 1]

Study on the performance of wax- bead temporary blocking agent used for refracturing in low- permeability reservoir

Evaluation of oil-soluble resin as an acid diverting agent

Laboratory/field study of oil-soluble resin-diverting agents in Prudhoe Bay, Alaska, acidizing operations

Performance evaluation of water soluble temporary plugging agent for fracturing

Study and application of water soluble temporary plugging agent

Water soluble temporarily plugging agent JYD-Ⅱ: Preparation and uses

Case study on the effectiveness of nitrogen foams and water zone diverting agents in multistage matrix acid treatments

Effect of foams used during carbonate acidizing

Matrix acidizing: A novel approach to foam diversion

A clean hydrochloric acidizing fluid of deep penetration and low damage owing to in-situ gelation at elevated pH value

Application and study of acid fracture technique using novel temperature control viscosity acid in carbonate reservoir, Tarim

Study on a self-diverting acid system for well stimulation based on novel visco-elastic surfactant

Application and future development of degradable materials in completion tools

Research progress of preparation and application of degradable materials

Industry status and trend analysis of biodegradable material