Introduction

The shale hydration effect has been investigated in China and abroad for borehole stability problem during drilling and improving the drilling fluid to prevent clay swelling caused by hydration[1,2,3,4,5,6]. The studies are usually implemented by establishing theoretical mechanical models, conducting macroscopic shale hydration experiments, or characterizing shale hydration procedure by 3D imaging methods like computed tomographic scanning. Numerous studies on the petrophysical property variations of shale rock before and after hydration have been done. Mao et al.[7] believed that clay minerals dominated the hydration process, and clay mineral particles in directional arrangement would have stronger hydration effect than clay mineral particles in disordered arrangement. Zhu et al.[8] found that hydration effect increased the argillization trend of shale, produced illite/smectite mixed-layer clay minerals, in the course, compact layer microstructure of shale gradually changed into loose flocculent structure, and micro-disintegration phenomenon appeared. Zheng et al.[9] concluded that the microstructure and the interlayer binding force of the water-saturated shale changed, leading to the increase of pores and fractures, so the shale shows drop of strength, reduction of ability to resist deformation, and denser and more interconnected fracture surfaces macroscopically. Huang et al.[10] considered the real reason of shale softening and disintegration was the microstructure characteristics, while the existence of montmorillonite was not the decisive factor. Results of the above studies suggest that water has a great impact on the mechanical properties of shale, and the variations in mineral composition and microstructure are the major factors affecting the mechanical properties of shale.

In recent years, as large-scale hydraulic fracturing stimulation technology in shale gas wells is applied widely and the concepts of volumetric fracturing and complex fracture network are presented[11,12,13], researchers found that the reservoir microstructure would be changed by hydration effect between fracturing fluid and clay minerals in the formation, which was considered to benefit the shale reservoir stimulation. By using nuclear magnetic resonance (NMR) and CT scanning technologies, Qian[14] conducted hydration experiments on shale samples under the confining pressure of 10 MPa to study the effect of hydration on the pores and fractures in shale formation. The study results proved that hydration not only offset the permeability drop caused by stress sensitivity, but also increase the pores-fracture volume in the core and connectivity due to the propagation of pore-fracture structure and creation of new microfractures, thus the permeability of the core increased. Gupta[15] conducted water imbibition experiment on shale samples and found that hydration effect enhanced sample porosity. Lu et al.[16] studied the anisotropic hydration damage characteristics of shale under high temperature by using the Longmaxi shale samples with natural fractures. They reached the conclusion that the damage behavior in the bedding-parallel plane was dominated by dilatation-closure-collapse process of natural microfractures, while the damage behavior perpendicular to the bedding is mainly the damage to dissolution pores. They also studied how temperature affected the damage behavior. Kang et al.[3] analyzed the crystal layer micro forces of clay minerals during the shale hydration process, and concluded that during the shut-in period of shale gas wells, hydration effect could induce development and extension of micro-fractures, further improving the stimulation effect of shale reservoirs. Zou et al.[17] proposed that post-fracturing shut-in could increase the water absorption in formation and reduce the flowback, which would further enhance swept area of fractures and in such way to increase the stimulated reservoir volume. The results mentioned above proved that shale hydration during the hydraulic fracturing could induce remarkable variation of reservoir microstructure and have a positive influence on stimulation effectiveness.

Meanwhile, microscopic fluid flow simulation has become a major means for studying the fluid flow mechanisms after fracturing stimulation in shale reservoirs[15,18-19]. To find out the reason of low flowback rate of fracturing fluid during hydraulic fracturing in shale, Zhang et al.[19] reconstructed shale digital core by Markov Chain Monte Carlo method with SEM scanning images, and then simulated the displacement between water and gas in pore-scale, then obtained distributions of two phases, but they didn’t discuss the reservoir microstructure changes due to hydration effect.

Based on the Field Emission Scanned Electronic Microscope (FESEM) and multi-point in-situ scanning, in this study, we observed and quantitatively analyzed the microscopic pore structure variations of shale samples before and after hydration, to find out the effects of clay mineral type and content, organic matter abundance, difference of parallel and vertical-bedding planes on the micro-pore structure changes of shale after hydration and changes of different types of pores and fractures during hydration. This study may provide some fundamental theoretical support for studying the fluid flow mechanism after fracturing in shale reservoirs by using microscopic fluid flow simulation such as digital rock technique etc.

1. Shale hydration experiment and SEM

fixed-point observation

In this study, FESEM was used to observe the micro-pore structures of shale outcrop samples during hydration. The experiments included mineralogy analysis, shale hydration experiment and SEM fixed-point observation.

1.1. Experimental apparatus

The X-ray powder diffraction mineralogy analysis (XRD) of shale samples was done on a QEMSCAN650F mineral analyzer with the resolution of 1 μm. The fixed-point observation of pore structure during hydration was completed with ZEISS Sigma 500 FESEM, which has the resolution of 0.8 nm at 15 kV and 1.6 nm at 1 kV under high-vacuum condition.

1.2. Rock samples

In this experiment, four shale outcrop samples were numbered as Samples 1 to 4. Samples 1 to 3 were collected from Pengshui, Zigong, and Fuling in Sichuan Province. Sample 4 was collected from Changqing field. First, standard core plugs of 25 mm in diameter and 50 mm long were taken and their porosity and permeability were tested with Smart-PermII ultra-low permeameter. The porosity was measured by the Helium injection method, and the permeability by unsteady-state pulse-decay method. The test results are listed in Table 1.

Table 1 Measured porosity and permeability of shale samples.

| Sample No. | Porosity/% | Permeability/10-3 μm2 |

|---|---|---|

| 1 | 1.96 | 0.004 1 |

| 2 | 3.15 | 0.006 5 |

| 3 | 4.38 | 0.004 9 |

| 4 | 1.91 | 0.003 1 |

One specimen parallel with the bedding and one perpendicular to the bedding were taken from each of the four samples, so eight specimens in total were obtained and numbered as 1H—4H (bedding-parallel plane) and 1V—4V (bedding-vertical plane) in order to observe by FESEM after hydration. They were cut and grinded into the size suitable for SEM scanning. Their surfaces were polished by argon ion and coated with carbon film.

Organic carbon content and total rock mineralogy and clay mineralogy of Samples 1 to 4 were analyzed. The analysis results show that quartz is the predominant component in non-clay minerals, which means all the samples are hard-brittle shale (Table 2). Sample 1 is characterized by the highest contents of plagioclase and clay minerals, rich illite and chlorite, the lowest content of TOC of 0.18%, and no carbonate minerals. Sample 2 contains plagioclase and a little calcite, moderate content of clay minerals, low content of chlorite, rich illite, the highest contents of montmorillonite, higher content of carbonate minerals such as calcite and ankerite, and moderate content of TOC. Sample 3 is reported as a typical organic-rich shale with the highest content of quartz, little carbonate minerals, the lowest content of clay minerals, and the highest content of TOC of 5.50%. Sample 4 has the lowest content of quartz, the highest content of carbonate minerals such as calcite and ankerite, lower content of clay minerals with rich illite and little montmorillonite, and moderate content of TOC.

Table 2 Results of organic carbon content analysis and XRD analysis for Samples 1 to 4.

| Sample No. | TOC value/% | Mineral content/% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clay | Quartz | K-feldspar | Plagioclase | Calcite | Dolomite | Pyrite | Ankerite | Illite | Chlorite | Kaolinite | Montmorillonite | ||

| 1 | 0.18 | 45.4 | 42.2 | 12.4 | 23.9 | 15.9 | 5.6 | ||||||

| 2 | 1.00 | 29.8 | 46.1 | 10.8 | 3.7 | 9.6 | 15.1 | 2.4 | 0.9 | 11.4 | |||

| 3 | 5.50 | 16.8 | 67.0 | 1.5 | 3.9 | 1.4 | 6.1 | 3.3 | 7.2 | 0.8 | 3.9 | 4.9 | |

| 4 | 0.81 | 18.9 | 37.5 | 0.4 | 5.0 | 14.4 | 1.3 | 2.3 | 19.8 | 17.6 | 0.8 | 0.4 | 0.5 |

1.3. Experimental method

Shale hydration experiment was conducted on all the eight specimens. Their micro-pore structures were scanned and observed by SEM under Secondary Electron mode before hydration, and after hydration for 3-day and 6-day respectively. To prevent water vapour from polluting the SEM sample compartment, the specimens were dried at a low temperature of 60 °C before SEM scanning every time. The shale specimens were soaked in distilled water under atmospheric pressure and room temperature in the hydration experiment.

Repeated removing-and-placing specimens were needed for alternative hydration and drying process to observe the specimens during all stages of hydration. To record the micro-pore structure changes of specimens accurately, all the specimens were observed before hydration and all feature points were marked and characterized microscopically. After placing the specimen and locating macroscopically, the original location could be determined by coordinate values and feature points. The specimens were scanned continuously under different magnifications. The highest magnification was 4000X with a resolution of 27.1 nm, and the observed area after splicing was 3.1 mm.

2. The results and discussion

2.1. Micro-pore before hydration

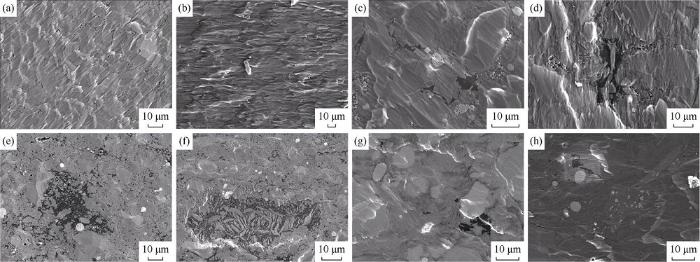

Before the hydration experiment, the original characteristics of micro-pore structure and distribution of fractures of 8 specimens were studied through fixed-point SEM observation, which could serve as the reference for studying hydration effect later on (Fig. 1).

Fig. 1.

Observed micro-pore structures of samples before hydration. (a) Bedding-parallel Specimen 1H from Sample 1; (b) Bedding-vertical Specimen 1V from Sample 1; (c) Bedding-parallel Specimen 2H from Sample 2; (d) Bedding-vertical Specimen 2V from Sample 2; (e) Bedding-parallel Specimen 3H from Sample 3; (f) Bedding-vertical Specimen 3V from Sample 3; (g) Bedding-parallel Specimen 4H from Sample 4; (h) Bedding-parallel Specimen 4V from Sample 4.

Comparing all the bedding-parallel specimens shows they differ widely in micro-pore structure: Specimen 1H with low content of TOC, minerals are the dominant components in the matrix, mineral grains have clear boundaries, and plagioclase grains can be seen obviously, little filling exists between mineral grains, and some mineral intergranular pores are observed, but no fracture is found (Fig. 1a). A small amount of organic matter in scattered patches and bands, no organic pores, and no evident fractures in matrix were observed in Specimen 2H (Fig. 1c). In Specimen 3H, there are a large number of mud pores and intergrowth of organic matter and mineral, many organic pores, and a large number of micro-fractures around minerals and within organic matter (Fig. 1e). Specimen 4H contains a small amount of intergrowth of organic matter and mineral, with few organic pores, some intergranular pores and micro-fractures around mineral grains (Fig. 1g). In addition, the corresponding bedding-vertical specimens also show similar characteristics as the parallel ones except two differ-ences. Firstly, the grain boundaries in Specimen 1V are not as evident as those in Specimen 1H (Fig. 1b), which indicates that the non-clay mineral grains of Sample 1 are predominantly directional arranged and parallel to the bedding plane. Secondly, organic matter in Specimen 3V appears as interstitial material filling between mineral grains (Fig. 1f), and is much less continuous on the plane than that in Specimen 3H.

2.2. Overall changes of microstructure after hydration

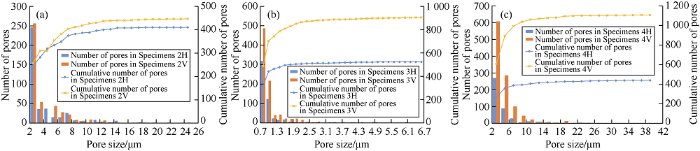

After binary image processing of the SEM images of the same magnifications, the number and size of newly generated dissolution pores were counted and compared.

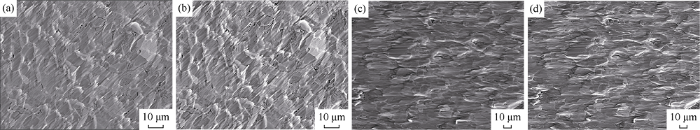

Sample 1 didn’t change much in micro-pore structure before and after hydration, indicating it wasn’t affected by hydration influence basically (Fig. 2). In Sample 4, a large number of dissolution pores appeared on the surface after 6 days hydration, and the newly generated pores reached 2 to 60 μm (Fig. 3). Obvious dissolution pores and fall-off mineral grains were also seen on the surfaces of Sample 2 and 3 after 6 days hydration. The bedding-parallel specimens were taken as representatives to count the number and average size of dissolution pores that appeared after 6 days hydration. Specimen 3H has the largest number of newly generated dissolution pores, but the smallest average and median pore sizes (Table 3).

Fig. 2.

Micro-pore structure characteristics of Sample 1 before and after hydration. (a) Bedding-parallel Specimen 1H, before hydration; (b) Bedding-parallel Specimen 1H, 6 days hydration; (c) Bedding-vertical Specimen 1V, before hydration; (d) Bedding-vertical Specimen 1V, 6 days hydration.

Fig. 3.

Micro-pore structure characteristics of Sample 4 before and after hydration. (a) Bedding-parallel Specimen 4H, before hydration; (b) Bedding-parallel Specimen 4H, 6 days hydration; (c) Bedding-vertical Specimen 4V, before hydration; (d) Bedding-vertical Specimen 4V, 6 days hydration.

Table 3 Statistics on the number and size of generated dissolution pores 6 days into hydration.

| Specimen No. | Number of dissolution pores | Average pore size/μm | Median pore size/μm |

|---|---|---|---|

| 2H | 410 | 3.75 | 2.74 |

| 3H | 523 | 0.81 | 0.55 |

| 4H | 436 | 4.53 | 2.72 |

By analyzing the areal porosity of Sample 2, 3, and 4 after 6 days hydration, we found that Sample 4 had the highest areal porosity due to the large number and size of dissolution pores generated after hydration. Although Sample 3 had a higher initial porosity, its areal porosity after hydration is lower due to smaller size of the newly generated dissolution pores (Table 4). It should be noted that the areal porosity values after hydration cannot represent the total porosity of the samples, and they can only characterize the degree of micro-pore change after hydration.

Table 4 Statistics on porosity before hydration and observed areal porosity after 6 days hydration.

| Sample No. | Initial porosity/% | Areal porosity after hydration/% |

|---|---|---|

| 2 | 3.15 | 1.87 |

| 3 | 4.38 | 0.52 |

| 4 | 1.91 | 2.91 |

Current studies on shale hydration are mainly about the relationship of clay minerals in shale with water-swelling and dispersibility of shale. The correspondences between clay mineral components and stability of shale presented by Obrien et al.[20] have been widely applied. They proposed that the shale with higher content of montmorillonite was usually softer and tend to be water-swelling with high dispersibility, while the shale with higher content of illite and chlorite was hard and brittle, thus less dispersive and not likely to swell, but easy to collapse when contacting with water. Experimental results from this study show that some carbonate minerals such as calcite, dolomite and ankerite may also affect the micro-pore structure of shale after hydration. In the hydration experiments of this study, Sample 1 has the highest content of clay minerals, mainly illite and chlorite, but no carbonate minerals, and its overall dissolution effect due to hydration is not obvious. Sample 2 has higher contents of montmorillonite and carbonate minerals, dissolution pores and fall-off mineral grains after hydration are evident, and the number and average size of the newly generated pores are both large. The contents of montmorillonite and carbonate minerals in Sample 3 are slightly lower than those in Sample 2, the number of dissolution pores generated and fall-off mineral grains after hydration are less, and the size of dissolution pores is smaller. Sample 4 has a very low content of montmorillonite but quite high content of carbonate minerals, the number of dissolution pores generated and fall-off mineral grains after hydration are the largest, and the size of dissolution pores is also large.

Based on the overall behavior of the micro-pore structure changes of shale samples after hydration, hydration has critical effect on the micro-pore structure changes, and the dissolution pores generated and fall-off mineral grains can improve the connectivity of original pores. The stimulation measure of extending well shut-in time after fracturing is also based on such theoretical consideration, which intends to improve the micro-pore structure of shale reservoir, further reduce fracturing fluid recovery and thus increase the stimulated reservoir volume and productivity through hydration. Therefore, the hydration effect on micro-pore structure of shale reservoirs should be taken into account in the studies on microscopic flow mechanism and post-fracturing productivity forecast.

2.3. Micro-pore structure changes during hydration

Researchers in China and abroad have presented a bunch of theories and methods for genetic classification of pore system in shale reservoirs, but there is not a unified classification reached yet. In this study, a representative classification method presented by Loucks et al. was adopted[21], which classifies the pores in shale reservoirs into organic pores, intergranular and intragranular pores in matrix. Based on such classifications, the shale samples were observed during hydration by using fixed-point SEM observation method, and the hydration effects on different types of pores have been analyzed.

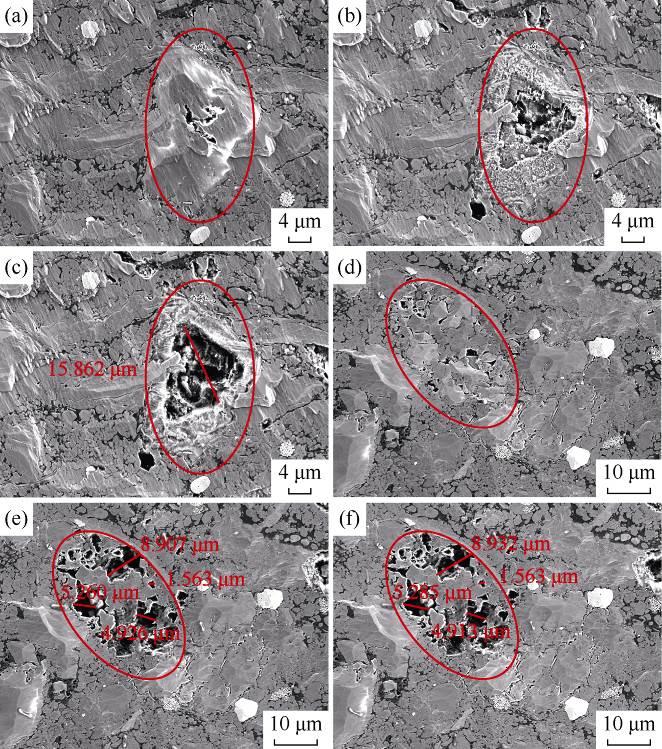

The results show that the matrix pores play an important role in hydration process, not only acting as the paths of water imbibition and diffusion, but also the starting points of hydration dissolution. It can be seen from Samples 2, 3, and 4 with obvious hydration effect, hydration all began from the boundaries of mineral grains. As time went on, the hydrophilic mineral grains finally fell off due to the intensified hydration effect. Through the single mineral grain fall-off observed of Specimen 2V, the boundary and inner structure of mineral grain can be seen clearly (Fig. 4). The dissolution of matrix intergranular pores and resulting in looseness and fall-off of large grains were observed in Specimens 3H and 3V (Fig. 5). Matrix pores have significant changes during hydration, both intergranular and intragranular pores have positive effects on hydration effect.

Fig. 4.

Micro-pore structure changes of Specimen 2V before hydration (a) and after 6 days of hydration (b).

Fig. 5.

Matrix pore changes of Specimens 3H and 3V during hydration. (a) Specimen 3H before hydration; (b) Specimen 3H after 3 days of hydration; (c) Specimen 3H after 6 days of hydration; (d) Specimen 3V before hydration; (e) Specimen 3V after 3 days of hydration; (f) Specimen 3V after 6 days of hydration.

The behavior of organic matter and pores in organic matter before and after hydration of Specimen 3H were observed (Fig. 6). Combined with the organic matter in other specimen, we could see that the hydration process doesn’t have noticeable influence on organic pores. This is because the geochemical properties of organic matter itself make it difficult to react with water. In addition, according to the microscopic pore wettability studies of shale, most nano-scale organic pores in shale are oil-wet, therefore water cannot enter the organic pores easily during hydration[22]. Unsurprisingly, no hydration effect was observed at the contacts of organic matter and matrix minerals in all specimens.

Fig. 6.

Micro-pore structure changes of the organic matter in Specimen 3H before hydration (a) and after 6 days of hydration (b).

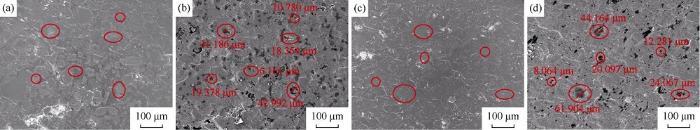

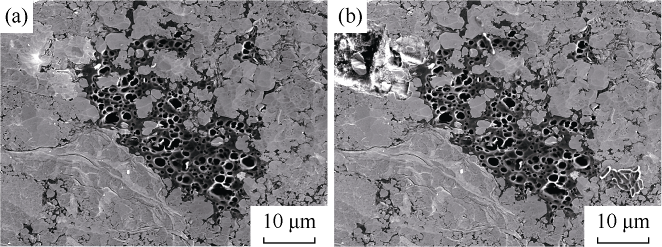

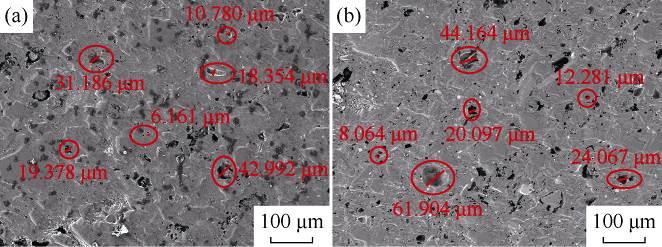

Matrix pores in Specimens 4H and 4V had significant variations after 6 days of hydration (Fig. 7). Compared with Specimen 4H, Specimen 4V showed more intensive dissolution and mineral grain fall-off. From the perspective of pore size distribution, the proportion of micro-pores in Specimen 4V is higher than that in Specimen 4H. Such differences may be caused by the way of mineral grain arrangement and cementation. The mineral grains in Sample 4 are mainly arranged, compacted and stacked along the bedding-parallel plane, thus there is a higher density of grain distribution at bedding-vertical plane, which are more likely to hydrate and generate dissolution pores. From the statistical results of the number and distribution of dissolution pores in Samples 2, 3 and 4 (Fig. 8), we found that Samples 3 and 4 have regularity similar to the above. In contrast, for Sample 2, the number and size of dissolution pores in bedding-parallel and bedding-vertical are similar, which is probably related to the non-directional arrangement of mineral grains in this sample.

Fig. 7.

Matrix pore changes in Specimens 4H (a) and 4V after 6 days of hydration.

Fig. 8.

Distribution of dissolution pores after 6 days of hydration at bedding-parallel and bedding-vertical planes.

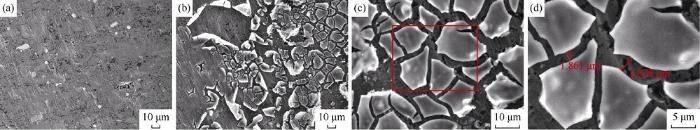

2.4. Microfracture changes during hydration

In the hydration experiments, no original and newly generated microfractures were seen in Samples 1, 2, and 3. In Specimen 3H, interbedding microfractures with large size partially filled by asphalt were observed before hydration, but the microfractures didn’t change obviously after hydration (Fig. 9). Distinct microfractures generated after hydration were found in Specimen 4H. The initialization, development and intercommunication of microfractures were observed clearly under different magnifications (Fig. 10). Observation at 4300x magnification showed that the microfracture initialization mainly started at the boundary of mineral grains in 4H after hydration for 3 days, then extended along the boundary and intercommunicated with other microfractures. The microfracture width was 0.112 μm (Fig. 10b) at that moment. Most of the newly generated microfractures continued to extend and reached 0.185 μm wide after 6 days of hydration (Fig. 10c). Observation at 200x magnification showed that the microfractures have penetrated through the specimen and become a macroscopic fracture after 6 days hydration. The fracture was 2.5 cm long and 6.575 μm wide (Fig. 10f). The macroscopic fractures appeared during hydration were formed by the intercommunication and development of microscopic dissolution pores and microfractures, and showed as different pore and fracture structures under different magnifications. Compared with the other three samples, Sample 4 has a higher content of carbonate minerals, which may be related with the generation and development of the microfractures during hydration. Further studies on the effect of carbonate minerals should be conducted since they are also brittle minerals and have a great impact on reservoir fracturing. A few cases of microfracture closure caused by the hydration expansion of clay mineral grains were also found in the experiments.

Fig. 9.

Comparison of interbedding microfractures in Specimen 3H before and after 6 days of hydration. (a) Before hydration; (b) Local amplification before hydration; (c) After 6 days of hydration; (d) Local amplification after 6 days of hydration.

Fig. 10.

Microfracture changes in Specimen 4H during hydration. (a) Before hydration, at 4300× magnification; (b) After 3 days of hydration, at 4 300× magnification; (c) After 6 days of hydration, at 4 300× magnification; (d) Before hydration, at 200× magnification; (e) After 3 days of hydration, at 200× magnification; (f) After 6 days of hydration, at 200× magnification.

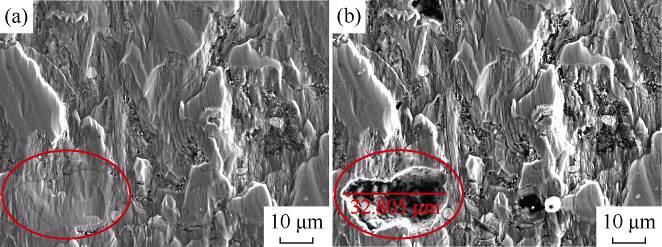

2.5. Sample disintegration during hydration

During the hydration experiments conducted in this study, the micro-pore structure changes of shale samples mainly consist of dissolution pore generation and microfracture propagation. However, surface partial disintegration appeared in Specimen 3S during the later repetitive experiments. Specimen 3S was cut from Sample 3. Comparing the SEM images before and after 6 days of hydration, the surface disintegration and falling fragments could be seen clearly. The disintegration fracture reached 2.978 μm wide (Fig. 11). According to related experimental studies of microscopic shale swelling characteristics when contacting water, it can be inferred that strong argillization and hydration expansion occurred during hydration of this specimen. Such disintegration may be related to the higher content of organic matter, while the specific reasons and influencing factors need to be investigated further theoretically and experimentally.

Fig. 11.

Microscopic disintegration after hydration in Specimen 3S along the bedding-vertical planes. (a) Before hydration, at 500× magnification; (b) After 6 days of hydration, at 500× magnification; (c) Local amplification after 6 days of hydration, at 2 000× magnification; (d) Local amplification after 6 days of hydration, at 4 000× magnification.

3. Conclusions

Higher contents of montmorillonite and carbonate minerals are conducive to the formation of dissolution pores and mineral grain falling-off during hydration. Original mineral grain alignment, cementation, and distribution of microfractures in shale samples also greatly impact the dissolution pore generation and mineral grain falling-off.

Hydration doesn’t change the organic pore structure, and the dissolution pores generated during hydration originate from matrix intergranular and intragranular pores. The dissolution of matrix pores also leads to the looseness and fall-off of mineral grains.

Due to the different mineral grain arrangement directions and compaction, when the mineral grains arrange and compact along the bedding-parallel planes, the density of dissolution pores and the number of dissolution pores of small size in bedding-vertical specimens are usually larger than that in bedding-parallel specimens.

For the shale samples with no natural microfractures, higher content of carbonate minerals may contribute to the generation and propagation of microfractures during hydration. A few cases of microfracture closure around the mineral grains were found during hydration.

Reference

Imbibition experiment of shale and its application in flowback analysis

Fracturing fluid imbibition into gas shale and its impact on engineering

Quantitative characterization of micro forces in shale hydration and field applications

A chemo-mechanical coupling model of deviated borehole stability in hard brittle shale

Study of meso-damage characteristics of shale hydration based on CT scanning technology

Hydration experiment of hard brittle shale of the Longmaxi Formation. Journal of Southwest Petroleum University (Science &

Evaluation of impact of clay mineral fabrics on hydration process

Experimental study of micro-characteristics of swelling for black shale under influence of water

Softening micro-mechanism and mechanical properties of water-saturated shale in Northwestern Hubei

Research on micro-mechanism of softening and argillitization of mudstone

The relationship between fracture complexity, reservoir properties, and fracture-treatment design

Development of a brittle shale fracture network model. Texas,

What is stimulated reservoir volume?

Experiments on shale reservoirs plugs hydration

DOI:10.1016/S1876-3804(17)30070-8 URL [Cited within: 1]

Experimental investigation for microscale stimulation of shales by water imbibition during the shut-in periods

Experimental study on hydration damage of anisotropic shale under high temperature. SCIENTIA SINICA Physica,

Shale gas in China: Characteristics, challenges and prospects (II)

Nanotomography of the spontaneous imbibition in shale.

The explanation of low recovery of fracturing fluid in shale hydraulic fracturing by pore-scale simulation

DOI:10.1360/N972014-00461 URL [Cited within: 2]

Stabilizing sensitive shales with inhibited, potassium-based drilling fluids

DOI:10.2118/4232-PA URL [Cited within: 1]

Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores

DOI:10.1306/08171111061 URL [Cited within: 1]

An NMR study on shale wettability.