Introduction

Among the developed oilfields in China, carbonate dissolution-vug reservoirs are taking a more and more important position, for example, the thin and non beaded fracture-vug reservoirs in the Ordovician carbonate rock of the Tahe oilfield with the reserves of 4.46×108 t (accounting for 86% of the non-producing reserves), which is an important domain for the future productivity replacement[1]. In recent years, waterflooding has been adopted mainly in Tahe oilfield to maintain formation pressure and stable production. The major layers of waterflooding are non beaded thin layer reservoirs, such as block 4[2] and block 6-7[3] of Tahe oilfield. As the waterflooding goes deeper, the injection-production structure is gradually refined and adjusted. According to the stratified waterflooding technology of sandstone reservoirs, the zoning water injection will become an important way to improve the development effect of carbonate reservoir.

The adjustment of the injection-production structure is the key for zoning water injection. Because of the large difference in the flow space and structure between the carbonate dissolution-vug reservoir and the sandstone pore type reservoir, the development knowledge and experience of waterflooding for the conventional sandstone reservoir cannot be used as reference for carbonate reservoir. Therefore, it is of great signification for zoning water injection, well pattern arrangement, injection-production adjustment in the epikarst zone to investigate waterflooding characteristics of the small-scale carbonate dissolution-vug reservoir.

In this study, volcanic rock outcrop was selected as sample to represent small-scale carbonate dissolution-vug reservoir core, and waterflooding experiments were designed based on the similarity criterion to find out development characteristics of waterflooding with different well patterns, analyze the effect of factors such as fractures and injection rates on waterflooding characteristics, and sort out the optimal waterflooding development mode to enhance oil recovery.

1. Reservoir characteristics and similarity criterion design

1.1. Development of dissolution-vug reservoir

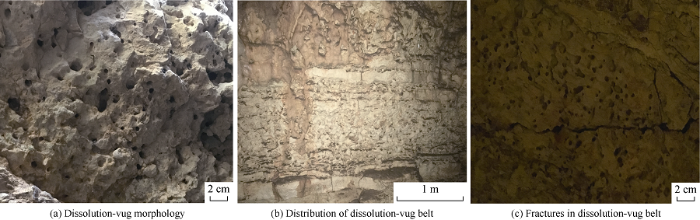

The dissolution-vugs refer to irregular pores and caves are 0.2-20.0 cm in diameter in layers or strips formed by dissolution, which constitute the layered or zonal fracture-vug system with the surrounding dissolution fractures[4]. According to the observation and analysis of imaging logging, cores, outcrops, and underground karst caves, the dissolution-vug reservoir is even and continuous laterally. The dissolution vugs formed in honeycomb, beads or irregular shapes, and are more than 2 mm in diameter in general. Most of the reservoirs are in thin layers[5,6,7,8]. Fig. 1 shows the morphology, distribution and fracture development of the dissolution-vug belt in San Antonio. It can be seen that there are some differences in the dissolution-vug connectivity and fracture development degree. The large-scale fractures or faults in local parts can greatly improve the connectivity of dissolution vugs. However, most parts have no fractures or only a few microscopic fractures, so the connectivity of the dissolution vugs is relatively poor[1,5,9-14]. The dissolution-vug reservoirs are generally 2-10% in porosity, 3-5%[10,15] on average.

Fig. 1.

Fig. 1.

Development characteristics of outcrops and dissolution-vugs in San Antonio.

1.2. Rock sample and similarity criterion design

The Ordovician weathering crust in the Tarim Basin is characterized by obvious zonation[4,16]. According to the longitudinal development of karstification, the interval of 0-60 m below the unconformity surface is classified as the epikarst zone, where dissolution vugs are abundant, thin layers with dissolution vugs are highly likely to be encountered, with the thickness of a few meters to dozens of meters[1]. This interval has no micro-fractures, but some large-scale fractures in N by E or N by W[10], so it is the typical dissolution-vug reservoir, and good object for the investigation of injection and production in dissolution-vug reservoirs.

It is difficult to obtain large-scale rock sample of real carbonate dissolution-vug reservoir at present. Therefore, the rock sample with similar characteristics easy to obtain was used in the experiments. Firstly, comparison between the carbonate dissolution-vug reservoir and volcanic vug reservoir shows they have similar wettability and mechanical properties[17,18,19,20]. Secondly, according to the analysis of the reservoir space type, characteristics and evolution pattern of carbonate and volcanic reservoirs by some researchers[21,22,23,24], the non beaded thin reservoirs and the volcanic basalt outcrop in the Tahe oilfield both have dissolution vugs as effective storage space and fractures and caves for connecting. Thirdly, both the carbonate rocks in weathering crusts epikarst belt and the volcanic vug reservoirs are of dissolution and weathering origin[25,26,27], and also show the distribution characteristics of dissolution vugs in layers and around faults[27,28,29]. In a word, these two kinds of rocks have similar reservoir type, origin, connectivity and distribution characteristics. Therefore, the volcanic outcrop sample was selected as the experimental sample.

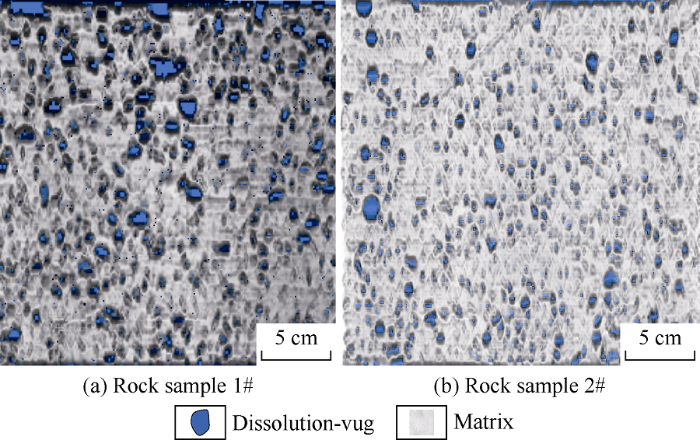

The rock sample has vugs of 2-20 mm in diameter, and an effective porosity of 4%-5%. Fig. 2 shows the vugs in the outcrop sample revealed by CT scanning. The vugs are distributed in honeycomb with better uniformity and continuity, which is similar to the target reservoir. That means the selected rock sample satisfies the experimental requirements.

Fig. 2.

Fig. 2.

CT scanning pictures of natural outcrop samples of dissolution-vug reservoirs.

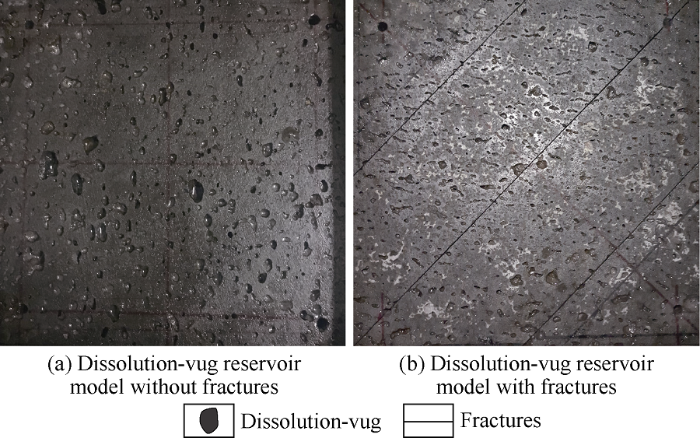

The experimental model was designed as a dissolution-vug outcrop plate of 25 cm long and 5 cm thick (Fig. 3). To study the effect of fractures or faults on waterflooding, a dissolution-vug model without fractures (1# model) and a dissolution-vug model with fractures (2# model) were designed. The fractures were made by cutting. Considering the fact that 2/3 of the large fractures are not filled in the actual reservoir[30], the fractures in experimental model were also not filled.

Fig. 3.

Fig. 3.

Waterflooding experimental models in dissolution-vug reservoirs.

In the experiments, the model size and injection-production parameters were designed according to the similarity theory. To ensure that the experiments can reflect the production performance of the actual reservoir, the key parameters should be focused on. The similarity criterion group was established based on the research of Tong Kaijun[31] and Wang Jing[32] (Table 1).

Table 1 Similarity criteria of waterflooding experiments in dissolution-vug reservoirs.

| Criterion classification | Similarity criterion | Physical meaning |

|---|---|---|

| Geometric similarity | η1=Lx/Ly | Ratio of appearance size in different directions (the appearance size is determined by well spacing), ratio of the thickness of the model to the reservoir |

| η2=Ly/Lz | ||

| η3=h/Lz | ||

| Flow similarity | η4=Qt/(ϕLxLyLz) | PV, Reynolds number |

| η5=μo/(ρovLz) | ||

| Dynamic similarity | η6=Δp/(ρogLx) | Ratio of injection-production differential pressure to gravity |

| Characteristic parameter of fractures | η7=nfLxLy | Ratio of fracture numbers and opening degree to characteristic length |

| η8=wf/Lx |

Table 2 Experimental characteristic parameters of waterflooding in dissolution-vug reservoirs.

| Para- meters | Parameter value of reservoir prototype | Parameter value of experimental model | Scaling factor (ratio of prototype to model) |

|---|---|---|---|

| Lx | 150 m | 25 cm | 600 |

| Ly | 150 m | 25 cm | 600 |

| Lz or h | 30 m | 5 cm | 600 |

| ϕ | 3%-5% | 3%-5% | 1 |

| Q | 5-50 m3/d * | 0.56-5.6 mL/min | 6 200 |

| t | 20 a | 300 min | 35 040 |

| μo | 20 mPa•s | 20 mPa•s | 1 |

| ρo | 0.82 g/cm3 | 0.82 g/cm3 | 1 |

| Δp | 2-40 MPa | 3.3-66.7 kPa | 600 |

| nf | 10-100/km2 | 12/m2 | 1/1 200 000-1/120 000 |

| wf | 1-10 mm | 10 μm | 100-1 000 |

Note: * indicates the injection rate under the condition of 1/4 well pattern in reservoir

2. Experiment of physical modelling

2.1. Experimental apparatus

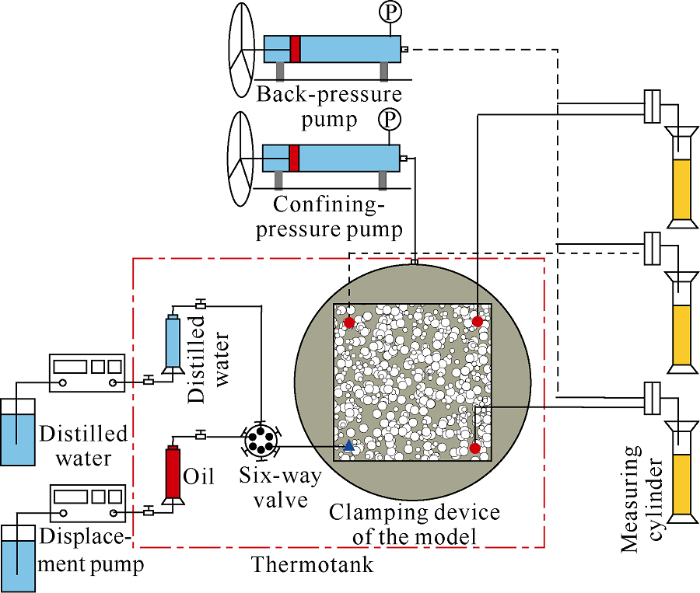

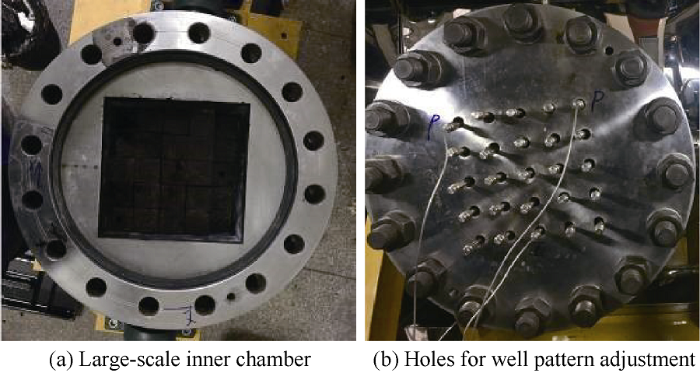

The experimental apparatus includes three parts: driving system, dissolution-vug reservoir model system, and metering system, as shown in Fig. 4. The model system has a large- scale inner chamber of 25 cm×25 cm, which can be used to clamp the dissolution-vug reservoir model (Fig. 5a). Before and after the installation of the model, sealing gaskets of 25 cm×25 cm must be added to the upper and lower surfaces of the model to avoid the injection fluid channeling from the contact surfaces. After clamping, the model was sealed by annulus pressure all around. 25 well holes were evenly arranged on the upper part of the clamping device. Before the experiment, the predetermined position of the dissolution-vug model and the corresponding position of the upper sealing gasket were drilled. In the process of experiment, the corresponding valves could be opened according to the needs to adjust the injection-production relationship and well pattern (Fig. 5b).

Fig. 4.

Fig. 4.

Experimental apparatus of waterflooding for the dissolution-vug reservoir model.

Fig. 5.

Fig. 5.

The dissolution-vug reservoir model system.

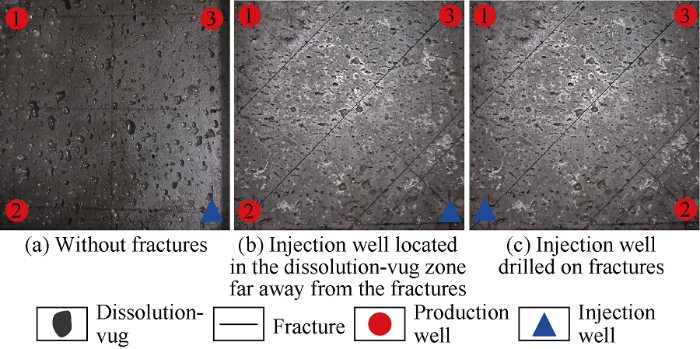

2.2. Design of experimental scheme

Seven groups of experiments were designed to investigate the effects of injection-production well pattern, fractures and water injection rate on the waterflooding characteristics of dissolution-vug reservoir. (1) Well pattern and adjustment experiment for dissolution-vug reservoir without fractures. First, the waterflooding experiment of 1/4 five-spot well pattern was carried out. When the water cut was closed to 98%, 2# and 3# wells were turned on to change the well pattern into nine-spot, and water was injected until the water cut reached 98% (Fig. 6a). The injection rate was 1 mL/min. (2) Waterflooding experiment of nine-spot well pattern for dissolution-vug reservoir without fractures. Waterflooding was carried out through the 1/4 nine-spot well pattern directly until the water cut was 98%. The injection rate was 1 mL/min. (3) Nine-spot well pattern and adjustment experiments for dissolution-vug reservoir without fractures. First, the 1/4 nine-spot well pattern experiment was conducted. Based on the results of experiment (1) and (2), when the water cut of 2# and 3# well reached 98%, 1# well was converted into interlaced well pattern, and water was injected further until the water cut was 98%. The injection rate was 1 mL/min. (4) Well pattern and adjustment experiment for dissolution-vug reservoir with fractures. First, the waterflooding experiment of 1/4 five-spot well pattern was carried out. The connecting line of injection well and production well was perpendicular to the fractures. When the water cut was closed to 98%, 2# and 3# wells were turned on to form a nine-spot well pattern, and waterflooding was carried on until the water cut reached 98% (Fig. 6b). The injection rate was 1 mL/min. (5) Nine-spot well pattern experiments for dissolution-vug reservoir with fractures. The 1/4 nine-spot well pattern was directly used. The injection well was located in the dissolution-vug zone far away from the fractures (Fig. 6b). The injection rate was 1 mL/min. When the water cut of the production well reached 98%, the well was shut down and other wells continued to produce until all the wells were turned off. (6) Nine-spot well pattern experiments for dissolution-vug reservoir with fractures. The 1/4 nine-spot well pattern was adopted. The injection well was drilled on the fractures (Fig. 6c). The injection rate was 1 mL/min. Waterflooding stopped when the total water cut was 98%. (7) Injection strength improvement experiment of nine-spot well pattern for dissolution-vug reservoir with fractures. The 1/4 nine-spot well pattern was directly adopted. The injection well was drilled on the dissolution-vug zone far away from the fractures (Fig. 6b). The injection rate was 3 mL/min. When the water cut of the production well reached 98%, it was shut down and other wells continued to produce until all the wells were turned off.

Fig. 6.

Fig. 6.

Distribution of injection-production wells in different types of dissolution-vug reservoir.

2.3. Experimental procedures

The experiments used 25# white oil and were conducted at the temperature of 45 °C and confining pressure of 5 MPa. The models were saturated with oil before waterflooding and the porosity of the model was calculated. Table 3 shows the saturated oil volume and porosity of all the experiments. The model was cleaned and dried after each experiment, then it was used to carry out the next group of experiment. Experiments 1-3 adopted 1# model and experiments 4-7 adopted 2# model.

Table 3 Calculated results of saturated oil volume and porosity for each experiment.

| Serial number | Saturated oil volume/mL | Poro- sity/% | Serial number | Saturated oil volume/mL | Poro- sity/% |

|---|---|---|---|---|---|

| 1 | 150 | 4.80 | 5 | 145 | 4.64 |

| 2 | 162 | 5.18 | 6 | 145 | 4.64 |

| 3 | 147 | 4.70 | 7 | 140 | 4.48 |

| 4 | 142 | 4.54 |

3. Results and discussions

3.1. Characteristics of waterflooding with different well patterns

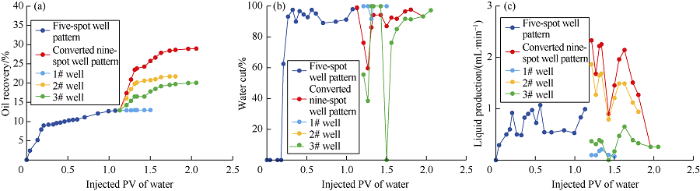

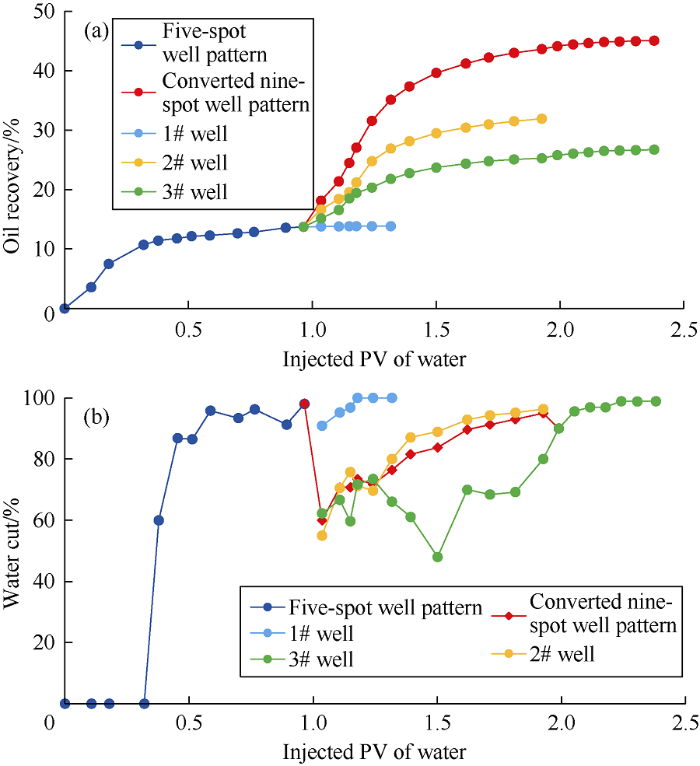

The development indexes of five-spot well pattern and converted nine-spot well pattern in the high water cut stage (experiment 1) were obtained (Fig. 7). It can be seen that the water-free recovery of five-spot well pattern was 7.93%, the ultimate oil recovery was 12.83% (Fig. 7a), and the water-cut fluctuates between 85% and 100% in the high water-cut stage (Fig. 7b). After the well pattern was converted into nine-spot, the total water cut decreased greatly, the oil recovery increased rapidly, and the ultimate oil recovery was 28.97%, which was 16.64 % higher than that of five-spot well pattern. In the nine-spot well pattern stage, 1# well produced little water. The productive effects of 2# and 3# wells were better and the initial recovery increased rapidly, which indicates that the injected water was channeling along the connecting line of injection well and production well, and there was more remaining oil on both sides of the main streamline.

Fig. 7.

Fig. 7.

Development indexes of five-spot well pattern (converted into nine-spot well pattern in high-water cut stage) for dissolution-vug reservoir without fractures (Q=1 mL/min).

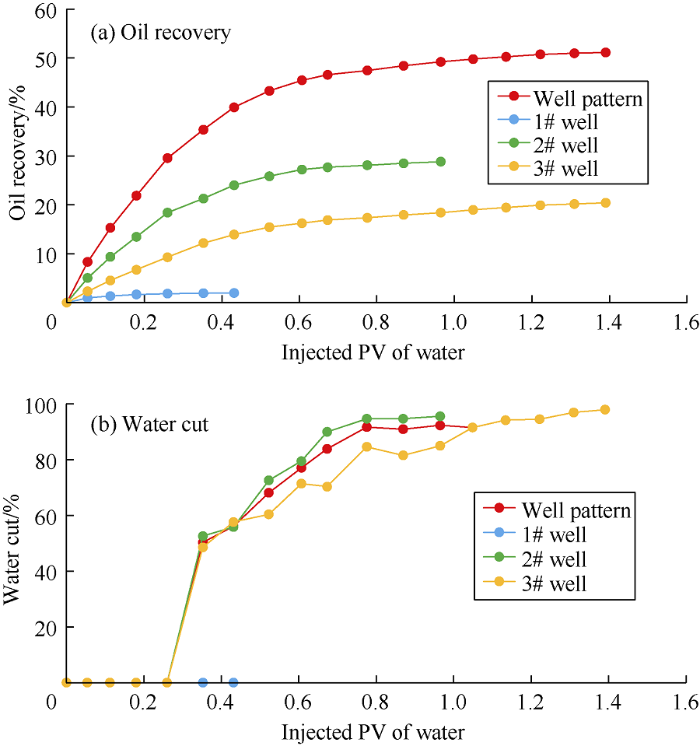

The development indexes of nine-spot well pattern of waterflooding indicate that the water-free recovery was 16.79%, the ultimate oil recovery was 34.36%, which are obviously better than five-spot well pattern and nine-spot well pattern converted from five-spot. When three wells produced simultaneously, 1# well produced no water but with low output, 2# and 3# wells closer to the injection well had low seepage resistance and higher production after short time of water injection.

Fig. 8.

Fig. 8.

Development indexes of nine-spot well pattern for dissolution-vug reservoir without fractures (Q=1 mL/min).

3.2. Effect of fractures on waterflooding characteristics for dissolution-vug reservoir

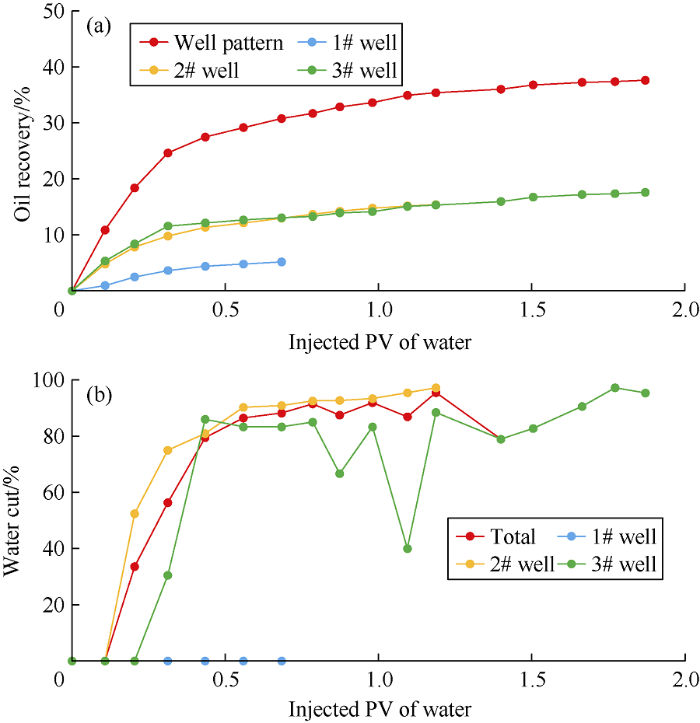

Fig. 9 shows the development indexes of five-spot well pattern and nine-spot well pattern in high-water cut stage for dissolution-vug reservoir with fractures. The connecting line of injection and production wells of five-spot well pattern was perpendicular to the fractured. The water-free recovery was 10.71%, and the ultimate oil recovery was 13.71%, both of which were slightly higher than the model without fractures. After the well pattern was turned into nine-spot well pattern, the total water cut decreased greatly, the oil recovery increased rapidly, and the ultimate recovery reached 45.07%, which was 31.36% higher than that of five-spot well pattern. It can be seen that the oil recovery is higher when the model has fractures, and the waterflooding effect of nine-spot well pattern is better. According to the variation of water cut, although 2# and 3# wells were drilled on the fractures, there was no water channeling phenomenon like that in porous type reservoir and the oil recovery increased greatly. This is due to the better conductivity of dissolution-vug than that of fractures, fractures will not form dominant seepage channels leading to water channeling, while fractures could effectively connect the poorly connected dissolution vugs to improve the development effect of waterflooding.

Fig. 9.

Fig. 9.

Development indexes of five-spot well pattern (converted into nine-spot well pattern in high-water cut stage) fpr dissolution-vug reservoir with fractures (Q=1 mL/min).

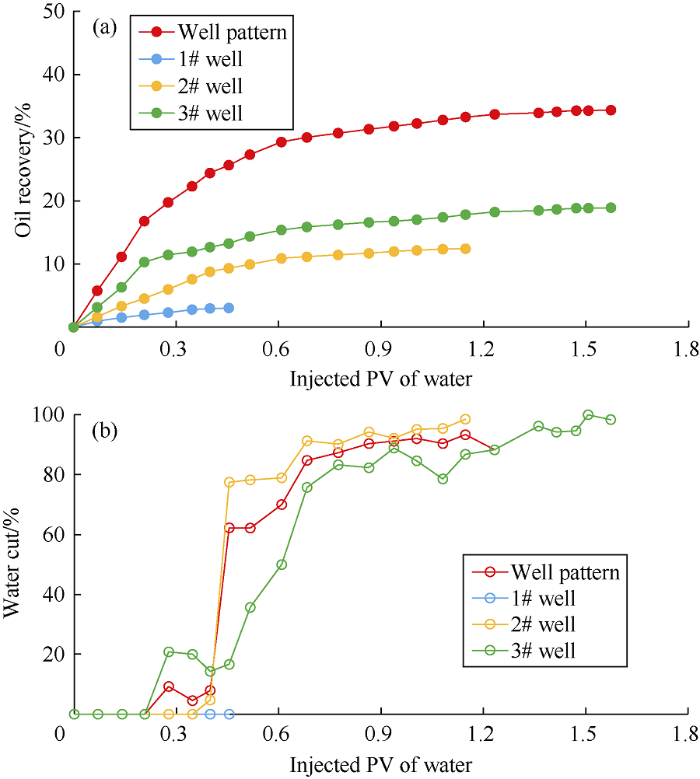

The development indexes of nine-spot well pattern with the injection well drilled on the dissolution-vug belt for the dissolution-vug reservoir with fractures (experiment 5) (Fig. 10) show that water-free recovery of the nine-spot well pattern was 29.52%, the ultimate oil recovery was 51.12%, which were all much higher than that of the model without fractures. 1# well had a low oil production. 2# and 3# wells had a higher oil production, the recoveries of which were 28.80% and 20.40%, respectively. The development effect of nine-spot well pattern is better than five-spot well pattern and five-spot converted to nine-spot well pattern.

Fig. 10.

Fig. 10.

Development indexes of nine-spot well pattern (injection well was drilled on the dissolution-vug zone) for dissolution-vug reservoir with fractures (Q=1 mL/min).

The development indexes of nine-spot well pattern with the injection well drilled on the fractures (experiment 6) for dissolution-vug reservoir with fractures were shown in Fig. 11. When a group of injection-production wells were drilled on the fractures, water breakthrough of the production well on the fracture (3# well) occurred quickly and the water cut increased sharply. The water-free recovery was only 4.54%. However, the other two wells located on the dissolution-vug zone didn’t produce water, had a low contribution to oil recovery, and the ultimate recovery was only 16.99%, which was far below the situation of injection well drilling in the dissolution-vug zone. Therefore, in the development of fractured reservoir, injection-production wells drilled on the fractures or close to the fractures simultaneously should be avoided.

Fig. 11.

Fig. 11.

Development indexes of nine-spot well pattern (with injection well drilled on the fractures) for dissolution-vug reservoir with fractures (Q=1 mL/min).

3.3. Effect of injection-production rate on waterflooding for dissolution-vug reservoir

It can be seen from experiments 2 and 5 that when the injection rate was 1 mL/min, the fluid production of the corner well of nine-spot well pattern was very low. The injection rate of experiments 3 and 7 was increased to 3 mL/min. Then, the waterflooding experiments of the dissolution-vug reservoir without/with fractures were carried out. The results were used to investigate the effect of injection rate on waterflooding characteristics of dissolution-vug reservoir comparing with those of experiments 2 and 5.

The injection rate of dissolution-vug reservoir without fractures was 3 mL/min. The development indexes variation of nine-spot well pattern (forepart of experiment 3) were shown in Fig. 12. As we can see, the water-free recovery was 10.85% and the ultimate recovery was 37.62%. Compared with the experiments with 1 mL/min injection rate, the water-free recovery decreased by 6.12% and the ultimate recovery increased by 3.26%. Moreover, the oil production of corner well far from the injection well increased slightly.

Fig. 12.

Fig. 12.

Development indexes of nine-spot well pattern for dissolution-vug reservoir without fractures (Q=3 mL/min).

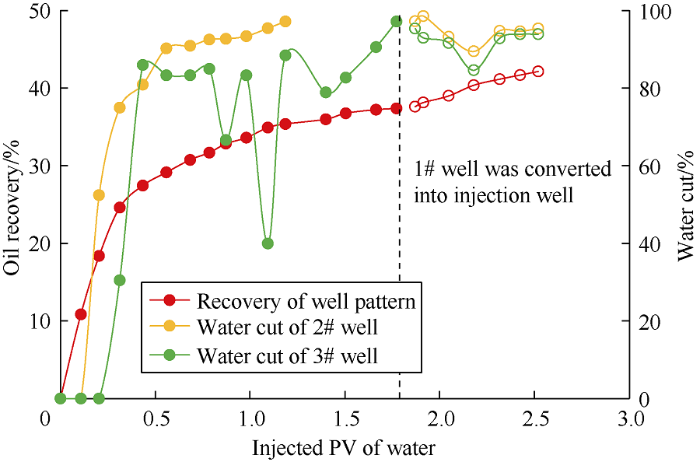

The results of forepart of experiment 3 show that even the injection rate was increased, the liquid production of corner well far from the injection well was still low, and the development effect was not improved significantly. Hence, the corner well (1#) was converted into injection well, the experiment of staggered line-drive pattern was conducted by transforming nine-spot well pattern (posterior part of experiment 3). Fig. 13 shows the variation of the development indexes. After the nine-spot well pattern was transformed into staggered line-drive pattern, the water cut of 2# and 3# wells decreased slightly, the ultimate recovery was 42.15%, increased by 4.77%.

Fig. 13.

Fig. 13.

Development indexes of nine-spot well pattern for dissolution-vug reservoir without fractures (Q=3 mL/min).

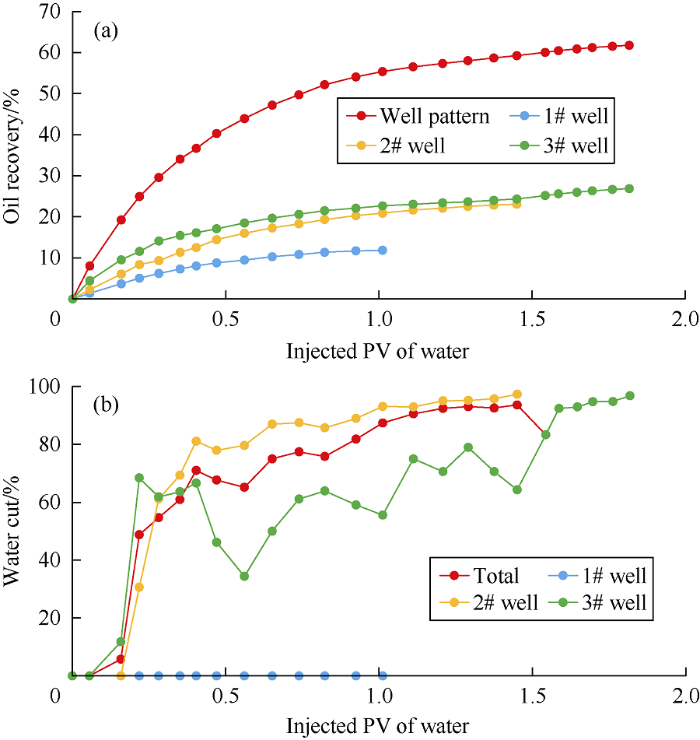

The injection rate of dissolution-vug reservoir with fractures was 3 mL/min. The development indexes of nine-spot well pattern (experiment 7) were shown in Fig. 14. It can be seen that water-free recovery was 8.02%, decreased by 8.77% with increase of water injection rate. However, the ultimate recovery was 61.77%, increasing by 10.65%, and the recovery of corner well (1#) increased by 8.81%. Hence, no matter whether there are fractures or not, increasing the injection rate will shorten the water breakthrough time, and the water-free recovery decrease greatly. However, development indexes of corner wells far from the injection well improved significantly and the ultimate recovery increased greatly.

Fig. 14.

Fig. 14.

Development indexes of nine-spot well pattern for dissolution-vug reservoir with fractures (Q=3 mL/min).

4. Conclusions

The dissolution-vug reservoir and volcanic outcrop have characteristics conforming to the similarity criterion. The selected volcanic outcrop sample can satisfy the experimental requirements of testing the effect of well pattern on the waterflooding characteristics of the dissolution-vug reservoir.

In the dissolution-vug reservoir without fractures, the five- spot well pattern has small sweeping area, with serious water channeling and low oil recovery. When the well pattern is converted from five-spot to nine-spot well pattern, oil recovery can be largely enhanced, but the effect of the corner well far from the injector is not obvious. In the dissolution-vug reservoir with fractures, when both injector and producer aren’t located on the fractures, fractures could effectively connect the poorly connected dissolution vugs to improve the development effect of waterflooding.

Whether the dissolution-vug reservoir has fractures or not, the development effect of nine-spot well pattern is evidently better than five-spot well pattern and five-spot converted to nine-spot well pattern, moreover, it is more evident when there are fractures, the development indexes of edge well are better than those of corner well. At the high-water cut stage of waterflooding with nine-spot well pattern, the oil recovery can be further improved by staggered line-drive pattern by transferring the corner well to production.

Increasing the injection rate of injector in nine-spot well pattern can increase the oil production of corner well far away. The ultimate oil recovery can be largely improved, but the water-free period would be greatly shortened and water-free recovery decrease.

Nomenclature

g—gravity acceleration, m/s2;

h—thickness of the model, cm;

Lx—well spacing (or length of the model), m (or cm);

Ly—well spacing (or width of the model), m (or cm);

Lz—thickness of the reservoir (or model), m (or cm);

nf—fracture density of the reservoir (or model), fracture/km2 (or fracture /m2);

Q—water injection rate of the reservoir (or model), m3/d (or mL/min);

t—development time of the reservoir (or model), a (or min);

v—flow velocity, m/d;

wf—fracture aperture of the reservoir (or model), mm (or μm);

Δp—injection-production differential pressure of the reservoir (or model), MPa (or kPa);

η1—8—similarity criterion;

μo—viscosity of crude oil, mPa•s;

ρo—oil density, g/cm3;

ϕ—porosity, %.

Reference

Quantitative prediction of flaggy reservoir of Ordovician Formation in Tahe Oilfield

The paper took the flaggy reservoir in Tahe oilfield as research objects and pointed out that flaggy reservoir space was solution pore,most in 0~60 meters thick,below T47 according to the well drilling logging data,The result of forward simulation proved that the seismic response of flaggy research was weak and shielded by the strong reflection of T47.The weak seismic signal of the flaggy reservoir can be identified through multi-wavelet decomposition and strong side-lobe energy was stripped through reconstruction technology.The quantitative prediction method was established by multi-wavelet decomposition and multi-attribute fusion with multiple linear regression.The prediction multiplicity of single attribute was decreased and the accuracy was improved.This method was applied in the east of block 10,Tahe oilfield.The relative error between prediction thickness and actual drilling thickness was less than 10%.It proved that the method achieved good application effect.

Affusion technique policy of development and effect analysis in the 4th block of Tahe Oilfield

The ordovician reservoir is control by structure fault and the multi-stage karst in the Forth Zone in Tahe, carbonate karst-fractured reservoir is formed by multi-sets fissure-cave system congruence in three-dimensional space. Reservoir space is mainly formed by karst cave; oil-water relationship is control by different fissure-cave system and manifestations are very complex, occlusive water exists in local space as well as large active bottom water exists in the bottom, so the oil reservoir has low productivity, low produced degree, low recovery rate. In this paper, efficient waterflooding technology and it's effect on the Forth Zone in Tahe are analyzed briefly, which is a very important guidance for improving recovery rate of this kind of oil reservoir.

Optimization research on water injection mode in typical units of weathering crust reservoir of Tahe Oilfield

The fractured-cavity reservoir formed by weathered crust karstification is the main type of Tahe Ordovician reservoir. Because these reservoirs mature plentiful fractures and cavity,they own strong heterogeneity. The current water flooding situation indicates that part of the fracture-cavity unit water flooding efficiency has been decreasing. In order to improve the water flooding efficiency in these reservoirs,the optimized injection combination of one typical fractured-cavity unit in Tahe Ordovician reservoir was investignted by numerical simulation. According to the water cut characters of the water injection efficient period,steady period and modification period,the injection method combination is simulated and the optimizing injection parameter is demonstrated. The simulation result shows the optimized water injection combination is first mild continuous water injection,then the cyclic water flooding and finally impulse water flooding. Due to the reservoir condition,the optimized three injection modes parameters are that the continuous water injection intensity is 200 m3/ d; the conventional cyclic injection period is 75 days including 60 days injection and 15 days well shutting up and the impulse injection is( 100 ~ 200) m3/ d for every30 days and shut well up for the same period.

Developmental pattern and distribution rule of the fracture-cavity system of Ordovician carbonate reservoirs in the Tahe Oilfield

DOI:10.7623/syxb201101015

URL

[Cited within: 2]

Ordovician carbonate fracture-cavity reservoirs in the Tahe Oilfield are a special type of reservoirs,in which fractures and cavities constitute the main reservoir space.In the Tahe area,the development of ancient karst is closely related with the regional tectonic evolution because Ordovician carbonate reservoirs in the Tahe Oilfield experienced karstification in the middle Caledonian and early Hercynian,and the karstification of the long-term exposed weathering crust during the early Hercynian played a major role in controlling the development of these karst reservoirs.Based on the geological survey of palaeokarst outcrops of the Yijianfang,Liuhuanggou,Sandaoban and Wudaoban regions in the northern margin of the Tarim Basin,developmental characteristics of reservoirs in the Tahe Oilfield revealed that there were three developmental patterns of the fracture-cavity system in Ordovician carbonate reservoirs: i.e.underground river system,karst caves,and corroded pores and fissures,of which the former two were the most dominant types for the reservoirs.The fracture-cavity system developed well in the vicinity of fault belts,and the horizontal distribution of the fracture-cavity system was controlled by palaeo-geomorphology.For instance,karst caves were extremely well-developed in peak-cluster of a karst platform,and then in knob-and-kettle topography on gentle karst slopes and in rugged country of valleys.Vertically,the development of karst cavities was apparently of zoning and superficial karst belts were the most important segment for karst development.

Characteristics and significance of the burial dissolution of dolomite reservoirs: Taking the Lower Palaeozoic in eastern Tarim Basin as an example

DOI:10.1016/S1876-3804(11)60045-1

URL

[Cited within: 2]

Based on the characteristics of core, thin-section, physical properties and carbon, oxygen and strontium isotope, the characteristics of Lower Paleozoic dolomite reservoirs, dissolution features and mechanism in eastern Tarim Basin were studied. Massive dissolution pore-cave dolomite is the main reservoir type in eastern Tarim Basin. The dissolution pores and caves are mainly medium to small with dense distribution. The fillings in dissolution pores and cracks commonly show negative 未 18O, generally far lower than the surrounding rock; slightly negative 未 13C, partially positive; slightly high 87Sr/ 86Sr. Proportion of CH 4 and CO 2 is high in fluid inclusions and some of them contain high proportion of H 2S, which demonstrated that the organic matter was at the high evolution stage when the inclusions were captured, suggesting deep burial circumstances. Silicification and high homogeneous temperature also indicate the presence of hydrothermal fluids. Dissolution includes organic acid dissolution and hydrothermal water dissolution. Acid fluid mainly includes organic acid, CO 2 and H 2S, which were mainly generated in the process of evolution of organic matter, with a little H 2S from sulfate reduction, a little CO 2 from volcanic activity. As the carrier of acid fluid, hydrothermal fluids overcome kinetic obstruction of dissolution and dissolve the deep dolomite. Major faults and associated faults provide channels for hydrothermal fluids, the acid fluid was further dispersed in dolomites through numerous inter-crystal pores caused by dolomitization and micro-cracks caused by compaction to complete dissolution for dolomite reservoirs.

Characteristics, origin and distribution of dolomite reservoirs in Lower-Middle Cambrian, Tarim Basin, NW China

DOI:10.1016/S1876-3804(16)30040-4

URL

[Cited within: 1]

The fault-reservoir displacement pressure differential method, as a quantitative evaluation method of fault sealing which considering diagenetic time of fault rock, was improved based on the study of fault sealing mechanism and its influencing factors. A geology and mathematical model of quantitative evaluation of fault sealing considering diagenetic time was established. First, the depth of surrounding rock which has the same shale content and diagenetic degree as the fault rocks at the target was determined using the method of successive approximation at the given step length. Second, the displacement pressure of target fault rocks was calculated based on the relationship between the displacement pressure and the product of shale content and burial depth that was established for the study area. And third, the sealing states and capacity of the faults were quantitatively evaluated by comparing the calculated displacement pressure with that of the target reservoir. By the actual data of reservoirs at Banqiao Fault in Qikou sag and the result comparison between fault rock shale content method (SGR) and fault-reservoir displacement pressure differential method without considering the diagenetic time, it is verified that this method is more feasible and credible.

Differences between formation conditions of Ordovician karstic reservoirs in Tazhong and Tahe areas

DOI:10.3321/j.issn:0253-9985.2005.02.013

URL

[Cited within: 1]

Comparative study shows that Ordovician karstic reservoirs in Tazhong and Tahe are quite different. In Tazhong, Ordovician dolomite reservoirs are characterized by small karst vugs, and limestone reservoirs are characterized by limited karst caves. While the karst cavernous reservoirs in Tahe are characterized by superimposition of multiple series of strata and continuous distribution in a large area. The main factors that have caused the differences of Ordovician karstic reservoirs in Tazhong and Tahe are tectonic evolution, lithofacies palaeogeography and dissoluble rock types. In Middle Caledonian, thrusting and folding were strong and well developed, dissoluble dolomites or limestones were dispersedly outcropped in narrow strips, and karst slopes were developed limitedly in Tazhong area; while tectonic movement in Tahe area was weak at that time. In Early Hercynian, Tahe area was wholly and largely uplifted, resulting in formations being strongly denuded and leveled, dissoluble limestone strata being flatly outcropped in large area, and karst slopes being well developed. Meteoric water flowed along the existing fracture systems and dissolved and reconstructed them in tubular flow, resulting in large cave systems. Several sets of cavernous reservoirs are distributed in large areas, due to multiple series of strata being superimposed and interconnected. However, tectonic movement in Tazhong was relatively moderate in Early Hercynian. Therefore, Tazhong area was dominated by Caledonian karst, while Tahe area was dominated by Hercynian karst.

Karst monadnock fine characterization and reservoir control analysis: A case from Ordovician weathering paleokarst reservoirs in Lungu area, Tarim Basin, NW China

DOI:10.1016/S1876-3804(17)30086-1

URL

[Cited within: 1]

Based on the fine characterization of weathering crust paleokarst landform of the Ordovician Yingshan Formation in Lungu area,Tarim Basin,the size,number and reservoir controlling characteristics of karst monadnocks have been investigated quantitatively.Impression method and karst monadnock volume formulas were employed to characterize the various levels of karst microtopography,to work out the number,relative relief,area,volume and other parameters of monadnocks,and analyze the reservoir development situation at different parts of monadnock.The results showed that the weathering crust karst reservoirs in Lungu area are 140-160 m in relative altitude,and thinning from karst highland to karst slope and terrace.Two hundred fifty-two karst monadnocks have been identified in the study area.Among them,type nd type onadnocks are fewer in number,but larger in bulk volume,and are favorable reservoir development zone.The monadnocks have a high coincidence ratio with current structural high points of 96.42%,and the monadnock morphology has remained basically unchanged during the late tectonic movement,thus "karstification-reservoir-accumulation" configuration has been kept good.In the main part (core) of karst monadnocks,there are cave,vug,fracture-vug,and fracture reservoirs,thicker high quality reservoir,and all reservoir parameters are better than those of karst monadnock wings.It is found that the relative amplitude of karst monadnock is positively correlated with single well productivity,and the scale and position of monadnock are closely related with productivity.

Features and hierarchical modeling of carbonate fracture-cavity reservoirs

DOI:10.1016/S1876-3804(16)30076-3

URL

[Cited within: 1]

Taking the Ordovician fracture-cavity carbonate reservoir of Tahe oilfield, Tarim Basin as an example, the fracture-cavity reservoir has been classified according to the type and size of reservoir space, and a 3-D geological model of fracture-cavity reservoirs was built according to their types and classes. Based on core, drilling, logging and seismic data, the fracture-cavity reservoir was divided into four types, namely cave, dissolved pore, fracture and Matrix block types, in which the cave was subdivided into two subtypes, large cave and small cave; and the fracture was subdivided into four subtypes, large scale fracture, meso-scale fracture, small scale fracture and microfracture. The large cave model was established using deterministic method via seismic truncation and pattern modification. The small cave model was built using the method of multiple-point geostatistical simulation with large cave model as the training image. The dissolved pore model was built using sequential Gaussian simulation. The large scale fracture model was established using the deterministic method of manual interpretation, meso-scale fracture model was built using deterministic method of ant tracking, the small scale fracture model was built using stochastic object-based modeling. The micro-fracture and Matrix block have no discrete distribution model established because of their poor storage quality. Then the different types of reservoir space models were merged into one model to get the discrete distribution model of typical fracture-cavity unit. The application in Tahe blocks 6 and 7 showed that this classified hierarchical modeling improved the reservoir model precision, guided the water-flooding effectively and advanced the development efficiency.

Study on the classification and modeling of fracture-vug oil deposition.

Experimental simulation of dissolution law and porosity evolution of carbonate rock

DOI:10.1016/S1876-3804(16)30072-6

URL

Experiments of acetic acid (initial 0.2%) with porous dolostone, fractured-porous-vuggy dolostone, porous limestone and fractured limestone were done in a continuous flow diagenesis simulation system to find out the controlling factor of dissolution and dissolution effect. The results show that the dissolution quantity of carbonate rock inversely proportional to temperature and directly proportional to pressure, and the temperature effect is greater than the pressure effect. Therefore, relatively shallow burial and lower temperature environment is more beneficial to the formation of large scale carbonate dissolution pores. Quantitative comparison of porosity volume and permeability variation, and evolution of pores inside the rock before and after the experiment show that pore structure has apparent control over the carbonate dissolution and pore evolution. After dissolution, porous dolomite with homogeneous pore distribution saw rise in pore volume (matrix pore volume) and permeability, and remained as pore type in terms of reservoir space; porous limestone, with significant heterogeneity in original pores and texture, saw significant increase in pore volume and permeability, but the increased pores were fracture type, so its reservoir space turned into fracture-pore type; dissolution increased the permeability of fracture-pore dolomite and fracture limestone remarkably by 2-3 orders of magnitude; and the pores increased were mainly along dissolution fractures, turning the reservoir space into fracture-cave type.

Research on dolomite reservoir characteristics of Cambrian Formation in central uplift belt, Tarim Basin

Integrated reservoir delineation in Karst Carbonate: Case study of Middle Tarim Basin, West China

Different equivalent simulation methods for fractured-vuggy carbonate gas condensate reservoirs

Characteristics and main controlling factors of the formation of Ordovician reservoirs in areas covered with salt layers in Tahe Oilfield

DOI:10.1111/j.1440-1789.2005.00601.x

URL

[Cited within: 1]

The most important distributional characteristics of Ordovician reservoirs in areas covered with salt layers in Tahe oilfield is well-developed fractures. Vugs, partly filled or unfilled structural fractures with high angles and solution-enlarged fractures are the main types of porosity space in the studied area. Large caves are less developed than the main areas of Tahe Oilfield. Vug-fissure and fissure-vug reservoirs are the main reservoir types. Within this areas, reservoirs in the west part are more developed than that in the east part, and the favorable reservoir belts are mainly extended in north-south direction. Reservoirs developed in the upper part of middle-lower Ordovician are more developed than that in the lower part. Reservoirs developed in Lianglitage formation of upper Ordovician are more developed than that developed in middle-lower Ordovician. The key factors that control the formation and distribution of Ordovician reservoirs in areas covered with salt are tectonic deformation, the karst process occurred in mid-Caledonian orogeny and its sedimentary facies.

Relationship between large scale unconformity surface and weathering crust Karst of Ordovician in Tazhong

DOI:10.1631/jzus.2007.B0900

URL

[Cited within: 1]

The Tarim basin has experienced periods of structure movements and developed a series of large stratigraphic unconformities.The Ordovician has two large unconformity surfaces T47 and T67 in central of Tarim,which are predominated by structure movements and sea level changes.Being exposed for a long time,the development of two periods regolith karst is locally controlled.The first period karst locates under the unconformity top of down-Ordovician,the second locates under the unconformity top of up-Ordovician.The character of two periods' darst are different for their different unconformities.The effects of the unconformity surface on karst mainly include two aspects:one is the configuration of unconformities which controls the development scale of regolith karst,another is the intensity of unconformities which controls the development depth of regolith karst.

Geologic characteristics and development rules of carboniferous volcanic reservoir in the 1st areas of Karamay Oilfield

Water flooding in Tuo 32 Block volcanic reservoir

Experiments on gas injection mechanisms in carbonate fracture-cavity reservoir using microvisual model.

Experiments on gas supply capability of commingled production in a fracture-cavity carbonate gas reservoir

An important reservoir space in igneous oil reservoir rocks: Gas pores

Recent exploration has continuously revealed that igneous rocks are an important type of reservoir in a subsided basin.Igneous rocks,therefore have been studied with greater effort.It is commonly recognized that fractare is the main reservoir space in an igneous oil reservoir.However,studies of the author leads to a conclusion that gas pores are main types of reservoir space also.This paper presents the results of studies performed by the author.

Accumulation characteristics of volcanic rocks in the middle section of Liaohe Oilfield

Description and evaluation of the development of carbonate fractured-cavity reservoirs

Study on the recognition of fracture-vuggy carbonate reservoir and fluid along with its appraisal: Taking Ordovician reservoir of 4, 6 area in Tahe oil field as example

Reservoir characteristics and impacting factors of Carboniferous volcanics in Malang sag, Santanghu basin

With Niudong oilfield as an example, the lithologic features, facies change, storage space types and petrophysical parameters (including porosity and permeability) are analyzed by combining core, core wafer, scanning electron microscope, conventional and special electric logging data. The result shows that the major oil-bearing volcanics in this region is the Upper-Carboniferous Kalagang formation (C2k),which is composed mainly of lava (andesite and basalt) and volcanoclastic rock. The lava has an average porosity of 10.6%, and permeability of 2.37×10-3 μm2 , while the volcanic breccia has an average porosity of 11.3%, and permeability of 1.88×10-3 μm2. The storage space is made up of original pores, residual pores, secondary dissolved pores (primarily almond shaped and phenocryst shaped), and fractures etc. Lithology, lithofacies and secondary reformation are major factors impacting the performance of the volcanic reservoir.

Differential modeling of dissolved vugs in carbonate fracture and vug reservoirs

The reservoir space types of carbonate fracture and vug oil reservoirs mainly consist of large cave,dissolved vug and fracture. Based on the origins of dissolved vugs,differential modeling method was used to build the geologic models of different origins of dissolved vugs respectively. Multipoint geostatistic modeling method was used for dissolved vug resulted from cavern collapse,fracture constrained zoning modeling method was used for dissolved vug developed around the fault,and karst facies controlled modeling method was used for the layered dissolved vug of weathered crust surface layer,revealing the spatial distribution characteristic of different origins of dissolved vugs and improving the geologic modeling accuracy of them. After applied in S80 fracture- cavity unit of the Tahe Oilfield,the favorable reservoir development zone and inter- well communication relation were predicted,and the practicality of this modeling method was verified.

Development and distribution of dissolution pores in Carboniferous Volcanic rocks in Chepaizi Bulge

DOI:10.12677/JOGT.2017.395090 URL [Cited within: 1]

Characteristics and formation mechanism of fissures in Ordovician strata of No.4 Block, the Tahe Oilfield

Three- dimensional physical modeling of waterflooding in metamorphic fractured reservoirs

DOI:10.1016/S1876-3804(15)30054-9

URL

[Cited within: 1]

To understand water-oil displacement characteristics and the mechanism of improving waterflood efficiency in metamorphic fractured reservoirs, taking JZ251S oil field as an example, a large-scale physical simulating model which meets the geometric similarity, kinematic similarity, dynamic similarity and dual media characteristic parameters similarity based on the theory of scaling criteria was designed to simulate the development of the reservoir by horizontal wells. The mechanism of water displacing oil in dual media reservoirs, the factors affecting fluid flow and waterflood characteristics, and the enhanced oil recovery (EOR) features of different water injection patterns were studied by experiments. The results show that: (1) Capillary imbibition is the main mechanism of enhancing matrix oil recovery in a dual media reservoir which is controlled by waterflooding; (2) whether or not there is crude oil draining from matrix, the water cut trend after water breakthrough can be divided into two stages, the first stage is quick rise stage of water cut in early water breakthrough period and the second stage is slow rise stage of water cut in mid-high water cut period; (3) displacement rate is the main factor controlling water-free production period, water cut trend and ultimate recovery; (4) compared with continuous injection, intermittent injection can give full play to the function of oil-water gravity segregation, reducing the water cut and improving the production rate of initial stages greatly.

Experiments on water flooding in fractured-vuggy cells in fractured-vuggy reservoirs

DOI:10.1016/S1876-3804(14)60008-2

URL

[Cited within: 1]

Based on the theory of scaling criteria, a physical experimental model of fractured-vuggy cell which meets the geometric similarity, kinematic similarity, dynamic similarity and characteristic parameters similarity was designed. The factors affecting fluid flow and water flooding characteristics, and the EOR features of different displacing modes were studied by experiments. The experimental results show that: Oil and water displacement effect caused by the density difference between oil and water is the main mechanism of water flooding; Injection rate has no effect on the remaining oil and water-cut; Fracture-vuggy connection is the dominant factor controlling water-free recovery, ultimate limit of remaining oil and water-cut variation in the fractured-vuggy cell; Oil-water viscosity ratio has an important effect on oil production rate, oil replacement ratio and economic limit remaining oil; When the filling degree is low, it has no effect on remaining oil, but when the filling degree is high, the remaining oil contains both ttic oil and the oil existing in porous media; Foam flooding after water flooding enhances oil recovery by starting the attic oil at the top of vugs, and the remaining oil is in the center of the vugs after foam flooding; Polymer flooding after water flooding enhances the economic limit recovery by increasing the oil production rate and oil draining ratio, but it has no effect on the limit remaining oil of water flooding.