Introduction

Stimulated reservoir volume fracturing is creating artificial fractures in reservoirs by hydraulic fracturing, which connected with natural fractures and rock beddings to form fracture network[1]. This technology is the key to the large-scale development of shale gas and the core means to improve the shale gas recovery. 99.5% of the fracturing fluid used in hydraulic fracturing is water and quartz sand[2,3]. During shale gas development, the flow-back of fracturing fluid is 9% to 53%[4,5,6], and most fracturing fluid is remained in reservoirs for hydration with shale matrix. Hydration refers to water permeating into the mineral crystalline lattice of rock soil mass or water molecules attached to the ions of soluble rock, causing the microscopic and macroscopic changes of rock structure to reduce the cohesion of rock soil mass[7]. Hydration is able to change shale microstructure and macrostructure, leading to changes in rock mechanical properties and physical parameters, so as to affect the stability of shale reservoir and the recovery of shale gas[8,9,10]. Therefore, the research on hydration of shale gas is of great significance for shale gas development.

Previous studies have shown that the strength of hydration is related to the types of clay minerals, the duration of action, the composition of fracturing fluid and other factors. Smectite and illite/smectite mixed-layer minerals have large specific surface areas and high imbibition abilities, so the shale with high contents of such two minerals has strong hydration, prone to soften[11,12]. Shale hydration and expansion are prone to fractures. Ma and Shi et al.[13,14] used distilled water to soak shale for studying the generation, expansion and connection of secondary micro-fractures in shale at different stages. It is found that over the duration of hydration, micro-fractures are continuously developed to form fractures with mutual connection, so as to damage the macrostructure of rock. Zhang et al.[15] injected clean water and KCl solutions of different concentrations in shale permeability test, and the results showed that compared with pure water, the KCl solutions with concentrations of 4% and 8% had a slightly weaker hydration effect on shale reservoir, that is, KCl solution could slightly reduce the damage to shale reservoir permeability. Previous studies mainly focused on the effects of different types of clay minerals and solutions on the hydration strength of shale, and the scale of research was mostly limited to macro-fracture and micron micro-structure. There are few studies on the correlation of the submicron and nanometer microstructure changes and those after hydration with physical parameters.

In this paper, shale samples in Wuxi region around Sichuan Basin are selected, and on the basis of previous research on hydration mechanism, FESEM and computed tomography (CT) scanning technology are used to study the effect from hydration on microstructure changes of shale, compare the changes in shale porosity and permeability before and after hydration, and analyze the impacts of shale hydration degree on physical parameters.

1. Samples and methods

1.1. Experimental samples

The experimental samples in this study were collected from Wuxi region in Chongqing City around Sichuan Basin. The samples were taken from the Lower Silurian Longmaxi Formation at buried depths of 1 900-1 980 m. The total organic carbon (TOC) content and mineral composition of the shale samples are shown in Table 1. The samples have TOC content of 1.4%-5.3%, and are composed of mainly quartz (content of 30%-40%, on average 34%), feldspar (content of 4%-11%), calcite (content of 7%-17%), dolomite (content of 6%-17%), pyrite (content of 3%-9%), illite (content of 8%-17%), chlorite (content of 5%-12%), and the illite/smectite mixed-layer at the mixed ratio of 15% (content of 8%-15%).

Table 1 TOC content and mineral components of shale samples.

| Sample No. | TOC/% | Non-clay mineral content/% | Clay mineral content/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspar | Calcite | Dolomite | Pyrite | Illite | Illite/smectite mixed-layer | Chlorite | ||

| W-1 | 1.4 | 33 | 10 | 10 | 9 | 3 | 16 | 14 | 5 |

| W-2 | 2.1 | 30 | 8 | 11 | 8 | 4 | 17 | 15 | 7 |

| W-3 | 3.0 | 36 | 11 | 10 | 6 | 4 | 12 | 9 | 12 |

| W-4 | 4.5 | 31 | 4 | 17 | 17 | 4 | 8 | 12 | 7 |

| W-5 | 5.3 | 40 | 10 | 7 | 12 | 9 | 9 | 8 | 5 |

1.2. Experiment method

Two samples were selected for microscopic characterization experiments before and after hydration by field emission scanning electron microscope (FESEM), to study the effects of hydration on micro-fractures and micro-pores of shale. The main component of fracturing fluid is water. In order to more directly reflect the hydration mechanism of shale, distilled water was used instead of fracturing fluid to conduct the modeling experiment of shale hydration in this study. Five plug samples were selected for micron CT scanning, porosity and permeability testing. After the test, the samples were put in a confined container for vacuum extraction, and then soaked in distilled water for 24 hours. The soaked samples were put in the centrifuge and centrifuged for 1 hour at centrifugal force of 2.1 MPa. Micron CT scanning, porosity and permeability testing were performed on the samples before and after centrifugation. The sample analysis tests were completed at the National Energy Shale Gas Research and Innovation (Experiment) Center and the Key Laboratory of Unconventional Oil and Gas, CNPC.

1.2.1. Field emission electron microscope scanning

The bulk regular sample with a size of about 2 cm×2 cm was selected. The surface of the samples was roughly polished with sandpaper and polishing liquid, and then polished and coated with carbon by argon-ion polishing instrument. The processed samples were placed in FESEM for scanning. The 685C-type argon ion polishing instrument produced by Gatan Company was used to polish the samples at the polishing voltage of 3 kV for 4 h in this study. In the FESEM experiment, the Helios650 FIB/SEM focused ion beam dual-beam scanning electron microscope produced by FEI Company was adopted to do the job at the scanning voltage of about 5 kV and the working distance of about 4 mm. After scanning, the samples were put into a confined container to vacuum, then soaked in distilled water for 24 h to simulate hydration. Subsequently, the samples were taken out and then placed in 60 °C oven for drying till constant weight. FESEM experiment was repeated on the samples after drying. The change laws of micro-fractures and micro-pores in shale before and after hydration were compared.

1.2.2. Micron CT scanning

The equipment used in micron CT scanning was Xradia MicroXCT-400 CT scanner of Zeiss Company. The scanning voltage used in the scanning experiment was 140 kV, the scanning time was 8 h, and the resolution was 34 μm. First, the plug sample was drilled by a drilling prototype with a diameter of 2.55-2.56 cm and a length of 1.93-2.45 cm(see Table 2). In the process of scanning, the positions of X-ray source and detector kept unchanged, and the samples were rotated at a constant speed from -180° to 180° to capture 5-10 pictures per rotation of 1°.

Table 2 Basic parameters of plug samples.

| Sample No. | Diameter/cm | Length/cm | Mass/g |

|---|---|---|---|

| W-1 | 2.56 | 1.93 | 25.91 |

| W-2 | 2.55 | 2.21 | 29.29 |

| W-3 | 2.56 | 2.45 | 32.84 |

| W-4 | 2.56 | 2.31 | 29.35 |

| W-5 | 2.55 | 2.10 | 26.81 |

1.2.3. Porosity and permeability tests

The porosity and permeability of shale samples were tested by Coreval700 poroperm tester produced by VINIC Company. The gas medium used in the test was nitrogen with a purity of 99.99%. The porosity was tested at the confining pressure of 10 MPa and the pore pressure of 1.4 MPa. Measurement procedure of porosity is as follows: The apparent density of the sample was measured by means of the rock density meter, the skeletal density of sample was measured by poroperm tester, and the porosity of the sample was calculated by equation (1).

where ρb—apparent density, g/cm3; ρg—skeletal density, g/cm3; ϕ—porosity, %.

The permeability test method was the pressure decltion method[16], which belongs to the unsteady method. The principle of gas permeability tester by pressure decltion method is shown in Fig. 1. The test steps are as follows: The plug sample is placed in the core holder under certain confining pressure; the downstream valve is closed to fill the upstream chamber with a certain amount of gas; after the pressure is balanced, the downstream valve and connecting valve are turned on successively. As the gas flows from the upstream chamber to the downstream end through core, the pressure in the upstream chamber decreases continuously. The permeability of plug sample is calculated according to the rate of pressure reduction in upstream chamber. The permeability in this study was tested at the confining pressure of 10 MPa and pore pressure of 1.4 MPa.

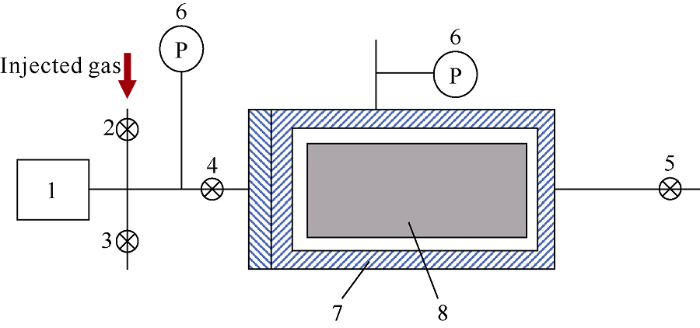

Fig. 1.

Fig. 1.

Principle of gas permeability tester by pressure decltion method. 1Upstream chamber; 2Gas inlet valve; 3Gas exhaust valve; 4Connecting valve; 5Downstream valve; 6Pressure gauge; 7Core holder; 8Core.

2. Result and discussion

2.1. Field emission scanning electron microscope results

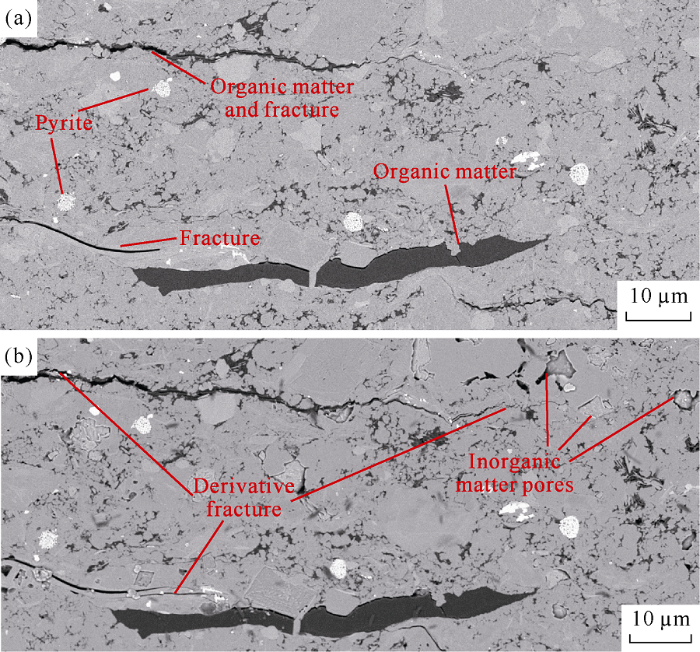

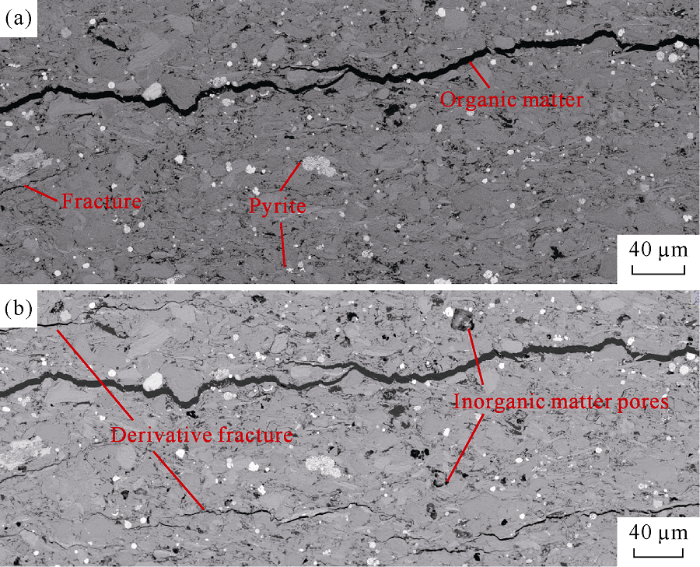

The variation of microstructure of samples W-3 and W-5 before and after hydration were compared (Figs. 2-5). FESEM experiments show that the organic matter in shale is mostly distributed in strip and dispersion. The organic matter is a plastic material susceptible to the effect of compaction, so the stripped organic matter has few internal pores (Fig. 2a), the scattered organic matter has more pores from 10 nm to 300 nm in diameter (Fig. 4). Organic matter and minerals are different somewhat in stress sensitivity. When the core is taken out from the stratum, micro-fractures less than 1 μm wide are likely to occur due to stress release (Fig. 2a). The pyrite in shale often appears in strawberry shape from a few microns to dozens of microns in diameter (Fig. 3a).

Fig. 2.

Fig. 2.

Microstructural characteristics of shale sample W-3 before (a) and after (b) hydration.

Fig. 3.

Fig. 3.

Microstructural characteristics of shale sample W-5 before (a) and after (b) hydration.

Fig. 4.

Fig. 4.

Microstructure of dispersed organic matter before (a) and after (b) hydration.

Comparing the images of two samples before and after hydration, it is found that the main morphology and position of organic matter in shale have no changes after hydration (Figs. 2 and 3), and the pores in dispersed organic matter show no obvious changes either (Fig. 4). The main reason is that the shale organic matter is the kerogen insoluble in non-oxidizing acids, alkali and non-polar organic solvents. Water is adsorbed on the surface of kerogen during soaking, but no dissolution nor chemical reaction occurs with organic matter[17]. The organic pores are formed after long thermal evolution of organic matter, and are main space for shale gas storage. The pore size of organic matter can also guarantee the flow of water molecules in the pores. Therefore, hydration has no obvious influence on the size and structure of pores in shale organic matter. After hydration, the fractures in shale increase in number and width, mainly shown as the extension of fractures between inorganic minerals and the creation of new fractures (Figs. 2b and 3b), and the width of fractures between stripped organic matter and inorganic minerals increase (Fig. 5b). During the soaking process, self-absorption effect happens to water along the fracture, and the stress of hydration is concentrated at the fracture tip, leading to the extension of fractures between inorganic minerals and the creation of new fractures[18]. The width of newly-created fracture is basically less than 10 μm. In clay minerals, Na+, K+, Ca2+ and other positive ions in illite and illite/smectite mixed-layer minerals can be hydrated and dissolved[18]. When water is discharged, these positive ions would gather on the surface of clay minerals, making the fractures between inorganic minerals and organic materials grow wider. After hydration, a large number of inorganic pores are formed in shale with sizes ranging from several microns to dozens of microns. These inorganic pores are mainly caused by the weak cohesion between clay minerals and non-clay minerals and the detachment of non-clay minerals after water soaking (Figs. 2b and 3b). In real stratigraphic conditions, because shale is in a confined state in the stratum, non-clay minerals are not easy to fall off to produce inorganic pores, but would be transformed into micro-fractures between clay minerals and non-clay minerals.

Fig. 5.

Fig. 5.

Microstructure of stripped organic matter before (a) and after (b) hydration.

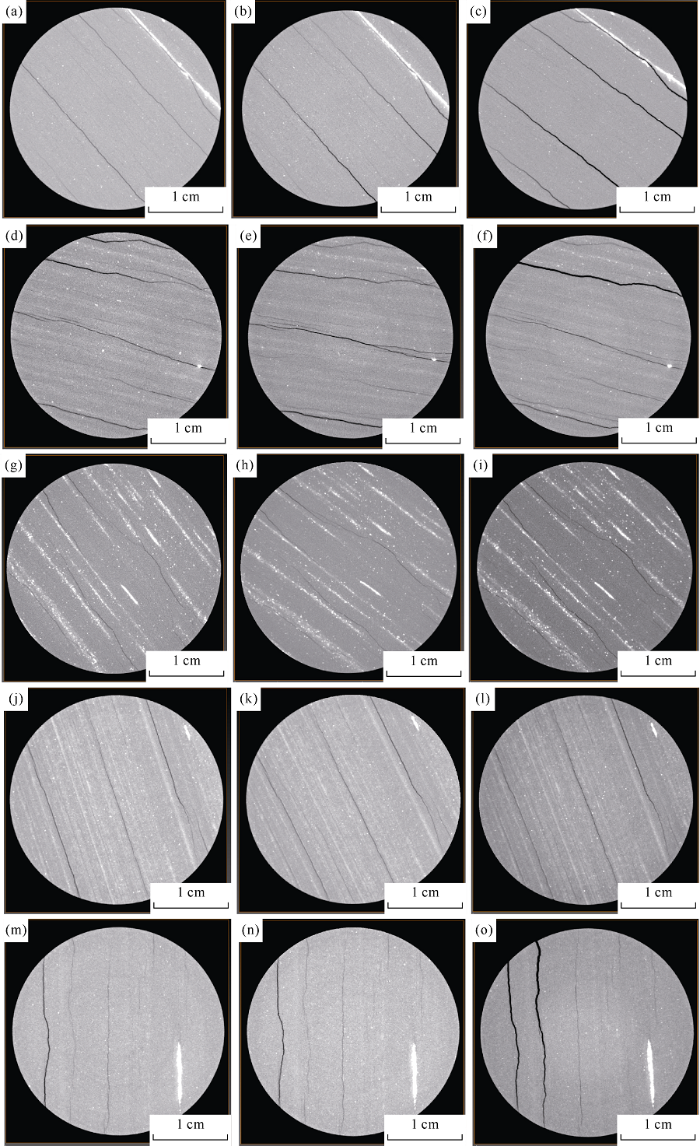

2.2. Micron CT scanning results

The water saturation experiment of shale samples was used to simulate hydration, and centrifugation experiment was adopted to simulate drainage process during shale development. Micron CT scanning was carried out on samples in three states, i.e., before hydration, after hydration and before centrifugation as well as after centrifugation experiment (Fig. 6). According to the principle of CT imaging, the higher the density of the medium, the brighter the medium image will be, and the lower the density, the darker the medium image will be. In Fig. 6, the white part is pyrite and the black part is fracture or pore. The selected samples have micro-fractures, samples W-1, W-2 and W-5 have more fractures, but no micron pores, and stripped pyrite is seen in some samples (Fig. 6a, 6g and 6m). Under the real stratigraphic pressure conditions, micro-fractures are usually closed, but these regions are the weak surfaces of shale with low cementing strength, and would be broken earlier than shale matrix, so that hydraulic fracturing can extend along these micro-fractures to achieve fracture expansion and volume stimulation[19].

Fig. 6.

Fig. 6.

Micron CT sections of shale samples before and after hydration and centrifugation experiment. (a) Shale sample W-1 before hydration; (b) Shale sample W-1 after hydration and before centrifugation; (c) Shale sample W-1 after centrifugation; (d) Shale sample W-2 before hydration; (e) Shale sample W-2 after hydration and before centrifugation; (f) Shale sample W-2 after centrifugation; (g) Shale sample W-3 before hydration; (h) Shale sample W-3 after hydration and before centrifugation; (i) Shale sample W-3 after centrifugation; (j) Shale sample W-4 before hydration; (k) Shale sample W-4 after hydration and before centrifugation; (l) Shale sample W-4 after centrifugation; (m) Shale sample W-5 before hydration; (n) Shale sample W-5 after hydration and before centrifugation; (o) Shale sample W-5 after centrifugation.

By comparing the results of micron CT scanning, it is found that hydration can make shale fractures extend and generate new fractures, of which the mechanism is the same as FESEM experiment. Hydration damage mainly extends along the developing direction of bedding or original fractures, and hydration has the most significant impact on the shale samples W-1, W-2 and W-5 with relatively developed fractures (Fig. 6b, 6e and 6n). Therefore, hydration intensity is controlled by the development degree of primary fractures, and the more developed the primary fractures, the stronger the hydration effect will be[20]. As the hydration time prolongs, these fractures would connect with each other to reduce the strength of the core and cause macroscopic damage of the rock[14]. After water is discharged from shale samples by centrifugal experiments, the fractures increase in width, to 2-5 times of the original width. Among the samples, samples W-1 and W-5 have the most obvious increase in fracture width (Fig. 6c and 6o).

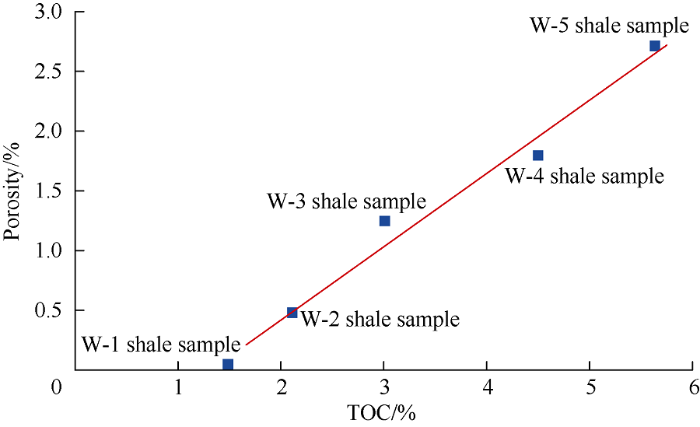

2.3. Porosity and permeability tests results

The results of FESEM and micron CT scanning experiments show that the shale samples selected have organic pores from 10 to 300 nm in size and micro-fractures from tens of nanometers to hundreds of microns wide. The poroperm tester was used to test porosity and permeability of the shale samples in three states, before hydration, after hydration and before centrifugation as well as after centrifugation. The measured porosity is effective porosity, ranging from 0.05% to 2.71% (Fig. 7). The samples have organic matter pores (Fig. 4), providing space for shale gas storage. Therefore, the samples with high TOC content have higher porosity, and the two are positively correlated (Fig. 7).

Fig. 7.

Fig. 7.

Relationship between TOC content and porosity of shale samples.

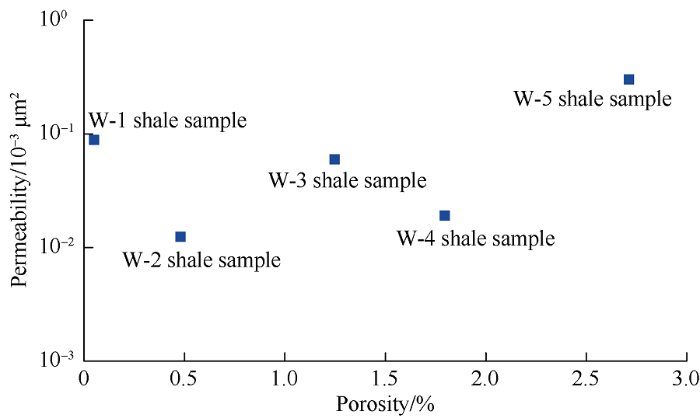

For conventional sandstone, porosity has a good correlation with permeability. Gamage et al.[21] found that porosity was positively correlated with the logarithm of permeability. The permeability distribution range of shale samples selected in this study is (0.01-0.30)×10-3 µm2, and the logarithm value of permeability is basically positively correlated with porosity (Fig. 8). In the meantime, the permeability is controlled by the degree of fracture development. Although the content of TOC and porosity of shale sample W-1 are low, its permeability is high due to relatively developed fractures. Apparently, shale permeability is mainly affected by porosity and fracture development degree.

Fig. 8.

Fig. 8.

Relationship between permeability and porosity of shale samples.

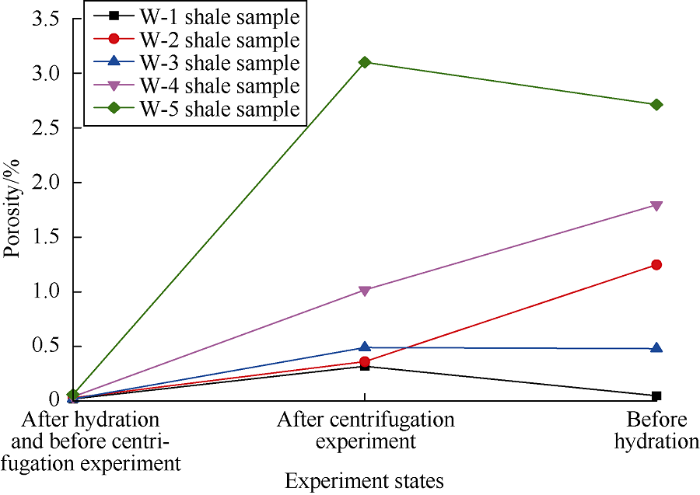

According to the porosity test results of shale samples under different states (Fig. 9), the water saturation of shale samples after hydration basically reached 100%, and the porosity of samples reached the detection limit of the instrument, so the indication of porosity test was basically zero. After the centrifugal experiment, most of movable water was centrifuged out, leading to the decrease in water saturation of the samples and significant increase in porosity, but the porosity increase differs widely in different samples. The porosities of samples W-2 and W-4 after centrifugation were lower than those before hydration. The porosity of sample W-3 after centrifugation was equivalent to that before hydration. The porosities of samples W-1 and W-5 after centrifugation are greater than those before hydration. Combined with the results of micron CT scanning (Fig. 6), it is found that samples W-2 and W-4 have few fractures developed and high bound water content after hydration. After centrifugation experiment, its water saturation doesn’t decrease much, leading to the porosity test result lower than that before hydration. After the hydration, sample W-3 have more fractures developed and high movable water content. After centrifugation experiment, its water saturation drops, so the test result of porosity is basically equivalent to that before hydration. After hydration, samples W-1 and W-5 present increase in number and width of fractures most significantly. After centrifugation experiment, their water saturation decrease and fractures expand, so the test results of their porosities are larger than those before hydration. The porosity of sample W-1 increases from 0.05% before hydration to 0.32%, and that of sample W-5 increases from 2.71% before hydration to 3.10%. Therefore, the degree of fracture development has certain influence on shale porosity.

Fig. 9.

Fig. 9.

Porosity test results of shale samples in different states.

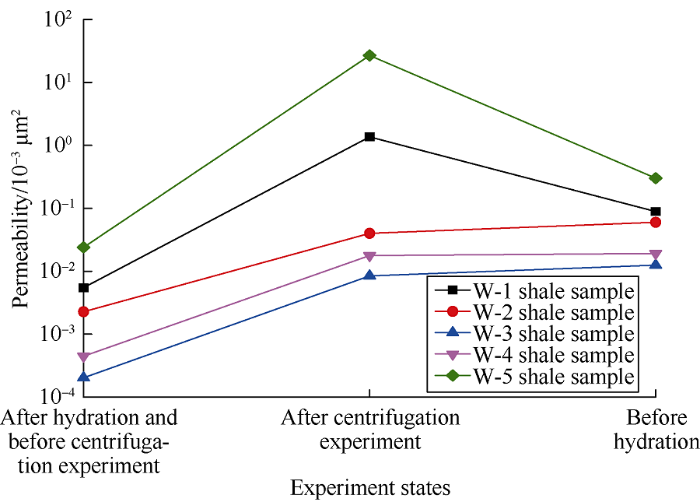

According to the permeability test results of shale samples in different experiment states (Fig. 10), the permeability of samples after hydration is lower than that before hydration. The main reason is that saturated water occupies the pores, fractures and throats of shale, leading to a decline in the nitrogen relative permeability of shale. After the centrifugation experiment, the rock permeability increased as the fluid was drained out, but the degrees increased are different. The permeabilities of samples W-2, W-3 and W-4 recovered to those before hydration. The permeabilities of samples W-1 and W-5 were greater than those before hydration. Combined with the results of micron CT scanning, it can be seen that the fractures of samples W-1 and W-5 increased significantly in width after centrifugation experiment, leading to the permeabilities greater than those before hydration. Therefore, shale permeability is mainly controlled by the degree of fracture development, and secondarily by porosity.

Fig. 10.

Fig. 10.

Permeability test results of shale samples in different states.

3. Conclusions

After hydration, the organic matter and organic pores of shale are basically unchanged, but the fractures are likely to form between organic matter and inorganic minerals, and micro-fractures are also prone to be generated or derived in inorganic minerals. Meanwhile, the cohesive force between mineral particles is weak. After hydration, the non-clay mineral particles fall off to form inorganic pores of several microns to dozens of microns in diameter. In real stratigraphic conditions, these inorganic pores may not be generated, but would be transformed into micro-fractures between clay and non-clay mineral particles.

The intensity of hydration is controlled by the development degree of primary fractures. The more developed the primary fractures, the stronger the hydration degree will be, and the more likely the secondary fractures will be developed. The experimental results of shale hydration show that the content of shale TOC plays a leading role in porosity, and the higher the content of TOC, the larger the porosity will be. Secondly, shale porosity is affected by the degree of fracture development. The permeability is influenced by the degree of fracture development and porosity, of which the degree of fracture development plays a leading role. After hydration, if the width of shale fracture increases significantly, the porosity of shale would increase slightly than the original porosity of the sample, while the permeability would increase multiply. When the fracture width increases little, the porosity of shale is smaller than that of the original sample, and the permeability is equivalent to that of the original sample. After hydration, the degree of fracture development has an influence on both porosity and permeability, but the influence on permeability is bigger than that on porosity.

Reference

Bacterial communities associated with hydraulic fracturing fluids in thermogenic natural gas wells in North Central Texas, USA

DOI:10.1111/j.1574-6941.2011.01196.x

URL

PMID:22066833

[Cited within: 1]

Hydraulic fracturing is used to increase the permeability of shale gas formations and involves pumping large volumes of fluids into these formations. A portion of the frac fluid remains in the formation after the fracturing process is complete, which could potentially contribute to deleterious microbially induced processes in natural gas wells. Here, we report on the geochemical and microbiological properties of frac and flowback waters from two newly drilled natural gas wells in the Barnett Shale in North Central Texas. Most probable number studies showed that biocide treatments did not kill all the bacteria in the fracturing fluids. Pyrosequencing-based 16S rRNA diversity analyses indicated that the microbial communities in the flowback waters were less diverse and completely distinct from the communities in frac waters. These differences in frac and flowback water communities appeared to reflect changes in the geochemistry of fracturing fluids that occurred during the frac process. The flowback communities also appeared well adapted to survive biocide treatments and the anoxic conditions and high temperatures encountered in the Barnett Shale.

Water management challenges associated with the production of shale gas by hydraulic fracturing

DOI:10.2113/gselements.7.3.181 URL [Cited within: 1]

Evaluating the environmental implications of hydraulic fracturing in shale gas reservoirs

Effect of electrostatic interactions on water uptake of gas shales: The interplay of solution ionic strength and electrostatic double layer

DOI:10.1021/acs.energyfuels.5b02990

URL

[Cited within: 1]

We conduct spontaneous imbibition experiments using different fluids (deionized, DI, water and brines) and different media (unwashed and washed shale powder) to study the wetting behavior of the shale samples from the Horn River Basin (HRB), a massive unconventional gas play in the Western Canadian Sedimentary Basin. As expected, unwashed shale powder imbibes DI water faster than brine. Surprisingly, washing the powders results in faster imbibition of DI water. The imbibition of DI water into washed shale powders, which have a reduced soluble/leachable ion content, cannot be fully explained by osmotic effects. We explain the observed imbibition profiles using the electrostatic interaction theory. We measure the ion concentration of the brines by ICP-MS analysis and determine the ionic strength, I, of the in situ formed brine. We also calculate the characteristic thickness of electrostatic double layer, 1, formed around the surface of charged shale powders. The results indicate that the imbibition rate d...

Microfracture and surfactant impact on linear co-current brine imbibition in gas-saturated shale

DOI:10.1021/ef5025559

URL

[Cited within: 1]

During and after hydraulic fracturing, fluid鈥搒hale interaction has a prominent impact on liquid retention and thus on gas phase permeability and gas productivity. By providing a low surface tension or wettability alteration, surfactants are widely used to decrease liquid retention after fracturing. To evaluate the liquid intake of a rock sample, an imbibition experiment is commonly used, especially when it is treated by a surfactant. However, conventional imbibition experiments with gas shale could not quantitate the imbibition behaviors as it does with conventional rocks because of the low porosity and extremely low permeability of gas shale. In this paper, a comprehensive experimental method was successfully developed to study the liquid imbibition in shale samples. Bulk shale easily fell apart during imbibition experiments. However, samples prepared with the coating method decribed herein remained intact except for fractures generated in them during the first imbibition. On each imbibition curve with i...

Impact of shale gas development on regional water quality

Mechanisms of water adsorption into partially saturated fractured shales: An experimental study

DOI:10.1016/j.fuel.2015.07.015

URL

[Cited within: 1]

The physico-chemical processes of water adsorption into water saturated shale rocks have been extensively studied in the past. However, the physico-chemical processes of water uptake into partially saturated shales, such as water loss to fractured organic-rich shales during hydraulic fracturing, are poorly understood which in turn has raised serious technical and environmental concerns. Therefore, we ran a series of experiments on partially saturated calcareous shale samples, with measured total organic carbon (TOC) of 1.935% and mean vitrinite reflectance (Ro) of 0.52%, to identify the potential mechanisms involved in the water uptake. The physico-chemical properties such as mineral and elemental compositions, initial water saturation and contact angles of solutions with different concentrations were measured. Free and confined adsorption tests were then performed on both the intact and artificially fractured shale samples. The experimental results of this study are explained by two proposed mechanisms; capillary hydration and surface smotic hydrations that can combine to influence the amount of water uptake into partially saturated shales. The results show that the crack initiation is a strong function of confining stress and cracks are formed parallel to weak structures of the rock (bedding planes and laminations). The results also reveal that the mineral hydration controls the permeability (and consequently water flow) of existing fractures within the shale sample.

Effect of water salinity on shale reservoir productivity

Spontaneous imbibition of brine and oil in gas shales: Effect of water adsorption and resulting microfractures

DOI:10.1021/ef4002814

URL

[Cited within: 1]

We measure spontaneous imbibition of aqueous (deionized water and KCl solutions of various concentrations) and oleic (kerosene and iso-octane) phases in several dry organic shale samples selected from two wells drilled in the Horn River basin. We find that the imbibition rate of aqueous phases is much higher than that of oleic phases even when plotted versus scaling dimensionless time, contrary to capillary-driven imbibition models. The observed difference is more pronounced in samples with higher day content. The results suggest that the excess water intake is due to (1) the additional driving force provided through water adsorption by clay minerals, and (2) the enhancement of sample permeability through adsorption-induced microfractures.

Experimental investigation on fracture surface strength softening induced by fracturing fluid imbibition and its impacts on flow conductivity in shale reservoirs

DOI:10.1016/j.jngse.2016.10.036

URL

[Cited within: 1]

61Discussions are conducted about the relationship among the spontaneous imbibition, surface softening of the shale crack, and the conductivity damage to the popped fracture are offered.61The range involved in the water-rock interaction is determined with the NMR imaging.61The time-dependent nature of the surface hardness damage of shale comprised of different minerals is analyzed.

Quantitative characterization of micro forces in shale hydration and field applications

DOI:10.1016/S1876-3804(17)30038-1

URL

[Cited within: 1]

Shales(illite was the dominant clay mineral) of Silurian Longmaxi Formation in Sichuan Basin and Triassic Yanchang Formation in Ordos Basin were taken as subjects to examine the mechanisms of shale-water interaction, quantitative characterization of hydration force and potential field applications based on micro forces analyses. Mica sheet with composition and property very similar to illite was tested for micro forces between the crystal layers. In electrolyte solution, micro forces between mica-solution-mica system include DLVO(Derjaguin-Landau-Verwey-Overbeek) force and hydration force; when the electrolyte concentration was low, the tested curve agreed with the theoretical DLVO curve; when the electrolyte concentration was higher than the critical value and the distance between mica sheets was less than 5 nm, the tested curve deviated from the DLVO curve completely, and the hydration force became dominant. Quantitative analysis indicated that the hydration force decayed in a rapid double-exponential type with the growth of distance. Field applications indicate that strict control of water invasion and reducing the strength of hydration force are the keys in designing collapse-preventing drilling fluids; meanwhile, during the shut-in period of shale gas wells, shale-water interaction can induce and extend micro-cracks, further improving the stimulation effect of shale reservoirs.

Study of meso-damage characteristics of shale hydration based on CT scanning technology

DOI:10.1016/S1876-3804(14)60029-X

URL

[Cited within: 1]

In view of the shale hydration problem in wellbore stability analysis during drilling in shale formation, a quantitative evaluation method based on CT scanning technology was proposed to research the meso-damage characteristics of shale hydration, and the CT scanning tests for shale samples in stages of shale hydration were conducted. The analysis results of CT images and their gray-level histograms show that the early period of soaking is the main period of meso-damage in shale samples, and as the soaking time increases, the meso-damage propagates slowly; the mark of meso-damage increasing dramatically is that the gray-level histogram of the CT image changes from unimodal style to bimodal style. The visual resolutions of CT images can be improved by the pseudocolor enhancement technique, and the integrity and damage degrees of CT images provide a convenient way for quantitative analysis. The relationship between damage variable and soaking time was obtained based on the segmentations of CT images, which shows that the meso-damage of shale hydration mainly occurs in the early stage of soaking, which is the initial stage and rapid evolution stage of meso-damage, from then on, as the damage variable increases continuously and slowly, the macro-damage of shale sample occurs.

CT imaging and mechanism analysis of crack development by hydration in hard-brittle shale formations

DOI:10.1038/aps.2011.157 URL PMID:4010276 [Cited within: 2]

Effect of water imbibition on hydration induced fracture and permeability of shale cores

DOI:10.1016/j.jngse.2017.06.008

URL

[Cited within: 1]

During a hydraulic fracturing operation with water-based fracturing fluids, in-situ compressive stress was applied on shale. To study whether or not hydration induced fracture can be created to improve oil and gas recovery under isotropic compressive stress conditions, time-elapsed computerized tomography (CT) was used to obtain cross section images of shale cores with confining pressures loaded. Based on CT data, cut faces parallel to the core axial through the middle of core and 3D fracture images were reconstructed. To study the effects of hydration on shale pore fluid flowing under isotropic compressive stress conditions, shale permeability was measured with Nitrogen (N 2 ), distilled water, 4% KCl solution, and 8% KCl solution. Hydration induced fractures came into being for Mancos shale with low confining pressure (15 psi) loaded. However, with high confining pressure (3000 psi) loaded, fractures tended to close eventually due to hydration. For the Eagleford shale, with either a low or a high confining pressure loaded, fractures eventually became nearly closed. In the Mancos shale which contained more swelling clay minerals, larger reduction of fracture apertures or permeability was observed than that in the Eagleford shale with confining pressure applied. Adding KCl into the water-based fracturing fluid during fracturing could decrease shale hydration and reduce shale permeability damage. Our study shows that 8% KCl solution could help reduce the permeability damage of Mancos shale, and 4% KCl solution was feasible to reduce the permeability damage of the Eagleford shale under isotropic compressive stress conditions.

Core analysis: A best practice guide

Core Analysis: A Best Practice Guide is a practical guide to the design of core analysis programs. Written to address the need for an updated set of recommended practices covering special core analysis and geomechanics tests, the...

The structural characteristics of kerogens in oil shale with different density grades

DOI:10.1016/j.fuel.2018.01.079 URL [Cited within: 1]

Experimental study on hydration damage mechanism of shale from the Longmaxi formation in southern Sichuan basin, China

DOI:10.1016/j.petlm.2016.01.002

URL

[Cited within: 2]

As a serious problem in drilling operation, wellbore instability restricts efficient development of shale gas. The interaction between the drilling fluid and shale with hydration swelling property would have impact on the generation and propagation mechanism of cracks in shale formation, leading to wellbore instability. In order to investigate the influence of the hydration swelling on the crack propagation, mineral components and physicochemical properties of shale from the Lower Silurian Longmaxi Formation (LF) were investigated by using the XRD analysis, cation exchange capabilities (CEC) analysis, and SEM observation, and we researched the hydration mechanism of LF shale. Results show that quartz and clay mineral are dominated in mineral composition, and illite content averaged 67% in clay mineral. Meanwhile, CEC of the LF shale are 94.4 mmol/kg. The process of water intruding inside shale along microcracks was able to be observed through high power microscope, meanwhile, the hydration swelling stress would concentrate at the crack tip. The microcracks would propagate, bifurcate and connect with each other, with increase of water immersing time, and it would ultimately develop into macro-fracture. Moreover, the macrocracks extend and coalesce along the bedding, resulting in the rock failure into blocks. Hydration swelling is one of the major causes that lead to wellbore instability of the LF shale, and therefore improving sealing capacity and inhibition of drilling fluid system is an effective measure to stabilize a borehole.

Hydraulic fracture propagation geometry and acoustic emission interpretation: A case study of Silurian Longmaxi Formation shale in Sichuan Basin, SW China

Experiments on shale reservoirs plugs hydration

DOI:10.1016/S1876-3804(17)30070-8 URL [Cited within: 1]

Permeability- porosity relationships of subduction zone sediments

DOI:10.1016/j.margeo.2010.10.010

URL

[Cited within: 1]

Permeability orosity relationships for sediments from the northern Barbados, Costa Rica, Nankai, and Peru subduction zones were examined based on sediment type, grain size distribution, and general mechanical and chemical compaction history. Greater correlation was observed between permeability and porosity in siliciclastic sediments, diatom oozes, and nannofossil chalks than in nannofossil oozes. For siliciclastic sediments, grouping of sediments by percentage of clay-sized material yields relationships that are generally consistent with results from other marine settings and suggests decreasing permeability as percentage of clay-sized material increases. Correction of measured porosities for smectite content improved the correlation of permeability orosity relationships for siliciclastic sediments and diatom oozes. The relationship between permeability and porosity for diatom oozes is very similar to the relationship in siliciclastic sediments, and permeabilities of both sediment types are related to the amount of clay-size particles. In contrast, nannofossil oozes have higher permeability values by 1.5 orders of magnitude than siliciclastic sediments of the same porosity and show poor correlation between permeability and porosity. More indurated calcareous sediments, nannofossil chalks, overlap siliciclastic permeabilities at the lower end of their measured permeability range, suggesting similar consolidation patterns at depth. Thus, the lack of correlation between permeability and porosity for nannofossil oozes is likely related to variations in mechanical and chemical compaction at shallow depths. This study provides the foundation for a much-needed global database with fundamental properties that relate to permeability in marine settings. Further progress in delineating controls on permeability requires additional carefully documented permeability measurements on well-characterized samples.