Introduction

Oil and gas production engineering is the process of extracting oil and gas from the formation to the ground. It covers a variety of operations, such as mechanical oil recovery, water injection, production testing, workover, sand control, stimulation, and water plugging and water injection profile control, each of which is a system that involves many aspects such as reservoir characteristics, oil and gas properties, wellbore conditions, and ground equipment conditions. Oil and gas production engineering is a key link in oil and gas field development, playing an important role in all stages from reserves discovery, productivity construction and enhanced oil recovery. In recent years, through continuous efforts in technological innovation, CNPC has achieved continuous progress in the core technology of oil and gas production engineering and the transformation of developing mode. This is mainly shown in continuous improvement in its technical capability, continuous lowering of the reserves grade developed, significant improvement of production performance indicators, mature and applicable techniques for oil and gas production of different types of oil and gas fields, the development and promotion of a large number of advanced and practical technologies, and the successful implementation of a number of major testing and research projects with good results.

At present, CNPC has developed the following three types of oil and gas resources[1]: (1) The medium to high permeability oilfields represented by Daqing Oilfield, which contribute a large proportion of reserves and about 50% of the production among oilfields that have been developed. At present, the medium to high permeability oilfields have all entered into the ultra-high water cut stage, with composite water cut of over 90% and the recovery ratio of the recoverable reserves of over 85%. It is increasingly harder to enhance recovery rate and recover the remaining reserves. (2) Low-permeability oilfields represented by Changqing Oilfield, which provide more than two thirds of newly found reserves and more than one third of total production; at present, the low-permeability oilfields have a low degree of recovery, but rapid rise of water cut and sharp production decline. It is very difficult to enhance oil recovery of these oilfields that have entered into the medium to high water cut stage. (3) Unconventional oil and gas resources represented by tight oil and gas and shale gas[2,3]. According to statistics, China has abundant unconventional resources. The recoverable resources of tight (shale) oil, tight gas and shale gas are 55×108 t, 12×1012 m3 and 22×1012 m3, accounting for 9.7%, 5.7% and 4.8% of the world total, respectively. Therefore, it is an inevitable strategic choice for China’s oil and gas industry to develop greatly unconventional oil and gas. In recent years, significant progress has been made in the exploration and development of unconventional oil and gas in China. However, it is difficult to find large-scale, effective reserves of unconventional oil and gas, due to complicated geological conditions, murky accumulation pattern of unconventional hydrocarbon, and difficult prediction and evaluation of “sweet spot”; at the same time, it is hard to develop them due to the poor grade of resources, low cumulative production and small amounts of controlled recoverable reserves per well, and low recovery rate.

It is expected that during the “13th Five-Year Plan” period and even longer period of time, with the deeper development of oil and gas fields, the resources will get increasingly poorer in grade, China’s environmental protection requirements will become more and more strict; at the same time, as China’s dependence on imported oil and gas will rise, China’s national energy security is facing a great challenge. Therefore, in its upstream oil business, CNPC must keep on the low-cost development way by reducing costs and enhancing efficiency in all processes and all factors. The development of unconventional oil and gas in the United States mainly relies on technological advances and management innovation, especially technological advances in drilling, fracturing and some other technologies. Its cost of unconventional oil and gas development has been on the decline. In 2017, its crude oil production reached 4.8×108 t and natural gas production reached 9 400× 108 m3, of which unconventional oil and gas accounted for 53.7% and 54.5%, respectively. At present, unconventional natural gas and tight oil production in China make up about 30% and less than 2% of the total gas and oil production in China. Therefore, CNPC must strengthen technical research on oil and gas production engineering and enhance its ability to improve engineering quality and efficiency to achieve its development goal of “stable oil production of 100 million tons and fast growth in natural gas” production and open up new prospects for the innovative development of oil and gas fields. Through a comprehensive review and analysis of the development of CNPC’s oil and gas field production engineering and technologies in recent years, this paper systematically analyzes, summarizes and describes its current state of technology development, its achievements and weaknesses, and forecasts the development tendency of the next step and proposes the main areas of technology research and development.

1. Technical achievements in oil and gas production engineering

The technical progress and application results of CNPC oil and gas production engineering and technology are mainly reflected in three aspects.

1.1. Increase of efficiency of oil and gas production system

By the end of 2016, CNPC had put into operation a total of more than 20×104 oil wells, with an operating rate of 72% and an average production per well of 1.7 t/d, among which 94% are artificial lifted. Through years of unremitting study and research, the efficiency of oil and gas production system has been continuously improved, as follows: (1) The efficiency of the pumping system and the pump inspection cycle have been enhanced year by year, with an average of 24.3% and 780d respectively. (2) Four types of artificial lift technologies have been developed, namely sucker rod pump (SRP), progressive cavity pump (PCP), electric submersible pump (ESP), and gas lift; meanwhile, the recently invented rodless pumping technology has been applied in small batches to cluster wells and highly deviated wells, satisfying the basic needs of production. (3) The invention of special-purpose pumping units, tower pumping units, energy-saving motors, energy-saving control cabinets and engineering software for oil production system optimization are playing an important role in energy saving and consumption reduction[4].

By the end of 2016, CNPC had put into operation nearly 20 000 gas wells, with an operating rate of 77.2% and an average production per well of 2×104 m3. Advanced technologies such as pipe string optimization, downhole throttling, hydrate prevention and control, foam deliquification, medium and low pressure gas gathering, and integrity evaluation of wells with high pressure, high sulfur, and high-risk have been established, strongly supporting the steady increase of natural gas production.

1.2. Large-scale unconventional oil and gas productivity construction supported by volume fracturing technology

By the end of 2016, CNPC fractured a total of 5563 horizontal wells, with the maximum horizontal lateral length of 3056 m, the maximum number of stages of 45, the maximum fracturing fluid volume of 8.8×104 m3, and the maximum sand volume of 4 402 m3. The average daily yield of the horizontal wells is about 3.9 times that of the vertical wells.

The domestic horizontal well multistage fracturing technology has helped reduce operating costs by 50% to 80%. Thanks to technological advances, the lower limit of the permeability of effectively developed reservoirs has been cut back substantially, making it possible to effectively develop shale gas, tight oil and gas and other unconventional oil and gas resources. For instance, in Changqing Oilfield, the permeability of the main oil reservoirs of the ultra-low permeability oilfield developed around year 2000 was 1.98×10-3 μm2, but by far, the lower limit of the permeability of effectively developed reservoirs has come down to 0.17×10-3 μm2.

The permeability of shale gas reservoirs is basically at the level of 1×10-9 μm2. These reservoirs have been effectively developed through continuous research. To date, CNPC has established three shale gas demonstration zones in Changning, Zhaotong and Weiyuan, with an annual gas production capacity of 30×108 m3.

1.3. Fine controlled separate layer water flooding

By the end of 2016, CNPC had about 9×104 water flooding wells, with a separate layer injection rate of 61%: (1) the third-generation separate layer flooding technology dominated by bridge eccentricity + cable direct measuring and adjustment has been applied to 4×104 wells with 2-3 segments, which account for 62% of total separate layer water injection wells; (2) the fourth-generation separate layer water injection technology coring on continuous monitoring and automatic measurement and control has been successfully tested in the field. Thanks to the technology, Daqing and Changqing Oilfield witnessed significant slow-down of the water cut rise rate, clear increase of water flooding producing degree and further improvement in the water flooding effect.

2. Progress in key technologies for oil and gas production engineering

After years of continuous research and development, CNPC has developed a series of key special technologies in oil and gas production engineering.

2.1. Optimization and decision-making platform for oil and gas production system[5,6,7]

The combination of Internet and oil and gas production engineering for optimization and decision-making is inevitable with the evolution of technology. Since the “11th Five-Year Plan”, through unremitting efforts in technological research, CNPC has made breakthrough in core technologies such as 3D mechanical simulation of oil and gas wells and big data based intelligent working condition analysis etc, and developed PetroPE, a robust network software for large-scale oil and gas production engineering, that enables real-time online optimization and rapid remote management of oil and gas well production. The software has been applied to 8 CNPC oilfields and become an important technical means for reducing costs and enhancing efficiency in oilfield production.

PetroPE has an indoor network version and a real-time mobile version, equipped with ten functions, suitable for all domestic equipment. It supports the optimal design, diagnosis and decision-making of major lifting techniques for all types of oil and gas wells in conventional oil and gas reservoirs, including vertical wells, inclined wells and horizontal wells. It can be dynamically linked to CNPC’s database for online use, breaking data islands and application barriers and facilitating the large-scale use of technologies.

The mobile version is equipped with the design method suitable for the optimization of mobile intelligent terminals and data security mechanism, enabling technical support to shift from indoor to field, to make real-time diagnosis and optimization of oil wells, providing field engineers with dynamic production data, pipe structure, diagnosis of working conditions of pumping units and some other specific technical support. In addition, the software also serves as a new means for oil and gas well IoT analysis and application and data value mining.

At present, the online version has been applied in more than 4×104 well-times, enhancing system efficiency by 2.52% on average, saving more than 1.6×108 kw·h of power annually, and reducing carbon emissions by 12.56×104t. More than 800 sets of the PetroPE mobile version have been used in domestic oilfields such as Daqing and Jilin. This software platform has significantly improved the production efficiency and refined management level of oil and gas wells.

2.2. Nanoparticle foam deliquification for gas wells

At present, there are 8200 water-producing wells in CNPC’s four major gas regions, accounting for 61.6%. In order to keep production of water-producing gas wells stable, starting from molecular structure design, CNPC has synthesized Gemini, a surfactant with a double hydrophilic and double amphiphilic structure that can greatly enhance the foaming of surfactant; meanwhile, through grafting and modification, a type of nanoparticle foam stabilizer has been invented, which can form vesicles of a special structure in aqueous solution through association to greatly enhance the foaming stability of the system[8]. By combining the Gemini foaming agent with the nanoparticle foam stabilizer, seven kinds of nanoparticle foaming agents in two categories resistant to high temperature/high salinity/high acidity and high condensate oil have been developed. In addition, based on these agents, a series of technologies and corresponding software have been invented, such as multi-factor gas well effusion diagnosis, downhole effusion quantitative prediction, and gas well drainage and gas production analysis, design and decision-making. In the past three years, they have been applied to 81 wells for 2991 times in four gas production regions (Daqing, Changqing, and Southwest), resulting in an average daily gas increase of 5200 m3 (an increase rate of 151%) and a reduction of comprehensive costs by more than 40%.

2.3. Horizontal well volume fracturing technology

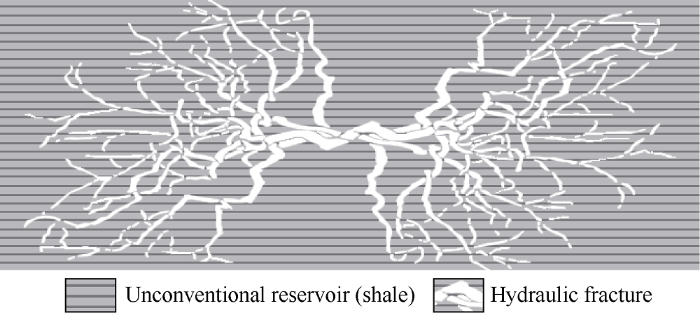

To address the challenges in unconventional reservoir development, the concept of horizontal well volume fracturing and corresponding technologies have been established, which tries to “smash” the reservoirs to form complex cracks (Fig. 1) to maximize contact area between the reservoir and fractures and minimize oil and gas seepage distance and the driving pressure difference required for flowing[9,10,11].

Fig. 1.

Fig. 1.

Schematic diagram of complex fractures formed in an unconventional reservoir.

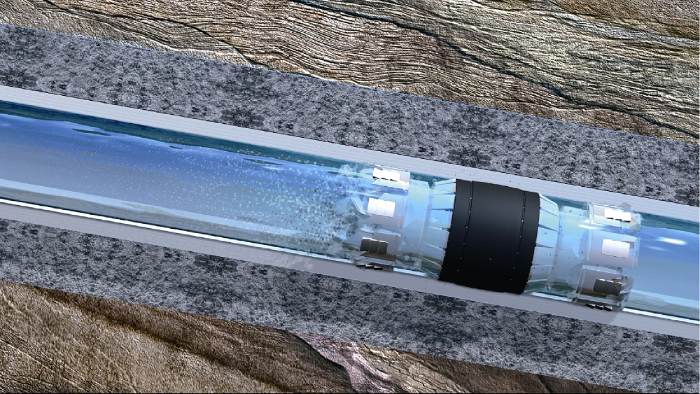

Guided by the volume fracturing technical theory, two main processes of horizontal well volume fracturing (bridge plug and perf and sliding sleeves) as well as the volume fracturing design concept and fracturing fluid system and fracturing monitoring technology in support of them have been developed, boosting the technological advancement of CNPC’s horizontal well fracturing and large-scale capacity building of unconventional resources. The main innovations in this aspect are as follows: (1) Large-scale polyaxial for fracture initiation and propagation has been established to reveal the fracture propagation mechanism. A method for optimizing the fracturing mode considering the brittleness, permeability and stress difference of the reservoirs has been set up. These two technical methods have been combined to form the fracturing design method for unconventional reservoirs and the fracturing technology to improve fracture complexity, effectively guiding the optimization and application of fracturing operation on site. (2) Ultra-low concentration guar and low viscosity slick water fracturing fluid have been invented, reducing the lower limit of foreign guar gum crosslinking (with the concentration for crosslinking dropping from 0.3% to 0.12%) and the dosage by 35%. With a viscosity of less than or equal to 3.0 mPa·s, the slick water results in a friction reduction rate of equal to or greater 70%, lowering the damage of the fracturing fluid to the reservoir and fracturing cost significantly. (3) Soluble plug tool for multistage fracturing has been developed (Fig. 2). Its main body is made of high-strength soluble metal with compressive strength of up to 550 MPa; the rubber element with the bionic surface texture and coating is made of soluble polymer material, and its complete dissolution time is less than 15 d. The soluble bridge plug has many advantages, such as self-dissolution after fracturing, no need for drilling, low operating costs and risks, and fast production. In 2016, the full-well shale gas soluble bridge plug fracturing was first completed in the Weiyuan 204H11 Platform, with the maximum fracturing stages of 26, the highest pump pressure of 86 MPa, and the average daily gas production after fracturing of 27×104 m3. By the end of 2017, the soluble plugs have been applied to more than 300 stages in six oil and gas fields, such as Southwest and Daqing, saving more than RMB 1500×104 Yuan in construction costs.

Fig. 2.

Fig. 2.

Schematic diagram of soluble bridge plug independently developed by CNPC.

2.4. The fourth-generation multi-layer zonal water injection technology

The fourth-generation zonal water injection technology with pressure sensor, flow rate sensor and control system permanently set in the well, allows the real-time monitoring of parameters such as pressure and flowrate of different layers and automatic adjustment of layer flowrate. With communication between the ground and underground realizing in wire or wireless ways, it is highly adaptable to different well types and depths. Through real-time monitoring of the pressure and flowrate of different layers in the injection well, it can easily perform the optimization and real-time adjustment of injection scheme, realizing the integration of reservoirs and engineering and the improvement of flooding effect[12]. At present, CNPC has developed three key technologies, namely real-time monitoring of parameters such as downhole flowrate and pressure of different layers, automatic adjustment of zonal flowrate, and two-way transmission of downhole data and office. As of late 2017, the fourth-generation zonal water injection technology had been applied to 130 wells, with maximum layers of up to 7 and water injection pass rate of over 90%. It has also helped save subsequent testing costs and reduce the overall cost.

2.5. Deep in reservoir conforming technology

This technology allows for the quantitative classification of dominant flow channels caused by reservoir heterogeneity by type and level and perform adjustments in an integrated way of “plugging, profiling and flooding”, and finally the technology concept of type-and-level-oriented adjustment for heterogeneous reservoirs has been established. Based on this concept, a series of chemical agents for plugging large channels and adjusting secondary channels with flexibility (such as high strength elastic slow-expansion particles, flexible diverting agents, flexible microgel particles, and local inorganic gels) has been developed; software for reservoir evaluation, integrated deep liquid flow steering and profile control have also been developed, which enable reservoir evaluation, pore throat characterization, dominant channel description, dynamic tracking, design optimization, and effect evaluation during profile control; 4 supporting technologies, namely, dominant channel identification and quantification by type and grade, optimization design of multi-slug combination of chemical agents and physical well group simulation, micro-seepage experiments for profile control on a micro-pore scale, and numerical simulation of dispersed phase flooding[13,14,15,16] have been established. The deep profile control technology has been applied to 562 wells, resulting in a total oil increment of 73.4×104 t, a newly added output value of 34.57×108 Yuan, water production reduction of 1,100×104 m3, and a direct economic benefit of 29.49×108 Yuan. The economic evaluation of 8 blocks adopting the technology in Xinjiang, Liaohe and North China shows a reduction of operating cost of 10.2% to 33.9%.

2.6. Submersible motor direct drive PCP technology

Driven by downhole motor, the submersible motor direct drive PCP technology allows rodless lifting of oil wells with a medium production rate of roughly 5-50 m3 daily. No retarding mechanism adopted, and using low-speed submersible motor to directly drive the screw pump, the technology has high reliability and wide adaptability. This technology is mainly composed of four key techniques: (1) The low-speed, high-torque downhole motor technique, which allows for stepless speed regulation at a rotating speed ranging from 50 to 500 r/min, and the motors suitable for (139.7 mm (5.5 in) and 177.8 mm (7 in)) casings have the maximum torque of 800 N•m and 1 490 N•m, respectively; (2) the direct-drive screw pump technique working at low-torque and high-speed; (3) the downhole flexible transmission technique; and (4) the remote monitoring and control technique. The submersible motor direct drive PCP technology is applicable to inclined wells and horizontal wells (together accounting for 60% of new wells). It can avoid eccentric wear of the rods and realize lifting in a high-efficiency, energy-saving, safe and environment-friendly manner. It has been applied to more than 100 wells, with an average pump efficiency of more than 60% and a pump inspection period of over 500 days. Compared with the same type of pumping unit, it reduces power consumption by more than 30%.

3. Major problems and challenges

As most oil and gas fields enter middle or late stage of development, the oil and gas exploitation is being shifted to low-permeability, unconventional, high water-cut, abnormally high-pressure, and deeper reservoirs, while oil prices are lingering at a medium or low level. Oil production engineering are facing great challenges, such as frequent workover operations, low well production, high costs, high energy consumption, and safety risks and strict requirements in environmental protection.

3.1. Huge challenges in the effective development of low quality resources

In recent years, the newly found proven oil reserves are largely low permeability reserves of poor grade. As of late 2016, CNPC’s cumulative proved oil reserves exceeded 200×108 t, of which, low-permeability proven reserves accounted for more than 50%, and the proportion of low-permeability reserves in new proven reserves is rising year by year (the proportion of low permeability oil reserves and gas reserves are over 80%, and over 90% respectively). At the same time, persistently low oil prices and declining returns pose greater challenges to cost-effective development. In recent years, with rising operating costs of crude oil and declining returns on investment, it is urgent for CNPC to research and develop technologies of effective stimulation to enhance its single well reserves.

3.2. Single well production declining year by year, and challenging work for stable production of old oil and gas fields

A large number of low-yield, low-efficiency wells have brought about a sharp increase in the workload of acid refracturing, making high-efficiency refracturing a prominent issue. At present, unremitting efforts have been put in the research and development of technologies for refracturing of high- water-cut, low-yield wells. With an increasing number of low-yield horizontal wells, it is urgent to innovate technologies for high and stable production and refracturing of horizontal wells too.

3.3. Insufficient technical reserves for cost-effective development of major oilfields with high water cut and high natural production decline

At present, CNPC’s oilfields with high water cut and high natural production decline still contribute the majority production, and needless to say, keeping production stable from them is increasingly difficult. In 2016, the oilfields have a recovery percentage of recoverable reserves of 76.04% and a composite water cut of 89.22%. Brown oilfields with water cut of over 80% have an annual production of over 5,000×104 t (accounting for 53.4% of total annual production), a natural decline rate of 9.39%, and a composite decline rate of 5.15%. Moreover, the brown oilfields witnessed aggravating interlayer contradiction and ineffective cycle of water flooding. At present, the separate layer injection rate of CNPC’s injection wells remains low. Meanwhile, water injectors adopting separate layer injection are facing more and more serious interlayer contradiction of injected layers, with the passing rate of measuring and adjustment dropping rapidly to about 60% within three months. Unqualified separate layer injection and serious ineffective circulation lead to substantial drop of flooding efficiency. For example, the water consumption per ton of oil in Daqing Oilfield increased from 5 tons in 1991 to 10 tons in 2015.

In addition, 94% of CNPC’s output is produced mechanically. The annual electricity consumption of the mechanical production system is as high as 180×108 kW•h, accounting for 54% of the energy consumption of the oilfield. And the system efficiency of rod-pumped wells and screw pumping wells are very low, at only 24% and 33%, respectively. Apart from that, sucker rod pumping is plagued by serious eccentric wear in directional wells and high-angle wells, further increasing energy consumption.

Oilfields are increasingly difficult to develop after entering the EOR stage. By 2016, the annual oil production of Daqing Oilfield through EOR had remained above 1 000×104 t for 15 years in a row. However, as production reservoirs gradually shift from Class I to Class II and Class III ones, chemical flooding is more and more difficult and getting gradually poorer in effect. The annual oil production through ASP flooding has reached 406×104 t. But the strong alkali ASP system is likely to cause scaling in oil layers, pipelines and equipment, and the produced fluid from ASP is difficult to treat.

3.4. Large gaps between North America and China in low-cost drilling and completion for development of deep and unconventional resources

Compared with North America, China lags behind in terms of drilling speed and well construction costs: (1) due to incomplete supporting technologies such as mud pumps and drilling fluid systems, the drilling cycle of shale gas wells in Weiyuan area of Sichuan Basin is 70-80 days, while the drilling cycle of shale gas wells in North America is only 12 to 20 days. (2) the long drilling cycle leads to a high construction cost: for a shale gas horizontal well with a horizontal section of 2 000 m long, the cost is about RMB 3 000×104 Yuan in North America, while the cost is 500×104 Yuan in CNPC, or 2.17 times that in North America.

Factory-like operation is an inevitable way to develop unconventional resources. However, CNPC has a long way to go before putting in place a truly efficient “well factory” model. Compared with North America, it has a smaller average number of wells on platform, poorer continuous operation capacity, and longer well construction period, restricting the efficiency in the “factory-like operation”: (1) The number of wells on a single platform is small, only about 6-8 wells, not conducive to batch line operations to enhance efficiency. (2) Restricted by technical maturity and operation level, downtime (or waiting time) for handling downhole conditions during drilling and fracturing is longer in China. For instance, domestically, for double-rig platform with 6 wells, the well construction period is 230-340 days, while the period is 240-280 days for a platform with 16 wells of Apache in North America.

4. Future work

4.1. To strengthen integration and application of low-cost technologies in light of the worsening of resource grade

Centering on safety, environmental protection, quality and efficiency, starting from program optimization and design, region-specific policies should be designed, selection of economical technologies and comprehensive support facilities should be strengthened, to ultimately achieve cost reduction and efficiency improvement through optimizing the well type and well structure, strengthening ancillary equipment, intensifying drilling parameters and reducing drilling fluid volume used, and carrying out other technical research.

In terms of drilling technology, drilling technology for ultra-long horizontal wells should be developed to improve the drilling-encounter ratio of good quality unconventional reservoirs and extend the life cycle of oil and gas wells. The research will focus on the following three aspects: (1) key technologies such as intelligent drilling rigs and rotating geosteering measurement and control system; (2) nanometer drill bits, high-strength and light special alloy drill pipes, and high-performance drilling and completion fluids; (3) 3D multi-layer horizontal well patterns and integrated engineering and geology drilling technology.

In terms of completion technology, fracture controlling fracturing technology should be adopted to stimulate tight reservoirs and improve the fracturing effect[17]. Through integrated research of geological conditions and engineering, the actual expansion pattern of cracks in the reservoir will be figured out to optimize well placement scheme and fracturing stage length and fracture spacing. Meanwhile, large-scale functional fracturing will be adopted to promote the transformation of the development mode of tight reservoirs. At the same time of fracturing, formation energy will be replenished to the same layer to enhance the ultimate recovery in a synchronous manner. The main technical means are: (1) to develop fracturing optimization design software integrating geological and engineering factors to achieve the best control of low-grade reservoir resources by fractures through fracture system optimization; (2) to develop efficient multi-functional fracturing fluid system to make full use fracturing, energy storage and imbibition displacement of fracturing fluid; (3) to give priority to the application of large-scale, low-cost fracturing technologies during on-site operation to realize one- time well completion and fracturing as far as possible.

In terms of the capacity guarantee of fracturing equipment, the capacity of fracturing equipment will be enhanced so as to increase the total water horsepower of domestic fracturing pump trucks in a short time. In terms of technical research: (1) The performance of the 2500 diesel-powered fracturing pump trucks currently in common use needs be improved, the service life of manifold products needs to be extended, and the safety and reliability of construction operations needs to be upgraded. (2) A complete set of electric fracturing equipment including series of electric fracturing pump equipment and power supply systems, electronic control systems, equipment configuration, and construction control research should be carried out to improve construction efficiency and achieve safe operation, environmental protection and noise reduction.

In terms of cost reduction, by replacing ceramsite with quartz sand and simplifying fracturing fluid formulation (replacement rate of fracturing proppant with quartz sand in unconventional oil and gas reservoirs in North America is as high as 69%-100%, as against only 20%-30% in China), the materials costs would be lowered and the proppant dosage used in unconventional reservoirs would increase while reducing costs. Meanwhile, a systematic and sound “factory-like” mode will be established to cut back costs and enhance efficiency of drilling and completion. Specific measures include: (1) to adopt large-platform multi-well mode, implement the development scheme ahead of schedule, carry out multi-year planning and unified deployment, and ensure the continuity of the whole process from drilling, fracturing to flowback fluid recycling and treatment; (2) to enhance on-site operation skills and efficiency to guarantee continuous work without downtime; (3) to develop noiseless drilling and fracturing technologies to achieve uninterrupted work 24 hours a day and enhance well construction efficiency.

4.2. To research, develop, and promote key technologies keeping production of old oil and gas fields stable

(1) The level of fine management and the potential for saving energy will be enhanced by optimizing the artificial lift system. Specifically, the measures will be taken include promoting digitalization of oilfields, speeding up popularize of the oil and gas production optimization decision-making platform, and giving full play to the cluster effect of Internet plus technology; big data intelligent analysis and decision-making system will be developed to digitalize well construction; lifting equipment, rodless energy-saving lifting in particular which can save energy and is highly efficiently, will be developed and popularized; with the reliability of hydraulic system improving year by year, hydraulic pumping units will be developed vigorously.

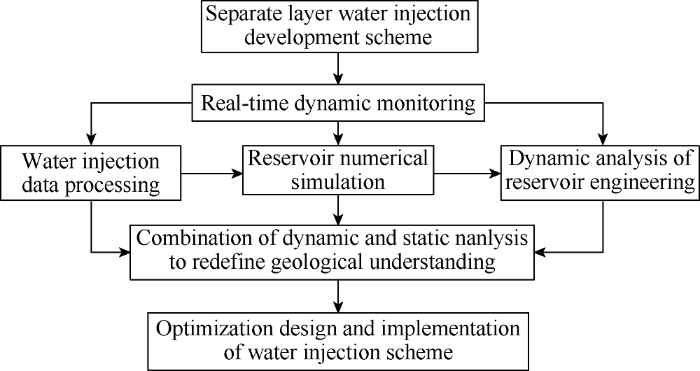

(2) Putting emphasis on separate layer water injection, the fourth generation of water injection technology will be promoted forcefully to truly realize the integration of reservoirs and engineering and enhance the development degree of flooding. Specifically, an platform integrating reservoir geological and engineering factors will be established (Fig. 3) to achieve the real-time monitoring of parameters such as layered pressure and flow rate; real-time dynamic production analysis and numerical simulation will be conducted to reconstruct the geological understanding of reservoirs by combining dynamic and static data; the water injection scheme will be optimized to realize dynamic adjustment in a real-time manner; the flooding effect will be analyzed and evaluated and then after flooding scheme adjustment, parameters of each layer will be re-monitered for re-optimization of the injection scheme.

Fig. 3.

Fig. 3.

Flow of separate layer water injection integrating geological and engineering conditions.

(3) We will make unremitting efforts in technical research, with a focus on refracturing to maximize the potential of remaining oil and gas. Through research on the dynamic relationship between remaining oil and the dynamic stress field space and refracturing technology for horizontal wells, the production decline of tight oil and gas and other unconventional resources will be put off.

4.3. Technology in reservation for future development

In order to meet CNPC’s major demand for oil and gas production and address a variety of challenges brought about by complicated reservoirs in the future, CNPC has committed to 3 forward-looking technical research programs in oil and gas engineering to gain power for future development.

(1) Downhole oil & water separation. Developed for wells with ultra-high water cut of more than 95%, the technology enables downhole oil and water separation, greatly reducing energy consumption in the process of lifting, gathering and transportation and water treatment and cutting back development costs. It has the following typical characteristics: highly efficient cyclone separation, with single-stage separation efficiency of over 98%; independent adjustment to lifting and re-injection and high adaptability; and real-time monitoring of parameters such as re-injection flowrate and pressure. At present, the technology has been used in pilot tests of 20 wells in oil fields, with the ground water cut dropping by over 70% on average.

(2) Water flooding with nanomaterials. At present, injected water can’t get into about 30% of small pores in low-permeability/ultra-low permeability reservoirs. For these impermeable pore areas, QS-SiO2, the first generation nano-oil displacing agent has been developed. Preliminary tests show that in the 1μm hydrophilic capillary, the flooding startup pressure gradient of the nano-oil displacing agent is only 0.09 MPa/m (as against 2.98 MPa/m of the normal water startup pressure gradient), and the capillary resistance is about 1/32 of that of ordinary water. The core displacement experiments show that the flooding swept volume (55.45%) can be further increased another 13.00% on the basis of waterflooding. The main principle is that the producing of small pores increases the swept volume of low-permeability areas. Therefore, it can reduce the water flooding startup pressure of low-permeability/ultra-low permeability reservoirs, especially the “threshold” permeability of water flooding. When applied to water flooding, the technology can increase the swept volume of low-permeability area of medium to high permeability oilfields and the swept volume of low-permeability oilfields, reduce remaining oil, and significantly enhance recovery. It is, therefore, a strategic replacement technology of chemical flooding for enhancing oil recovery[18,19,20]. In addition, the nano-oil displacing agent can be used as an additive of the fracturing fluid. By weakening intermolecular and extra-molecular forces, the smart nano- oil displacing agent can enter tiny fractures to improve the local oil flow environment of the fractures. Thus, it facilitates the flow of crude oil in these tiny fractures and allows crude oil to flow from tight reservoir matrix to the fractures and the well at last.

(3) High-energy metal battery technology. In the battery, the high-energy metal plate is used as the anode and the multi-layer catalytic composite material is used as the cathode, which react directly in water to generate electricity. With zero pollution and a long service life, the battery can be used both on the ground and down in the well. Therefore, it can provide electric power to electrical equipment in the oil and gas fields. At present, researches on basic metal battery construction, high-energy metal discharge mechanisms, and metal anode material optimization have been completed, and a variety of power supply devices including multi-layer composite cathodes based on catalysts have been structured and prepared.

5. Conclusions

CNPC has made considerable progress in key technologies for oil and gas production in recent years. Nevertheless, it still faces many challenges, including the effective development of low quality resources, stable production of old oilfields, cost-effective development of major oilfields with high water cut and a high natural decline, and the development of deep unconventional resources.

During the “13th Five-Year Plan” period and for a period of time to come, CNPC must carry out technical research on the fracture controlling fracturing and the integrated application of factory operation and other low-cost technologies, develop key refracturing technology for old wells in mature oilfields, and promote the fourth generation multi-layer water injection technology, water injection with nanomaterial and injecting and producing in one well technologies, so as to better support the sustainable development of oil and gas fields in China.

Reference

Unconventional hydrocarbon resources in China and the prospect of exploration and development

DOI:10.1016/S1876-3804(12)60026-3

URL

[Cited within: 1]

Based on analysis of the characteristics of unconventional hydrocarbon resources, this paper assesses the potential for unconventional hydrocarbons in China, summarizes the key technical progress in exploration and development, and discusses the prospects and developing strategies of unconventional hydrocarbons. The resources of unconventional oil and gas in China are abundant. The recoverable tight gas ranges from 8.8×1012 m3 to 12.1×1012 m3, the recoverable shale gas is from 15×1012 m3 to 25×1012 m3, the recoverable coalbed methane 10.9×1012 m3, the recoverable tight oil from 13×108 t to 14×108 t, and the recoverable shale oil 160×108 t. There is also some resource potential for oil sand. Such key techniques as the full-digital seismic exploration, low permeability and low resistivity reservoirs identification have been developed and their applications in oil and gas fields have achieved good results. Tight gas and tight oil are the most realistic resources to develop in China and the development and utilization of coalbed methane and shale gas are at a pioneer stage. In the next ten or twenty years, the production of unconventional hydrocarbon in China will increase considerably and play a major role in national hydrocarbon resources.

Geological features, major discoveries and unconventional petroleum geology in the global petroleum exploration

DOI:10.1016/S1876-3804(10)60021-3

URL

[Cited within: 1]

Large and extra-large oil/gas fields are mainly distributed in Tethys areas, passive margins, foreland thrust belts, and craton basins in the world. Unconventional oil/gas fields are mainly distributed in foreland slopes, basin (depression) centers, craton synclines, and tundra. Since the 21 st century, the major exploration discoveries across the globe have been mainly concentrated in the deep water area of passive margins, carbonate rock, lithologic-stratigraphic zone, foreland thrust belt, mature exploration area, new basin and unconventional oil/gas reservoir (field). These major discoveries involve conventional and unconventional oil/gas resources. The conventional oil geology stresses the oil/gas migration and reservoir-forming rules in individual traps; the unconventional oil geology focuses on unconventional resources, reservoir, reservoir-formation and technologies. The geological features, classification program, research content, evaluation method and exploration phase of unconventional oil/gas reservoirs (fields) are different from those of conventional ones. Research should be strengthened on unconventional oil geology to develop unconventional oil geological theories.

Optimized design of oil and gas well production system and diagnostic and decision- making software (PetroPE) V1.0

Based on diversified artificial lifting process and a large amount of oil and gas wells, including the present conditions of deflecting wells, low-yield wells and high water-cut wells, as well as the technological demand of engineers, the first set of large-scale web-based diagnostic and decision-making software was successfully developed with our independent intellectual property right.It can satisfy the need for optimization of design, diagnosis of working conditions and management of production for more than 80 percent of China's oil and gas wells. It can be put on line for data sharing. The latest industrial technology was integrated into this software to create the way to optimize the quantitative lifting method, make a breakthrough in 3D mechanical analysis of wellbore, come up with the design conception on coordination of production, energy consumption and service life and the conception on performance of the equivalent system, and establish the new method for appraisal of the system efficiency. The software reached the international advanced level. With good results of field application and reduction of energy consumption, the system will become the effective tool for optimization of design and management of production.

A nano-particle foam unloading agent applied in unloading liquid of deep gas well

DOI:10.1016/S1876-3804(16)30081-7

URL

[Cited within: 1]

To solve the problem of unloading liquid of deep gas well with high gas temperature and salinity, high concentrations of H2S gas and condensate oil, a nanoparticle foam unloading agent was developed and evaluated, and the field test was carried out. The liquid phase foam unloading agent was prepared by blending high temperature resistant anionic surfactant, high salinity and H2S resistant zwitterionic surfactant and the condensate oil resistant fluorocarbon surfactant. The nanoparticle foam unloading agent was developed by introducing silane coupling agent modified nano silica spheres into the liquid phase foam unloading agent as the solid foam stabilizer. The property of nanoparticle foam unloading agent was studied through lab experiment, and the results show that: the agent has temperature resistance as high as 150 C, salinity resistance up to 250 g/L, H2S resistance up to 0.04%, condensate oil resistance up to 30%, which proves high foaming ability and foam stabilizing ability. The optical microscope and zeta potential results show that: the mechanism of enhancing the property of liquid phase foam unloading agent by nanoparticles lies in the fact that the nanoparticles can adsorb onto the gas-water interface to form a solid particle film, and it has the best foam stabilizing effect at the modified nano-silica sphere concentration of about 0.002%. The field test results show that: the agent has steady performance, meets the site construction requirements, and can improve the water drainage gas recovery efficiency in gas well and reduce the cost.

Volume fracturing technology of unconventional reservoirs: Connotation, optimization design and implementation

DOI:10.1016/S1876-3804(12)60054-8

URL

[Cited within: 1]

The connotation, design optimization and implementation of the Volume Fracturing technique are discussed. The connotation includes five aspects as follows: (1) break up reservoirs to form complex fracture network, and “artificial” permeability; (2) the fracture initiation involving not only single open-fracture but shear failure and slip; (3) “breakthrough” the traditional fracturing seepage theory model, greatly shorten the effective fluid seepage distance; (4) more suitable for highly brittle formations; and (5) multi-stage and multi-cluster perforation mode to improve well productivity. Research shows that: the time required to seep through matrix with 0.000001 × 10613 μm2 permeability to fracture for 100 m distance is about more than 100 × 104 years, and only Volume Fracturing can realize the “shortest distance”seepage. Cluster spacing optimization, non-uniform stage (cluster) interval and proppant filling mode are the key to achieve Volume Fracturing. Small cluster interval technology, multiple stop-injection construction mode and tip screen-out fracturing technology are the key techniques to realize Volume Fracturing in low brittle formations. Volume fracturing technique has a good application prospect in tight oil (gas), volcanic and carbonate reservoirs, and the further developed “integrated” volume fracturing (based on multi-layer and multi-branch well technology) is the future development direction for unconventional resources.

The core theories and key optimization designs of volume stimulation technology for unconventional reservoirs

DOI:10.7623/syxb201404011

URL

[Cited within: 1]

The key for effective development of shale gas reservoirs with nano-darcy permeability in North America is maximizing stimulated reservoir volume,which in terms of technology system,is called "volume stimulation technology".It emphasizes "breaking up" reservoir to get the largest contact area between fracture surface and reservoir matrix,further achieving three dimensions stimulation of the reservoir.In this study,volume stimulation technology is defined in "narrow" and "broad" sense according to different characteristics of shale and tight gas reservoirs.The "narrow-sense" definition is derived from three elements including object(shale),technology(horizontal well drilling fracturing),and verification(micro seismic fracture diagnosis).The " broad-sense" definition refers to multi-interval horizontal well and multi-layer vertical well fracturing techniques for tight oil and gas reservoirs.Despite their different objects of reservoir,two techniques have the same ultimate goal.The core theory of volume stimulation technique is proposed as follows: "breaking up" the reservoirs to form complex fracture networks for artificial permeation,enabling porous flow from the matrix to the fracture in the shortest distance,and maximally reducing the driving pressure of oil and gas flow in the matrix.Further,the core reservoir conditions for volume stimulation are put forward,including obvious brittleness,development of natural fractures and bedding,and small difference between the maximum and minimum stresses.Here the brittleness index measures the speed(or difficulty) of transient changes(i.e.,fracture formation and expansion) prior to the breaking of the rocks.The key optimization design for volume stimulation includes 'reversal design',multi-cluster perforation,and optimization of hole number and fracture spacing.Field test demonstrates that multi-cluster perforation ensures the effective opening of each cluster with an optimal hole number of 40 to 50.The relationship between optimal hole number and output volume can be obtained,and the smaller fracture spacing,the easier fracture reorientation.Additionally,theoretical models and calculation results of perforation optimization,optimal fracture spacing for achieving stress interference,and matrix segmentation are presented.The above theory and optimization design of volume stimulation technology have great guidance value for improving the post-fracturing performance of unconventional reservoirs.

Concept, technology and practice of “man-made reservoirs” development

DOI:10.1016/S1876-3804(17)30019-8

URL

[Cited within: 1]

Oil and gas resources in low permeability and unconventional reservoirs are playing more and more important role in global energy supply, and are confronted with pressing problems in hard development, quick production decline, low recovery efficiency and high exploitation cost. Therefore, new development concept “man-made reservoirs” and a complete set of techniques and methods are proposed. With “sweet spots” as units, an integrated way of fracturing, injection and recovery is presented for the low permeability oil and gas resources to reconstruct the underground seepage field and petroleum output system and finally to realize enhancement of the recovery efficiency. Well-group development, fracturing and targeted fluid injection are applied to change the underground seepage field, supplement the formation energy, and form “man-made high permeability area” and “reconstructed seepage field”. By integration of information technology including big data, cloud computing, artificial intelligence etc., an integrated information management platform of “man-made reservoirs” including geology, development, production, management and decision has been set up, and large-scale, effective and sustainable development of this kind of resources are realized. Five series techniques are developed including 3D seismic geological evaluation for sweet spot area, well-group platform development, intellectual volume fracture, imbibition displacement and energy complement development, and intellectual management development based on cloud computing for “man-made reservoir”. In China, five blocks of shale gas and tight oil have been tested 235 times, and the effect of tight oil fracturing and output was 2 times better than that before, has achieved business development and showed bright perspectives.

Connotation, application and prospect of the fourth-generation separated layer water injection technology

DOI:10.1016/S1876-3804(17)30073-3 URL [Cited within: 1]

Deep fluid diverting mechanism of soft diverting agent

Soft diverting agent features high chemical stability.Uniaxial extension and compression tests indicate that the agent could be deformed randomly and hard to be broken for its high tenacity.1D pore throat model tests indicate that there is an exponential relationship between threshold-pressure of the agent and throat-particle diameter ratio.If the formation pressure differential is higher than the threshold-pressure,the agent can move;otherwise,the agent will remain in the reservoir.Network model test indicates that the particles of the agent migrate alternatively in four forms: elastic deformation,plastic deformation,grain generation and grain conglutinating,and are distributed at microthroats in the formations like skirmishers,thus forming a temporary plugging peristalsis strip through overlapping to realize the whole-process profile control over the formation and finally settle at the deep section of the reservoir,so the diverting of deep fluid is completed.The field test of Guan74 block in Wangguantun Oilfield,with expected results obtained,illustrated that the soft diverting agent can overcome the problems of inefficient circulating of injected water in large pore channels between oil and water wells and of the low sweep efficiency in late development of high water cut oilfields.

A novel particle-type polymer and IOR/EOR property evalution

The economic analysis and application strategies of EOR technology in low-oil-price period

Development and performance evaluation of a novel high temperature resistant expansive polymer material

The “fracture- controlled reserves” based stimulation technology for unconventional oil and gas reservoirs

To solve the problems facing the economic development of unconventional oil and gas, a new concept and corresponding technology system of reservoir stimulation based on "fracture-controlled reserves" are put forward. The "fracture-controlled reserves" stimulation technology is to realize the three-dimensional producing and economic and efficient development of unconventional hydrocarbon resources by forming a fracture system that well matches "sweet spots" and "non-sweet spots". The technical route of the stimulation technology is "three optimizations and controls", that is, control the scope of sand body through optimizing well spacing, control the recoverable reserves through optimizing fracture system, and control the single well production reduction through optimizing energy complement method. The "fracture-controlled reserves" stimulation emphasizes the maximization of the initial stimulation coefficient, the integration of energy replenishment, stimulation and production, and prolonging the re-fracturing cycle or avoiding re-fracturing. It aims at realizing the three-dimensional full producing and efficient development of reservoir in vertical and horizontal directions and achieving the large-scale, sustainable and high profitable development of unconventional oil and gas resources. The stimulation technology was used to perform 20 pilot projects in five typical tight-oil, shale gas blocks in China. The fracturing and producing effects of tight oil improved and the commercial development for shale gas was realized.

Molecular dynamics simulation of adsorption behavior of alkly-modified SiO2 nanoparticles at oil/water interface

Discussion on expanding swept volume technique of water flooding in low permeability oilfield

A facial route for preparation of hydrophobic nano-silica modified by silane coupling agents

DOI:10.4028/www.scientific.net/KEM.727.353

URL

[Cited within: 1]

Nano-silica was prepared using tetraethylorthosilicate (TEOS) as precursor by sol-gel technology based on st0102ber method. These silica nanoparticals were further modified with silane coupling agents, i.e., Hexadecyltrimethoxysilane (HDTMS), dimethoxydiphenylsilane (DMMPS), to introduce organic functional groups on the surface of SiO2 nanoparticles. The Fourier transform-infrared (FTIR) spectra indicated that these silane coupling agents were anchored on the surface of silica particles. And the obtained organic090009inorganic hybrid SiO2 particles showed an improvement in hydrophobicity, which can effectively inhibit these silica particles from aggregating.