Introduction

With the exploration and development of terrestrial clastic reservoirs for about 100 years in China, especially the development practice in the recent 60 years, many complex geological and development engineering problems have been solved, and great progress has been made in both development theory and practice. Terrestrial oilfields in China are characterized by multiple oil layers with strong heterogeneity, thus, studies must be carried out by a layer-by-layer manner in order to develop these oilfields effectively, the. Therefore, the “separate layer development theory” is fundamental for the terrestrial oilfield development [1]. However, the exploration and development of the marine carbonate oilfield, especially the heterogeneous fractured-vuggy reservoir with uneven fractured-vuggy body as the main oil storage space and development unit, is totally different from the traditional layered clastic reservoirs and fractured-porous carbonate reservoirs, in both development idea, technology and method and reservoir structure description and percolation mechanisms etc[2].

The carbonate fractured-vuggy reservoirs in the Tarim Basin are of a special kind, which comprise many huge caves and large vugs as well as large fractures. The dissolution caves are several to tens of meters in size, mostly “hall-type” or “corridor-type”, and often filled by the solids of different origins. The caves and fractures are distributed in disorder manner, resulting in many difficulties to development. There is no precedent of this type of reservoir development in terms of geophysical engineering, drilling engineering, reservoir stimulation, reservoir engineering, and EOR. Considering the irregular vug (cave) shape, different vug (cave) sizes and complicated oil-water relation of fractured-vuggy reservoirs. Starting with the identification and structural description of three-dimensional fractures and vugs body, researchers continuously sum up the oilfield development experiences, examine the development characteristics and distribution mechanisms of different scales of fractured-vuggy bodies, and have made great progress in both theory and application.

Through years of exploration, research and practice, the researchers in Tahe oilfield have put forward an idea of “volumetric development” for fractured-vuggy carbonate reservoirs, and established the corresponding technology and management model centering on “the 3D fractured-vuggy body, multi well-type volumetric development exploitation, multi-technology volumetric development, and multi injecting-media volumetric injection-production”, enabling the whole process volume development of one or multiple fractured-vuggy bodies in an all-round way[3,4,5,6,7,8]. During the “12th Five Year Plan”, the Tahe carbonate reservoirs have maintained production at more than 600×104 t annually. By the end of 2018, the produced geologic reserves of Tahe oilfield reached 9.1×108 t, and the new recoverable reserves amounted to 1.4×108 t, realizing continuous production increase and high-efficient development of this type of reservoir.

1. Particularities of Tahe fractured-vuggy reservoir development

1.1. Concept and meaning of fractured-vuggy unit

The Ordovician fractured-vuggy carbonate reservoirs are very special. Buried at 5 350-6 200 m, the reservoirs are very tight, the tight oil-free matrix and the fractures, pores and vugs (caves) formed by multi-stages of tectonic movements and karstification, combine in various patterns in space and differ vastly in scale, including dissolved pores at micrometer level, fractures at millimeter level, and caves from several to tens of meters, with 6-7 orders of magnitude apart. The vugs were empty in the early stage but later collapsed or filled, making the inner storage space more complicated in shape, shrink or even disappear. Meanwhile, the oil and water are distributed in different patterns inside the cave reservoir, which is totally different from the continuously layered sandstone reservoirs.

The development practice demonstrates that the production unit of the Tahe Ordovician oil reservoir is made up of hundreds of fractured-vuggy units with different sizes. The fractured-vuggy unit refers to an aggregate uniform hydrodynamic system comprising one or multiple vugs connected by fractures which are separated by a widely distributed matrix of poor permeability. Large caves serve as the major storage space, while the fracture system serves as the connective path between the caves and also the secondary storage space. The internal structure of the fractured-vuggy unit is very complicated. Experiencing superimposed reformation of karstification in Caledonian and Hercynian periods, the main body of the Tahe oilfield is typical weathered karst landform. Large dissolved caves are controlled by ancient fractures, ancient faults, and peleoflows and peleo-environment. They are strongly heterogeneous in distribution, and each fractured-vuggy unit has an independent oil-water system. The oil well connecting independent vug body often has a high production in the initial stage and a followed rapid declines, while the oil well connecting multiple vug bodies often has both high production which maintains a long and stable stage.

1.2. Concept and meaning of “volumetric development”

Focusing on the characteristics of the Tahe fractured-vuggy carbonate reservoir, we have put forward the concept of “volumetric development” after long time exploring and probing, which includes two aspects of meanings:

(1) The flowing mechanism is completely different from that of terrestrial multi-layer clastic reservoirs. The vugs, fractures and dissolved pores inside the fractured-vuggy unit are different in scale, leading to different flow states that comply with different flow regimes. The flow in the microscopic and small fractures and dissolved pores complies with Darcy’s law, while the flow in medium-sized fractures and dissolved vugs complies with the nonlinear Darcy’s law or tube flow; whereas as the main body of reservoir space, the large dissolved caves are empty inside, where the flow complies with the vug flow described by Navies-Stokes equation. With the recovery going on, the oil-water contact inside the vug rises constantly, showing as dynamic contact[11,12,13].

When a well is drilled into vugs and commences production, the bottom hole flowing pressure (BHFP) drops, and the pressure drop quickly spreads to the whole fracture-vug system including the fractures and dissolved pores, etc., and the fluids in different media flow comply with their own rules flowing into the cave and are recovered by the well at last. The fluid in the fractured-vuggy unit flows as a whole and is produced gradually, this is one of the “volumetric development” mechanisms.

If there is original formation water or bottom water inside the vug (cave), there would be an oil-water contact (OWC) in the vug; when flowing to the vuggy cavity through the fracture, the formation fluid meets little resistance as there is no capillary force, the driving force for the fluid is mainly gravity. Due to density differences, all the fluids (oil and water) entering the vugs take on gravity differentiation, as a result, water goes downward and oil upward. As the production going on, the OWC rises, pushing the oil in the upper part to the well. When the injected water enters the vugs, due to the same density difference, the oil rapidly separates from water, the sinking of water would push the OWC upward, driving the oil above the OWC to the well while keeping sufficient formation pressure. Apparently, no matter it is depletion recovery or water-flooding, the oil water two-phase flow in the large and medium-sized vugs mainly shows the spatial replacement between the oil and water, which is a major rule of the oil and water flow and another “volumetric development” mechanism.

(2) In the development of the fractured-vuggy reservoir, the oil and gas in fractured-vuggy bodies controlled by the well and around the well will be produced body by body, realizing “volumetric development” of the fractured-vuggy carbonate reservoir.

After over 20 years of research and exploration and development practice, we have got a deeper and deeper understanding on the fractured-vuggy reservoir, and made great progress in the rolling development evaluation, volumetric reserve producing and residual oil development in the carbonate fractured-vuggy reservoir. Through the stereoscopic description of fractured-vuggy bodies of different sizes and shapes, research into the well-vug position and spatial fracture-vug configuration, and re-discovering the connecting relationship inside the vugs, multiple well types (vertical, large deviation and short-radius sidetrack) have been adopted to realize the volumetric control and producing of reserves in fractured-vuggy bodies controlled by and around the well. Deep penetration acid fracturing, volumetric acid fracturing, high pressure water injection combined with acid fracturing have been adopted to realize the stereoscopic recovery of oil in the vugs around the well. By making use of the density difference between water and nitrogen, the EOR technology to produce residual oil at the bottom, periphery and top of the fractured-vuggy bodies, has been established, special volumetric development management of fractured-vuggy reservoir has been established, realizing high efficient and orderly development of this kind of special unconventional reservoir.

2. Key technologies and knowledge of the volumetric development of the Tahe fractured-vuggy reservoir

2.1. 3D depiction and volumetric reserve recovery of the fractured-vuggy body

2.1.1. 3D spatial depiction of the fractured-vuggy body

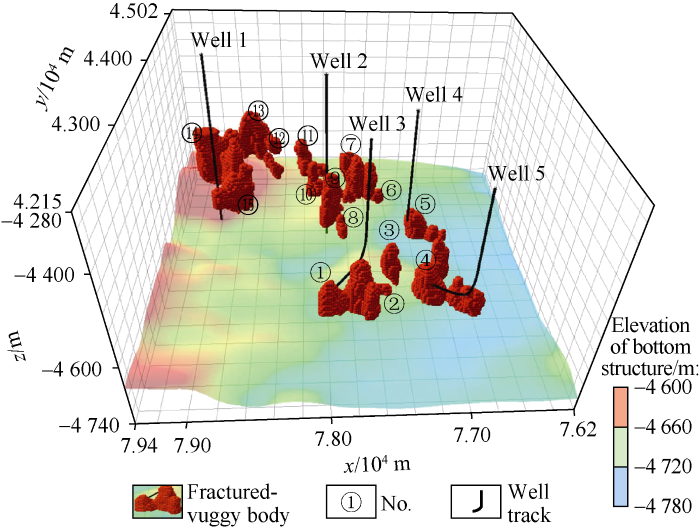

The deep burial of the fractured-vuggy body and the limited seismic data resolution make it difficult to identify and predict fractured-vuggy bodies. In the past few years, with the progress in the 3D high-resolution seismic survey and depth migration processing, we have a better understanding of seismic responses of the fractured-vuggy body. According to the high-precision 3D seismic image processing, forward modeling and comparison of seismic reflection features of high-production fractured-vuggy bodies, it is found that beaded reflections on the seismic section are the most typical feature of dissolved cave. Therefore, in development, fractured-vuggy bodies were identified and well locations were designed in places where beaded strong reflection, chaotic reflection and strong amplitude occur[14,15]. A series of technologies including the multi-attribute integration (amplitude, wave impedance, frequency division frequency and discontinuity, etc.), 3D visualization and seed point track have been innovated to depict the geometric shape and spatial distribution of seismic anomalies at different depths, enabling characterization of the 3D connecting relationship and configuration of fractures and vugs. Hence the apparent volume and reserve scale of the fractured-vuggy body can be assessed (Fig. 1, Table 1), promoting the fracture-vug identification and prediction from 2D to 3D, and laying a foundation for the volumetric development and stereoscopic tapping on the fractured-vuggy bodies around and between the wells with multiple well types (vertical, large deviation, horizontal and short radius sidetrack) and technologies of deep penetration acid fracturing, volumetric acid fracturing, high pressure water injection, and acid fracturing.

Fig. 1.

Fig. 1.

Spatial distribution of fractured-vuggy body depicted with 3D seismic data.

Table 1 Apparent volume and oil initially in place (OIIP) of different fractured-vuggy bodies.

| No. | Apparent Volume/106 m3 | OIIP/ 104 t | No. | Apparent Volume/106 m3 | OIIP/ 104 t |

|---|---|---|---|---|---|

| 1 | 41.44 | 56.34 | 9 | 20.59 | 27.96 |

| 2 | 0.75 | 1.02 | 10 | 6.19 | 8.40 |

| 3 | 6.44 | 8.76 | 11 | 6.84 | 9.30 |

| 4 | 40.52 | 55.02 | 12 | 2.92 | 3.96 |

| 5 | 11.50 | 15.63 | 13 | 27.29 | 37.05 |

| 6 | 1.25 | 1.71 | 14 | 44.98 | 61.08 |

| 7 | 29.99 | 40.71 | 15 | 54.27 | 73.71 |

| 8 | 1.79 | 2.43 |

2.1.2. Well deployment modes of volumetric development of fractured-vuggy body

The connotation of the fractured-vuggy body volumetric development with drilling method is: according to the distribution, scale, and size of fractured-vuggy bodies, to control and produce multiple fractured-vuggy bodies at different depths in vertical direction, and control and gradually produce all the fractured-vuggy bodies around the well with vertical well plus multiple sidetracks, so the well deployment mode of “one well controlling multiple fractured-vuggy bodies horizontally and vertically” has been established to maximize the control of the fractured-vuggy bodies and realize high efficient development. Through years of development practice, the production capacity construction pattern of deploying wells according to vug distribution, developing body by body and rolling production capacity building has been taken shape gradually. Well deployment follows the principle of “considering the good bodies first and poor bodies secondly”, aiming at drilling large-sized fractured-vuggy bodies mainly and medium-small ones secondarily. The bodies of different scales at different depths are generally controlled and produced in batches.

During the “12th Five Year Plan”, the volumetric develop-ment was taken to produce oil from the fractured-vuggy bodies one by one, totally 682 fractured-vuggy body groups were produced with vertical wells, with a productivity of 432×104 t; 97 medium-small vugs were tapped with sidetrack wells, with a productivity of 72×104 t, and the newly recoverable reserves amount to 270×104 t.

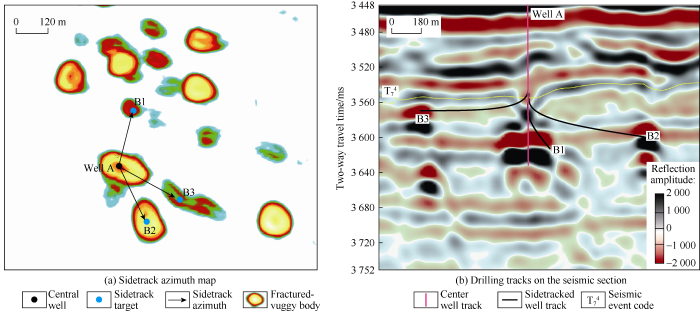

2.1.2.1. Horizontal control and production

For the large vug groups and relatively independent medium-small bodies 0-60 m below the weathering crust, wells are deployed in two ways for two situations (Fig. 2): (1) Drilling vertical wells to preferentially produce the large bodies at the center of the group, later using short-radius (horizontal displacement less than 200 m from the central well) directional side track to gradually produce the residual oil inside the large vugs. (2) For the relatively independent fractured-vuggy bodies around the well (200-800 m horizontal displacement from the central well), following the principle of “bodies close to the well first and bodies far from the well second, big ones first and small ones second”, the fractured-vuggy bodies at different depths of different scales inside the range of 360° were produced by the casing windowing and open hole short-radius sidetracking gradually body by body. The directional sidetrack technology not only increases the drilling rate of the fractured-vuggy body but also improves the production construction rate of oil wells, which is an effective method to produce oil and gas in fractured-vuggy bodies. For example, the vertical well TK821XCH3 was tested dry, and no production was constructed; it was sidetracked to the due north yet produced 0.2×104 t of oil in total, later it was shut down due to the sand burial at the bottom. It was sidetracked toward southwest secondly, produced 0.9×104 t of oil in total and then was shut down due to the insufficient fluid supply. Thirdly, it was sidetracked toward northwest and produced 1.9×104 t of oil cumulatively, realizing the producing of three fractured-vuggy bodies one by one around the well.

Fig. 2.

Fig. 2.

Sidetracking multi-vugs in multi-directions.

2.1.2.2. Vertical control and production

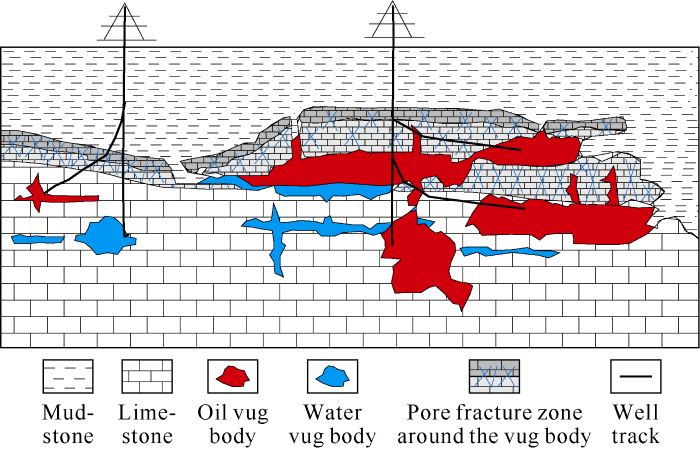

For fractured-vuggy bodies, 60-200 m or deeper below the weathering crust, vertical or large deviation wells are used to generally develop the individual bodies. The vertical well shall penetrate as many bodies as possible, and the bodies at different depths were produced from the bottom up gradually. For the bodies that cannot be produced with vertical well, the large deviation well was employed to reach multiple bodies at their top (Fig. 3).

Fig. 3.

Fig. 3.

Volumetric development mode for fractured-vuggy bodies by vertical and sidetracked wells.

The weathering karst zone in the northern Tahe oilfield has several sets of fractured-vuggy bodies vertically and several sets of underground streams locally, where the drilling rate of fractures and vugs is up to 51.3%, and the vugs are 8.6 m high on average. The reserves are tapped with vertical or large deviation wells. For example, Well T738 drilled two vugs, the first is at 127-155 m below the weathering crust and produced 11×104 t of oil totally after acid fracturing, and the second is 38-50 m below the weathering crust and produced 11×104 t of oil cumulatively after acid fracturing, with a total oil production of 13×104 t. In contrast, the vugs in the southern Tahe, Yuejin, and Shunbei areas are apparently controlled by fault zones, forming “narrow, long and deep” “tabular bodies”[16,17,18,19], allowing developing the fractured-vuggy bodies vertically. The development practice shows that different segments in the strike-slip zone should take the development strategies: for the compressional segment, horizontal wells (or large deviation wells) should be deployed in the crushed belt, and the well can be sidetracked to two flanks multiple times to tap fractured-vuggy bodies at different depths; for the slip or tensional segment, the horizontal well should be deployed at the margin of the fault zone and cut through the fault zone obliquely, and the well can be sidetracked multiple times at different depths to extract oil in main fractured-vuggy bodies.

2.2. Volumetric development technology and knowledge of fractured-vuggy bodies around the well

In the early development stage of the Tahe oilfield, wells put into production directly after circulation loss during drilling was around 31%, about 70% of wells could not be drilled into the large fractured-vuggy bodies directly to test production, rather the reservoirs needed to be stimulated (acid fracturing, acidizing, and high pressure water injection etc.) to improve the connecting relationship between the well and the surrounding vugs to realize the volumetric development. Based on the spatial model of fractured-vuggy bodies, following the idea of “stereoscopic stimulation and volumetric development”, technologies and processes have been innovated continuously, forming a set of effective volumetric stimulation and remaining oil tapping techniques, enabling the “volumetric” employment and development of reserves around the well. For the fractured-vuggy bodies in weathering crust zones with better connectivity, the development followed the acid fracturing idea of “deep penetration, high conductivity, and single fracture”. By introducing the retarded acid system and enhancing acidizing scale, the effective etching fractures have been extended to 120 m long, increasing the probability of connecting natural fractures and vugs and meeting the requirements of oil gas development in the main area of Tahe oilfield. The reservoir research shows that some development wells drill multiple fractured-vuggy bodies, which provides the material conditions for acid fracturing of individual vugs and produce them one by one. For this purpose, the technology series of “upward and downward acid fracturing” has been formulated coring at fracture height control, enabling the volumetric production of multiple vugs vertically. For example, Well S67 has two vugs at 0-50 m and 200-220 m below weathering crust respectively. After acid fracturing of the deeper vug, the well produced 28×104 t of oil cumulatively, and then was shut in due to high water cut. Later after small- scale acid fracturing of the shallow vug, and the well produced 4.78×104 t of oil cumulatively. During the “12th Five-Year Plan”, the upward/downward stimulation was applied 189 well times, with a success rate of 67%, and cumulative oil production of 170×104 t.

Towards the issue that the oil in fault-controlling fractured-vuggy bodies in the non-principal stress direction around the well at the Tahe periphery can’t be fully produced, the volumetric acid fracturing technology has been worked out, which changes the “traditional acid fracturing” along the single direction into the “complex volumetric acid fracturing” in all directions through acid fluid pretreatment and activating natural fractures by temporary blocking agent. With this technology, the acid fracturing depth reaches 7 320 m, and effective acid etching length 140 m, allowing connecting and producing fractured-vuggy bodies less than 45° from the principal stress direction and less than 80 m from the well. This technology has been used 33 well times, with a cumulative oil production of 34.9×104 t. From 1999 to 2015, the acid fracturing was conducted 2277 well times in the Tahe oilfield, producing oil reserves of 3.5×108 t and oil of 2490×104 t cumulatively.

For more than 300 isolated fractured-vuggy bodies with low cumulative production and poor fluid supply, the technical thought of volumetric development is to open up the flow channel near the well and connect the untapped reserve far from the well, and the technologies of high pressure water injection and small constant volume expansion acidification have been come up to tap the oil in fractured-vuggy bodies far from the well. These technologies have been used 53 well times, increasing oil production by 8.6×104 t.

2.3. Technology and understanding of volumetric development on energy supplement and residual oil

2.3.1. Volumetric development of fractured-vuggy bodies with natural energy

If fractured-vuggy units are produced by natural depletion with elastic energy, the single well production would decline quickly due to energy loss, with a decline rate up to 40%- 50%, resulting in low recovery rate of 3%-5% in general. For larger vug groups, there is a great probability of natural water drive, but the natural water drive energy is insufficient, and the recovery rate would usually, increase to 10%-15%, 12.4% on average merely. Therefore, the water injection should be adopted to maintain the formation pressure and enhance the recovery rate.

2.3.2. Tapping residual oil with water injection and gas injection

Since 2005, by investigating water injection development mechanism and well-vug relationship, the high-density formation water has been injected into the vugs for huff and puff, and an injection-recovery recycling period of “water injection-shut in-oil recovery” completed. The volumetric development is fulfilled through gravity differentiation between the oil and injected water and the resulting OWC rise, after multiple rounds of huff and puff processes, the oil recovery rate in the vug can be gradually enhanced.

(1) At first, the reserve scale, natural energy, and connectivity of more than 500 large, medium and small-sized vuggy units were evaluated and classified, on this basis, the single well water injection huff-and-puff for each vug was conducted to displace the oil. For example, the first water injection huff-puff well (TK471) in Tahe oilfield drilled an isolated vug with 4.5×104 t of oil reserves and commenced production in April 2004, with the initial oil production reaching up to 430 t/d. Later the well was shut in due to insufficient oil supply. During the natural depletion period, it declined in production quickly, with a cumulative oil production of only 2 724 t, and a recovery rate of only 6.1%. In March 2005, the water injection huff-puff was implemented 15 cycles, with a cumulative injected water of 2.31×104t, cumulative oil increment of 6375 t, and recovery rate increment of 14.2%.

(2) For large group composed of multiple vugs, according to the connectivity of fractures and vugs and configuration between injection and production wells, different injection-production relations, water injection ways and parameter optimization methods were taken for different units, the technology of “water injection in low position and producing oil at higher position, and injection in fracture and production from vug” and asymmetric unstable water injection, and the development model of “stereoscopic-differentiated” water injection and energy charge for fractured-vuggy reservoir has been established. To date, 642 single fractured-vuggy bodies and 126 multi-vug units have been developed by water injection, with recovery rate increasing by 2.45%.

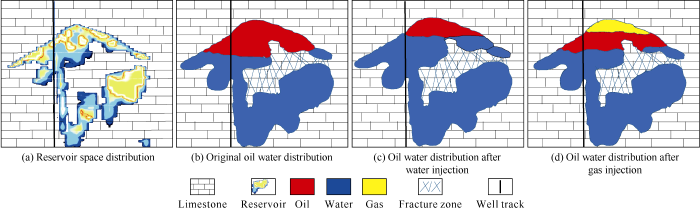

(3) In the case of water injection development, when the OWC rises to the inlet at oil well bottom, the injected water would channel into the oil well, the oil production would drop sharply, and water cut increase quickly, the oil above the inlet cannot be recovered, called “attic oil”. To produce this type of residual oil, the injecting medium must be changed, namely from water to gas from the top, then under the gravity differentiation of oil and gas, the injected gas drives the “attic oil” downward to the well and ultimately enhances the recovery rate. In Tahe oilfield, nitrogen that is easily compressed, large in expansion coefficient, and small in density was selected as top gas drive medium, and the volumetric development was conducted on the basis of density difference between the nitrogen and oil to produce the “attic oil” unable to be produced by waterflooding (Fig. 4). This kind of volumetric development was firstly tested in Well TK404 successfully and then was applied to multi-well units. The combination of nitrogen injection and water injection enables volumetric residual oil development in the fractured-vuggy bodies and enhances the recovery rate significantly. At present, nitrogen injection has been applied in 505 single vugs and 408 multi-well vuggy units, with recovery rate increasing by 2.16% periodically.

Fig. 4.

Fig. 4.

Residual oil development mode combining water and gas injection.

3. Conclusions

Through years of development practice and theoretical studies, the volumetric development idea of the fractured-vuggy body has been advanced creatively for fractured-vuggy reservoirs. The fluid flow mechanisms in volumetric development have been clarified according to the dynamic contact theory of oil-water cavity flow in hydro-mechanics. Based on a variety of methods (e.g. geophysics, drilling engineering and acid fracturing) the volumetric development theory and technology have been established. The theory implements fractured-vuggy unit as fundemantal element which is on the basis of exploration and management. This package of theory and technology has guided the scientific and high-efficient development of the Tahe fractured-vuggy reservoirs.

Based on precise depiction of the 3D spatial distribution of vuggy bodies, various well types (including vertical, deviation and horizontal) are used to develop the vug bodies one by one around the well at different depths. A volumetric development pattern is formed in which one well controls multiple fractured-vuggy bodies laterally and vertically. As a result, an overall control and batch producing of vug bodies can be realized.

Following the idea of “stereoscopic stimulation and volumetric development”, the technologies and processes have been innovated constantly, forming the retarded acid system with deep penetration and high conductivity and effective stimulation techniques with acid fracturing in complex vugs. In this way, connecting probability between the well and vugs can be improved. This technology has worked well in realizing “volumetric” production and development of reserves around wells, which results in an outstanding incremental oil recovery in field.

The enhanced oil recovery process using water and nitrogen injection in fractured-vuggy carbonate reservoir is special. Through multi-examining the injected medium develop-ment mechanisms, spatial relationship (between the well and vugs), fracture-vug conductivity and injection-production relationship, along with the gravity differentiation theory of oil, water and gas, a new method has been created. In this way, water can be injected to displace the oil in the middle-lower part of the fractured-vuggy body and nitrogen can be injected to produce the “attic oil” which is unable to be developed with water flooding. Therefore, energy supplement and volumetric development of residual oil in singe-vuggy units and multiple-vuggy elements can be realized.

The volumetric development management has ensured high-efficient development of the carbonate fractured-vuggy reservoir. The basic development procedure of this kind of reservoir complies with the principle: “whole-process evaluation, hierarchical development, and gradual deepening”. A variety of development wells, various technological methods and multiple kinds of injection media are used to enhance oil recovery by volumetric development in an all-around method on the basis of spatial configuration and reserve scale of the fractured-vuggy units.

Reference

Review and revelation of oil/gas discoveries in the Paleozoic marine strata of China

Exploration practice and experience of Tahe giant oil and gas field, Tarim Basin

Exploration practices in frontiers of Tahe oilfield

Exploration practice and prospects of giant carbonate field in the Lower Paleozoic of Tarim Basin

Oil and gas breakthrough in ultra-deep Ordovician carbonate formations in Shuntuoguole uplift, Tarim Basin

Progress and prospects of reservoir development geology

A study of the paleo-cavern system in fractured-vuggy carbonate reservoirs and oil/gas development: Taking the reservoirs in Tahe oilfield as an example

Theories and practices of carbonate reservoirs development in China

Theoretical discussion on resolution of maximum height of cavity in the Tahe oilfield based on seismic amplitude

Method and technique for prediction of super-deep carbonate reservoirs in north Tarim Basin

Significance and prospect of ultra-deep carbonate fault-karst reservoirs in Shunbei area, Tarim Basin

Characteristics and development practice of fault-karst carbonate reservoirs in Tahe area, Tarim Basin

The control action of fault to paleo-karst in view of Ordovician reservoir in Tahe area

Significance of oil and gas exploration in NE strike-slip fault belts in Shuntuoguole area of Tarim Basin