Introduction

Eastern Yunnan and western Guizhou are important coal and CBM resource areas in southern China, with the CBM geological resources of the Upper Permian accounting for approximately 10% of the whole country[1]. The coal reservoirs have the geological characteristics of numerous thin layers, high in-situ stress, low water content, and complex coal structures[2]. In order to develop CBM resources economically and effectively, the basic geological research must be done well in the initial development stage in consideration of the complex geological conditions in this area. Meanwhile, the favorable areas and layers must be selected accurately. In recent years, early development evaluations have been carried out mainly from the perspective of resources and geology. The favorable areas for development have been picked by considering the influence of gas content, permeability, reservoir pressure and structural complexity on development effect[3]. An amount of fruitful results have been obtained. However, the key work to optimize the favorable areas for the development of primarily coal seams has been constrained due to the lacking of comprehensive and detailed research on the complex geological conditions of the area. It is mainly manifested in the following aspects: (1) The geological characteristics of many thin coal seams and complex coal structures have not been fully considered. (2) Low permeability reservoirs need to be fractured. Fracability has a great influence on gas well productivity, but little research on quantitative evaluation of reservoir fracability has been done. (3) The distribution of physical properties of multi-seam and full-horizon reservoirs were described by relatively simple conventional research methods, and thus not elaborate enough. (4) The research work of "Target Selection" under the condition of multi-layer mining has not been carried out yet.

The 3D geological modeling is the effective means for reservoir description, which is mature and is mostly used to describe physical properties, sedimentary facies and structural evolution of conventional oil and gas reservoirs[4,5,6]. In recent years, a large amount of data on CBM fields has been obtained from large-scale seismic acquisition, logging interpretation and formation testing. Therefore, there are abundant reservoir physical properties data for CBM 3D geological modeling, especially for characterizing the physical properties of all coal seams in a CBM reservoir. In this study, based on the productivity equation of CBM wells, the method of dividing development units under the condition of multi-coal seams was put forward and the quantitative indexes of development unit division were worked out by considering the key physical parameters affecting the CBM production potential of coal reservoirs. Meanwhile, the 3D geological modeling technology was used to re-construct multi-seam geological body to realize fine analysis and characterization of physical properties of all seams in a reservoir. Based on the geological model and the evaluation indexes, the CBM development units of single coal seam and commingled coal seams were divided, the potential of coal reservoir was evaluated and the favorable areas for development were selected.

1. Development unit division

The appropriate division of development units for the CBM field is one of the key links for effective development of CBM. When dividing development units, it is necessary to comprehensively consider the factors such as thickness of the CBM reservoir, CBM content, permeability, coal structure, reservoir pressure and fracability of the reservoir, then formulate proper quantitative indexes for dividing development units and evaluate the production potential of the CBM reservoir accurately.

1.1. Division method of development units

Yang Zhaobiao et al.[7] proposed a “Three-Step Method” for the optimization combination of multi-coal layers based on the productivity formula of CBM wells. The selection index for main production layer defined in it can be used to evaluate the major production layer in the vertical multi-coal strata.

The production capacity formula of CBM well is:

The selection index of major production layer is:

Under the condition of multi-coal seams, the main production layer index defined by the capacity formula can be regarded as the single-layer CBM potential index. The scientific significance is that the calculation formula is similar to the production formula, and the calculation result can represent the production capacity of single coal seam. In the selection index of major production layer, the comprehensive impact coefficient B of CBM well engineering (influenced by artificial factor and hard to determine) and the bottom hole pressure p0 are neglected, as the bottom hole pressure is approximately a certain value within a tolerant variance at the stable production stage; while a coal structure factor S with veto power is added. The Eq. (2) can be used to divide planar development units of single coal seam.

In the Eq. (2), the permeability (K) is the in-situ permeability (the permeability without the reservoir stimulation), and in most cases of CBM development of the low-permeability coal reservoir, the reservoir stimulation is indispensable[8]. In order to reflect the real production capacity of the CBM reservoir after fracturing, here the permeability (K0) after fracturing is used to replace the in-situ permeability K, therefore the Eq. (2) can be corrected to:

The main geological factors affecting the permeability after fracturing are the in-situ stress[9,10,11] and the brittleness index of the coal reservoir. Brittleness index is an important evaluation index for shale reservoir fracability, it has been introduced into the evaluation of coal reservoir fracability in recent years[12]. Basically, low in-situ stress and large brittleness index of coal seam are conducive for reservoir stimulation, and the permeability after fracturing would be higher.

The permeability of coal reservoir after fracturing can be obtained by correcting the in-situ permeability with a correction coefficient.

The correction coefficient is calculated with the equation proposed by Rickman et al.[13].

According to the Eq. (3), the potential index of the single-layer CBM production layer can be calculated. The larger the value for a certain area, the greater the potential of single-layer production of the area will be, indicating that the area is a favorable block for development.

1.2. Key parameter boundaries for development unit division

Considering the simplicity and practicability of the method, the physical parameters in the calculation formula of the potential index of CBM formation were taken as the key evaluation indexes for development unit division. Furthermore, according to the actual situation and some preliminary research results of CBM exploration and development of CBM fields in eastern Yunnan and western Guizhou, the coal reservoirs were classified into I, II and III grades.

1.2.1. Coal seam thickness

The thickness of coal seam affects the gas production potential of the coal reservoir[14]. The thin, medium and thick coal seams are generally divided by 1.3 m and 3.5 m[15]. Considering the development of coal seam groups with mostly thin coal seams in the eastern Yunnan and western Guizhou, the dividing value of I, II and III grades coal seams are appropriately lowered to 1.0 m and 3.0 m, which is consistent with the lower limit (3.0 m) of the single coal seam thickness of the favorable target area in the technical specification for CBM resource exploration[16] (GB/T 29119-2012).

1.2.2. CBM content

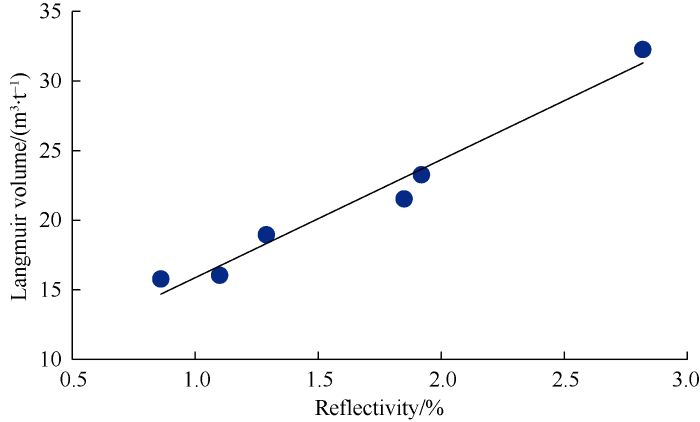

CBM content is an indispensable parameter for determining CBM resources and development potential[17,18,19]. The main coal seams in the eastern Yunnan and western Guizhou, despite wide ranks from middle to high, have higher CBM content. According to the lower limit of CBM content[20] in the CBM resource/reserve specification (DZ/T 0216-2010), the lower limit of the CBM content of the coal seam can be uniformly set at 8 m3/t, that is, the CBM content demarcation value between the class II and III coal reservoirs. Meanwhile, to obtain high yield from CBM wells in the low-permeability area of eastern Yunnan and western Guizhou, high CBM content of coal seam is particularly important[21, 22]. High CBM content of coal seam means that gas saturation and storage ratio (ratio of critical desorption pressure and reservoir pressure) are large, and the recoverability is good. The relationship between gas saturation of coal seam and daily production of single well in China from statistics shows that all CBM wells with a daily gas production of more than 1 000 m3 have gas saturation of over 60%[23], so do the high-yield wells in eastern Yunnan and western Guizhou. For example, Well YMC-1 has a gas saturation of more than 70%[22]. The coal in the study area is of medium-high rank largely. At the experimental temperature of 30 °C, the air-dried basis Langmuir volume of coal increases with the increment of coal rank (Fig. 1). The theoretical gas saturation of medium-high rank coal reaches 60%, and its average CBM content is roughly around 12-14 m3/t. Therefore, 12 m3/t can be taken as the CBM content boundary value between the class I and II coal reservoirs, with gas saturation of 60%-100% in general.

Fig. 1.

Fig. 1.

Relationship between air-dried basis Langmuir volume and reflectivity of coal samples from eastern Yunnan and western Guizhou.

1.2.3. Permeability of coal reservoir after fracturing

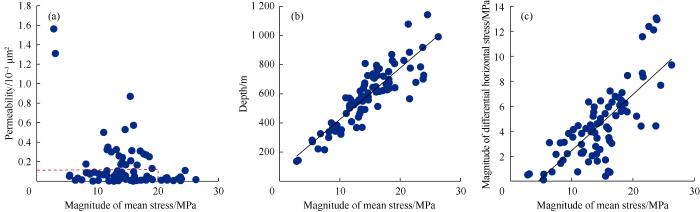

Coal seam permeability is an important geological factor affecting the mobility and developability of CBM[14, 19]. Coal seams in the eastern Yunnan and western Guizhou are commonly low in permeability, and mostly low-medium permeability reservoirs. Fu Xuehai et al.[24] defined the demarcation criterion for low and medium permeability reservoirs in China as reservoirs with in-situ permeability of less than 0.1×10-3 μm2. According to this standard, the mean boundary magnitude of ground stress can be determined to be about 20 MPa (Fig. 2a) by the relationship between the permeability of the test wells and the in-situ stress of about 80 wells in the eastern Yunnan and western Guizhou. In the meantime, the well test permeability decreases with the increase of the ground stress, and the mean value increases with the increase of buried depth (Fig. 2b). With the increase of burial depth, the permeability tends to decrease. In the process of fracturing, the smaller the differential horizontal stress is, the easier it is to form complex fracture network[25], and the more favorable it is for reservoir stimulation. The mean ground stress is positively correlated with the differential horizontal stress (Fig. 2c). Therefore, the mean ground stress is not only the main controlling factor of the original reservoir permeability, but also the main controlling factor of reservoir fracturing effect. With the increase of burial depth, the in-situ stress increases, adding difficulty to reservoir fracturing.

Fig. 2.

Fig. 2.

Relationships between mean ground stress and permeability (a), buried depth (b) and differential horizontal stress (c).

Brittleness index can reflect the complexity of fractures created after reservoir fracturing, and the higher the value, the more likely it is to form complex reticular fractures. The coal seams in San Juan and Piceance Basins of the US have an average brittleness index of 40%, and the wells there have good fracturing effect[12]. Rickman et al.[13] considered that when the rock has a brittleness index of more than 40%, it can be regarded as brittle rock. Referring to this, 40% can be taken as the demarcation value of brittleness.

According to the Eq. (4), when the in-situ permeability, average ground stress and brittleness index are 0.1×10-3 μm2, 20 MPa, 40% respectively, the calculated permeability of the coal reservoir is 0.2×10-3 μm2, this value can be taken as the permeability boundary between class I+II and III coal reservoirs after fracturing.

1.2.4. Coal reservoir pressure

CBM flow is driven by coal reservoir pressure, and the pressure increases with the increase of buried depth. Reservoirs in eastern Yunnan and western Guizhou varies from underpressure to overpressure. In the case with the same geological conditions, the higher the pressure of coal reservoir, the easier it is to drain the reservoir, and the more conducive it is to produce from the CBM well. From the actual situation of CBM development in China, the development effect is good when the reservoir pressure is over 5 MPa. Most of the high-yield wells in eastern Yunnan and western Guizhou are more than 500 m deep, and the reservoir pressure is generally above 5 MPa[21,22]. Therefore, pressure of 5 MPa can be taken as the value dividing class I+II and III coal reservoirs.

1.2.5. Coal structure

Coal structure is another important factor affecting CBM fracturing. Cataclastic coal and primary structure coal are easy to be fractured, while structural coal is almost impossible to be fractured. In the process of drainage and mining, the more fragmented the coal structure, the more pulverized coal will be produced, the more serious the crack closure will be, and the easier it is to cause blockage of drainage channel[26, 27]. Confirming coal structure is a key issue in CBM exploration and development. Generally, the geological intensity factor GSI method[28] is adopted to calculate the coal structure index, and then coal structure is interpreted from logging data. According to the degree of coal fragmentation, coal structure can be divided into four classes: primary structure coal, cataclastic coal, granulated coal and mylonite coal. When the coal structure index is greater than 45, the coal structure factor is equal to 1, which can be regarded as a quantitative index for the identification of I+II coal reservoirs; when the coal structure index is less than 45, the coal structure factor is equal to zero, which can be taken as a quantitative index for identification of class III coal reservoirs.

1.3. Quantitative index of development unit division

According to the values of the key parameters dividing coal reservoirs of Class I, II and III, the productivity potential index was calculated by Eq.(3). (1) If a single layer has a productivity potential index of greater than 36×10-15 m6·MPa/t, it can be classified into class I coal reservoir, the coal reservoirs with a productivity potential index between 8×10-15 m6·MPa/t and 36×10-15 m6·MPa/t can be classified as class II, and the coal reservoirs with a productivity potential index of or less than 8×10-15 m6·MPa/t are classified as class III. (2) The production layers need to be combined in commingled production based on combination conditions in the "Three-Step Method"[7]. That is to say, the first step is to select the main production layer in multi-coal seams according to the production layer selection index. The second step is to complete the expansion combination of the main production layers according to the combination index. The combination index mainly considers that the reservoirs should have small pressure gradient difference and critical desorption pressure difference to ensure that the reservoir fluid properties are similar, and that the main production layers produce gas smoothly and the combined production layers can produce gas collectively. The third step is to complete the optimized combination of production layers according to the productivity contribution index. Based on the economic evaluation of production layers and the second step, the production layers with poor economic value are eliminated to get combination of production layers. When the average productivity potential index of the combined production layers is greater than 36×10-15 m6·MPa/t, between 8×10-15 m6·MPa/t and 36×10-15 m6·MPa/t, and less than 8×10-15 m6·MPa/t, the areas are classified as the distribution area of class I, II, and III coal reservoirs respectively (Table 1). According to field development experience, the class I coal reservoir is the most favorable development area, class II coal reservoir is in the second place, and class III coal reservoir is the least favorable.

Table 1 Quantitative indexes for dividing CBM development units.

| Development unit class | Coal seam thickness/m | CBM content/ (m3·t-1) | Permeability after fracturing/10-3 μm2 | Reservoir pressure/MPa | Coal structure factor | Production potential index (Single or commingled layers)/(10-15 m6•MPa/t) |

|---|---|---|---|---|---|---|

| Class I | ≥3 | ≥12 | ≥0.2 | ≥5 | 1 | ≥36 |

| Class II | 1-3 | 8-12 | 8-36 | |||

| Class III | ≤1 | ≤8 | <0.2 | <5 | 0 | ≤8 |

2. Evaluation process of favorable area

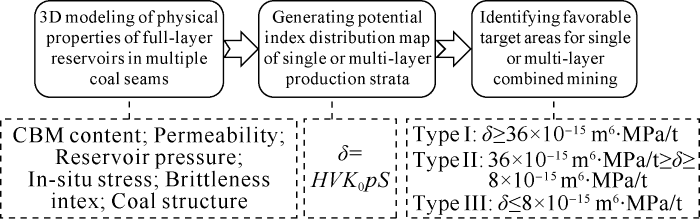

The most important link in dividing the development units of CBM field is to describe the spatial distribution of the physical parameters of reservoirs in detailed. Of the current technical means, 3D modeling of oil and gas (CBM) reservoir is relatively mature, and can meet the technical requirements. There are three main steps to evaluate the favorable develop-ment areas of CBM fields: (1) Reconstructing the 3D fine physical properties model of the full reservoir with all coal seams based on the existing geological data and knowledge. (2) Calculating the production potential index of each grid, and drawing the contour of production potential index under the condition of single or multi-layer commingled production. (3) Based on the distribution of production potential index contour, the distribution areas of class I, II and III coal reservoirs are plotted by quantitative indexes dividing development units, and the favorable areas for development are sorted out.

2.1. The 3D modeling of physical properties of the full reservoir with all coal seams

The geological data of seismic, well testing, well logging, core, etc. of the study area were collected. Petrel (or other) geological modeling software is adopted to construct 3D geological model of physical parameters of the coal reservoir, such as CBM content, permeability, reservoir pressure, coal structure, in-situ stress and brittleness index, etc. This process can be done in 7 steps: (1) Data preparation, (2) logging interpretation, (3) modeling data processing, (4) construction of stratigraphic framework, (5) construction of lithofacies model, (6) construction of attribute model, and (7) construction of reservoir physical property model. Under the constraint of the attribute model, the physical property parameter model of each reservoir is constructed, then the average value of the vertical grid (formation group) is adopted to carry out plane projection transformation, and finally the 2D plane map and the profile through typical wells are generated.

2.2. Plane distribution of production layer potential index and evaluation of favorable areas

Based on the reservoir physical parameters of each grid in the geological model, the Eq. (3) is adopted to calculate the production layer potential index of the corresponding grid, and then the plane projection transformation is adopted to generate the 2D plane parameter field. The contour of the average production layer potential index of individual layers or multiple coal seams are drawn. The technical flow chart for the division of CBM development units and the evaluation of favorable areas are shown in Fig. 3.

Fig. 3.

Fig. 3.

Technical flow chart for development unit division and favorable area evaluation in multi-coal seam commingled production.

For a single layer, the production layer potential index mainly produces contours containing 8×10-15 m6·MPa/t and 36×10-15 m6·MPa/t. Based on the criterion of production layer potential index of CBM development unit, the distribution areas of class I, II and III coal reservoirs are delineated, and the class I area is the most favorable development area.

For joint-mining, the "Three-Step Method" is adopted to optimize the combination of production layers in typical wells[7]. On the basis of determining the main commingled coal seams in the work area, the contours including 8×10-15 m6·MPa/t and 36×10-15 m6·MPa/t are plotted on the planar map of the average production potential index of the commingled coal seams, and the distribution areas of class I, II and III coal reservoirs are outlined, of which the class I area is the most favorable development target area.

3. Application

The Yunnan Yuwang block with an area of 81.75 km2 is located in the south wing of the Laochang anticlinorium. It is known as a gentle monoclinic structure bounded by curved faults with sub-level wide folds and sparse faults inside. The coal- bearing formation is the Upper Permian Longtan Formation. The recoverable coal seams in the whole area are 7 layers, No. 2#, 3#, 7#, 8#, 9#, 16#, 19# coal seams, with a combined thickness of 32.28 m. The recoverable coal seams in most part are 4#, 13#, 17# and 18#. The coal rank is lean-anthracite coal, and the coal structure of some coal seams is relatively broken. The average CBM content is approximately 12 m3/t, the permeability from well test is low, at the average of 0.13×10-3 μm2, the average reservoir pressure gradient is 1.05 MPa/100 m, and the reservoir pressure state ranges from normal to overpressure.

In the early stage, 4 development wells and 11 parameter wells were deployed in Yuwang block. Since 2016, with the implementation of the "13th Five-Year Plan" national science and technology major project "CBM development technology and pilot test in eastern Yunnan and western Guizhou", 6 new test wells have been deployed, which are now in the initial stage of drainage. With fairly abundant geological and development data, this block has basic conditions for selecting favorable development areas.

3.1. 3D modeling of coal reservoir physical properties

Models of physical parameters such as CBM content, permeability, reservoir pressure, coal structure, in-situ stress and brittleness index of coal reservoirs in the study area were built with Petrel geological modeling software. The main parameters have the following distribution characteristics on the plane and in the longitudinal direction.

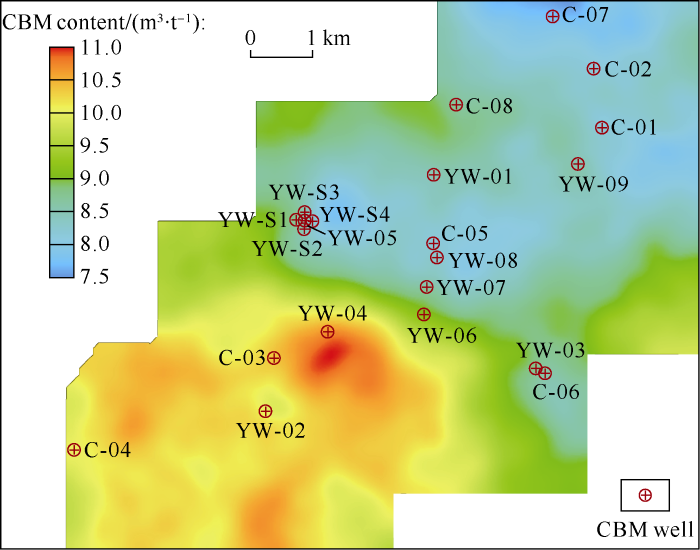

3.1.1. CBM content

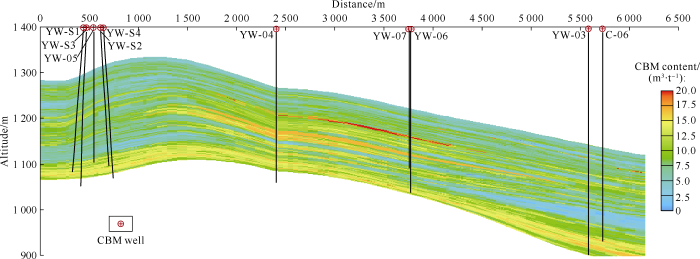

The CBM content of the block is 0.78-19.75 m3/t, and the average CBM content is higher in the southwestern part and lower in the northeast on the plane (Fig. 4). Vertically, the CBM content in single coal seam increases with the increase of the buried depth on the whole, but the CBM content of different coal seams don’t accord to this rule with fluctuation (Fig. 5). This is consistent with the basic characteristic of superimposed CBM system[29,30].

Fig. 4.

Fig. 4.

Planar distribution of CBM content of coal seam in Yuwang block.

Fig. 5.

Fig. 5.

Connected well profile of CBM content in Yuwang block.

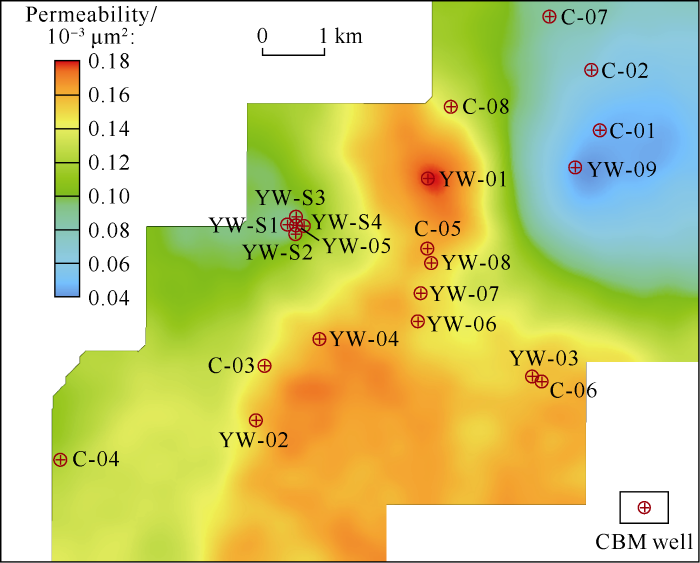

3.1.2. Permeability of coal reservoir

The well test permeability of Yuwang block is (0.005 6- 0.870 0)×10-3 μm2, and 0.130 0×10-3 μm2 on average. The average logging permeability is (0.046-0.270)×10-3 μm2, representing medium-low permeability reservoir. In general, medium and low permeability reservoirs take the majority, while medium permeability reservoirs occur locally.

Fig. 6.

Fig. 6.

Planar distribution of coal reservoir mean permeability in Yuwang block.

Fig. 7.

Fig. 7.

Connected well profile of coal reservoir permeability in Yuwang block.

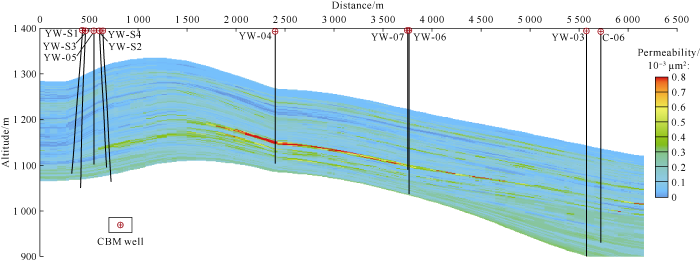

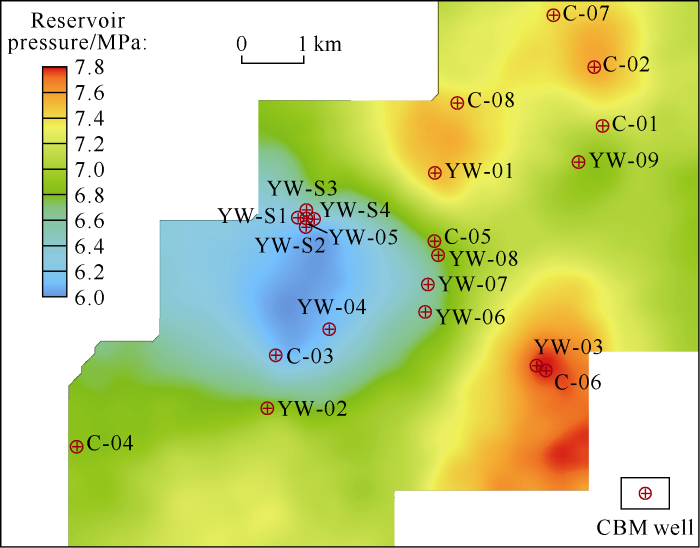

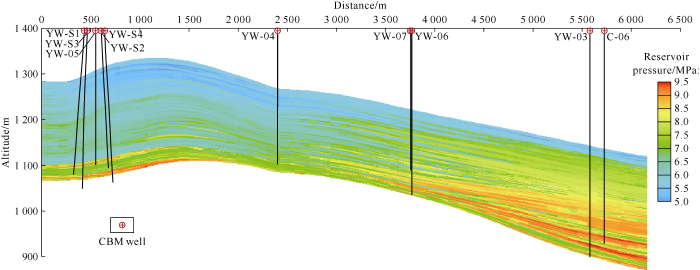

3.1.3. Coal reservoir pressure

Coal reservoir pressure is the force driving CBM flow. According to the measured values in well test and the interpretation results of well logging, the coal reservoirs in Yuwang block have a pressure of 3.71-10.85 MPa, and 6.77 MPa on average. The pressure coefficient ranges widely from 0.63 to 1.43, with an average of 1.07. There are both underpressure and overpressure reservoirs. The reservoir pressure on the planar is lower in the northwest and area near Well YW-S1, and higher in the southeast (Fig. 8). Vertically, the reservoir pressure gradually increases with the increase of buried depth in general but fluctuates in local parts (Fig. 9). It is generally consistent with the buried depth of the coal seam, and the deep coal reservoirs have higher energy.

Fig. 8.

Fig. 8.

Planar distribution of coal reservoir mean pressure in Yuwang block.

Fig. 9.

Fig. 9.

Connected well profile of coal reservoir pressure in Yuwang block.

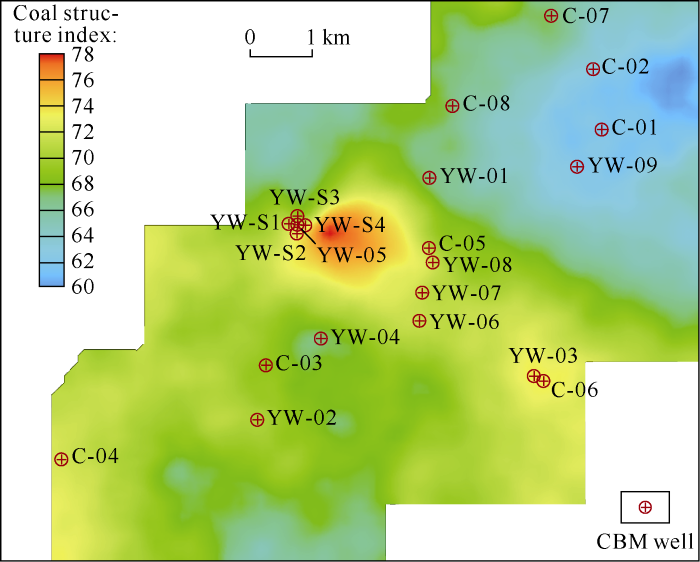

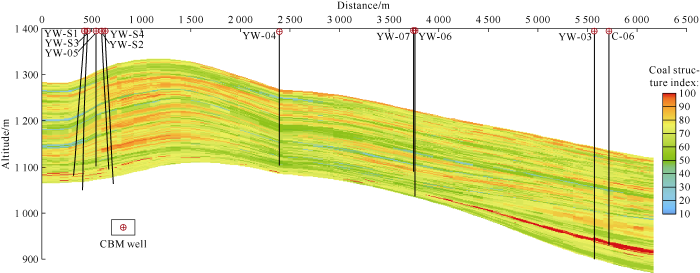

3.1.4. Coal structure

In the Yuwang block, primary structure coal, cataclastic coal, and combined granulated coal and mylonite coal account for 47%, 33% and 20% respectively. The coal structure near YW-S1 well group and in the southwestern part is better, but is poor the in the northeastern part (Fig. 10). Vertically, the coal in the middle layers is more fragmented, while that in the shallow and deep layers are more complete (Fig. 11).

Fig. 10.

Fig. 10.

Planar distribution of coal mean structure index in Yuwang block.

Fig. 11.

Fig. 11.

Connected well profile of coal structure index in Yuwang block.

In addition, the 3D modeling of in-situ stress and brittleness index was completed, which shows the local difference in planar distribution and fluctuation vertically. This won’t be elaborated here.

3.2. Division of development units and evaluation of favorable areas

3.2.1. Evaluation of single-layer favorable areas

Based on the modeling of key parameters, the distribution of potential index of some main coal seams (No. 7#+8#, 9#, 13#, 19#) were mapped (Fig. 12). (1) For the No. 7#+8# coal seam, class I area is mainly distributed near Well YW-02, the class II area is widely distributed; the class III area is scattered, mainly concentrated in the southeast of the study area. (2) For the No. 9# coal seam, the class I area is mainly distributed in the middle of the study area, that is, the shallow area; the class II area is scattered in the middle area, and the class III area is mainly distributed at the edge of the block in strips with large area. (3) For the No. 13# coal seam, the class I area is mainly distributed in the areas near wells of YW-02 and YW-04; the class II area is mainly distributed in the northeast; the class III area is scattered at the edge of the block. (4) For the No. 19# coal seam in NE-strike stripe, the class I area is mainly distributed in the central part of the study area and area near well YW-03; the class II area is mainly distributed in the northeast and northwestern margins; the class III area is scattered in the northeast.

Fig. 12.

Fig. 12.

Evaluation of favorable development areas in individual layers of Yuwang block.

Comprehensive evaluation shows that the favorable development zones of the 4 coal seams are quite different in distribution pattern. Among them, the No. 7#+8# and 19# coal seam have the smallest class III area, and the No. 9# coal seam has the largest class III area.

In the previous research, the multi-coal development unit division usually adopted evaluation results of the CBM production potential of a single main coal seam as standard, which has certainly some defects in identifying favorable development zones involving all the coal seams. The results are low in accuracy, and can’t guide the selection of commingled production areas in CBM development.

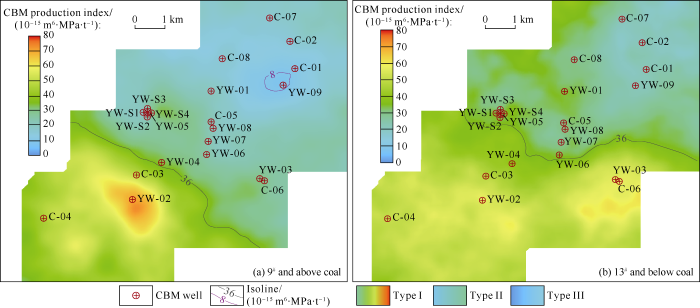

3.2.2. Evaluation of favorable commingled production areas

According to the "Three-Step Method"[7] and cluster analysis combination method[31], the production layer combinations in the study area were optimized, and two combinations, the main production layers of No. 9# and above coal seams and No. 13# and below coal seams were obtained[32], in both of which the coal seams have similar physical properties and fluid properties and are highly compatible. Based on this, the productivity potential index of the 2 combinations were calculated to generate the average productivity potential index map (Fig. 13), then the class I, II and III areas were delineated.

Fig. 13.

Fig. 13.

Evaluation results of favorable development zones for commingled production in Yuwang block.

It can be seen from the evaluation results that the class I areas of No. 9# and above coal seams are mainly distributed in the southwestern part of the study area, and the area near Well YW-02 has the best joint-mining effect. The class II areas are distributed in the central and northeastern parts of the study area. The class III area has a small distribution range and only exists in the northeastern part of the study area. For the coal seams of No. 13# and below, the class I areas are mainly distributed in the central, southwestern and southeastern parts of the study area, the class II areas are mainly distributed in the northeastern part, and there is no class III area.

It can be seen that the No. 13# and below coal seams are suitable for large-scale joint-mining. In the southwestern part of the study area, the class I areas of the two production layer combinations overlap somewhat, making the area more suitable for joint-mining. There is no type I area in the northeastern part of the study area, and thus is not suitable for joint-mining. In the middle of the study area, only the No. 13# and below coal seams have class I areas, so only this combination is suitable for commingled production.

3.3. Reliability of favorable area evaluation results

In the Yuwang block, a CBM cluster well group was deployed in the early stage, including five CBM wells (YW-05, YW-S1, YW-S2, YW-S3, YW-S4). The wells had been produced for about 2 years and then shut down, with a highest daily CBM production of 23.96-1864.00 m3, and an average daily CBM production of 4.14-477.04 m3. The development effect is not good. The reasons are: (1) The development coal seams of 4 wells in the well group were No. 7#+8# and 19# coal seam, and the development coal seam of 1 well was No. 19# coal seam. According to optimized combination results by the “Three-Step Method”, No. 7#+8# and 19# coal seams should not be combined[32]. (2) From the evaluation results of the favorable area of single coal or commingled multi-coal seams, for either single coal seam production of No. 7#+8# and No. 19# coal seams, or commingled production of the two combinations, No. 9# and above coal seams and No. 13# and below coal seams near the YW-S well group has only class II secondary favorable zones, with lower productivity potential, the development effect is not good.

Among the six CBM wells currently being drained (YW-01, YW-02, YW-03, YW-04, YW-CS1, YW-CS2), the development coal seams in YW-01 are No. 7#+8# and No. 13#, and those in the other wells are the coal seam No. 13# and below, and their combinations were optimized by the “Three-Step Method”[32]. By September, 2018, these wells have been drained for more than four months, and are in the stage of balanced water production and have not produced gas yet. According to the distribution of these CBM wells, they are mainly deployed in the central, southwestern and southeastern parts of the study area, which are the favorable zones for single-layer production and commingled production. For the combination of No. 9# and above coal seams, Well YW-02 is located in the class I area. For the combination of No.13# and below coal seams, Well YW-02, YW-03, and YW-04 are located in the class I favorable area, Well YW-01 is located in the class II area (Fig. 13). It can be seen that, except individual wells, the wells deployed are basically in favorable development areas, and it is expected that good development results will be achieved.

4. Conclusions

Based on the productivity equation of CBM wells, and considering the influence of coal reservoir stimulation on the gas production capacity of CBM wells, the main production layer optimization index in the "Three Step Method" for optimized combination of production layers was modified. CBM potential index was proposed to evaluate the favorable development area of commingled CBM production in multi-layer reservoirs, which can reflect the production potential of multiple coal seams better.

Quantitative grading evaluation system of multi-seam CBM development unit division is derived from the key parameters of coal reservoirs which affect the production potential index. The evaluation method of development favorable area together with geological modeling technology has been proved effective in overcoming the shortcomings of evaluation based on gas production potential of a single main coal seam, and higher in evaluation accuracy. This method can meet the requirement of selecting commingled production areas in CBM development.

Nomenclature

B—comprehensive influence coefficient of gas well engineering, 1015 t/(d•m3•MPa2);

BR—brittleness index, %;

E—Young's modulus, GPa;

E0—constant, 1 GPa;

H—coal seam thickness, m;

K—primary permeability, 10-3 μm2;

K0—permeability after fracturing, 10-3 μm2;

p—reservoir pressure, MPa;

p0—bottom hole pressure, MPa;

Q—CBM well production, m3/d;

S—coal structure factor, when the coal is primary structure or cataclastic coal, S=1, when the coal is granular coal and mylonitic coal, S=0;

U—Poisson's ratio, dimensionless;

V—gas content, m3/t;

α—correction factor, dimensionless;

β—constant, 100 MPa;

δ—CBM potential index (optimization index of main production layer), 10-15 m6•MPa/t;

σh,min—minimum horizontal principal stress, MPa;

σh,max—maximum horizontal principal stress, MPa;

σv—vertical stress, MPa.

Reference

Geological condition, exploration and exploitation strategy of coal-bed methane resources in Guizhou, China

Construction of index system of “Hierarchical progressive” geological selection of coalbed methane in multiple seam area of eastern Yunnan and western Guizhou

3D structural modeling and its application in the Termit Basin, Niger

Development of the theory and technology for low permeability reservoirs in China

3-D geological modeling concept, methods and key techniques

DOI:10.1111/j.1755-6724.2012.00727.x URL [Cited within: 1]

Optimized combination method of production layer for coalbed methane development in multi-coal seams

Geological concepts, characteristics, resource potential and key techniques of unconventional hydrocarbon: On unconventional petroleum geology

Characters of in-situ stress field in Huainan mine area and its influence on stability of coal roof and floor

Hydraulic fracturing curve types of coal reservoirs in Zhengzhuang block, Qinshui basin and their geological influence factors

Vertical transformation of in-situ stress types and its control on coalbed reservoir permeability

Coalbed methane development in China: Engineering challenges and opportunities

A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the Barnett shale

Factors controlling high- yield coalbed methane vertical wells in the Fanzhuang Block, Southern Qinshui Basin

Enrichment mechanism and exploration and development technologies of high rank coalbed methane in South Qinshui Basin, Shanxi Province

Well pattern design and deployment for coalbed methane development

Progress and development trend of unconventional oil and gas geological research

Analysis on geological factors of single CBM well productivity in Zhijin block

Geologcial characteristics of coalbed methane and optimization for favorable productive intervals of Yangmeishu syncline in Liupanshui area

Research and application of appraisal variables for the prioritizing of coalbed methane area featured by different coal ranks

Relations between productivity of CBM vertical wells and coal structure in Encun mine field

Coal structure affected to coalbed methane development in Qinnan region

Prediction model of coal-body structure and spatial distribution law based on logging parameters

Investigation on coal seam gas formation of multi-coalbed reservoir in Bide-Santang Basin Southwest China

DOI:10.1007/s12517-014-1640-3 URL [Cited within: 1]

Resources and geology of coalbed methane in China: A review

DOI:10.1080/00206814.2017.1408034 URL [Cited within: 1]

Production layer combination selection for coalbed methane development in multicoalseams based on cluster analysis

Development methods and development geological unit for superposed CBM-bearing system