Introduction

The tight sandstone gas field in the Sulige area of Ordos Basin is typical tight gas in China. The reservoirs are highly heterogeneous, with poor physical properties, high irreducible water saturation, and high gas percolation resistance; and wells in the reservoir often see fast decline in energy, small effective sweeping range, and low recovery of reserves. The Sulige gas field was discovered in 1996 and put into development in 2005. It is now the largest natural gas field in China with the largest reserves and production. In the gas enrichment area, the production capacity of 250×108 m3 was constructed at the end of 2014, and the annual output reached 230×108 m3. The enrichment area generally refers to the high-quality reserve area with abundance of more than 1.5×108 m3/km2, relatively high reserve concentration, and final cumulative well production of more than 2 000×104 m3. Since 2015, the Sulige gas field has kept a stable production, and will keep so for more than 20 years according to the development plan. Different from conventional gas reservoirs, tight gas wells have hardly any stable production period, and to keep long-term stable production, new wells need to be drilled to make up for the decline. There are two ways to maintain stable production. One is to build new production blocks for successive production, and the other is to increase the producing reserve and gas recovery in the developed enrichment area through infilling the well patterns. From the current development situation of the Sulige gas field, most of the unproduced blocks are either lower in reserve abundance or higher in water saturation, and the wells there have generally lower production than infilling wells in the enrichment area. Therefore, it is more economically effective to increase the recovery in the enrichment area, and keep the unproduced blocks as resource reserve for long-term stable production.

Development practices both in China and abroad show that infilling well pattern is one of the effective measures to improve gas recovery. Regarding the analysis of rational well pattern density, in the early stage, the well pattern density was designed as no more than 3 wells/km2[1] for the following reasons: focusing on the matching of well pattern and reservoir distribution, and keeping each effective sand body controlled by only one well so as to avoid interference as much as possible; ensuring the rate of class I + II wells and single well development efficiency; the designed well pattern was the optimal technological well pattern. Presently, for the maximum efficiency of gas field development and increasing gas recovery, a certain extent of inter-well interference is accepted when profitable, the well pattern of the best economic efficiency is designed, and four methods to estimate the rational well pattern density, i.e. quantitative geological modelling, dynamic drainage area, production interference and economic and technical index evaluation have been proposed. With progressive demonstration, it is concluded that in the enrichment area the 600 m×800 m framework well pattern can be infilled to 4 wells/km2, which will enhance the recovery rate from 32% to about 50%. In addition, other matching measures such as vertical well sidetracking, repeated fracturing, and water drainage gas recovery can also tap the remaining reserves of old wells to some extent, and increase gas recovery by about 5%. Centering on the production demand of improving gas recovery in tight gas enrichment area, this paper presents in details the research results on factors affecting recovery rate, description of remaining reserves, optimization of well patterns and matching measures for improving gas recovery.

1. Basic geological characteristics of tight gas reservoirs

The Sulige gas field is located on the northwest side of the Yishan slope in the Ordos Basin. The main pay zones are the Permian He 8 and the Shan 1 members. They are continental facies braided river sediments. With the board and gentle tectonic setting, the river channel experienced multiple diversion and stack, forming large-scale sandstone areas of several thousand to over ten thousand square kilometers distributed continuously in patches. After intense compaction and cementation, etc., the sandstone layers become tight reservoirs, with largely secondary pores. Under the general low permeability-tight sandstone background, the sand bodies with higher porosity, permeability and gas content are “effective sand bodies”, which are the main targets of proven reserves calculation and contributors to production. Different from the continuous distributed large-scale sand bodies, the effective sand bodies are small in scale, and appear as multiple lenticular beds. The huge continuous sandstone patches and the small effective ones form a binary structure of “sand-in-sand”.

The tight gas reservoirs have complex pore throat structure, poor physical properties, low gas filling degree and relatively high water saturation. The average water saturation of Sulige gas field is about 40%, and the formation water occurs in free water, retained water and irreducible water. Except the west and the northern part of the east area of Sulige, the free water is generally low in proportion. The formation water in the main blocks of the gas field is retained water and irreducible water, coexisting with the natural gas in the form of gas-water layer or a gas-bearing water layer, which is different from the “upper gas-lower water” gas-water separation mode of the conventional gas reservoir. In production, the production of water in tight gas wells is quite common. Due to rapid decline of formation energy in the near-well zone, the gas well production is low, with poor liquid carrying capacity, and liquid is very liable to accumulate in the well bottom without taking water drainage measure, blocking gas production.

2. Factors affecting tight gas recovery

From the matching relationship of effective sand body scale and well pattern macroscopically and influence of pore structure and fluid percolation characteristics on gas production microscopically, the factors affecting tight gas recovery can be attributed to the following three. (1) Reservoir heterogeneity: If the reservoir is heterogeneous, the gas-bearing sand bodies could be poor in continuity and connectivity, and thus the well pattern is likely not dense enough to control all the reserves. (2) Reservoir permeability: The reservoir is tight, with poor pore connectivity and weak percolation capacity. (3) Gas- water two-phase flow: Gas and water two-phase flow in the reservoir would cause high percolation resistance to gas, and thus low production and weak liquid carrying capacity of gas well, and the wellbore fluid accumulation causes the gas well abandonment pressure to rise.

2.1. Reservoir heterogeneity

The sedimentary environment of the Sulige tight gas reservoirs is mainly continental facies river sedimentary system featuring great variation of hydrodynamic conditions, so the single-stage river channels are small in scale[2] and complex in stack pattern, and the effective sand bodies are mostly in the gritstone at the bottom of the river channel and in the mid-bottom of the central bar, forming a binary structure of “sand-in-sand” with the matrix sand body. About 80% of the effective sand bodies in the gas field are single-stage and isolated, with big difference in scale[3]. The effective sand bodies are 1-10 m thick, mostly 1.5-5.0 m, and 50-1 000 m wide and long. The fitting calculation of gas reservoir engineering shows that the drainage area controlled by single well is 0.15 to 0.30 km2, obviously smaller than the 0.48 km2 of the single well in the 600 m×800 m well pattern in present Sulige gas field, clearly, the development well pattern isn’t dense enough to control all the reserves.

The frequent migration of braided river channels in multiple stages resulted in gas-bearing sand bodies of small scale in multiple vertical sections[4], which cross laterally and stack with each other to form large complex effective sand bodies. These sand bodies are generally heterogeneous inside[5], in which the tight and fine or argillaceous interlayers deposited at weak hydrodynamic conditions become “blocking zones”, blocking the fluid percolation channel, and making it difficult to produce the reserves in the complex effective sand body fully and the gas recovery reduce. According to the outcrop anatomy of the modern braided river (Yongding River), on the downstream sedimentary section, multiple siltation intercalations are formed in the upper part of the central bar and at the intersection of the braided channel and the central bar[6]. Therefore, it is difficult to fully control the gas-bearing sand bodies with single well high-output pattern for the tight gas reservoir[7,8,9,10], and the recovery rate is often low.

2.2. Reservoir permeability

The tight gas reservoirs are low in porosity and permeability, so the pressure transmission is much weaker than that in the conventional gas reservoirs. The fluid-rock adsorption make the reservoirs have a starting pressure, and when the production pressure difference is small and the flow rate is low, the gas cannot overcome the starting pressure gradient and flow to the wellbore, resulting in almost no natural production capacity after well is completed. To obtain industrial gas flow the reservoirs must be fractured, and the fracture network connects the near-well reservoir to improve reservoir permeability, increase reservoir producing degree, single well production, and realize the efficient development. However, as the scale of reservoir fracturing is limited, the recovery rate of tight gas reservoirs is still lower than that of conventional gas reservoirs.

2.3. Gas-water two-phase flow

Due to rock wettability and capillary pressure[11,12], the water occupies the small pore throat and pore wall in priority in the rock; when the gas flows in water-bearing pores, it first flows into the large pores, and gradually drives the water in the small throats or makes the water film on the pore wall thinner with the increase of the flow pressure difference. The water saturation in the core varies with the flow of the gas. When the flow rate is low, the gas flow increases non-linearly with the increase of the pressure difference. The gas front jumps forward and is easily blocked by water. Therefore, when the gas flows in the water-bearing pores, a certain starting pressure (critical flow pressure) is also required; the higher the water saturation, the bigger the starting pressure will be needed.

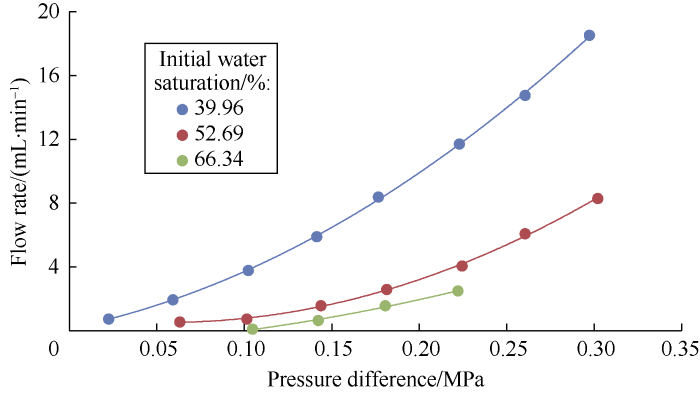

The relationship between the gas flow pressure difference and the flow rate of the core sample is shown in Fig. 1. The starting pressure of the rock samples with different initial water saturations can be obtained by data fitting. The rock samples with the initial water saturation of 66.34%, 52.69% and 39.96% have a starting pressure of 0.086 40, 0.009 73, and 0.002 39 MPa, respectively. The ratio of the starting pressure to the core length (4.5 m) is the starting pressure gradient of the core, which is 0.019 20, 0.002 10, 0.000 53 MPa/m respectively for these samples. As the water saturation decreases, both the starting pressure and starting pressure gradient decrease (Table 1). For reservoirs with active formation water or high water saturation, the gas flow percolation resistance increases due to the production of water. When the production reduces to a certain level at which it fails to carry the liquid out of the well, the liquid begins to build up in the wellbore, which makes the production reduce further, and the well production enters into a vicious circle. In such circumstance, water drainage has to be carried out to prevent flooding of gas wells. Liquid loading will increase the gas well abandonment pressure and decrease the recovery rate. At the same time, taking water drainage measures will increase the development cost and reduce economic efficiency.

Fig. 1.

Fig. 1.

Flow rate-pressure difference curves at different water saturations.

Table 1 Starting pressure gradient under different water saturations.

| Water saturation/% | Average permeability/ 10-3 μm2 | Inverse permeability/ 10-3 μm2 | Starting pressure/ MPa | Starting pressure gradient/ (MPa·m-1) |

|---|---|---|---|---|

| 66.34 | 0.315 2 | 3.173 | 0.086 40 | 0.019 20 |

| 52.69 | 0.456 0 | 2.193 | 0.009 73 | 0.002 10 |

| 39.96 | 0.624 0 | 1.603 | 0.002 39 | 0.000 53 |

3. Evaluation of remaining reserves in developed areas of tight gas fields

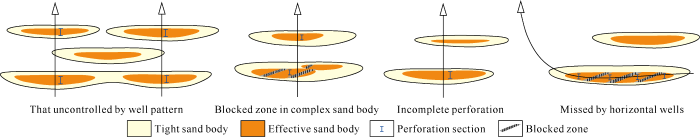

Due to the special structure of tight sandstone gas reservoirs, it is difficult to fully control the gas-bearing sand bodies of different scales in order to maximize the production of vertical wells, resulting in incomplete production of reserves. The development practice proves that the main well pattern of 600 m×800 m in present Sulige gas field is only able to control the main gas-bearing sand bodies, and difficult to control the smaller-scale gas-bearing sand bodies, which leads to remaining reserves between the wells and between layers. By using geology, geophysics, gas reservoir engineering and other methods, the remaining reserves in blocks, wells and layers have been estimated carefully. Combined with gas production technology, the remaining reserves in the developed areas can be classified into four types: that uncontrolled by well pattern, that in blocked zone of complex sand body, that missed due to incomplete perforation and horizontal wells (Fig. 2).

Fig. 2.

Fig. 2.

Different types of remaining reserves.

3.1. Reserves uncontrolled by well pattern

The effective sand bodies in the tight gas reservoirs of Sulige gas field are small in scale, poor in horizontal connectivity, low in development frequency, and mostly isolated. In the early stage of gas field development, a 600 m × 1 200 m well pattern was set up, and the well pattern density is bigger than that of the conventional gas reservoir of 1 to 3 km. With the deepening of gas field development, the main well pattern was adjusted from 600 m × 1 200 m to 600 m × 800 m after 2010, and the well density was adjusted from 1.4 wells/ km2 to 2 wells/ km2, as a result, the producing reserve was greatly enhanced. But still the gas-bearing sand bodis were not fully controlled. Calculated with the final cumulative output of 2 400 × 104 m3 for a single well and the reserve abundance of 1.5 × 108 m3/km2, the current recovery rate is only 32%. The uncontrolled isolated remaining reserves account for 50%-60% of the total remaining reserves, and is the main part for remaining reserves.

3.2. Reserves in blocked zone in complex sand body

The horizontal well trajectory geological section shows that the complex sand body is not connected inside, with several “blocked zones” extending in perpendicular to the water flow direction, with a width of 10 to 30 m and an interval of 50 to 150 m. The gas test data indicates that there exist flow boundaries in the sand bodies in a vertical well, confirming that the "blocked zone" affects the percolation capacity of the complex sand bodies and the reserves producing degree of vertical wells, and thus a certain amount of gas would be left. The remaining reserves in the blocked zones of complex sand bodies account for 25% of the total remaining reserves. Multi-stage fracturing of horizontal wells is able to overcome the influence of the blocked zones.

3.3. Incomplete perforation

Effective sand bodies can be classified into two groups according to differences in physical properties and gas content: poor gas layer and pure gas layer. In comparison, the poor gas layer has thinner effective sand body of 1 to 3 m, poorer physical properties with porosity of 5% to 7%, and burden pressure permeability of (0.01 to 0.10) × 10-3 μm 2 ; lower gas saturation of 45%-55%; higher water saturation of more than 45%, lower gas relative permeability and poor fluidity. In the early stage of development, limited by the vertical well fracturing technology, residual gas was formed due to imcomplete perforation or fracturing of poor gas layers. Based on the drilling and logging data of 1200 wells in the Sulige gas field, the quantity, thickness, porosity, gas saturation, etc., of the effective sand bodies drilled in a single well were counted to screen out the reserviors with incomplete perforation. Together with the geological peremeters such as width- to-thickness ratio and length-to-width ratio, the reserves in the reservoirs of incomplete perforation and their ratios in the whole remaining reserves were estimated. The results show that on average the perforation incomplete remaining reserves account for 14% of the well-controlled reserves, and these reserves are mainly in a few development wells and evaluation wells put into operation in the early stage. From 2008, with the advancement in the separate-layer fracturing technology, such remaining reserves basically no longer occur any more. Therefore, this type of remaining reserves can be taken as potential target in certain wells, but are not significant to the the overall recovery improvement of gas reservoirs.

3.4. Reserves missed by horizontal wells

In the Sulige gas field, there are multiple tight gas reservoirs, and the reserves in major reservoirs He 8 and Shan 1 account for about 80% of the geological reserves. By increasing the contact area between horizontal well and the reservoir, and using multi-stage fracturing to break the blocked zone, the producing degree of the reserves in the main sections can be enhanced. However, the geological feature of multiple gas-bearing layers makes it inevitable for the horizontal well to miss some reserves vertically. According to the statistics of drilled effective reservoirs in more than 1300 horizontal wells, the horizontal wells can control 60%- 70% of the geological reserves, and leave off 30%-40% of the reserves. Estimated at the average single well control area of 1 km2, the total remaining reserves missed by the horizontal wells is (600-800)×108 m3, and the average abundance of the remaining reserves is 0.5×108 m3/km2. In this case, the economic efficiency of the measures to tap remaining reserves can be guaranteed.

4. Main technologies to improve the recovery of tight gas reservoirs

Subtracting the accumulated producing reserves of the completed well from the geological reserves of different blocks in the Sulige gas field, the general remaining reserve is obtained. According to the anatomical analysis on 39 gas reservoir sections through connected wells, the various types of remaining reserves were calculated, and then the ratio of various remaining reserves to the remaining general reserves were worked out. For remaining reserves in the isolated gas-bearing sand bodies not controlled by well pattern or blocked in the complex sand bodies, the essential reason of their being is that the well pattern is not able to control them, so the two are classified as inter-well unproduced reserves. For the reserves missed by incomplete perforation or horizontal wells, as detained in the longitudinal layers, they are classified as inter-layer unproduced reserves. The inter-well reserves accounted for about 82%, and the inter-layer for 18% (Table 2). Therefore, optimizing and infilling the well pattern to improve the producing degree of inter-well remaining reserves is the main measure to increase gas recovery. To be more specific, there are two measures: vertical well pattern infilling and combination of vertical and horizontal wells.

Table 2 Statistics on remaining reserves in the enrichment area of the central Sulige gas field.

| Remaining reserve | Genetic type | Ratio |

|---|---|---|

| Inter-layer remaining reserve | Thin layer or gas-bearing layer left by incomplete perforation in vertical wells | 9% |

| Minor layers missed by horizontal wells | 9% | |

| Inter-well remaining reserve | Isolated gas-bearing sand bodies uncontrolled by well patterns | 57% |

| Gas blocked in complex sand bodies | 25% |

4.1. Vertical well pattern infilling to improve gas recovery

The vertical well pattern infilling is applicable to the area where mutiple gas-bearing layers scatter, and the core is to work out the economically effective well pattern density and optimize the well pattern geometry. Tight sandstone gas reservoirs are characterized by extensive hydrocarbon generation and continuous reservoir formation, with large gas-bearing area and poor physical properties. The reservoir structure exhibits strong heterogeneity microscopically. The author's team has long devoted to the research on tight gas stable production and recovery enhancement. In the early-stage, our coginitions mainly included: in the reservoir geological evaluation, not only the reserve scale should be studied, the distribution pattern of the reservoirs and the influence of gas content on the output also needed to be investigated[1]. For the indexes of infilling, multiple parameters should be optimized and integrated, scientific infilling principles and systematic evaluation indexes should be set up[13]. One of the characteristics of the early stage research was to infill the well pattern according to reserve types, i.e. different types of reserves corresponding to different well pattern densities.

Based the previous researches, and after further sorting, summarizing and refining, 4 well pattern density evaluation methods have been come up, namely quantitative geological modelling, dynamic drainage ranging, output interference rating and economic-technic index evaluation. Of the 4 methods, the factors considered increase in turn, and the constraints also increase. Comprehensive research showed that in the enrichment area of Sulige large-scale tight sandstone gas field the well pattern density could be infilled to 4 wells/km2. Compared with the previous research results, the progresses made this time include: (1) Combined with the analysis on output interference rate, 4 stages of recovery variation with the well pattern density have been identified, and the specific well pattern density of each stage has been determined; (2) the theoretical connotation of the final cumulative output of single well, gas production increase volume of infilled well and well pattern infilling, have been deenpened, and the original conceptual models have been gradually quantified, making them increase in application value in field; (3) following the development of tight gas, the economic evaluation has been strengthened, and suitable well pattern density under conditions of different gas prices has been discussed as the internal rate of return of tight gas was lowered from 12% to 8%.

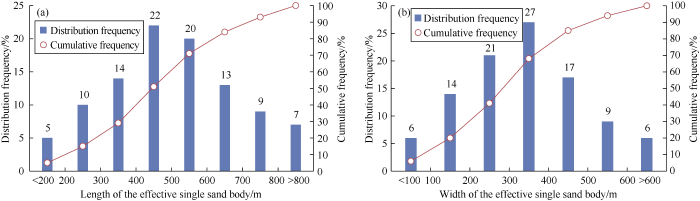

4.1.1. Quantitative geological modelling

The core of the quantitative geological modelling is to define the scale and distribution frequency of the effective single sand bodies. According to the main data (thickness, width, length, etc.) of the effective single sand bodies, the class and reserve producing degree of sand bodies effectively controlled by the current well pattern were evaluated. Fine description of core is an important means to analyze the thickness of the effective single sand body. Based on the calibration of the rock-electricity relation and in combination with the logging data, the effective single sand body thickness of non-coring wells were estimated carefully. The results shows that the isolated effective single sand bodies in Sulige gas field are mostly 1.5-5.0 m thick. The width and length of the effective single sand body can be estimated by dissecting the infilled well pattern, or by getting the width-to-thickness ratio and length-to-width ratio of the sediment in the corresponding sedimentary environment from outcrop observation and sedimentary physical simulation, and then with the thickness of the sand body, the length and width of the effective sand body can be calculated. The research results show that in the Permian He 8 and Shan 1 of Ordos Basin the width-to-thickness ratio of the river channel filling is 50-120, the length-to-width ratio is 1.2-4.0. In Sulige gas field, the isolated effective single sand bodies are largely 200-500 m wide, accounting for 65%; and largely 300-700 m long, accounting for 69% (Fig. 3). The effective single sand bodies are mostly 0.08-0.32 km2, 0.24 km2 on average. Calculated with the average abundance of reserves and size of effective single sand bodies, there are 20 to 30 effective sand bodies developed in 1.00 km2 stratum. 80% of the effective sand bodies are isolated and small in scale, at less than 400 m × 600 m on average; the rest 20% are vertically stacked and laterally overlapped, and larger in scale, holding 45% of the total reserves.

Fig. 3.

Fig. 3.

The length and width distribution frequency of the effective single sand bodies in the Sulige gas field.

With the present 600 m×800 m main development well pattern, the development area covered by one well is 0.48 km2, which is twice the average size of effective single sand body. A large number of effective sand bodies are missed between the wells, which causes low producing degree of reserves. According to the quantitative geological model analysis, the well pattern density needs to reach 4 wells/km2 (the reciprocal of 0.24 km2).

4.1.2. Dynamic drainage ranging

The presence of starting pressure in tight gas at low flow rates would make the open flow capacity of the gas well lower, the abandonment pressure of the gas reservoir rise, and the recovery drop. The rational well space was estimated according to the core experiment analysis and the relationship between the starting pressure gradient and the formation permeability[14] before: when the original formation pressure was 40 MPa and the formation permeability was 0.1×10-3 μm2, the maximum well space was 88.6 m, i.e. the well drainage radius didn’t exceed 44.3 m. The successful development of tight gas is inseparable from the progress in the reservoir stimulation technologies. The tight gas reservoir is also called “artificial gas reservoir”, of which the permeability includes matrix permeability and artificial permeability. The value and distribution of the artificial permeability are difficult to measure accurately, which results in a large difference between the rational well spacing obtained by the previous researchers and the actual situation.

The pressure and output data during development is reliable basis for drainage range analysis. In fact, during gas well production, the presence of starting pressure gradient causes changes in gas well pressure and production. In dynamic drainage ranging method, the gas wells with production time of more than 500 days and basically reaches the quasi-stable state, are chosen, with their pressure and output, and in comprehensive consideration of the parameters of artificial fractures and physical properties of the reservoir, important indexes such as the dynamic drainage ranging, producing reserve, final gas well cummulative output, etc. are fitted and determined, the distribution frequency of the dynamic drainage range is calculated and analyzed, thus the reserve producing degree of the present well pattern is evaluated. Through the fitting with Blasingame and the flowing material balance methods, it is found that the drainage area of the vertical wells in the gas field differ greatly, from the minimum of less than 0.1 km2 to the maximum of above 1.0 km2, mostly between 0.1-0.5 km2, and 0.27 km2 on average. The above data is consistent with the conclusion of geological analysis, and reflects the insufficiency of reserves control by the existing 600 m × 800 m framework well pattern. According to the analysis of the gas drainage range, the well pattern density needs to be 3.7 wells/km2. In fact, the gas well drainage range is affected by multiple factors, including reservoir scale, reservoir stacking pattern, blocked zone location, and artificial fracture form. As the well pattern is generally an irregular polygon, i.e. when the well pattern density is less than 3.7 wells/km2, the drainage areas of wells could overlap, so the wording "drainage radius" is not accurate.

4.1.3. Output interference rating method

Whether the well space is rational is evaluated mainly according to the interference test on site. In interference test, the well production regime is adjusted and excited by shut-in and opening, and the changes of pressure and output in the observation wells are tracked to find out whether there is inter-well interference in the tested well group. One gas well usually drills an average of 3 to 5 effective sand bodies. A new well drilled can encounter new reservoirs, but some effective sand bodies of larger scale and better connectivity might by controlled by two or more wells, increasing the interference possibility between wells. Meanwhile, most isolated reservoirs of smaller scales have no interference yet. In addition, in the Sulige gas field, separated-layer fracturing, commingled production and downhole throttling are adopted. However, it is difficult to carry out layer-by-layer output test in the interference test, and is not able to determine the inter-well connectivity layer by layer. Therefore, it is impossible to truly reveal how much the output is affected by the interference well ratio, so the application of this method in the Sulige gas field is obvious limited.

To solve this problem, the index of output interference rating is proposed to quantitatively characterize the influence of well pattern infilling on the average production of gas wells in a certain area of tight gas reservoir, and to reasonably evaluate the feasibility of well pattern infilling. The output interference rate is defined as the ratio of the difference of average single well cumulative output before and after the well pattern infilling in a certain area to the average single well ccumulative output before infilling.

where IR—output interference rate, %; ΔQ—difference of average single well cumulative output before and after infilling, 104 m3; Q—average single well cumulative output before infilling, 104 m3.

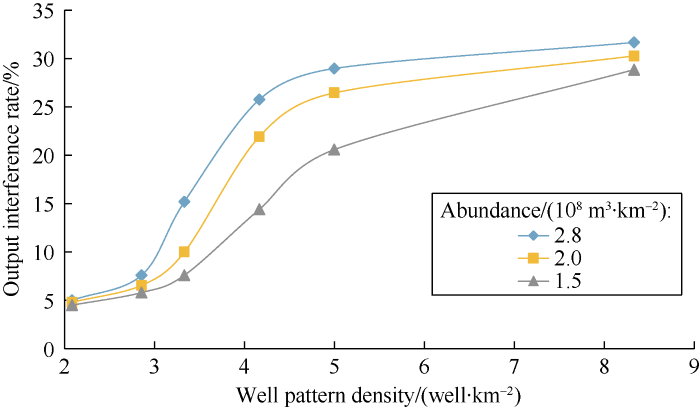

The interference tests of 42 well groups in the gas field show that when the well pattern density reaches 4/km2, about 60% of the gas wells have interference. The interference would be taken as very serious in traditional view, but the actual interference rate is only 20% to 30%, which mean the interference is slight. By selecting typical blocks and combining geological modelling and numerical simulation, the relationships between reservoir abundance, well pattern density and output interference rate of Sulige tight gas reservoirs were studied (Fig. 4). The results show that the output interference rate increases with the increase of well pattern density. When the well pattern density is 2.5-4.5 wells/km2, the output interference rate increases rapidly, indicating that the gas drainage range of most gas wells is 0.22-0.40 km2, and testifying the previous conclusion. When the well pattern density reaches 4.5 wells/km2, the output interference rate increases slowly. Generally, the larger the average abundance of the block, the more the reservoirs and the larger the cumulative thickness of reservoirs, the stronger the continuity of sandbodies between wells, the more likely it is to cause interference, and the earlier the inflection point occurs. The average reserve abundance of the Sulige gas field enrichment area is 1.5×108 m3/km2, which means that the well pattern in the Sulige gas field has the potential to be infilled to 4 to 5 wells/km2.

Fig. 4.

Fig. 4.

Relationships between reserves abundance, well pattern density and output interference rate.

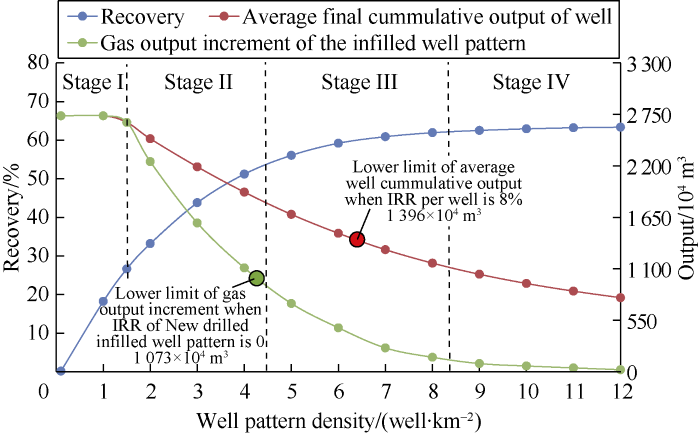

Based on the actual production data of 8 infilled well pattern test areas in the gas field, a diagram shows the relationship between the recovery, average final cumulative production of well, and gas production increment of the infilled wells, etc., with the density of the well pattern, has been compiled (Fig. 5). The gas production increment of the infilled well is defined as the increase in gas production per square kilometer of adding of 1 well/km2 than that of the original well density. The authors believes that “gas production increment of the infilled wells” is more scientific than “final cumulative output of the infilled wells”: the final cumulative output of the infill wells is related to the infilling time. The later the infilling starts, the lower the final cumulative output; while the output increment of infilled well is produced from the inter-well non-connected effective reservoirs, which is independent of the infilling time, and is more closely related to the final recovery. As the density of well pattern increases, the interference between wells increases, the average cumulative output of single well continuously decreases, and the increase amplitude of recovery becomes smaller and smaller. This process can be divided into four stages (Fig. 5). ): stage I, at well pattern density of 0-1.6 well/km2, no inter-well interference, the increase in gas output of the infilled well pattern is equal to the cumulative output of the old wells, and the recovery increases linearly with the increase of the well pattern density; Stage II, at the well pattern density of 1.6-4.5 wells/km2, there is certain interwell interference, the gas output increment of the infilled well pattern is smaller than the cumulative output of the old wells, but the interference is not serious, and the recovery increases with the increase of the well pattern density; Stage III, at the well pattern density of 4.5-8.4 wells/km2, and the interwell interference gradually enhances, the gap between the gas output increment of the infilled well pattern and the cumulative gas output of the wells continuously expands, and the increase of the recovery drops with the increase of the well pattern density. Stage IV, at the well pattern density of more than 8.4 wells/km2, the well pattern basically controls the reservoir completely, the infilled well can hardly drill new reservoirs anymore, and the output of the new well is low, the recovery has reached the limit by well pattern infilling. According to the percolation test simulation and modelling, numerical simulation, the technical limit recovery of Sulige tight gas field by well pattern infilling is 63%[15].

Fig. 5.

Fig. 5.

Four stages of recovery changes with the well pattern density.

4.1.4. Economic-technical index evaluation

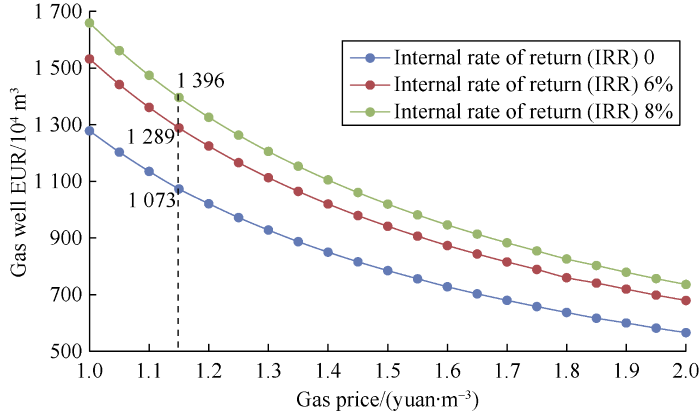

The tight gas reservoirs of low permeability are poor in physical properties, and the prediction of effective reservoir is difficult. The reservoir stimulation requires better technology and large investment, however the single well output is low, and the development profit gets poorer. Therefore, reducing the development cost and pursuing economic efficiency are very important in tight gas reservoir development. The 3 methods mentioned above are mainly cut in from the perspective of geology or gas reservoir, and don’t consider the economic factors fully. The economic-technical index evaluation method is a comprohensive assessment method orienting around the development economic efficiency, and determining the well pattern density with the internal rate of return (IRR) as the core evaluation index. The IRR is a key indicator for evaluating the investment efficiency internationally, which refers to the discount rate when the total present value of capital inflows is equal to the total value of capital outflows and the net present value (NPV) is zero, and can be understood as the capability that the project investment income can withstand the currency devaluation and inflation. The IRR of 0 corresponds to the breakeven point. In recent years, natural gas is in a booming period. The domestic oil and gas industry lowered the IRR of tight gas development from the previous 12% to 8%. Presently, preferential policies are applied, and the IRR standard is expected to be lowered to 6% in the next three years. Calculated with the fixed cost of 8.0 × 106 CNY, bank loans 45%, interest rate 6%, operating costs 1.2 × 106 CNY, depreciation duration of 10 years, and considering urban construction, resource taxes and other related taxes and fees, the lowest ECP (estimated cumulative production) of gas well corresponding to IRR 8%, 6% and 0 were estimaited at different gas prices. The higher the gas price, the lower the gas well ECP required to reach the IRR standard will be (Fig. 6). When the gas price is 1.15 CNY/m3, the lower limit of the gas well ECP required to reach the IRR standard 8%, 6%, 0 are 1 396×104, 1 289×104 and 1 073×104 m3 respectively. In the future with the advancement of technology, rise of gas price or lower of IRR standards, the development economic efficiency of gas fields is expected to increase further.

Fig. 6.

Fig. 6.

Lower limit of ECP corresponding to gas well development economic efficiency at different gas prices.

Estimating the appropriate well pattern density requires balancing the recovery, single well output, and development economic efficiency. If the well pattern is too sparse, the reserves can’t be effectively utilized, and the recovery would be low; if the well pattern is too dense, geological conditions and productivity interference would limit the development economic efficiency. In this paper, three basic principles of infilling adjustment are proposed, i.e., the recovery rate is significantly improved, wells are economically efficient overall, and the newly drilled infill wells can be kept above breakeven line. Hereunder are the details. (1) Great enhancement of gas recovery: to achieve this goal a certain degree of inter- well interference can be accepted. According to the previous analysis the well pattern density can be infilled to 1.6-8.4 wells/km2. (2) The average IRR of all the wells in the block reaches 8%, and the corresponding average final cumulative output of the gas wells is not less than 1 396×104 m3, the density of the well pattern is no more than 6.3 wells/km2. (3) No infilled well shall lose money and meet the requirement of IRR being 0. The infilled wells can improve gas recovery, although not necessarily reach 8% of IRR, they should not lose money, i.e. the output increment of the infilled well is not less than 1 073×104 m3, and the rational well pattern density is no more than 4.2 wells/km2.

With the above analysis, also in consideration of the current economic and technical conditions, to meet the 3 basic principles of infilling adjustments, and at the same time in combination of the existing framewoek well pattern, the suitable density of well pattern is considered to be 4 wells/km2. In the model, the average single well output of Sulige gas field simulated by using 600 m×800 m well pattern is 2420× 104 m3, and the average gas well output after infilling is about 1 920×104 m3, which still meets the economic efficiency of the development plan. The average output increment of infilled well is 1 110×104 m3, which is higher than the corresponding increased output when the IRR is 0. The recovery after infilling is about 50% (Fig. 5).

The appropriate well pattern density under different economic conditions were examined. From the perspective of geological conditions and gas reservoir dynamics, to meet the requirement of enhancing gas recovery significantly, the appropriate well pattern density should be maintained at 1.6-8.4 wells/km2 and does not vary with gas price; from the perspective of economic evaluation, to meet the goals of keeping the average IRR at 8% and the infill well profitable, with the increase of gas price, the density of well pattern would increase gradually. When the gas price is 1.0-1.1 CNY/m3, the suitable well pattern density is 3 wells/km2; when the gas price is 1.1-1.5 CNY/m3, the suitable well pattern density is 4 wells/km2; when the gas price reaches 1.5-2.0 CNY/m3, the suitable well pattern density is 5 wells/ km2 (Table 3).

Table 3 Suitable well pattern density at different gas prices.

| Gas price/ (CNY·m-3) | Average IRR of 8% per well | Breakeven of infilled well | Comprehensive judgement | ||

|---|---|---|---|---|---|

| Ave. well EUR/ 104 m3 | Well pattern density/ (well·km-2) | Output increment of infilled well/104 m3 | Well pattern density/ (well·km-2) | Well pattern density/ (well·km-2) | |

| 1.00 | ≥1 659 | ≤5.1 | ≥1 278 | ≤3.4 | 3 |

| 1.10 | ≥1 396 | ≤6.3 | ≥1 073 | ≤4.2 | 4 |

| 1.30 | ≥1 206 | ≤7.5 | ≥928 | ≤4.4 | 4 |

| 1.50 | ≥1 020 | ≤9.0 | ≥785 | ≤4.8 | 4 |

| 1.80 | ≥826 | ≤11.5 | ≥637 | ≤5.3 | 5 |

| 2.00 | ≥736 | ≤12.8 | ≥566 | ≤5.6 | 5 |

4.2. Well pattern combining vertical wells and horizontal wells to improve the recovery

The combination well pattern of veritcle and horizontal wells is mainly suitable for the blocks with obvious major gas reservoirs (major gas reservoir profile reserve ratio is bigger than 60%), by which the breaking blocked zone and high in-layer recovery of horizontal well can be made use of fully, to save development investment and improve economic returns. In reality, the well pattern is in the form of grid. Firstly, the target area is divided into grid units according to the horizontal well spacing (600 m × 1 600 m in Sulige gas field), then the reservoir structure of each unit is defined through detailed reservoir description, and finally the corresponding well pattern is deployed according to the structural characteristics. From the analysis of typical blocks, in Sulige gas field there are 30% of grid units suitable to be developed with horizontal wells, and the remaining 70% area should be developed by vertical wells.

In the 150 km2 area of the SU 6 block, 3 designs, i.e. basic well pattern (600 m × 800 m vertical well pattern), infilling well pattern (4 vertical wells in 1 km2), combined well pattern (1 horizontal well or 4 vertical wells in 1 km2) were simulated to compare. With the infilling well pattern (400 m×600 m infilled from the 600 m×800 m basic well pattern), the cumulative output of single well decreases by 21.9%, and the recovery increases by about 18% from 31.94% to 49.89%, and all the wells are economically efficient. With the combination of vertical well and horizontal well, the recovery is basically equal to that of the infilled well pattern. However, since the horizontal well investment in Sulige area is about three times that of the vertical well, the horizontal well pattern density is about one quarter of the veritcal well pattern, which means the investment of one vertical well per square kilometer is saved. Compared with the infilled well pattern, the well pattern combining horizontal and vertical wells increases the recovery from 49.89% to 50.70%, and decreases the investment from 49.14×108 CNY to 45.61×108 CNY, saving about 7% of the investment (Table 4). In recent years, in Changqing Oilfield the Second Accelerated Development Plan is proposed, according to which, within 3 years more than 5 000 vertical wells and 1 000 horizontal wells will be deployed. The above research results can provide strong support for the oilfield on-site capacity construction.

Table 4 Comparison of simulated indexes of the combined well pattern and the infilled well pattern.

| Simulated plan | Number of vertical wells/well | Average vertical well cumulative output/104 m3 | Number of horizontal wells/well | Average horizontal well cumulative output/104 m3 | Recovery/ % | Investment/ 108CNY |

|---|---|---|---|---|---|---|

| Basic well pattern | 300 | 2 306 | 0 | 0 | 31.94 | 24.57 |

| Infilled well pattern | 600 | 1 801 | 0 | 0 | 49.89 | 49.14 |

| Combined well pattern | 432 | 1 771 | 42 | 7 932 | 50.70 | 45.61 |

5. Matching technologies for improving recovery of tight gas reservoirs

For the four types of remaining gas in the tight gas reservoirs, the two main technologies, infilled well pattern and well pattern combining vertical well and the horizontal well are mainly used to produce the inter-well remaining gas, and can increase the recovery of the enrichment area from 32% to about 50%. The rest remaining gas needs to be recovered by relevant supporting technologies to improve the reservoir permeability and well drainage capacity to further enhance the recovery. In the developed enrichment area, 5 matching measures have been taken to enhance the recovery, namely tapping potential of old wells, technology optimization for new wells, optimization of production system, water drainage and gas recovery, and reduction of abandonment production rate. These measures are expected to increase the recovery by about 5% by increasing producing degree of minor gas layers.

5.1. Tapping potential of the old wells

The technical measures for tapping potentials of old wells mainly include producing new reserviors in old wells, sidetracking in old vertical wells, and repeated fracturing of old wells. Among them, producing new reserviors in old wells included reviewing gas-bearing layers in old wells, including up to HE 6 member and down to MA 5 member besides the current major reservoirs, HE 8 and Shan 1 members, and reforming the missed reserviors to improve production. The sidetracking horizontal well from the old well is mainly for Class II and III gas wells in the favorable blocks. Firstly, the gas well condition was evaluated, the 3D inter-well reservoir was predicted for gas wells meeting the sidetracking requirements, to find out the connectivity between the production wells, and the cumulative output of the sidetracking horizontal well was predicted by numerical simulation, finally the remaining gas of wells that are economically efficient was tapped to improve the effective production of the inter-well residual reserviors. The repeated fracturing is mainly for gas wells with large differences in dynamic and static evaluation. Firstly, the fracturing in original perforation layer and completion situation were analyzed, meanwhile the pressure relief of the well to be treated was compared with that of the surrounding wells to evaluate the feasibility of repeated fracturing, finally the remaining reserves due to engineering factors were produced, at the same time the missed reservoirs re-checked.

5.2. Technology optimization for new wells

After nearly 10 years of exploration and development, based on the continuous optimization and upgrading of the reservoir fracturing technology, the Sulige gas field has been developed effectively and become the largest natural gas field in China. At the same time, tight gas fields such as the Daniudi and the Denglouku are also successfully developed[16,17,18]. The fracturing in vertical well or directional well has evolved from mechanical packers to coiled tubing separated layer fracturing, which integrates precise positioning, sandblasting perforation, high flow rate fracturing, and zone isolation, to increase the layers fractured and improve significantly tight gas vertical reserve producing degree, and at the same time the wellbore conditions are more convenient for later operation. The technology solves the problems of limited flow rate, poor wellbore integrity, and low operation efficiency of the cluster well group, etc in the separate layer fracturing of vertical wells with multiple tight gas layers in the Sulige gas field. The multi-fracture fracturing technology in horizontal well section has made breakthrough. Degradable temperory plugging agents of different paritcle sizes and fiber compositions have been developed, which are similar in pressure bearing capacity and degrading time with overseas products. By using them, the effective fracturing volume of the tight gas horizontal well has been greatly increased. The problems of poor isolation in the external packer staged fracturing in horizontal wells and low fracturing degree of staged multi-cluster fracturing with bridge plugs.

5.3. Optimization of production system

The tight gas reservoirs have low porosity, serious heterogeneity, rich secondary pores and small throats, and complicated gas-water relationship, etc., which lead to the complexity of the percolation mechanism of underground fluid. This is usually manifested in production as small sweeping range of gas well pressure, rapid pressure drop, low natural productivity, and high decline rate[19,20,21]. To ensure long-term effective gas recovery, a rational production system is essential for increasing the cumulative production of the well and extending the relative stable production period. The dynamic physical simulation experiment of pressure release and pressure control exploitation in low permeability-tight sandstone gas reservoir shows that pressure release recovery has faster gas production rate, shorter production time, but lower cumulative gas production and recovery rate; pressure controlled recovery can use the formation pressure effectively and has higher gas recovery in unit pressure drop and final recovery. For gas-water producing wells, for example the gas wells in the west of Sulige gas field generally produce water, and the reservoir water body has a significant impact on the gas percolation capacity. The gas expands when pressure drops and pushs the water body to flow. Under the influence of the pressure gradient, the gas percolation capacity reduces and the water percolation capacity increases[22,23,24,25]. In this case, it is necessary to comprehensively consider the pressure control degree and liquid carrying capacity of the gas well, and set a rational output to achieve smooth production and higher recovery. The dynamic optimization method of production allocation proposed by Li Yingchuan etc.[26] considered the material balance principle, gas well productivity, wellbore temperature and pressure distribution and continuous liquid-carrying theory. According to this method, in the initial stage of production, the gas production is controlled slightly higher than the critical liquid flow at the wellhead, so as to make full use of the liquid carrying capacity of the gas well, reduce the workload of water drainage, save development cost and enhance the final recovery rate. This method has been applied to the production allocation of water-gas wells in the western area of Sulige gas field. As a result, the continuous liquid-carrying gas production wells account for about 90%, and the wells need to take water drainage measure are only about 10%, which has ensured the recovery rate and improved the development efficiency simultaneously.

5.4. Water drainage gas recovery

Tight gas wells usually have low output, weak liquid carrying capacity, relatively active formation water, and almost no pure gas enrichment zone[27]. Often from the beginning of production, they produce water and see rise of water cut. They are not able to drain the liquid loading by themselves. By the end of 2018, the wells with liquid loading exceeded 60%. In order to maximize production capacity, the effective production period, and the final cumulative gas production, many research and application tests have been carried out for the Sulige gas field, forming a series of water drainage technologies suitable for geological and technological characteristics of the gas field.

In the aspect of assisting the drainage of water in wells, a series water drainage technologies including the main measure, foam drainage, and acceleration string and plunger gas lift. In restoring production of liquid loading dead gas wells, compressor gas lift and high pressure nitrogen gas lift are employed[28,29,30]. Among them, the foam drainage is to convert the liquid at the well bottom into a low-density and easy-to- carry foamy fluid to improve the liquid-carrying capacity, to drain the water out of the wellbore. It is suitable for liquid loading wells with production of more than 0.5×104 m3/d, and has the advantages of simple equipment, easy operation, and no influence on the normal production, etc. In water drainage and gas recovery with acceleration string, the coiled tubing of small diameter is suspended at the wellhead as production string to increase the gas flow rate so as to enhance the liquid carrying capacity, and drain the water out of the wellbore with the energy of the well itself. It is suitable for the liquid loading wells with production of more than 0.3×104 m3/d, and has the advantage of one-time construction and no afterward maintenance needed. In water drainage gas recovery with plunger gas lift, the plunger is used as the mechanical interface between gas and liquid, and the energy of the well is used to push the plunger to carry out liquid periodically in the tubing, this way can effectively prevent the gas breakthrough and the liquid fall-back. It is suitable for the wells with gas production of more than 0.15×104 m3/d, and has advantages of high degree automation, safety and environmental friendliness, etc. Compressor gas lift drains the water in the well with the pressure energy of the gas, during the lifting the natural gas produced from the tubing is injected into the gas well continuously by the compressor along the annulus between tubing and casing, and the injected natural gas is then taken up from the tubing, sent through the seperator and then is pressed into the wellbore again by the compressor, by such circulation the liquid loading is drained out. High pressure nitrogen gas lift is to inject high-pressure nitrogen from the tubing (or casing), to discharge the liquid loading through the casing (or oil pipe) to restore the gas well production.

5.5. Reduction of abandonment production rate

Abandonment production rate is an important economic and technical index for gas field development and the main basis for evaluating the final recovery of gas fields[31]. The determination of the abandonment output depends on the gas price and cost. Tight gas wells often enter into production decline shortly after being put into production, with output decreasing constantly. Finally, with comprohensive consideration of the pressure system matching of the formation, wellbore and export pipeline, the well is produced at fixed pressure at higher decline rate, until the annual cash inflow of the well is equal to the cash outflow, then the well is to be abandoned, and the gas output at this point is the abandonment production rate. The final abandonment production has strong impact on the recovery of the gas well and gas field. If the abandonment production rate of Sulige gas field reduces from 0.14×104 m3/d to 0.10×104 m3/d, the cumulative gas production per well would increase by 150×104 M3, the recovery increase by about 2%. At present, wellbore water drainage and wellhead pressurization are used to reduce the abandonment pressure and the abandonment production rate, so as to realize the goal of increasing the final cumulative production and recovery of gas wells.

6. Conclusions

Three major factors cause lower technical ultimate recovery of tight gas reservoirs (60%-70%) than conventional gas reservoirs (80%-90%), namely, serious heterogeneity, poor percolation capacity, and existence of gas-water two-phase flow. Based on the analysis of reservoir geology and gas reservoir development performance, the remaining reserves of the Sulige tight gas field are divided into four types: uncontrolled by well pattern, missed by horizontal wells, incomplete perforation, and left in blocked zone of complex sand body. Among them, the reserves uncontrolled by well pattern and left in blocked zone of complex sand body are inter-well unproduced reserves, accounting for 82% of the total remaining reserves, and are the major targets for tapping remaining gas. Well pattern adjustment is the major means to improve the production rate and recovery of such reserves.

In order to improve gas field recovery and gas well development economic efficiency, two kinds of well pattern adjustment, infilling of vertical well pattern and combined well pattern of vertical and horizontal wells have been proposed. The relationship diagram of the final cumulative production, gas production increment of infilled well, and degree of inter-well interference with the change of well pattern density has been established. Four stages of recovery variation with well pattern density have been identified, and the corresponding well pattern densities determined. In the Sulige tight gas field, the rational well pattern density is 4 wells/km2 under the present gas price of 1.1-1.5 CNY/m3, and when the gas price is 1.5-2.0 CNY/m3, the rational well pattern density is 5 wells/km2. The combined well pattern is similar in recovery with the infilled vertical well pattern, but can save about 7% of development investment. In general, the two main technologies of infilled vertical well pattern and the combined vertical well-horizontal well pattern can enhance the recovery from the current 32% to about 50% in the enrichment area.

For the unproduced residual gas missed by the horizontal well and incomplete perforation, a series of matching technologies to improve recovery have been established, including tapping potentials of old wells, technology optimization for new wells, production system optimization, water drainage gas recovery, and reduction of abandonment production rate, etc., which can increase the recovery rate by another 5% on the basis of well pattern optimization.

Reference

Reserve classification and well pattern infilling method of tight sandstone gasfield: A case study of Sulige gasfield

Tight sand gas development technologies and practices in China

Well spacing optimization for Sulige tight sand gas field, NW China

The architecture analysis of the underground point bar: Taking Gudao oilfield as an example

Well type and pattern optimization technology for large scale tight sand gas, Sulige gas field

Development of geological reservoir modeling in past decade

Logging interpretation of sedimentary facies controlled reservoir in central Sulige

Analysis on controlling factors and characteristics of sandstone reservoir of He 8 (Upper Paleozoic) in the northern Ordos Basin

Reservoir geology modeling of lithological reservoir with low permeability in Xifeng oilfield, Ordos Basin

Research achievements on reservoir geological modeling of China in the past two decades

Application of high resolution sequence stratigraphy to the sand reservoir prediction for 8th Member of lower Shihezi Formation in Sulige gas field, Ordos Basin

An application of sequential simulation to reservoir modeling

Well pattern infilling strategy to enhance oil recovery of giant low-permeability tight gasfield: A case study of Sulige gasfield, Ordos Basin

DOI:10.1038/aps.2017.193 [Cited within: 1]

A research on gas flow property and starting pressure phenomenon

Recovery factor calculation method of giant tight sandstone gas field

Practice and understanding of sidetracking horizontal drilling technology in old wells in Sulige Gas Field

Propagation law of hydraulic fractures during multi-staged horizontal well fracturing in a tight reservoir

Volume fracturing and its practices in Sulige tight sandstone gas reservoirs, Ordos Basin

Present state of low permeability reservoir percolation study

Characters of micro-structure and percolation in tight sandstone gas reservoirs

The research of percolation mechanism and technical countermeasures of tight sandstones gas reservoirs

Experimental research on gas-water two phase flow and confined gas formation mechanism

Influence of the threshold pressure gradient on tight sandstone gas reservoir recovery

Seepage mechanism and strategy for large and low permeability and tight sandstone gas reservoirs with water content

Water production mechanism and development strategy of tight sandstone gas reservoirs

Study on dynamic production optimization for water produced gas wells in Daniudi low permeability gas reservoirs

Water and gas distribution and its controlling factors for large scale tight sand gas fields: A case study of western Sulige gas field, Ordos Basin, NW China

Study and application of drainage gas recovery technology in Sulige gas field

Progress and measurement of drainage gas recovery technology in Sulige gas field

Study and application of digitized drainage gas recovery system in Sulige gas field

Prediction of gas well abandonment production in the Sulige gas field