Introduction

Coalbed methane (CBM) decompression and desorption mainly go through three stages: formation water single-phase flow stage before fluid pressure drops to critical desorption pressure, gas-water two-phase flow stage when adsorbed gas starts to release a little, and gas single-phase flow stage after water in matrix pores and cleavage is basically drained[1,2,3,4]. According to the survey of drainage and gas extraction methods in major coal-bed methane producing countries such as the United States and Australia, for the medium-low rank coal seams with high permeability in general[5,6,7], the pressure reduction method is relatively simple, and water drainage method is to pump the wellbore water level below the coal seam at the fastest speed and keep the coal seam continuously exposed above the water surface. China began to develop CBM in the 1990s. Well Dacan 1 in the middle rank coal development area of Dacheng bulge in Jizhong Depression of Bohai Bay basin was trial-produced with the above drainage method, obtaining relatively high initial gas production, but the gas production rapidly declined. Researchers believed that the main reason for the rapid decline of the well production is that the rapid drainage and pressure reduction rate caused a large amount of pulverized coal to migrate and block the gas-producing channels[8]. Based on this understanding, researchers put forward the concept of pressure control and slow drainage[9,10,11,12], that is: (1) to reduce pressure by draining water slowly, to maximize the scope of pressure drop funnel before methane desorption, and provide the basis for effective supply of gas source after desorption; (2) Control the strength of water extraction to prevent the pulverized coal from migrating in the reservoir and plugging pores that would lead to the decline of permeability.

Huabei oilfield began large-scale CBM exploration and development in the high-rank coal development area of Qinshui basin, Shanxi Province in 2006, and has adhered to the concept of slow drainage and pressure control. On this basis, it has developed and deepened the five-stage, three-pressure and four-point drainage control method[13,14]. This method has worked well in Fanzhuang block, but failed to increase output and boost production capacity in the large-scale CBM development of Qinnan, Xiadian, Zhengzhuang and other blocks. The field production test results show that rapid depressurization and drainage can achieve better gas production effect for the coal-bed gas area with good geological conditions.

The above questions prompted the author to think deeply about the necessity of pressure control and slow drainage strategy. Existing references mostly focus on the simulation of reservoir permeability change and pulverized coal migration[15,16,17], and there is almost no modeling experiment on the effect of drainage and pressure reduction rate on gas production. In this study, a modeling experiment of pressure reduction and desorption of coal under stratum conditions was designed to compare the instantaneous gas production and cumulative gas production under different depressurization rates and the same fluid saturation sequence (adsorption of saturated gas first, adsorption equilibrium followed by high-pressure water injection), and find out the effect of depressurization rate on the coupling process of high-rank coal desorption and seepage.

1. The experiments

1.1. The equipment

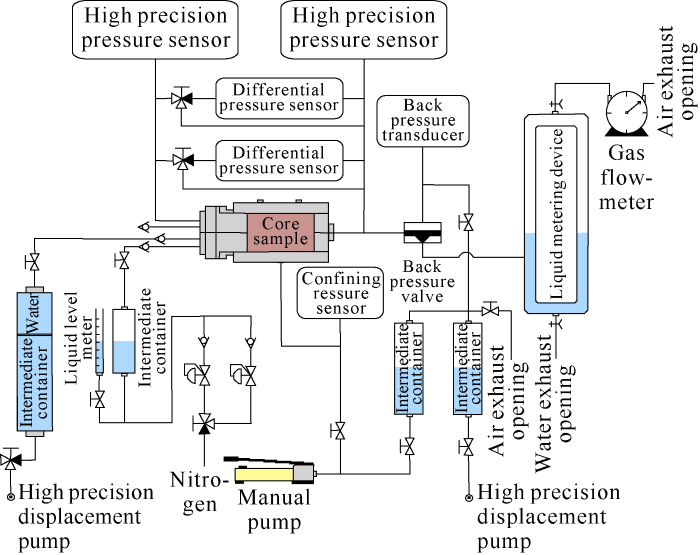

The experimental equipment was the BRP-350 gas-liquid phase permeameter produced in France. It can monitor 10 parameters in real time. All experimental parameters are automatically collected and recorded by computer, and the minimum data collection time interval is 1 s. High precision pressure sensors were used to record the pressure, pressure difference, confining pressure, back pressure and threshold pressure at both ends of the clamp in real time. The high-precision wet gas flowmeter was used to measure the tiny amount of gas that couldn’t be measured by the mass flowmeter. The permeability was accurately measured for samples with a permeability of less than 1.0×10-7 μm2 by calculating the average gas flow rate over a long period. The whole experimental device is shown in Fig. 1.

Fig. 1.

Fig. 1.

Schematic diagram of BRP-350 gas-liquid permeameter.

In order to ensure the stable control of the depressurization rate, the back-pressure system was modified. The intermediate container filling by high-pressure gas was used as buffer unit. Meanwhile, high-precision displacement pump set (Fig. 2) was used to boost and reduce the pressure according to a program to ensure the accurate control of back-pressure to simulate the process of water drainage and depressurization.

Fig. 2.

Fig. 2.

High-precision displacement pump set used to control depressurization.

1.2. The samples

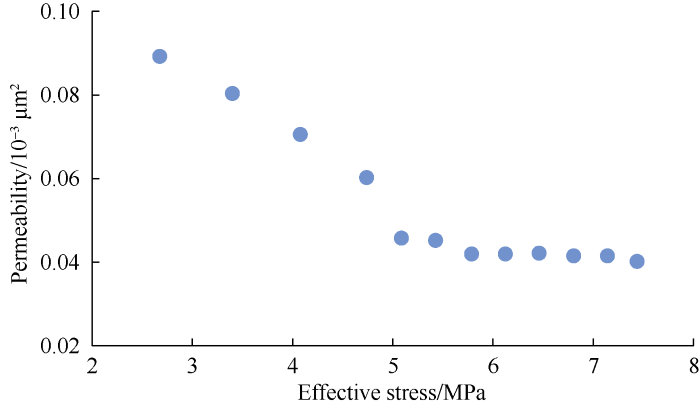

The experimental samples were taken from the underground of Jincheng Daning coal mine, and the parts with relatively uniform cleats were selected. A cylindrical sample of 214.5 g, 78.58 mm long and 50 mm in diameter was drilled along the horizontal bedding. Water permeability of the coal sample measured at 8 MPa confining pressure was 0.001 8×10-3 μm2. The experimental gas was helium, the confining pressure was kept at 8 MPa, the flowing pressure was gradually reduced, and the pressure difference between inlet and outlet was kept at about 0.34 MPa. The permeability of air dry base samples was tested under varying flow pressure to get the change curve of permeability with effective stress (Fig. 3). The experimental results show that the gas permeability decreased gradually with the increase of effective stress, and when the effective stress increased to 6 MPa, the gas permeability stabilized at around 0.04×10-3 μm2.

Fig. 3.

Fig. 3.

Variations of gas permeability with effective stress.

Permeability of several samples were tested under overburden pressure. The permeability of most samples were (0.010-0.112)×10-3 μm2 (Table 1). In Zhengzhuang block, 78.9% of evaluated wells have permeability of less than 0.1×10-3 μm2 according to well test. Kang Yongshang et al.[18] mentioned that the 3# coal in Shizhuang block of Qinshui basin had a permeability of (0.010-0.075)×10-3 μm2, and 34% of coal layers in China had a permeability of less than 0.1× 10-3 μm2. The above data shows that the permeability of the sample is close to that of most test data in Fanzhuang and Zhengzhuang blocks, and has a good representativeness.

Table 1 Measured permeability of cylindrical coal samples from the south of Qinshui Basin.

| Sample No. | Confining pressure/ MPa | Inlet pressure/ MPa | Outlet pressure/ MPa | Test medium | Permea- bility/ 10-3 μm2 |

|---|---|---|---|---|---|

| Sihe-1 | 6.30 | 2.59 | 1.97 | Helium | 0.010 4 |

| Sihe-2 | 6.20 | 4.09 | 3.11 | Helium | 0.021 4 |

| Gucheng-1 | 1.38 | 0.50 | 0 | Helium | 0.016 9 |

| Anze-1 | 11.00 | 3.50 | 3.00 | Helium | 0.028 6 |

| Sihe-3 | 6.21 | 1.30 | 0 | Air | 0.070 1 |

| Sihe-4 | 6.21 | 1.30 | 0 | Air | 0.112 0 |

| Sihe-5 | 6.21 | 1.30 | 0 | Air | 0.011 0 |

The vitrinite reflectivity test, isothermal adsorption test and industrial analysis were carried out on the peripheral samplesafter the cylindrical coal sample was drilled. The average vitrinite reflectance of Huagu, Huaxi 3# coal in Fanzhuang area of Jincheng city is 3.51%, and that of coal 3# in 39 evaluation wells in Zhengzhuang block is 3.29%-3.98%, with an average of 3.67%. The sample in this experiment has a vitrinite reflectivity of 3.38%, consistent with the evolution degree of coals in Fanzhuang and Zhengzhuang blocks. The sample in this study has a moisture of 2.91%, ash of 10.10%, volatiles of 6.73%, and vitrinite reflectivity of 3.38% according to industrial analysis, belonging to typical anthracite.

1.3. Experimental methods

The experimental system was put in an environment at the constant temperature of 25 °C. The confining pressure of the core holder was kept at 8 MPa to model the stress acting on the coal at a depth of 500 m. The sample was saturated with methane at the pressure of 2.5 MPa for more than 7 d, and when the pressure change was less than 0.007 MPa after the air source was closed in 24 h, it was considered the saturation was completed to model the critical desorption pressure. After saturated with methane, water was injected into the sample till the water and gas reached balance at injection pressure of 5 MPa. At this time, the pressure of the outlet back pressure valve was maintained at 3.0 MPa to ensure that the adsorbed methane didn’t desorb. This was to model competitive adsorption of gas and water under formation fluid pressure. The water injection process lasted for more than 48 h, till water was observed flowing out from the outlet, which indicated that the free space and coal fractures in the system had been filled by water. The actual water injection amount was 20 mL, which exceeded the fracture volume in the coal according to calculation. About 12 h after the water was observed flowing out of the outlet, it was considered the sample reached gas and water equilibrium, that is to say the reconstruction of gas and water saturation under formation conditions was completed. The same gas and water saturation operation was carried out before the start of each experiment process to ensure that the initial conditions of samples were as consistent as possible.

The process of water drainage and pressure reduction was modeled by gradually reducing the pressure of outlet back- pressure valve, the back pressure was controlled by precision displacement pump program to ensure that the pressure reduction rate decreased continuously at desired rate, so as to simulate the system pressure drop caused by the gradual drop of wellbore liquid level in the actual drainage and production process. The instrument automatically recorded the gas output and pressure changes at both ends of the sample during the experiment. The experiment was completed when the gas production rate was less than 2 mL/h. Considering that the sample used in the experiment is smaller than that of the actual system, the gas production of the whole system will change slightly with time if the depressurization rate is too low, so the depressurization rate of 0.5 MPa/d was taken first in the experiment. As the depressurization rate of the actual production block was about 0.1 MPa/d, experiments at depressurization rates of 0.3, 1.0, 3.0 MPa/d were done later.

2. The results and analysis

2.1. Final desorption rate

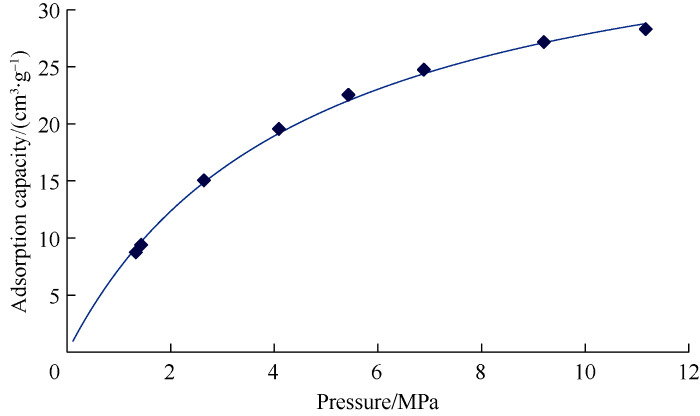

Isothermal adsorption experiment was conducted on the peripheral samples after the cylindrical sample was drilled. The experimental temperature was 25 °C, which was consistent with the formation temperature of the main blocks in Qinnan area and with the temperature of the whole modeling experiment. Under the condition of water equilibrium, the sample had a Langmuir volume of 40.544 cm3/g and a Langmuir pressure of 4.561 MPa (Fig. 4). Therefore, the methane adsorption capacity of the coal at 2.5 MPa was estimated at around 14.2 cm3/g. The final desorption gas volume of the sample at four depressurization rates were all close to 3000 mL (Table 2), with the desorption rate of over 90%. This indicates that the methane adsorbed to coal can effectively desorb no matter how fast or slow the pressure reduction rate is, as long as the desorption time is long enough. It also shows that the coal cylindrical sample reached adsorption equilibrium at the early stage when saturated with methane.

Fig. 4.

Fig. 4.

Isothermal adsorption test results of equilibrium water.

Table 2 Final desorption volume at different decompression rates.

| Depressuri- zation rate/ (MPa·d-1) | Desorption time/h | Desorption volume/mL | Theoretical adsorption capacity/mL | Desorption rate/% |

|---|---|---|---|---|

| 3.0 | 197 | 2788.2 | 3046 | 91.54 |

| 1.0 | 255 | 2969.5 | 3046 | 97.49 |

| 0.5 | 281 | 2978.7 | 3046 | 97.79 |

| 0.3 | 355 | 2875.5 | 3046 | 94.40 |

2.2. Gas production rates at different depressurization rates

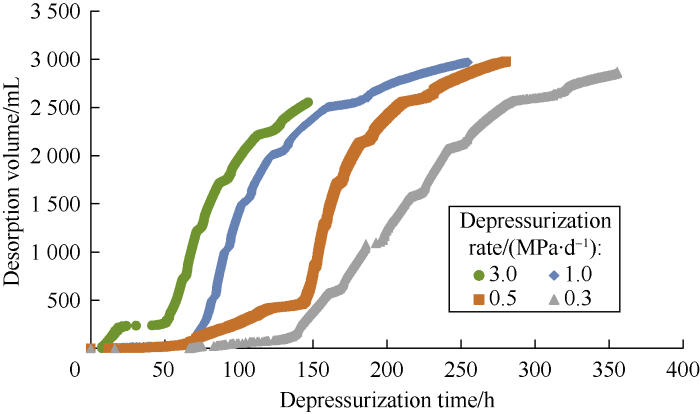

The curves of methane output with time under different depressurization rates shows that there is an obvious inflection point during the desorption process. After the inflection point, the methane output rate increases significantly and a stage of rapid desorption and gas production occurs (Fig. 5). The time needed to reach the inflection point prolongs with the decrease of the depressurization rate. When the depressurization rates are 3.0, 1.0, 0.3 MPa/d, the time needed to reach the inflection point are 48, 69 and 138 h respectively. In the actual production, the time when inflection point appears should be the time when the gas production of the gas well rises rapidly and reaches the peak.

Fig. 5.

Fig. 5.

Curves of desorption gas volume with time under different pressure reduction rates.

2.3. Relationship between gas production and pressure at front-rear ends of coal cylindrical sample

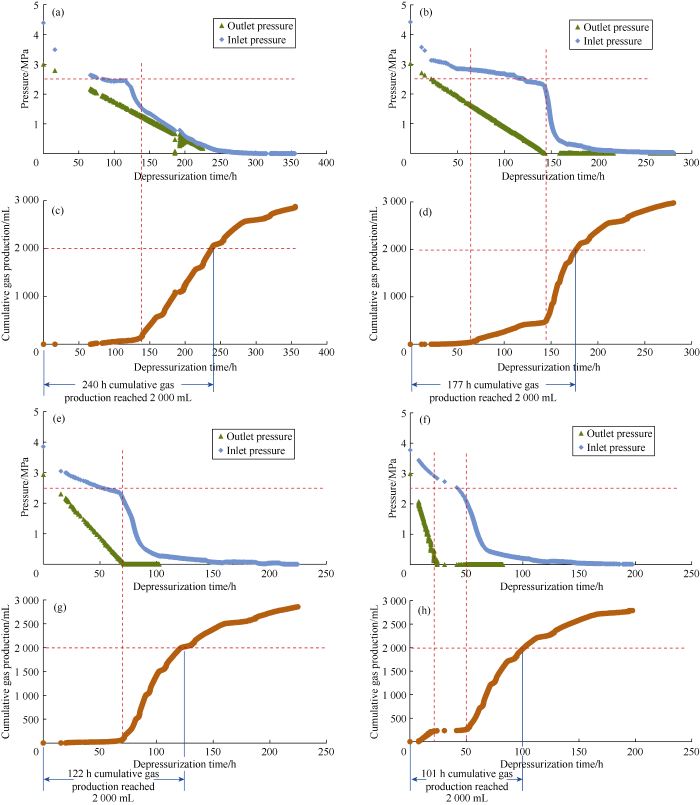

By comparing the pressure at the front and rear ends of the coal sample with the curve of gas production in the process of decompression and desorption (Fig. 6), it can be seen that the time node of sudden change in gas production is exactly when the inlet pressure (distal pressure) of the coal sample fell below the desorption pressure. This is because when the distal pressure drops below the critical desorption pressure, the whole coal body has started to desorb and produce gas. At this point, the residual water saturation in the cleat system is lower and the gas saturation is higher, and the gas-phase permeability increases rapidly, leading to a rapid increase in gas-producing rate. The rapid desorption stage occurred after the pressure at the sample inlet (distal end) decreased to 2.5 MPa saturation pressure. Under different depressurization rates, the outlet (proximal end) pressure varied greatly when fast desorption nodes appeared (Fig. 6). The above phenomenon shows that no matter how fast or slow the pressure reduction rate is, the rapid gas release stage always occurs when the coal body starts to produce gas on the whole and the water in the fractures is displaced completely by gas.

Fig. 6.

Fig. 6.

Comprehensive comparison of changes in pressure and gas production at both ends of the sample under different pressure reduction rates. (a) Pressure curve at both ends of the sample at the depressurization rate of 0.3 MPa/d; (b) Pressure curve at both ends of the sample at the depressurization rate of 0.5 MPa/d; (c) Curve of gas production at the depressurization rate of 0.3 MPa/d; (d) Curve of gas production at the depressurization rate of 0.5 MPa/d; (e) Pressure curve at both ends of the sample at the depressurization rate of 1.0 MPa/d; (f) Pressure curve at both ends of the sample at the depressurization rate of 3.0 MPa/d; (g) Curve of gas production at the depressurization rate of 1.0 MPa/d; (h) Curve of gas production at the depressurization rate of 3.0 MPa/d.

2.4. Economic benefits at different depressurization rates

Based on isothermal adsorption experiment results, it is estimated that the coal sample can adsorb 3 046 mL of methane under the saturation pressure of 2.5 MPa, and the desorption rate is nearly two-thirds when the cumulative gas production reaches 2 000 mL, and the cumulative gas production of 2 000 mL taken as the economic benefit evaluation benchmark under different pressure reduction rates. The gas production curves at different depressurization rates (Fig. 6) show that after the cumulative gas production exceeds 2 000 mL, the gas production rates begin to decrease.

According to the statistical results of gas production volume and time in stages (Table 3), it takes shorter time to reach the stage of rapid gas production under rapid pressure reduction than slow pressure reduction. It took 48 h to reach the rapid gas production stage at the depressurization rate of 3.0 MPa/d, and 138 h at the depressurization rate of 0.3 MPa/d. At the beginning of the experiment, the outlet pressure was reduced from 3 MPa. If the outlet pressure was reduced from the system equilibrium pressure of about 5 MPa, it would take much longer time to start gas production at the slow depressurization rate.

Table 3 Statistics on periodical gas production and time at different depressurization rates.

| Depressuri- zation rate/ (MPa·d-1) | Starting time of rapid desorption/h | Time to reach total gas production of 2 000 mL/h | Rapid gas production rate/ (mL·h-1) | Duration of rapid gas production/h |

|---|---|---|---|---|

| 3.0 | 48 | 101 | 32.75 | 53 |

| 1.0 | 69 | 122 | 36.60 | 53 |

| 0.5 | 142 | 177 | 44.00 | 35 |

| 0.3 | 138 | 240 | 18.14 | 102 |

The time needed to reach the total gas output of 2 000 mL at rapid depressurization rate is also earlier than that at slow depressurization rate. The experimental results show that with the decrease of depressurization rate, the time needed to reach the total gas production of 2 000 mL becomes longer gradually. At the depressurization rate of 3.0 MPa/d, it took only 101 h, while at the depressurization rate of 0.3 MPa/d, it took 240 h. The results indicate that at rapid depressurization rate, not only the time needed to reach high yield is shorter, but also the overall desorption efficiency is higher than that at slow depressurization rate.

Under the rapid depressurization mode, although gas production stagnation occurred in the early stage of desorption for a spell, both the time needed for the pressure to drop below the desorption pressure and the time to reach the desorption volume of 2 000 mL after the channels were open are shorter than those under the slow desorption mode. Therefore, from the economic point of view, the drainage at rapid pressure reduction is obviously better than that at slow pressure reduction.

3. Experimental phenomena and discussion

3.1. Factors affecting desorption rate in fast desorption stage

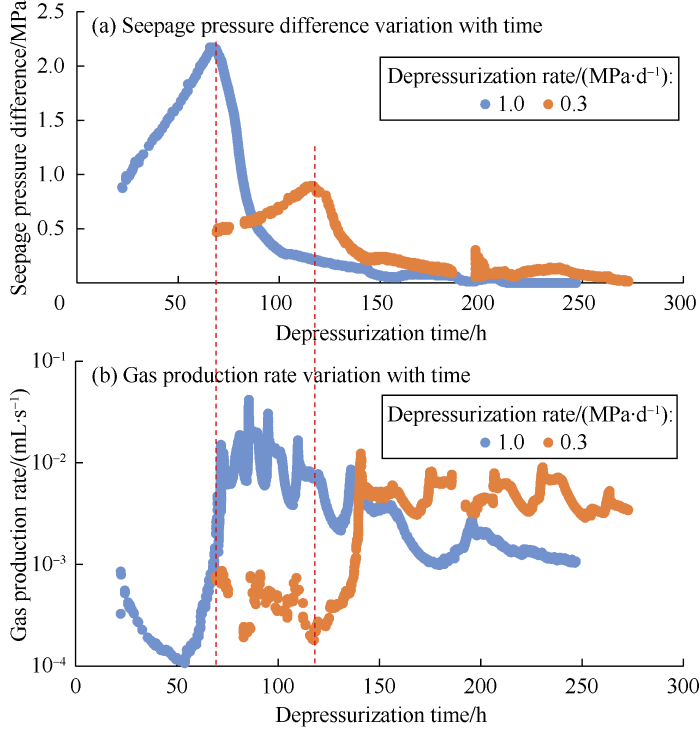

From the perspective of gas production rate after rapid desorption, the unit gas production rate of the sample at rapid pressure reduction was much higher than that of the sample at slow pressure reduction. It is concluded from analysis that the difference in pressure difference between the two ends (i.e., seepage pressure difference) after the passage is unblocked is the cause of this phenomenon. The change curve of inlet and outlet pressures at the depressurization rate of 3.0 MPa/d shows that after CBM started to desorb from the coal, the proximal pressure had already dropped to zero, while the distal pressure just dropped below the desorption pressure, and the maximum seepage pressure difference could reach 2.2 MPa, and the unit gas production rate was high (Figs. 6f and 6h). At the depressurization rate of 1.0 MPa/d, the seepage pressure difference could also reach about 2.2 MPa, and the unit gas production rate was higher (Figs. 6e and 6g). In comparison, at the depressurization rate of 0.3 MPa/d, the pressure dropped too slowly. When the distal pressure dropped to 1.8 MPa, the proximal pressure dropped to 1.3 MPa only. At this time, although all the seepage channels were cleared, the gas production rate was much lower than that in the first two depressurization processes (Figs. 6a and 6c) because the seepage pressure difference between the two ends of the sample was only 0.5 MPa.

The curves of seepage pressure difference with gas production rate at the depressurization rates of 1.0 MPa/d and 0.3 MPa/d (Fig. 7) show with the gradual rise of seepage differential pressure, the gas production rate gradually reduces first and then increases rapidly. Although the desorption rate does not reach the highest synchronously when the seepage pressure difference is maximum, the gas production rate at high seepage pressure difference is obviously higher than that at low seepage pressure difference when rapid desorption occurs. With the extension of desorption time, the desorption rates showed a decreasing trend. The results show that the desorption rate of methane is greatly affected by the difference of seepage pressure. High seepage pressure difference is conducive to rapid gas desorption.

Fig. 7.

Fig. 7.

Comparison of seepage pressure difference and gas production rate at different depressurization rates.

3.2. Analysis of reason of gas production stagnation in the early stage during rapid depressurization

When the rate of depressurization was 3.0 MPa/d, gas production interrupted and a platform appeared during 24-48 h into depressurization (Fig. 6h). This phenomenon did not appear in other slower depressurization processes, and the reasons need to be examined in-depth.

The pressure at the outlet reduced to atmospheric pressure after 24 h of depressurization at the depressurization rate of 3.0 MPa/d, and the pressure at the inlet was 2.84 MPa, still higher than the methane saturation pressure of 2.5 MPa. This indicates that the desorption at the inlet end of the coal sample (the distal end of desorption) has not yet begun, and the desorption interface still stayed inside the coal sample, the gas production was 233.7 mL, much higher than other slow desorption processes. The slow stage of gas production ended after 48 h of depressurization, the pressure at the outlet end was still atmospheric pressure, and the pressure at the inlet end dropped to 2.25 MPa, lower than the saturation pressure, indicating that the desorption interface in the coal sample had conducted to the farthest end at this moment.

The change curve of inlet and outlet pressures at the depressurization rate of 1.0 MPa/d shows (Fig. 6e) that the conduction time of desorption interface basically matches the depressurization speed. It took 72 h for the outlet pressure to drop to atmospheric pressure, and about 69 h for the inlet pressure to drop to 2.25 MPa. If 2.5 MPa is taken as the desorption pressure, the desorption interface conduction time at depressurization rates of 1.0 MPa/d and 3.0 MPa/d are 57 h and 44 h, respectively.

According to the statistics on gas production in the early stage (Table 4), at the depressurization rate of 3.0 MPa/d, the gas production in the 24-48 h stage was 17.3 mL, higher than that in other processes; the gas production reached 1 221 mL after 72 h of depressurization as the desorption entered the fast desorption stage after 48 h of depressurization. In comparison, at the pressure drop rate of 1.0 MPa/d, the desorption just entered the fast desorption stage after 72 h into the depressurization, and the gas production was only 155 mL, while the actual gas production was only 60 mL after 69 h into depressurization.

Table 4 Statistics on gas production in the early stage under different depressurization rates.

| Depressurization rate/(MPa·d-1) | Starting time of rapid desorption/h | Gas production in the first 24 h of depressurization/mL | Gas production after 48 h into depressurization/mL | Periodical gas production/mL | Gas production after 72 h/mL |

|---|---|---|---|---|---|

| 3.0 | 48 | 233.7 | 251.0 | 17.3 | 1 221 |

| 1.0 | 69 | 8.5 | 21.7 | 13.2 | 155 |

| 0.5 | 142 | 1.5 | 13.9 | 12.4 | 105 |

| 0.3 | 138 | 0 | 0 | 0 | 16 |

According to the above analysis, the gas production in the desorption interface conduction stage is very low, and the pressure drop is mainly consumed on the seepage output of fracture water. The pressure drop velocity at the 1.0 MPa/d depressurization mode matches the conduction velocity of the desorption interface, water in fractures continues to be produced, and the adsorbed gas in the coal matrix is inhibited by fracture water and difficult to desorb, so the gas production in the whole depressurization period is very small. At the depressurization rate of 3.0 MPa/d, the pressure drop rate at the outlet end of the sample is much higher than the conduction rate of the desorption interface, which does not match the seepage output velocity of fracture water. As a result, some fractures in the front end of the coal sample were filled with desorption gas, a part of the desorption channels opened and part of the gas in the front end of the coal sample desorbed. When the outlet pressure dropped to atmospheric pressure, the gas in the middle-back ends of coal sample hasn’t started to desorb, the water in the fractures hasn’t drained out yet. As the water behind the desorption interface flew towards the front end of depressurization, the fracture space at the front end of the coal sample was filled with water again, the seepage channel was blocked, and the gas permeability decreased rapidly, then gas production interrupted. With the gradual discharge of water from coal at the middle and back ends, the pressure of coal at the far-end dropped to desorption pressure, the seepage channel opened again, and the CBM in the coal began to desorb rapidly.

At the depressurization rate of 0.3 MPa/d, the fracture water had sufficient seepage time, so its pressure conduction interface reached the far end smoothly, and when the outlet pressure drop was not large, the whole coal sample has entered desorption stage. In this mode, although the gas production would not decline rapidly, the gas production before the rapid desorption stage was only 150.5 mL, and the overall pressure reduction time is much longer than the rapid pressure reduction.

3.3. Discussion on increasing coalbed methane production by slow pressure reduction

Chinese researchers generally believe that CBM drainage should adhere to the principle of "slow, long-term, sustainable and stable". Through numerical simulation, Zhao Qun et al.[9] concluded that the reason for the abrupt decline of gas production of a well in Ningwu Basin of Shanxi Province was the excessive fast speed of drainage and pressure reduction. Based on numerical simulation, Kang Yongshang et al.[19] proposed that stepwise slow pressure reduction could realize larger swept volume. Li Jinhai et al.[10] suggested that the rapid reduction of gas production to zero in a well in Jiaozuo mining area was mainly due to premature fracture closure caused by fast pressure reduction rate. Most subsequent literatures discussed the sensitivity of coal stress in different regions based on these understandings, and all maintained that rapid pressure reduction would lead to a rapid decline in coal permeability around the wellbore, thus resulting in a decline in gas production.

The calculation and analysis of above theoretical model ignored the impact caused by the prolongation of extraction and depressurization time caused by slow depressurization. Although a larger swept volume is obtained in drainage at slow depressurization rate, it does not mean that a higher average daily gas output can be obtained, especially when all drainage and depression-reduction time is taken into account. At the same time, the theoretical model is based on the wellbore model with the wellbore as the center of pressure drop funnel and the funnel spreading radially. However, in actual production, all coalbed methane wells need to be fractured, the percolation model after fracturing is drastically different from the theoretical model, so the simulation results will have deviation.

In production practice, many reasons can lead to the rapid decline of early gas production of CBM wells. According to the data analysis of CBM development wells in the southern block of Qinshui Basin, it is considered that discontinuous drainage caused by frequent pump shutdown due to the blockage of drainage and production equipment by pulverized coal was the most important factor, while the impact of the speed of pressure reduction during drainage period is not clear. Li Jinhai et al.[10] considered that the liquid level of Well X-1 in Jiaozuo mining area dropped rapidly to the floor of coal seam during drainage, because the liquid level fluctuated up and down the coal seam due to repeated pump stoppage, the gas production decreased from 500 m3/d to 300 m3/d accompanied by pulverized coal production, which indicated that pulverized coal had been transported through the seepage channel, and the pump stoppage would cause reservoir damage and thus reduce gas production. Zhao Qun et al.[9] considered that the reason why a well in Ningwu Basin rapidly reduced from the initial peak gas production of 3 112 m3/d to 1000 m3/d was that the liquid level declined too fast, resulting in small swept area and insufficient gas supply. But the drainage and production curves show that although gas pro-duction declined sharply in the later stage, water production remained at a high value of about 150 m3/d, and bottom hole flowing pressure changed slightly, which indicates that the reservoir seepage channels have been unobstructed and the permeability has not decreased significantly, that means the rapid drainage and pressure reduction in the early stage did not cause significant damage to the coal seam.

Compared with depressurization at slow rate, the permeability damage of coal does not increase obviously at fast depressurization rate. Although the effective stress on the coal matrix increases rapidly under the mode of rapid depressurization, and the decrease of permeability in the same time is larger than that under slow depressurization; when the magnitude of pressure reduction is the same, the permeability values are basically the same. Xu Xiaokai[20] carried out a modeling experiment on the influence of depressurization strength on permeability with 5 coal samples, and the results showed that the damage degree of different depressurization rates on the overall permeability of coal samples was limited. Gao Caixia et al.[21] conducted a series of experiments on the stress sensitivity of high-rank coal in Qinshui basin. They found that although the permeability of high-rank coal decreased sharply with the increase of stress before the coal was damaged by stress, the permeability could basically restore after the stress was released.

The simulation results in this study show that rapid depressurization and drainage can make the coal bed reach gas production peak as soon as possible, and the overall economic benefit is better than slow depressurization and drainage. But due to the limited representativeness of and the small number of samples used in the experiments, the universal applicability of the findings cannot be fully proved.

4. Case study

Huabei oilfield carries out commercial development of CBM in Fanzhuang block and Zhengzhuang block in the south of Qinshui basin. Fanzhuang block was put into development in 2006, and the main production coal seam is 3# coal seam of Shanxi Formation, including Fanzhuang, Chengzhuang, Zhengcun well areas. Zhengzhuang block was put into development in 2011, and the main production coal seam is 3# coal seam of Shanxi Formation. By the end of 2017, a total of 1162 vertical wells had been drilled in Fanzhuang block, with the production capacity of 7.70×108 m3/a. 1135 vertical wells were drilled in Zhengzhuang block, with a production capacity of 7.87×108 m3/a.

In production, the period from CBM well drainage and pressure reduction to casing pressure occurring in wellbore is called gas breakthrough time, and the period from pressure reduction to expected gas production is called achieving designed production time. The speed of depressurization has a direct effect on gas breakthrough time and achieving designed production time.

The large-scale development of coalbed methane in Fanzhuang block has lasted for 12 years so far. The strategy of long-term slow drainage and pressure reduction was adopted in the early stage. From 2006 to 2011, the average pure drainage time of 6 batches of vertical wells[22] before gas breakthrough was 103 d, and the actual time to reach peak production was 6-18 months, and 12 months on average. From 2016 to 2018, rapid pressure reduction strategy was adopted in the 3×108 m3 stable annual production adjustment wells in the old area of Fanzhuang. The control mode of low constant casing pressure was adopted after gas breakthrough. The drainage time before gas production was reduced to about one month, and it took about five months to reach the production of 1 000 m3 from the beginning of production.

Table 5 Statistics on CBM well production indexes under different depressurization modes.

| Production block | Production period | Well number | Average gas break- through time/d | Average production achieving time/d | Average single well gas production/(m3•d-1) |

|---|---|---|---|---|---|

| Fan Zhuang | 2006-2011 | 753 | 103 | 360 | 1 200 |

| 2016-2018 | 132 | 35 | 150 | 1 500 | |

| Zheng Zhuang | 2012-2013 | 840 | 133 | 500 | |

| 2017-2018 | 49 | 60 | 180 | 2 600 |

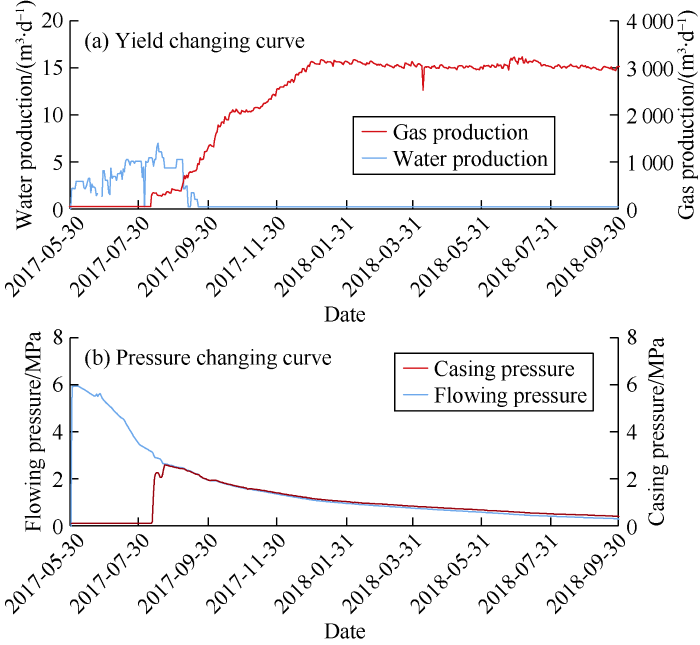

Similar to Fanzhuang block, different drainage and production strategies were also adopted in neighboring Zhengzhuang block. From 2012 to 2013, the long-term slow drainage and pressure reduction strategy was adopted, and the average drainage and production time before gas breakthrough was 133 d, and most wells didn’t have high gas production, with an average gas production per well of only 500 m3/d. From 2017 to 2018, 49 test wells in subsequent production adopted the rapid pressure reduction strategy, and the gas breakthrough time was shortened to 2 months, greatly improving the pressure reduction speed, meanwhile, the average gas production per well exceeded 2 600 m3/d, achieving the effect of rapid production rise, short production achieving time and high stable gas production (Fig. 8).

Fig. 8.

Fig. 8.

Production curves of Well Zheng 4-11-1.

The production practice in the above two blocks shows that the slow pressure reduction strategy cannot improve the gas production of CBM wells in the areas with poor geological conditions, while the fast drainage pressure reduction strategy can significantly improve the production performance of CBM wells. Therefore, the principle of "slow and long-term" drainage and pressure reduction of CBM wells is debatable.

5. Conclusions

Simulation results of drainage and field production practice show that no matter how fast or slow the drainage and pressure reduction rate is, the adsorbed gas of high rank coal can effectively desorb, the final desorption rate of CBM is high, and the gas production rate greatly increases after the overall desorption of coal. Methane production curves at different depressurization rates all have an obvious inflection point, after which the methane production rate increases significantly. The rapid gas generation stage occurs after gas desorbs from the whole coal, and the gas production rate is controlled by the pressure difference between the two ends of the coal at that time. The coupling rate of methane desorption and flow is greatly affected by the pressure difference, and high seepage pressure difference is conducive to the fast desorption of gas. Both the time for the whole coal block to fall under the desorption pressure and the total time for the desorption of most adsorbed gas (about 66%) are shorter in the fast pressure reduction mode than the slow pressure reduction mode. Therefore, from the perspective of economic benefits, the strategy of rapid pressure reduction and drainage is better than the slow pressure reduction and drainage.

Reference

Review on desorption- diffusion-flow model of coal-bed methane

.

Preliminary approach on the low of gas diffussion and permeation on coal seams

Transport mechanism of desorbed gas in coalbed methane reservoirs

Diffusion micro-mechanism of coal bed methane in coal pores

Ground water flow associated with coalbed gas production, Ferron sandstone, east central Utah

DOI:10.1016/S0166-5162(03)00077-6 URL [Cited within: 1]

Hydrogeologic factors affecting gas content distribution in coal beds

DOI:10.1016/S0166-5162(02)00135-0 URL [Cited within: 1]

Development and application of a compositional coalbed methane production model

New theory for coalbed gas exploration in China

Study on mechanism of harm to CBM well capability in low permeability seam with quick drainage method

Relationship between discharge rate and productivity of coalbed methane wells

Research on reasonable depressurization rate in initial stage of exploitation to coal bed methane

Optimization methods of production layer combination for coalbed methane development in multi-coal seams

Output characteristics of vertical wells and dewatering control method used in Fanzhuang Block of Qinshui CBM Field

Study on coal reservoir damage mechanism in dewatering and extraction process of CBM wells

Study on stress sensitivity of coal reservoir during drainage of coal-bed methane well in Southern Qinshui Basin

Study on CBM production mechanism and control theory of bottom-hole pressure and coal fines during CBM well production

Experimental study on large coal sample desorption under successive depressurization

Discussion on classification of coalbed reservoir permeability in China

Discussion about the CBM well draining technology

Stress sensitivity and pressure drop propagation law of coal reservoir during drainage process of CBM vertical well

Study on characteristics of stress sensitivity and permeability variations of high-rank coal in Qinshui Basin

Coalbed methane development characteristics and management in Fanzhuang Block of Qinshui Basin