Introduction

According to the types of reservoir space, carbonate reservoirs can be divided into 3 types: porous carbonate reservoir, fractured-porous carbonate reservoir and fracture-cavity carbonate reservoir. According to the latest oil and gas resources evaluation results, by the end of 2015, the cumulative proven petroleum reserves in China's carbonate reservoirs were 29.34×108 t[1], and the fracture-cavity reservoirs accounted for nearly 2/3. Fracture-cavity carbonate reservoirs in China are mainly distributed in the Tarim Basin. The reservoirs space consists of karst caves, fractures and dissolved vugs with various shapes and sizes[2,3]. The development characteristics and modes are different from clastic reservoirs, fractured- porous or porous carbonate reservoirs[4,5]. The Ordovician oil reservoir in Tahe Oilfield is the largest fracture-cavity carbonate reservoir in the world. After more than 20 years of development, the main blocks have been heavily flooded and are declining in water flooding efficiency. It is more and more important to know the distribution of remaining oil after water flooding in order to make development adjustment and enhance oil recovery.

Wang et al.[6], Liu[7], Cheng et al.[8], Zhang et al.[9] studied the distribution characteristics and law of remaining oil in fracture-cavity carbonate reservoirs through experiments and numerical simulations. Rong et al.[10] divided the remaining oil into 4 categories and 5 sub-categories according to the distribution characteristics based on reservoir fine description, and analysis of testing and production dynamic data. Xiong et al.[11] classified the remaining oil in District 2 of Tahe oilfield into 3 categories and 9 sub-categories using the similar method. Tang et al.[12] classified the remaining oil from three aspects: macroscopic, microscopic and apparent. Wu et al.[13], Li et al.[14] examined the factors controlling residual oil in fracture-cavity reservoirs based on physical experiments. Artun et al.[15], Goudarzi et al.[16], Kurt et al.[17], Ameri et al.[18], Ayatolahi et al.[19] proposed to extract the remaining oil in the matrix blocks of the fractured buried hill reservoirs through cyclic waterflooding, surfactant flooding, and gas flooding, etc. These researches have guided the development of fracture-cavity carbonate reservoirs. However, it also can be seen that the studies of remaining oil distribution and EOR (Enhanced Oil Recovery) in foreign carbonate reservoirs are mainly for fractured reservoirs, researches on fracture-cavity reservoirs in China are mostly based on bottom water drive, and are mainly laboratory experiments and numerical simulation, and lacking systemic researches on the controlling factors of remaining oil and EOR methods in the late stage of waterflooding.

In this study, the influences of controlling factors such as multi-scale characteristic of reservoir space, type of FCB (fracture-cavity body), shape and distribution of FCB, configuration between FCB and wells on the distribution of remaining oil were investigated, the main controlling factor model of remaining oil distribution after waterflooding was established based on comprehensive analysis of core, well logging, seismic and production performance data, and the methods of EOR have been sorted in line with the development practice of the Tahe oilfield.

1. Geological characteristics of fracture-cavity carbonate reservoirs

The fracture-cavity carbonate reservoir is different from clastic reservoir, fractured-porous or porous carbonate reservoir in geological structure characteristics. The difference in geologic structure leads to the difference in formation and distribution of remaining oil.

1.1. Multi-scales of storage space

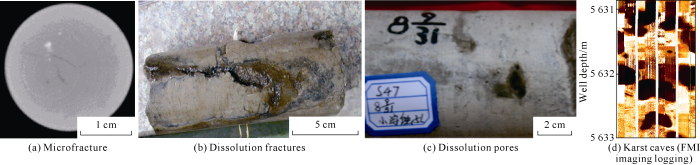

Fracture-cavity carbonate reservoirs contain many types of storage space which vary greatly in scale (Fig. 1). The smallest storage space includes micron-scale intergranular pores, intergranular pores, and microcracks. The medium scale storage space includes millimeter-scale dissolution pores and dissolution cracks. The large-scale storage space consists of meter-scale karst caves. Most large-scale caves have been filled. According to FMI imaging logging data, there are at least 0.2 m unfilled karst voids in the Ordovician of Tarim Basin (Fig. 1d).

Fig. 1.

Fig. 1.

Storage space of different scales observed from core and logging.

From micron-scale intergranular pore, intergranular pore to meter-scale unfilled karst void, the different types of storage space in fracture-cavity reservoirs can be 5-6 orders of magnitude different in scale (clastic reservoir is mostly 1-2 orders of magnitude different[20]). According to capillary model, the theoretical permeability difference is as high as 10-12 orders of magnitude. In the process of waterflooding and gas flooding, it is easier for natural bottom water or injected media to flow along high conductivity channels, such as karst conduits or large-scale faults, and the remaining oil is likely to exist in storage space with small-scale.

From the perspective of development, all macro-heterogeneity is caused by the multi-scale of reservoir storage space. The multi-scale of storage space is also one of the typical characteristics of fracture-cavity reservoirs different from other types of reservoirs.

1.2. FCB Type

The fracture-cavity body (abbreviated FCB) is the basic unit of oil and gas storage and development target. They are smaller in scale, but can group together into large-scale oil and gas-bearing area.

According to reservoir description and production performance, FCB can be divided into 3 categories and 5 sub-categories: (1) Karst cave type, showing as "strong bead" reflection on seismic profile (Fig. 2a and 2b), drilling break and mud loss may occur during drilling process[21,22]. The wells drilled in such FCB with good connectivity, strong bottom water energy and weak filling degree are characterized by high initial production, high cumulative production and long period of water free oil production, while wells drilled in FCB with poor connectivity, weak bottom water energy or high filling degree have the characteristics of low initial production, low cumulative production and insufficient liquid supply. According to the origin and shape, this type of FCB can be further subdivided into monadnock FCB, fracture-controlled FCB and channel type. Monadnock FCBs located near the crust of weathering, are formed by weathering leaching and dissolution during exposure period; fracture-controlled FCBs are located near fractures and formed through dissolution expansion on the basis of fractures; channel FCBs are mostly formed by long-term dissolution of groundwater near the ancient water table. Most of the monadnock and fracture-controlled FCBs are isolated (Fig. 2a), while the channel FCBs are in pipeline shape along the river (Fig. 2b). The karst-cave FCB is the main type of FCB in fracture-cavity reservoir, more than 70% of geological reserves are in such FCBs. (2) Fracture-vug type, which shows the reflection characteristic of "wide wave trough" on seismic profile (Fig. 2c). The wells drilled in such FCB are characterized by low initial production, low cumulative production, short period of water free oil production, slightly insufficient energy and gradual increase of water content. (3) Fracture type, which often shows the reflection characteristic of "weak insider" on seismic profile (Fig. 2d), with development characteristics of flooding and low cumulative production. Different types of FCBs have different structures, physical properties, development characteristics and remaining oil distribution.

Fig. 2.

Fig. 2.

Seismic profiles and geological models of different kinds of FCBs in fracture-cavity carbonate reservoirs.

It should be pointed out that reservoir body type is only one factor affecting development characteristics and remaining oil distribution. The development performance and remaining oil distribution of the same type of reservoir bodies with different filling, reserves scale, configuration with other reservoir bodies or production wells and aquifer energy would be different widely.

1.3. Spatial distribution of FCB

As FCBs are distributed discretely in space, the distribution and configuration of them have great influence on development. The connecting channel is the key to bottom water development and waterflooding development. The connected channel is a combination of single or multiple FCBs between two wells, or between bottom water and a well, which can be used as water driving channel. Only when there are connected channels, can the injection-production relationship be constructed.

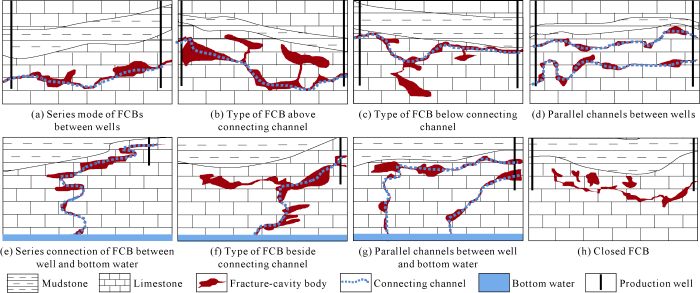

Based on reservoir description, according to the relationship between FCBs and connected channels, the spatial distribution patterns of FCBs can be classified into 3 categories and 8 subcategories. In the first category, the connected channel is located between two wells, which can be further subdivided into 4 sub-categories: (1) Series mode of FCBs between wells, FCBs are located on the connecting channel (Fig. 3a); (2) Type of FCB above connecting channel, the FCBs are located above the connecting channel, with only one channel connected with the connecting channel (Fig. 3b); (3) Type of FCB below connecting channel, the FCBs are below the connecting channel, with only one channel connected with the connecting channel (Fig. 3c); (4) Parallel connecting channels of FCB between wells, there are two or more connecting channels between two wells in parallel (Fig. 3d). In the second category, the connected channel is located between bottom water and the production well, which can be further subdivided into 3 subcategories: (1) Series connection of FCB between well and bottom water, the FCBs are distributed on the connecting channel (Fig. 3e); (2) Type of FCB beside connecting channel, the FCBs are located on the outside of the connecting channel, with only one channel connected to it (Fig. 3f); (3) Parallel channels between well and bottom water, there are two or more connected channels between the bottom water and production well in parallel (Fig. 3g). In the third category, the FCB are not connected with any channel. The close FCB can be one or more FCBs, as long as they can’t communicate with bottom water and form injection-production relationship (Fig. 3h).

Fig. 3.

Fig. 3.

Spatial distribution models of fracture-cave bodies.

1.4. FCB segmentation

According to the different segmenting media, the FCB segmentation can be divided into 3 types: (1) Tight matrix segmentation type, FCBs which are close in position but separated by matrix and not connected with each other, and independent in oil-water system; (2) FCBs separated by fillings, some original continuous channel FCBs divided into several discontinuous parts by tight barriers of different types of fillings and different filling degrees; (3) Segmentation by faults, in some FCBs, there were high conductivity faults running through originally that were migration channels of fluid and fillings, they were gradually filled and blocked by foreign materials, losing the ability of conduction and dividing the FCBs into separate parts.

2. Spatial configuration of FCBs and production well

The geologic structure of the fracture-cavity carbonate reservoir is the reason of the formation of remaining oil, and the configuration of production well and FCB is the direct reason of the formation of remaining oil. According to years of development experience of fracture-cavity carbonate reservoirs in Tahe Oilfield, the spatial configuration of FCB and production well can be classified into 4 categories.

2.1. Production well located at the highest point of the FCB

During the migration of oil and gas, hydrocarbon would enrich at the top of FCB due to the density difference of oil and water[25,26]. Therefore, during the development of fracture-cavity carbonate reservoirs, wells are better deployed at the highest point of FCB. This configuration can be subdivided into 2 categories and 4 subcategories.

(1) Wells located at the top of a single FCB. It could be subdivided into 2 categories: the well is located at the top of a single FCB with regular shape. The FCB is simple in shape and only has one high point. Another category is when the wells are located at the top of a single FCB with irregular shape. The top surface of the FCB fluctuates and has several local highs. Generally, the well is deployed at the highest point.

(2) The well is located at the top of the main FCB of connected FCBs. There are two configurations of the main FCB and the secondary FCB: the main FCB is in the higher position and in the lower position than the secondary FCBs. The production well is located at the highest point of the main FCB, and the remaining oil in the secondary ones is often difficult to produce, which becomes the main target to tap in the middle and late stages.

2.2. Production wells away from the highest point of FCB

Due to the comprehensive influence of reservoir description accuracy, drilling and completion construction, and unfavorable geological factors, these wells fail to connect directly or through fractures with the highest point of FCB. The junction between the well (or fracture) and FCB becomes an "overflow point", and the upper part provides room for remaining oil.

2.3. Production well located in the upper part of segmented FCB

When the well is located on the upper part of segmented FCB, since other FCBs are not connected to this one, the fluid in it can’t flow, and so the well can’t control all FCBs at the same time, leaving remaining oil in the unconnected FCBs. For example, a vertical well, TK222 in the District 2 of Tahe Oilfield didn’t produce oil at first. After the first sidetracking, the well had very low oil production with high water cut, but produced 25 t of oil per day in the initial stage without water after the second sidetracking to the north. By July 2018, it had produced 8.19×104 t of crude oil cumulatively.

2.4. Production wells located in the main channel (larger branch channel)

Channel FCBs are mostly in branch or net shape, with main and branch channel types, which are important sites for hydrocarbon accumulation. FCBs in the main channels or larger branch channels are large in scale and rich in oil and gas, making them preferred locations for production wells. The small branch channels with relatively small reserves tend to have fewer wells. Branch channels are small in scale individually, but large in number, so they also control considerable oil reserves .

3. Main factors controlling distribution of remaining oil after waterflooding

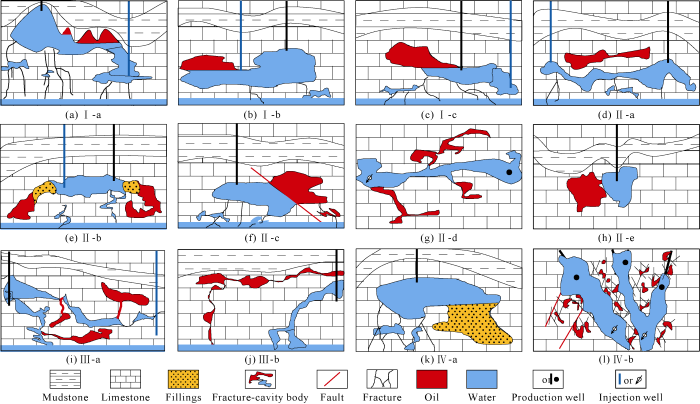

The distribution of remaining oil in fracture-cavity carbonate reservoirs after waterflooding is controlled by multi-scale storage space, FCB type, spatial distribution of FCB, segmentation, configuration with production wells and so on. By analyzing the influence, the main control factors could be summarized into 4 types (Table 1 and Fig. 4).

Table 1 Factors controlling remaining oil distribution in fracture-cavity reservoirs after water flooding.

| Category No. | Controlling factors | Subcategory No. | Reservoir type | Spatial configuration of reservoir and production well |

|---|---|---|---|---|

| Ⅰ | Local high point | a | Monadnock | Located at (or deviating from) the highest point of FCB |

| b | Irregular shape FCB | Located at (or deviating from) the highest point of FCB | ||

| c | Regular shape FCB | Deviating from the highest point of FCB | ||

| Ⅱ | Insufficient well control | a | FCB segmented by tight matrix | Located at the main FCB |

| b | FCB segmented by fillings | Located at the main FCB | ||

| c | FCB segmented by fractures | Located at the main FCB | ||

| d | Blind ends of branch channel in underground river system | Located at the main (large branch) channel | ||

| e | Multiple FCBs with small reserves and no bottom water | Located at (or deviating from) the highest point of the main FCB | ||

| Ⅲ | Flow channel shielding | a | FCBs at the upper, lower or lateral part of the connecting channel | Located at the connected channel |

| b | Poorly connected channel | Located at the better connected channel | ||

| Ⅳ | Local low permeability and weak hydrodynamics | a | Isolated FCB and filled part of underground river FCB | Located at the unfilled part of FCB |

| b | Fracture-vug FCB | Located at the cave reservoir |

Fig. 4.

Fig. 4.

Main controlling factor model of remaining oil distribution in fracture-cavity reservoirs after waterflooding.

(1) Local high point. If the well is located at the top of a regular FCB, the maximum recovery can be achieved by natural bottom drive or artificial water flooding, with little remaining oil left. But the Ⅰ-a and Ⅰ-b FCBs in Table 1 have one or more sub-highs. Ⅰ-c FCB is regular in shape, but the production well deviates from the top of the FCB, the remaining oil is often trapped above the "overflow point" due to the density difference between water and oil during the water flooding, and the local high point becomes the enrichment area of remaining oil (Fig. 4a-4c).

(2) Insufficient well control. Because of the strong anisorpy of distribution of FCBs in space, it is difficult for wells to control all geological reserves, especially when the FCBs are small or with tight isolated medium between them (or inside), the reserves in the sealed (segmented) FCBs can’t be effectively controlled. Just as II-a-II-c in Table 1, the reserves of the sealed (segmented) sub-FCB and the blind end of small branch channels (II-d), no matter how well is laid out, are difficult to be controlled effectively (Fig. 4d-4g). In addition, there are many closed FCBs (Fig. 4h, II-e), which do not connect with bottom water, and can’t construct injection-production relationship either because of their small reserves. Oil could only be replaced by injecting water (ROIW) via gravitational differentiation from wells located on the main FCB. The well could not control the secondary FCB efficiently, resulting in the retainment of remaining oil in the secondary FCB.

(3) Communication channel shielding. During water flooding, only when there are both "inlet" and "outlet" for water in one FCB, can it be swept by injected water (or bottom water). As shown in Fig. 4i (III-a), the FCB is located outside the connecting channel, and the FCB has only "entrance" but no "exit" for water, which makes it difficult to form a water drive channel, leading to the enrichment of residual oil. The other is shown in Fig. 4j (III-b), there are two or more parallel connection channels between the injection wells or between bottom water and production well (or local part). Injected water (or bottom water) flows easily along high permeability channels such as large fractures, resulting in sudden water flooding of the production well, blocking other connection channels, and thus residual oil is left.

(4) Local low permeability and weak hydrodynamic. Because of the differences in tectonic movement, dissolution and filling, low permeability areas are easily formed in areas with strong filling or weak dissolution. During water flooding, these areas are relatively weak in hydrodynamics and low in sweeping degree. As shown in Fig. 4k (IV-a) and 4l (IV-b), remaining oil is enriched in the filling part of FCB or in the area with poor physical properties. At present, it is considered that the filling of fracture-cavity reservoir is serious, 70%-80% of the fracture-cavitys are filled[27], and nearly 50% of the reserves are trapped in the filling media. Therefore, the effective development of the remaining oil of type IV-a is of great significance to the improvement of development effect.

It should also be noted that the distribution of remaining oil is the joint result of multiple factors, and the situation that remaining oil controlled by single factor in reservoir is rare. A variety of control factors influence each other, forming various remaining oil enrichment patterns. In practical production application, we should tap the remaining oil according to the main influencing factors while taking into account the minor ones.

4. Methods of EOR

Both domestic and foreign research[28,29] and development practice of Tahe Oilfield show that for reservoirs with multiple types of storage space and large scale difference, oil in large-scale space would be first recovered during development, once the larger space is occupied by water, it is often very difficult to improve the development performance. Therefore, EOR in fracture-cavity carbonate reservoirs is a systematic project, which cannot be done only in the late stage of waterflooding development, it must run through the whole development cycle: in the early stage, optimizing development design according to reservoir geological characteristics to minimize remaining oil; in the middle and late stage, the remaining oil should be tapped precisely according to the distribution characteristics of different types of remaining oil; in addition, water flooding recovery in fracture-cavity carbonate reservoirs is generally low, it is necessary to study backup techniques, carry out laboratory research and field test to further improve recovery.

4.1. Early optimum design

The development of fracture-cavity carbonate reservoirs in the early stage mainly depends on natural energy and water flooding. The development practice of Tahe oilfield shows that 50%-60% of recoverable reserves in fracture-cavity reservoirs are recovered by using natural energy. The key to efficient development by natural energy is to control production and prevent bottom water from flooding production wells. When formation pressure drops to a certain extent (to about 85% of the original according to laboratory experiments), water must be injected as soon as possible to prevent the loss of recoverable reserves due to fracture closure.

There are two kinds of water injection technologies for fracture-cavity carbonate reservoirs, displacing oil with injected water for single well fracture-cavity unit[30] and artificial water flooding for multi-well fracture-cavity units[31]. The key of artificial water flooding is the construction of injection-production well pattern, the design of which should be optimized by taking the types of reservoirs, connectivity and spatial location of reservoirs etc. into account, so that the water flooding control degree can be enhanced to reduce remaining oil through spatial structured water injection.

4.2. Remaining oil exploitation in the middle and late stage

With the increase of water cut and the number of flooded wells, the development enters the middle and late stages. The development practice of Tahe oilfield shows that after the annual comprehensive water cut exceeds 40%, the rise rate of water cut will increase obviously, and the reservoir enters the development adjustment stage with the main purpose of enhancing recovery.

Fracture-cavity carbonate reservoir is a discrete medium reservoir, with FCBs distributed discretely in space (similar to potato-like sand body in clastic reservoir). The EOR methods for this kind of reservoir are different from those for layered continuous medium reservoirs. The recovery of layered continuous medium reservoir is related to sweeping coefficient and oil displacement efficiency. To improve recovery, we should also start from improving sweep coefficient (e.g. polymer flooding) and oil displacement efficiency (e.g. surfactant injection). The recovery of fracture-cavity carbonate reservoir is not only related to sweeping coefficient and oil displacement efficiency, but also to the degree of reserves control, which can be expressed as:

where ED—oil displacement efficiency, %; ES—degree of reserves control, %; EV—sweep coefficient, %; η—recovery, %.

Development practice shows that for such discrete reservoirs small in scale individually, no matter it is clastic reservoir[32] or carbonate reservoir, increasing the degree of reserves control is the most direct and effective way and the basis to improve oil recovery, followed by improving sweeping coefficient, and finally improving oil displacement efficiency.

Therefore, the remaining oil should be tapped from 3 aspects in the middle and late stage of development of fracture-cavity carbonate reservoirs. (1) To strengthen well control by deploying adjustment wells, sidetracking and acid fracturing to improve reserves control degree; (2) To expand the water sweeping range by making use of gravity differentiation and imbibition (such as replacing oil with injected water and gas injection) and disturbing (or changing) flow fields (periodic water injection, profile control and water shutoff); (3) To improve water injection effect and oil displacement efficiency by adding surfactants. In the specific implementation process, the choice should be made according to the distribution characteristics and main control factors of remaining oil.

4.2.1. Strengthen the well control

The reason for the formation of class II-a, II-b and II-c remaining oil in Table 1 is that pressure can’t reach the unconnected FCBs. Although the main controlling factors for the formation of class II-d, II-e and IV-b remaining oil are different, the direct reason is that these parts cannot be swept by the injected water. The most direct and effective way to recover these types of remaining oil is to strengthen well control through adjustment wells, sidetracking, acid fracturing and expand the water sweeping range by making use of gravity differentiation and imbibition, disturbance flow field at the same time.

According to the scale and location of remaining oil, there are 3 main ways to strengthen well control: (1) New wells can be drilled to control FCBs and branch channels with geological reserves greater than 10×104 t and more than 500 m away from existent wells; (2) Short radius horizontal wells can be side-tracked from existent well to control FCBs with larger reserves and 150-500 m away from existent wells; (3) FCBs near existent wells (distance smaller than 150 m) can be produced by acidizing fracturing and high pressure water injection. It should be pointed out that the above indicators are not fixed values, which need to be determined by considering drilling, acid fracturing technology level, cost and oil price etc. comprehensively.

From 2016 to 2017, 13 new wells (including sidetracking) were deployed to tap the remaining oil left by insufficient well control in 4, 6 and 7 Districts of Tahe Oilfield, with an average daily oil production of 47.8 t. Acidic fracturing and high-pressure water injection are effective means to explore remaining oil near existent wells. Taking Unit S80 as an example, this unit has 27 vertical wells and 8 acid fracturing wells. By December 2017, 8 wells had a cumulative oil increment of 14.2×104 t, that is 1.5 times of that of water injection in this unit. In December 2017, displacing oil by water injection failed in Well T753CH. Through high pressure water injection (200 m3 per day, at 15.3 MPa of wellhead pressure), the connectivity of reservoir was improved and the remaining oil of class II-e was explored. After opening, the well blew out, and has produced 1715 t of oil cumulatively.

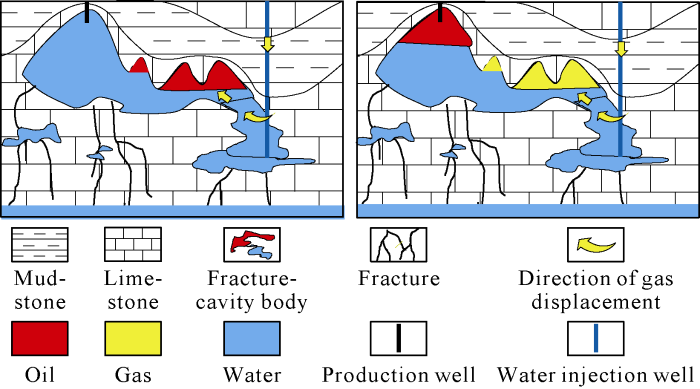

4.2.2. Gravity differentiation and imbibition

The remaining oil of class I and class III-a (in the FCBs above the connected channel) in Table 1 can be produced by single well cyclic gas injection or gas flooding. The recovery mechanism is that the injected gas enters the local high point of the FCB (or upper FCBs) due to gravity differentiation, and drives the residual oil at the top of the FCB (or upper FCBs) by forming secondary gas cap with immiscible displacement (Fig. 5). Considering gas source and gas density, nitrogen is the first choice of gas source for gas flooding in fracture-cavity reservoirs of Tarim Basin.

Fig. 5.

Fig. 5.

Schematic diagram of recovering class I-a remaining oil by gasflooding.

Take Well AD9 in 12 District of Tahe oilfield as an example. This well was put into production in October 2007 and shut down on June 19, 2012 because of high water cut. Reservoir description results show that the well was drilled in the lower part of the FCB, and it was considered that there was class I-c remaining oil at the top of the FCB. Since December 2012, nitrogen has been injected to produce the remaining oil at the top of the FCB, with a cumulative oil production increase of 3668 t by now. Gas (nitrogen) injection huff and puff and gasflooding tests were started in Tahe Oilfield in 2013, and the cumulative oil production was 154.7×104 t by December 2017.

The remaining oil of class IV-a and class III-a (located in the lower part of the connected channel) in Table 1 can be produced by oil-water displacement and imbibition. The shut-in of well during displacing oil with injected water, the stop of water injection during cyclic water flooding and shut-in coning of well with high water cut are all typical examples of gravity differentiation replacement and imbibition. During disruption of injection (production), oil and water exchanges for a long time under the actions of density difference, buoyancy and capillary force, and then oil gathers at the upper part of FCBs, and is produced after opening well.

Take well TH10323X in District 7 of Tahe Oilfield as an example. After the well was flooded by bottom water in August 2010, cyclic water injection was adopted to displace oil. The water consumption per ton of oil in the first round was 2.8 m3, and in the second round, the water consumption per ton of oil soared to 159 m3. In order to produce the remaining oil of class IV-a in the filling media, surfactant was added in the third round of water injection started in October 2012, and the water consumption per ton of oil reduced to 2.7 m3. This shows that it is feasible to increase oil displacement efficiency and improve development effect by adding surfactant in gravity differentiation or imbibition process.

Fracture-cavity reservoirs have thick production intervals, so under the action of gravity, oil, gas and water can exchange vertically. Making full use of gravity differentiation and capillary imbibition is of great significance for producing remaining oil in local high points (class I, class III-a) and low permeability areas (class IV-a, class III-a).

4.2.3. Disturb (change) flow field

The class III-a and III-b remaining oil in Table 1 is formed because the inrush of injected water or bottom water along high permeability channels such as large fractures or karst conduits shields the flow of crude oil in low permeability areas of reservoirs. These two types of remaining oil can be produced by injection-production adjustment (changing injection-production parameters, adjusting injection mode), plugging high permeability channels, shutting down well (reducing production) and inhibiting water coning. These methods can disturb (change) flow field, and make use of oil-water gravity difference and capillary imbibition to improve sweep efficiency of injected water (bottom water) and in turn development effect and oil recovery.

Class III-a remaining oil located around the waterflooding channel can be recovered by cyclic water flooding and stopping injection. During water injection, the pressure in the channel is high and the remaining oil around the channel is sealed. After stopping injection, the pressure in the channel decreases. The remaining oil in the fractures and caves around the channel enters the channel under the action of pressure difference, gravity and buoyancy. Then water is injected again to displace the remaining oil to the bottom of the well. Taking TK836CH-S86 injection-production well group in District 8 of Tahe oilfield as an example, water was injected continuously through well TK836CH starting from March 2011, and in August 2011, well S86 rose rapidly in water cut and witnessed watering-out. It was concluded through research that there was a high permeability channel between the two wells shielding the remaining oil. And then cyclic water injection was adopted to produce the remaining oil. The measure has been working well with water cut basically controlled below 75% and stable daily oil production of about 12 t.

Class III-b remaining oil is formed by the interference of different water displacement channels. This kind of residual oil can be produced by changing flow field through profile control and water shutoff measures. For this kind of remaining oil, Tahe Oilfield had implemented profile control and water shutoff in 5 well groups successively from 2016 to 2017, resulting in a cumulative oil production increment of 1.4×104 t.

It should be pointed out that there may be many types of remaining oil in the same FCB. Even the same type of remaining oil may be tapped by different technologies because of different reserves abundances and distribution location of the remaining oil. Therefore, in the actual development process, scheme to tap remaining oil should be made through comprehensive analysis, and pertinent measures should be taken to maximize recovery.

4.3. Backup technologies

Unlike buried hill fractured carbonate reservoirs in Bohai Bay Basin and porous carbonate reservoirs in the Middle East, the tricky points in the development of fracture-cavity carbonate reservoirs in Tarim Basin are the poor connectivity and continuity of reservoirs. The reservoirs have great difference in connecting channels and displacement ways of different displacement media. To improve the recovery of such reservoirs, we must focus on the key issues and make researches in 3 aspects in advance: (1) The research of new reservoir stimulation technologies such as acid fracturing and so on which can improve the connectivity of reservoirs and reserve control degree; (2) Lab research and field tests of new injection media such as foam and synergistic action of different media, to improve the injection mode, these are backup technologies to be used for development after water flooding and gas flooding; (3) Combination of information technology and artificial intelligence etc. with the development of oil and gas fields, through the overall optimization of reservoirs, wellbore, surface and management system, labor costs can be reduced and the fine and intelligent injection and production can be realized to improve development efficiency.

5. Conclusions

The distribution of remaining oil in fracture-cavity carbonate reservoirs after water flooding is influenced by the reservoir spatial scale heterogeneity, reservoir type, shape and spatial distribution of FCBs, segmentation of FCBs, spatial configuration of reservoir and production well and other geological factors. The main controlling factors can be classified into four categories: local high point, insufficient well control, communication channel shielding and weak hydrodynamic force.

EOR of fracture-cavity carbonate reservoir is a systematic project. In the stage of natural energy development, production control should be done to prevent bottom water from channeling; in the early stage of water injection development, injection-production well pattern should be built according to type, connectivity and spatial location of FCBs to improve water flooding control and producing degree and minimize remaining oil; in the middle and late stage of water flooding development, according to the main controlling factors and distribution characteristics of remaining oil, well control should be strengthened, gravity differentiation and capillary imbibition can be utilized, and disturbance (modification) of flow field and other measures can be applied to explore remaining oil accurately. At the same time, we should study backup technologies of reservoir stimulation, new injection media, and intelligent optimization which can replace water injection and gas injection to maximize oil recovery.

Reference

Distribution and fundamental science questions for petroleum geology of marine carbonate in China

Multi-layered Ordovician paleokarst reservoir detection and spatial delineation: A case study in the Tahe Oilfield, Tarim Basin, Western China

The theory and method for development of carbonate fractured-cavity reservoirs in Tahe Oilfield

Theories and practices of carbonate reservoirs development in China

Formation mechanism and distribution law of remaining oil in fracture-cavity reservoirs

Analyses of the remained oil and EOR methods for Tahe paleokarst reservoirs

Analysis of major occurrence modes of remaining oil in karstic-fracture reservoirs

Formation mechanism of remaining oil and improve development effect in fractured-cavity reservoir

Remaining oil distribution patterns and potential-tapping countermeasures in carbonate fracture-cavity reservoir

Remaining oil distribution patterns and recovery measures in fracture-cave oil reservoir

Distribution of remaining oil and improved oil recovery methods in fractured-vuggy carbonate reservoirs

Reservoir remaining oil distribution characteristics and influencing factors analysis of fracture-cavity carbonate reservoirs in Tahe Oil field

Remaining oil types and influence factors for fractured-vuggy carbonate reservoir. Fault-Block Oil and

Performance evaluation of cyclic pressure pulsing in a depleted, naturally fractured reservoir with stripper-well production

Surfactant oil recovery in fractured carbonates: Experiments and modeling of different matrix dimensions

Influence of viscous and buoyancy forces on the mobilization of residual tetrachloroethylene during surfactant flushing

Effect of non-equilibrium gas injection on the performance of (immiscible and miscible) gas oil gravity drainage in naturally fractured reservoirs

Investigation of thermal gas-oil gravity drainage (GOGD) in fractured carbonate reservoirs

Pore-throat sizes in sandstones, tight sandstones, and shales

Gas kick during carbonate reservoirs drilling and its risk assessment

Karst monadnock fine characterization and reservoir control analysis: A case from Ordovician weathering paleokarst reservoirs in Lungu area, Tarim Basin, NW China

Separation of fractures and cavities in carbonate reservoirs in the Tahe Oilfield

Description of the separation in fault- karst carbonate reservoirs in Tahe Oilfield

The characteristic analysis of paleo-karst Monadnock reservoir controlling in carbonate fractured reservoirs: By taking region 5 of Tahe Oilfield for example

Carbonate rock reservoir features and oil-gas accumulating conditions in the Ordovician of Tahe Oilfield in northern Tarim Basin

Comprehensive evaluation of fracture-cave units in karst carbonates in Tahe Oilfield, Tarim Basin

Experimental investigation on water flooding and continued EOR techniques in buried-hill metamorphic fractured reservoirs

Single well water injection production in Tahe fracture-vuggy reservoir

Discussion about pattern of water flooding development in multi-well fracture-cavity units of carbonate fracture-cavity reservoir in Tahe Oilfield

Relation between well pattern density and recovery factor through the whole period of development adjusting in sandstone reservoir