Lacustrine shale oil resource potential of Es3 L sub-member of Bonan Sag, Bohai Bay Basin, Eastern China

1

2017

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

Classification and oil system of continental shale: Es3 L sub-member of Bonan Sag, Jiyang Depression, Eastern China

1

2016

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

Shale oil occurring between salt intervals in the Dongpu Depression, Bohai Bay Basin, China

1

2015

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

Geochemical and geological characteristics of the Es3 L lacustrine shale in the Bonan Sag, Bohai Bay Basin, China

2

2015

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

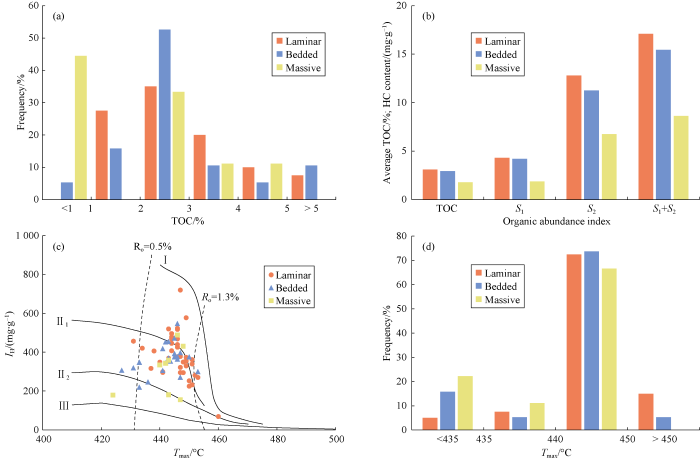

... The Shahejie Formation shale in the Jiyang depression has higher organic matter abundance. TOC values of some samples exceed 5%, and TOC shows different features in different lithofacies. The lamellar and bedded shales are similar in organic matter abundance, while the massive shale is slightly lower in organic matter abundance, and the cracked hydrocarbon content (S2) also shows the same characteristics (Fig. 2a and 2b). According to the classification of organic matter types by IH-Tmax (IH is hydrogen index, Tmax is the maximum pyrolysis temperature for kerogen) relationship, the laminar samples have types I and II1 organic matter, the bedded samples have mainly type II1 and a small amount of type II2 organic matter, and the massive samples have type II1 and type II2 organic matter. This means that the organic matter in lamellar and bedded samples have higher oil generation capacity (Fig. 2c). According to Tmax value, the samples taken are chiefly at mature stage (Fig. 2d). The Shahejie Formation in the Dongying sag has similar TOC with the Shahejie Formation in the Bonan sub-sag, but slight difference in organic matter type. The Shahejie Formation in the Bonan sub-sag has mainly type I organic matter[4]. ...

Qualitative description and full-pore-size quantitative evaluation of pores in lacustrine shale reservoir of Shahejie Formation, Jiyang Depression

3

2018

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

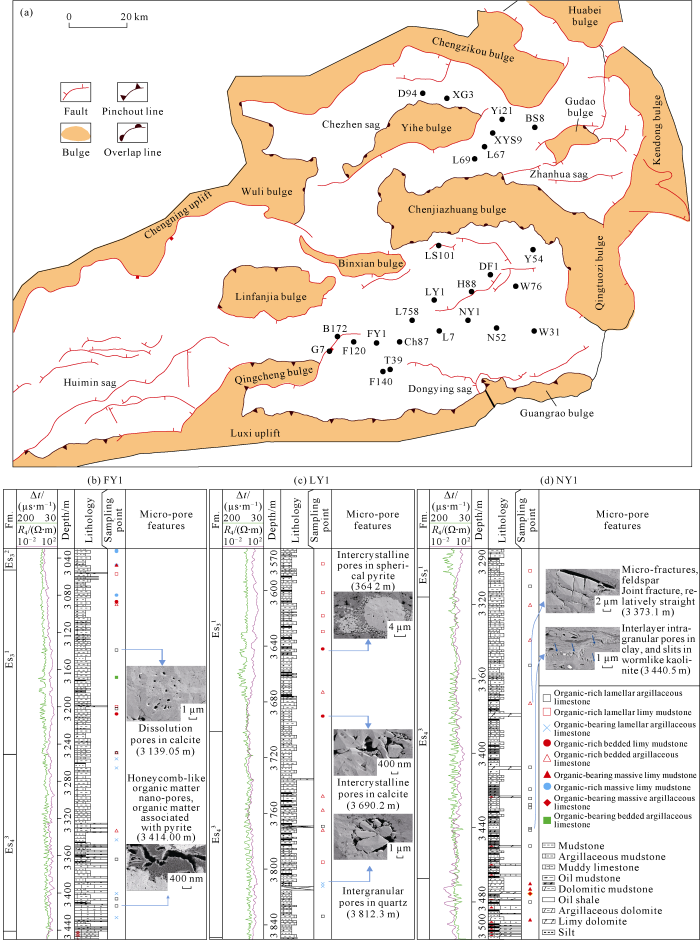

... Located in the southeastern part of the Bohai Bay Basin, the Jiyang depression consists of the Chezhen, Zhanhua, Huimin and Dongying sags and uplifts between them, with an area of about 2.5×104 km2. The Dongying sag is the largest (about 6 000 km2). On the plane, it is a NE complex half- graben with fault in the north and overlap in the south, deeper in the north and shallower in the south. The nearly EW and NE tensional and torsional large faults in the north control its sedimentary structure. Its tectonic evolution experienced rifting stage, faulting stage and depression stage[5, 28-29] (Fig. 1a). The upper sub-member of the fourth member of the Shahejie Formation (hereinafter referred to as Es4) and the lower sub- member of the third member of the Shahejie Formation (hereinafter referred to as Es3) of Paleogene in the Dongying sag have good shale oil and gas shows. Es41 (Shahejie Formation upper sub-member) is saltwater- brackish lacustrine deposit, and composed of grayish-brown calcareous laminar and stratified mudstone interbedded with marl and dolomite etc.[30] During early Es3, the lake basin enlarged, the basin faulting strengthened and the accommodation space became larger, so Es31 (Shahejie Formation lower sub-member) is freshwater-brackish lacustrine deposit. In this study, samples were taken from six wells, including Well LY1, Well NY1 and Well FY1 in the Dongying sag (Fig. 1b-1d), Well Wang31, and Well XYS9 and Well Luo67 in the Bonan sub-sag of the Zhanhua sag. Detailed information on the sedimentary environment, lithology and structure of the Shahejie Formation in the Bonan sub-sag were discussed in references [4, 31-32]. ...

... Researchers have studied shale oil resources in the Shahejie Formation in the Jiyang depression, and recognized that the potential of shale oil resources was huge[36], and many researchers have described shale oil reservoir characteristics, and found that the shale pores in the study area were smaller, mainly nano-pores and a small number of micro-pores[5,37]. But the amount and occurrence state (adsorbed, free) of shale oil in different grades (scales) of pores directly affect the mobility or the amount of movable shale oil, that is, the movability of shale oil is closely related to its occurrence mechanism, and the research in this field is weak. ...

Reservoir forming regularity and resource potential evaluation of shale oil and gas

1

2013

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

Classification of microscopic pore-throats and the grading evaluation on shale oil reservoirs

2

2018

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

... [7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

Geological characteristics of shale rock system and shale oil exploration in a lacustrine basin: A case study from the Paleogene 1st sub-member of Kong 2 Member in Cangdong sag, Bohai Bay Basin, China

1

2018

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

1

2014

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

The potential and exploring progress of unconventional hydrocarbon resources in SINOPEC

1

2012

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

Classification and evaluation of shale oil

1

2012

... Shale oil refers to the oil occurring in shale-dominated strata (shale and thin non-source rock interbeds). Shale oil occurs widely in the Daqing, Jilin, Shengli, Liaohe, Jianghan and Nanyang oilfields in central and eastern China[1,2,3,4,5,6,7,8]. Shale oil is the most challenging resource in terms of science and technology, and may be a revolutionary among unconventional oils and the first to succeed in China[9]. However, the horizontal well and large-scale fracturing copied from shale gas development don’t work so well in shale oil development. For example, Well BYP1, a well drilled specially for shale oil development in the Shengli Oilfield, had an initial oil production of only 8.22 m3/d after two times of fracturing, which quickly dropped to 1.6 m3/d. The well has a cumulative oil production of only more than 100 m3. The wells BY-HF1 and BY-2HF known as the wells with the best performance and the first major breakthrough to continental shale oil in China witnessed fast drop of production to about 1 m3/d, although they delivered high oil flows of 23.6 m3/d and 32.0 m3/d, respectively, after being fractured from the shale layers in Biyang sag of Nanyang Oilfield. Because of high drilling/operating cost, the current shale oil production is far short of commercial development value[7,10-11]. The root cause is that strong adsorption between shale oil and mineral/organic matter, and its higher viscosity than shale gas, restrict its mobility in shale, thus affecting its recovery. Mobility of shale oil is also related to the molecular composition, occurrence state and occurrence space of shale oil, therefore, evaluation of the occurrence mechanism (amount, state and pore size) and mobility of shale oil is of great significance for selecting favorable target areas and making development plan. ...

The main control factors of shale oil enrichment in Jiyang Depression

2

2015

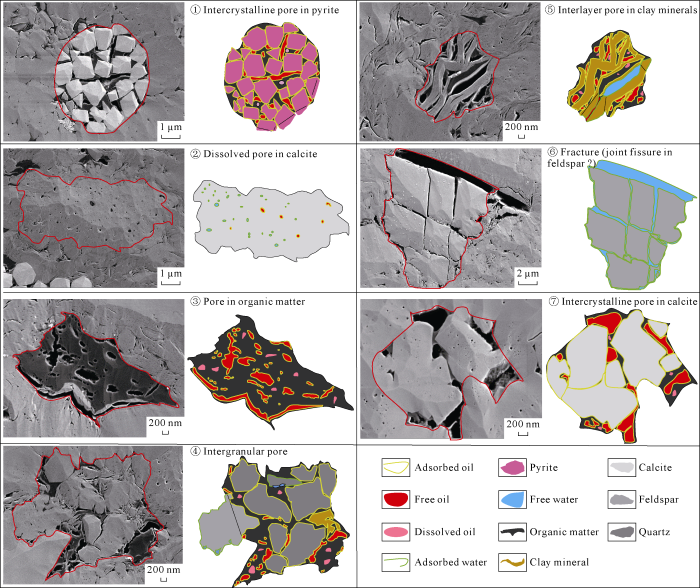

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

... Unlike shale gas, no experimental study on the effect of temperature and pressure on the adsorption performance of shale oil has been reported. But with the increase of temperature, the oil will decrease significantly in viscosity and increase in mobility, so the amount of adsorbed oil is deemed to decrease. In fact, molecular dynamics simulation has confirmed that temperature has an important effect on shale oil adsorption[47]. With the increase of temperature, the adsorption between shale oil and pore surface weakens, so the amount of adsorbed oil decreases gradually. Although it has been found from molecular dynamics that pressure has no significant effect on shale oil adsorption[47], pressure, as a driving force, has a significant effect on shale oil mobility or recoverability. The amount of oil-soluble gas has a significant effect on the adsorption of shale oil. With the increase of gas content, the adsorption capacity of shale oil decreases, resulting in the decrease of adsorption amount. Molecular dynamics simulation also confirmed that with the increase of small molecular hydrocarbon components, the adsorption amount gradually drops[47]. The increase of pressure under geological conditions can increase the amount of dissolved gas, decrease the adsorptive capacity and the viscosity of shale oil and enhance the mobility of shale oil. Therefore, many researchers considered pressure or overpressure in shale oil evaluation[12,14,29]. ...

Occurrence mechanism of shale oil with different lithofacies in Jiyang Depression

2

2017

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

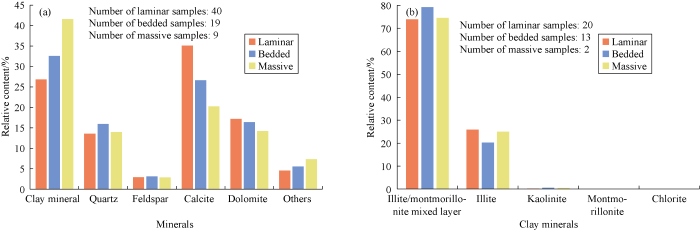

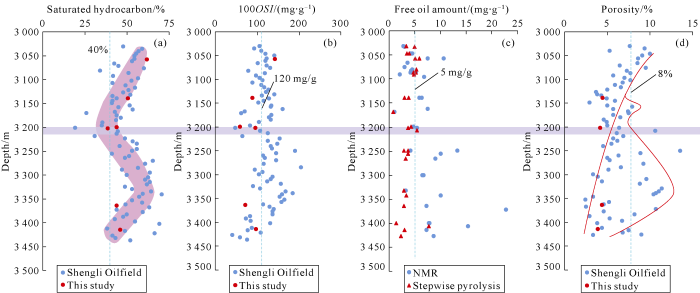

... In this study, the lithofacies of the samples were divided according to organic matter abundance, sedimentary structure and rock composition[13,17,35]. According to organic matter abundance, the samples are divided into organic-rich shale (TOC>2%), organic-bearing shale (TOC=1%-2%), and organic-lean shale (TOC<1%). Through observation of 68 shale core samples and thin sections, it is found that the samples can be divided into laminar (less than 1 mm thick per layer), bedded (more than 1 mm thick per layer) and massive (with no lamina) shale. According to rock mineral composition, the samples are mainly divided into argillaceous limestone, limy mudstone and mudstone. Previous statistics show that 73% of the shale oil producing intervals in Jiyang depression are lamellar argillaceous limestone and lamellar limy mudstone[14], so the samples used in this study were dominated by organic-rich lamellar argillaceous limestone, followed by organic-rich lamellar limy mudstone and organic-bearing lamellar argillaceous limestone, organic-rich lamellar limy mudstone and organic-bearing massive mudstone. ...

Factors controlling oil production from Paleogene shale in Jiyang Depression

3

2015

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

... In this study, the lithofacies of the samples were divided according to organic matter abundance, sedimentary structure and rock composition[13,17,35]. According to organic matter abundance, the samples are divided into organic-rich shale (TOC>2%), organic-bearing shale (TOC=1%-2%), and organic-lean shale (TOC<1%). Through observation of 68 shale core samples and thin sections, it is found that the samples can be divided into laminar (less than 1 mm thick per layer), bedded (more than 1 mm thick per layer) and massive (with no lamina) shale. According to rock mineral composition, the samples are mainly divided into argillaceous limestone, limy mudstone and mudstone. Previous statistics show that 73% of the shale oil producing intervals in Jiyang depression are lamellar argillaceous limestone and lamellar limy mudstone[14], so the samples used in this study were dominated by organic-rich lamellar argillaceous limestone, followed by organic-rich lamellar limy mudstone and organic-bearing lamellar argillaceous limestone, organic-rich lamellar limy mudstone and organic-bearing massive mudstone. ...

... Unlike shale gas, no experimental study on the effect of temperature and pressure on the adsorption performance of shale oil has been reported. But with the increase of temperature, the oil will decrease significantly in viscosity and increase in mobility, so the amount of adsorbed oil is deemed to decrease. In fact, molecular dynamics simulation has confirmed that temperature has an important effect on shale oil adsorption[47]. With the increase of temperature, the adsorption between shale oil and pore surface weakens, so the amount of adsorbed oil decreases gradually. Although it has been found from molecular dynamics that pressure has no significant effect on shale oil adsorption[47], pressure, as a driving force, has a significant effect on shale oil mobility or recoverability. The amount of oil-soluble gas has a significant effect on the adsorption of shale oil. With the increase of gas content, the adsorption capacity of shale oil decreases, resulting in the decrease of adsorption amount. Molecular dynamics simulation also confirmed that with the increase of small molecular hydrocarbon components, the adsorption amount gradually drops[47]. The increase of pressure under geological conditions can increase the amount of dissolved gas, decrease the adsorptive capacity and the viscosity of shale oil and enhance the mobility of shale oil. Therefore, many researchers considered pressure or overpressure in shale oil evaluation[12,14,29]. ...

Enrichment controls and models of shale oil in the Jiyang Depression, Bohai Bay Basin

1

2017

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

Main control factors of enrichment characteristics of shale oil in Jiyang Depression

1

2015

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

Genetic connection between mud shale lithofacies and shale oil enrichment in Jiyang Depression, Bohai Bay Basin

2

2016

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

... In this study, the lithofacies of the samples were divided according to organic matter abundance, sedimentary structure and rock composition[13,17,35]. According to organic matter abundance, the samples are divided into organic-rich shale (TOC>2%), organic-bearing shale (TOC=1%-2%), and organic-lean shale (TOC<1%). Through observation of 68 shale core samples and thin sections, it is found that the samples can be divided into laminar (less than 1 mm thick per layer), bedded (more than 1 mm thick per layer) and massive (with no lamina) shale. According to rock mineral composition, the samples are mainly divided into argillaceous limestone, limy mudstone and mudstone. Previous statistics show that 73% of the shale oil producing intervals in Jiyang depression are lamellar argillaceous limestone and lamellar limy mudstone[14], so the samples used in this study were dominated by organic-rich lamellar argillaceous limestone, followed by organic-rich lamellar limy mudstone and organic-bearing lamellar argillaceous limestone, organic-rich lamellar limy mudstone and organic-bearing massive mudstone. ...

Molecular simulation of oil mixture adsorption character in shale system

1

2017

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

Oil adsorption in shale nanopores and its effect on recoverable oil-in-place

2

2015

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

... [19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

Occurrence state and mobility analysis of shale oil in Jiyang Depression

1

2015

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

Nuclear magnetic resonance T1-T2 map division method for hydrogen-bearing components in continental shale

1

2018

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

Adsorption of mudstone source rock for shale oil: Experiments, model and a case study

1

2016

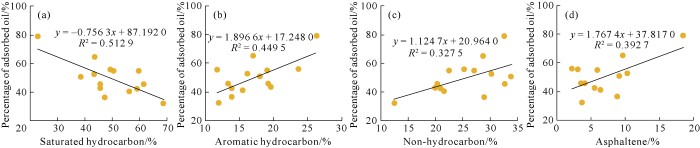

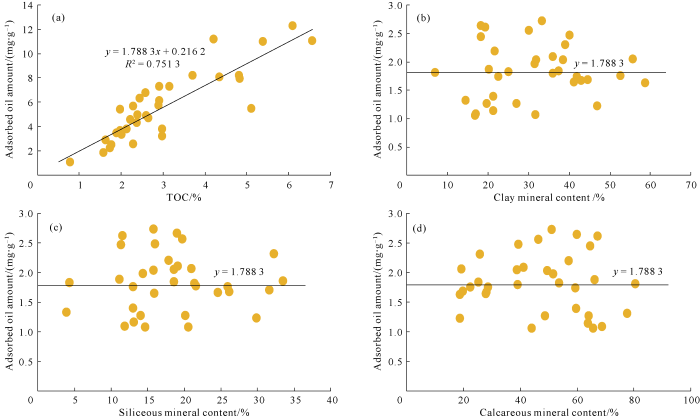

... In order to eliminate the influence of organic matter content, the relationship between mineral content and oil content per unit organic matter was obtained by dividing the content of adsorbed oil by TOC of the sample (Fig. 10b-d). It can be found that there is no correlation between the content of clay minerals, siliceous minerals and calcareous minerals and the content of adsorbed oil. Although some inorganic pore surface also show oil wettability, and can adsorb shale oil, but the on one hand pore/specific surface is not completely controlled by mineral content, and on the other hand, the specific surface of the sample with shale oil adsorption capacity follow no rules, especially, the pores of clay minerals which control the specific surface area are not all oil-wet, so there is no obvious correlation between the amount of adsorbed oil and mineral content. Results of previous studies by mass and concentration methods show that clay minerals have higher oil adsorption capacity, while calcite and quartz minerals have lower oil adsorption capacity[22,47]. But this conclusion is based on dried samples, rather than wettability/adsorption of water-bearing samples. According to the results of molecular dynamics simulation, clay, calcite, and dolomite etc. all show hydrophilic characteristics under the coexistence of oil, water and rock three phases[48,49], and the content of adsorbed hydrocarbons in shale decreases sharply under water-bearing condition[50,51]. In this study, the adsorption capacity was tested under water-bearing condition, and the results show the adsorptive capacity is mainly controlled by kerogen (especially TOC) and has no obvious relationship with mineral contents. ...

Characterization of organic matter fractions in an unconventional tight gas siltstone reservoir

0

2015

Occurrence of stable and mobile organic matter in the clay-sized fraction of shale: Significance for petroleum geology and carbon cycle

0

2016

Quantitative characterization of shale oil in different occurrence states and its application

1

2016

... (1) Stepwise pyrolysis. The sample was crushed to 124-150 μm (100-120 mesh) and 100 mg powdered sample was taken for pyrolysis analysis with a Rock-Eval 6 instrument. The product S1-1 was tested after the sample was heated to and kept at 200 °C for 1 min; and then the sample was heated to 350 °C at the temperature rise rate of 25 °C/min and kept at 350 °C for 1 min, then the product S1-2 was tested. After 350 °C, the sample was heated to 450℃ at the temperature rise rate of 25 °C/min and kept at the temperature for 1 min, and then the product S2-1 was tested. After exceeding 450 °C, the sample was heated to 600 °C at the temperature rise rate of 25 °C/min and then the product S2-2 was measured. S1-1 stands for movable oil, (S1-1+S1-2) for free oil (i.e. the maximum movable oil), S2-1 for adsorbed oil, and S2-2 for kerogen cracking oil[25]. It should be noted that, strictly, the product, such as free oil, obtained by the hydrogen flame ionization detector in the Rock-Eval is actually free hydrocarbon, while the product obtained by other means, such as oil washing/extraction, is oil (hydrocarbon + non-hydrocarbon), referred as movable oil, free oil and adsorbed oil in this paper. ...

Quantitative characterization of extractable organic matter in lacustrine shale with different occurrences

0

2017

Hydrocarbon and crude oil adsorption abilities of minerals and kerogens in lacustrine shales

2

2015

... Previously, researchers mainly tried to reveal the factors controlling the enrichment of shale oil in the Jiyang depression from macroscopic analysis of well location and production, lithofacies, overpressure, fracture development, interlayer, porosity, permeability and movability (S1/TOC) of shale oil[12,13,14,15,16,17], and found that lamellar shale was favorable for shale oil and gas development; high pressure, interlayer, fracture development and mobility were factors controlling local high production of shale oil. In terms of the occurrence mechanism of shale oil, molecular simulation was used to reveal the adsorption mechanism of shale oil/alkanes at micro-scale[18,19], and it was found that there were four adsorption layers of crude oil (n-decane) in nano-fractures in quartz. The methods studying occurrence state of shale oil include direct and indirect methods. Direct methods, like scanning electron microscopy (SEM), environmental scanning electron microscopy (E-SEM), CT scanning, electron beam charge effect, energy spectrum and other technologies, can observe and simulate oil directly to find out the occurrence states and pore types of oil[20]. Indirect methods, like nuclear magnetic resonance (combined with centrifugal/displacement), Rock-Eval pyrolysis experiment, extraction experiments with different polar solvents and molecular dynamics simulation, characterize the pore diameter, occurrence state and content of oil[19, 21-27]. It is recognized that shale oil exists in adsorbed, free and soluble (dissolved) states. ...

... The amount of adsorbed oil is related not only to the composition of shale oil, but also to the abundance of organic matter and mineral composition of shale. It can be seen from Fig. 10 that there is a good linear positive correlation between the amount of adsorbed oil and TOC: the higher the TOC value, the higher the adsorbed oil amount will be (Fig. 10a). Therefore, for the shales with the same oil content, the lower the TOC, the less the adsorbed oil amount and the higher the movable oil ratio will be. The adsorbed oil obtained from stepwise pyrolysis is mainly from dissolved kerogen. In addition, the pores associated with organic matter are oil-wet, so their surface can adsorb a certain amount of oil. It can be seen from Fig. 10a that the retained oil (dissolved + adsorbed) is about 179 mg/g per unit of TOC. It is noteworthy that the fitting equation in Fig. 10a doesn’t cross the origin, indicating that the residual oil includes not only the oil dissolving organic matter and adsorbed to organic pore surface, but also some oil adsorbed by some inorganic pore surface. The amount of adsorbed oil in inorganic minerals is about 0.2162 mg/g per unit of rock (the intersection with the Y axis). The amount of adsorbed/dissolved oil is related not only to the type of kerogen, the degree of thermal evolution of kerogen and the development of organic pores associated with kerogen, but also to the composition of oil. It can be seen that a consensus hasn’t been reached on the understanding of organic matter adsorption/dissolved oil. Pepper et al. used S1/TOC of 0.1 or “A”/TOC of 0.2 as the boundary of adsorption saturation of marine source rock[43,44]. According to theoretical calculation, Tian Shansi et al.[45] believed that the oil content related to type I and type II1 kerogen (adsorbed + swelled) is 130-150 mg/g organic carbon per unit mass. Wei et al.[46] found through experiments that the amount of adsorbed oil related to kerogen in the Dongying depression was 40-120 mg/g per unit of TOC. Through swelling experiments, Zhang Linye et al.[27] considered that the retained oil amount in Es3 and Es4 was 123.07 mg/g per unit mass of kerogen and 142.29 mg/g kerogen respectively. The oil composition (43.49% of saturated hydrocarbons, 17.78% of aromatic hydrocarbons, 17.46% of non-hydrocarbons and 6.98% of asphaltene) used in Zhang Linye's experiment is similar to that of the sample extracts (49.52% of saturated hydrocarbons, 17.13% of aromatic hydrocarbons, 25.59% of non-hydrocarbons and 7.05% of asphaltene) in this study. Assuming that the conversion coefficient between kerogen and TOC is 0.8, then the conclusion reached by Zhang Linye et al. is consistent with the statistical result of this study. Compared with the conclusion from this study, the adsorption capacity of pure minerals in previous studies is generally higher. The main cause is that the adsorption occurs only on the pore surface related to minerals, not on all surface of pure minerals in the experiment, and the existence of bound water on the surface of some minerals under geologic conditions reduces the adsorption capacity. It can be seen that it is more appropriate to work out the adsorption/dissolution amount of shale oil and the adsorption capacity of minerals by statistical analysis in specific areas. ...

Geochemical evaluation of shale oil in Lower Es3 and Upper Es4 in Jiyang Depression

1

2015

... Located in the southeastern part of the Bohai Bay Basin, the Jiyang depression consists of the Chezhen, Zhanhua, Huimin and Dongying sags and uplifts between them, with an area of about 2.5×104 km2. The Dongying sag is the largest (about 6 000 km2). On the plane, it is a NE complex half- graben with fault in the north and overlap in the south, deeper in the north and shallower in the south. The nearly EW and NE tensional and torsional large faults in the north control its sedimentary structure. Its tectonic evolution experienced rifting stage, faulting stage and depression stage[5, 28-29] (Fig. 1a). The upper sub-member of the fourth member of the Shahejie Formation (hereinafter referred to as Es4) and the lower sub- member of the third member of the Shahejie Formation (hereinafter referred to as Es3) of Paleogene in the Dongying sag have good shale oil and gas shows. Es41 (Shahejie Formation upper sub-member) is saltwater- brackish lacustrine deposit, and composed of grayish-brown calcareous laminar and stratified mudstone interbedded with marl and dolomite etc.[30] During early Es3, the lake basin enlarged, the basin faulting strengthened and the accommodation space became larger, so Es31 (Shahejie Formation lower sub-member) is freshwater-brackish lacustrine deposit. In this study, samples were taken from six wells, including Well LY1, Well NY1 and Well FY1 in the Dongying sag (Fig. 1b-1d), Well Wang31, and Well XYS9 and Well Luo67 in the Bonan sub-sag of the Zhanhua sag. Detailed information on the sedimentary environment, lithology and structure of the Shahejie Formation in the Bonan sub-sag were discussed in references [4, 31-32]. ...

Movability of lacustrine shale oil: A case study of Dongyin Sag, Jiyang Depression, Bohai Bay Basin

2

2014

... Located in the southeastern part of the Bohai Bay Basin, the Jiyang depression consists of the Chezhen, Zhanhua, Huimin and Dongying sags and uplifts between them, with an area of about 2.5×104 km2. The Dongying sag is the largest (about 6 000 km2). On the plane, it is a NE complex half- graben with fault in the north and overlap in the south, deeper in the north and shallower in the south. The nearly EW and NE tensional and torsional large faults in the north control its sedimentary structure. Its tectonic evolution experienced rifting stage, faulting stage and depression stage[5, 28-29] (Fig. 1a). The upper sub-member of the fourth member of the Shahejie Formation (hereinafter referred to as Es4) and the lower sub- member of the third member of the Shahejie Formation (hereinafter referred to as Es3) of Paleogene in the Dongying sag have good shale oil and gas shows. Es41 (Shahejie Formation upper sub-member) is saltwater- brackish lacustrine deposit, and composed of grayish-brown calcareous laminar and stratified mudstone interbedded with marl and dolomite etc.[30] During early Es3, the lake basin enlarged, the basin faulting strengthened and the accommodation space became larger, so Es31 (Shahejie Formation lower sub-member) is freshwater-brackish lacustrine deposit. In this study, samples were taken from six wells, including Well LY1, Well NY1 and Well FY1 in the Dongying sag (Fig. 1b-1d), Well Wang31, and Well XYS9 and Well Luo67 in the Bonan sub-sag of the Zhanhua sag. Detailed information on the sedimentary environment, lithology and structure of the Shahejie Formation in the Bonan sub-sag were discussed in references [4, 31-32]. ...

... Unlike shale gas, no experimental study on the effect of temperature and pressure on the adsorption performance of shale oil has been reported. But with the increase of temperature, the oil will decrease significantly in viscosity and increase in mobility, so the amount of adsorbed oil is deemed to decrease. In fact, molecular dynamics simulation has confirmed that temperature has an important effect on shale oil adsorption[47]. With the increase of temperature, the adsorption between shale oil and pore surface weakens, so the amount of adsorbed oil decreases gradually. Although it has been found from molecular dynamics that pressure has no significant effect on shale oil adsorption[47], pressure, as a driving force, has a significant effect on shale oil mobility or recoverability. The amount of oil-soluble gas has a significant effect on the adsorption of shale oil. With the increase of gas content, the adsorption capacity of shale oil decreases, resulting in the decrease of adsorption amount. Molecular dynamics simulation also confirmed that with the increase of small molecular hydrocarbon components, the adsorption amount gradually drops[47]. The increase of pressure under geological conditions can increase the amount of dissolved gas, decrease the adsorptive capacity and the viscosity of shale oil and enhance the mobility of shale oil. Therefore, many researchers considered pressure or overpressure in shale oil evaluation[12,14,29]. ...

Pore evolution of shale oil reservoirs in Dongying Sag

1

2018

... Located in the southeastern part of the Bohai Bay Basin, the Jiyang depression consists of the Chezhen, Zhanhua, Huimin and Dongying sags and uplifts between them, with an area of about 2.5×104 km2. The Dongying sag is the largest (about 6 000 km2). On the plane, it is a NE complex half- graben with fault in the north and overlap in the south, deeper in the north and shallower in the south. The nearly EW and NE tensional and torsional large faults in the north control its sedimentary structure. Its tectonic evolution experienced rifting stage, faulting stage and depression stage[5, 28-29] (Fig. 1a). The upper sub-member of the fourth member of the Shahejie Formation (hereinafter referred to as Es4) and the lower sub- member of the third member of the Shahejie Formation (hereinafter referred to as Es3) of Paleogene in the Dongying sag have good shale oil and gas shows. Es41 (Shahejie Formation upper sub-member) is saltwater- brackish lacustrine deposit, and composed of grayish-brown calcareous laminar and stratified mudstone interbedded with marl and dolomite etc.[30] During early Es3, the lake basin enlarged, the basin faulting strengthened and the accommodation space became larger, so Es31 (Shahejie Formation lower sub-member) is freshwater-brackish lacustrine deposit. In this study, samples were taken from six wells, including Well LY1, Well NY1 and Well FY1 in the Dongying sag (Fig. 1b-1d), Well Wang31, and Well XYS9 and Well Luo67 in the Bonan sub-sag of the Zhanhua sag. Detailed information on the sedimentary environment, lithology and structure of the Shahejie Formation in the Bonan sub-sag were discussed in references [4, 31-32]. ...

Study on formation stages of oilgas reservoirs in Bonan sub-sag, Zhanhua Sag

0

2012

Genetic types and distribution characteristic of crude oils from Shehejie Fromation in Bonan Subsag, Zhanhua Sag, Jiyang Depression

0

2014

Pore distribution of source rocks as reavealed by gas a dsorption and mercury injection methods: A case study on the first Member of the Cretaceous Qingshankou Formation in the Songliao Basin

0

2013

Multifractal characteristics of microscopic pore of Shahejie Formation shale in Dongying Sag, Jiyang Depression

0

2019

Lithologic characteristics of Lower Es3 shale in Luojia area, Zhanhua Sag

1

2012

... In this study, the lithofacies of the samples were divided according to organic matter abundance, sedimentary structure and rock composition[13,17,35]. According to organic matter abundance, the samples are divided into organic-rich shale (TOC>2%), organic-bearing shale (TOC=1%-2%), and organic-lean shale (TOC<1%). Through observation of 68 shale core samples and thin sections, it is found that the samples can be divided into laminar (less than 1 mm thick per layer), bedded (more than 1 mm thick per layer) and massive (with no lamina) shale. According to rock mineral composition, the samples are mainly divided into argillaceous limestone, limy mudstone and mudstone. Previous statistics show that 73% of the shale oil producing intervals in Jiyang depression are lamellar argillaceous limestone and lamellar limy mudstone[14], so the samples used in this study were dominated by organic-rich lamellar argillaceous limestone, followed by organic-rich lamellar limy mudstone and organic-bearing lamellar argillaceous limestone, organic-rich lamellar limy mudstone and organic-bearing massive mudstone. ...

Resource evaluation method for shale oil and its application

1

2013

... Researchers have studied shale oil resources in the Shahejie Formation in the Jiyang depression, and recognized that the potential of shale oil resources was huge[36], and many researchers have described shale oil reservoir characteristics, and found that the shale pores in the study area were smaller, mainly nano-pores and a small number of micro-pores[5,37]. But the amount and occurrence state (adsorbed, free) of shale oil in different grades (scales) of pores directly affect the mobility or the amount of movable shale oil, that is, the movability of shale oil is closely related to its occurrence mechanism, and the research in this field is weak. ...

Reservoir Characteristics of Lacustrine Shale and Marine Shale: Examples from the Songliao Basin, Bohai Bay Basin and Qiannan Depression

1

2016

... Researchers have studied shale oil resources in the Shahejie Formation in the Jiyang depression, and recognized that the potential of shale oil resources was huge[36], and many researchers have described shale oil reservoir characteristics, and found that the shale pores in the study area were smaller, mainly nano-pores and a small number of micro-pores[5,37]. But the amount and occurrence state (adsorbed, free) of shale oil in different grades (scales) of pores directly affect the mobility or the amount of movable shale oil, that is, the movability of shale oil is closely related to its occurrence mechanism, and the research in this field is weak. ...

Pore structure characteristics of coal-bearing shale using fluid invasion methods: A case study in the Huainan-Huaibei Coalfield in China

1

2015

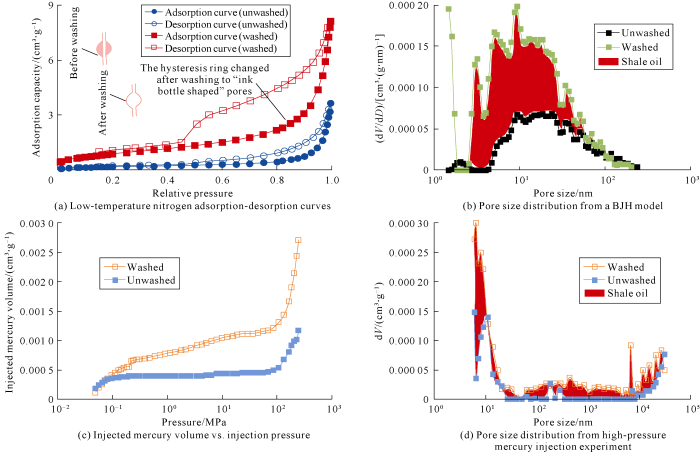

... The results of low-temperature nitrogen adsorption and high-pressure mercury intrusion experiments of washed and unwashed shale samples were compared to find out the sizes of pores in which shale oil exists (Fig. 4). It can be seen from Fig. 4a that the low-temperature nitrogen adsorption and desorption values of the washed samples are much higher than those of the samples not washed, which indicates that shale oil released during washing, and the hysteresis rings changed after washing, from wedge-shaped pores to ink bottle-shaped pores. From the change of pore diameters before and after oil washing, shale oil mainly occurs in pores of 3-80 nm (Fig. 4b). The experimental results of high-pressure mercury injection before and after oil washing (Fig. 4c) show that the volume of mercury entering after oil washing increased obviously, and shale oil exists in the pores of several nanometers to more than ten microns (Fig. 4d). It should be noted that the mercury injection pressure is high (up to 200 MPa). For unwashed samples, higher injection pressure may cause residual free oil to move and squeeze into smaller pores. In addition, organic matter/asphalt/clay minerals with relatively strong plasticity may shrink at higher pressure, making the smaller pore volume higher at high pressure. Wang et al. found through study that[38], when the pressure was higher than 25 MPa, the small shale samples with injected mercury would deform. Li Zhuo et al.[39] adopted 80 nm pore diameter to splice the shale pore diameter characterize by low-temperature nitrogen adsorption and high-pressure mercury injection. In this study, through comprehensive consideration, 65 nm pore diameter was taken as the splicing point of the results of the two kinds of experiments. ...

Lithofacies characteristics and its effect on pore structure of the marine shale in the low Silurian Longmaxi Formation, Southeastern Chongqing

1

2017

... The results of low-temperature nitrogen adsorption and high-pressure mercury intrusion experiments of washed and unwashed shale samples were compared to find out the sizes of pores in which shale oil exists (Fig. 4). It can be seen from Fig. 4a that the low-temperature nitrogen adsorption and desorption values of the washed samples are much higher than those of the samples not washed, which indicates that shale oil released during washing, and the hysteresis rings changed after washing, from wedge-shaped pores to ink bottle-shaped pores. From the change of pore diameters before and after oil washing, shale oil mainly occurs in pores of 3-80 nm (Fig. 4b). The experimental results of high-pressure mercury injection before and after oil washing (Fig. 4c) show that the volume of mercury entering after oil washing increased obviously, and shale oil exists in the pores of several nanometers to more than ten microns (Fig. 4d). It should be noted that the mercury injection pressure is high (up to 200 MPa). For unwashed samples, higher injection pressure may cause residual free oil to move and squeeze into smaller pores. In addition, organic matter/asphalt/clay minerals with relatively strong plasticity may shrink at higher pressure, making the smaller pore volume higher at high pressure. Wang et al. found through study that[38], when the pressure was higher than 25 MPa, the small shale samples with injected mercury would deform. Li Zhuo et al.[39] adopted 80 nm pore diameter to splice the shale pore diameter characterize by low-temperature nitrogen adsorption and high-pressure mercury injection. In this study, through comprehensive consideration, 65 nm pore diameter was taken as the splicing point of the results of the two kinds of experiments. ...

Nanometer-scale pore characteristics of lacustrine shale, Songliao Basin, NE China

1

2015

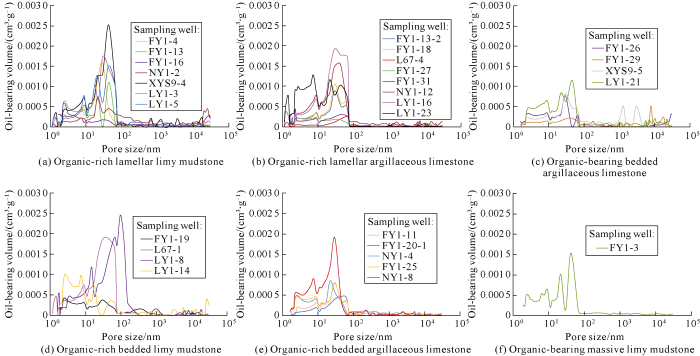

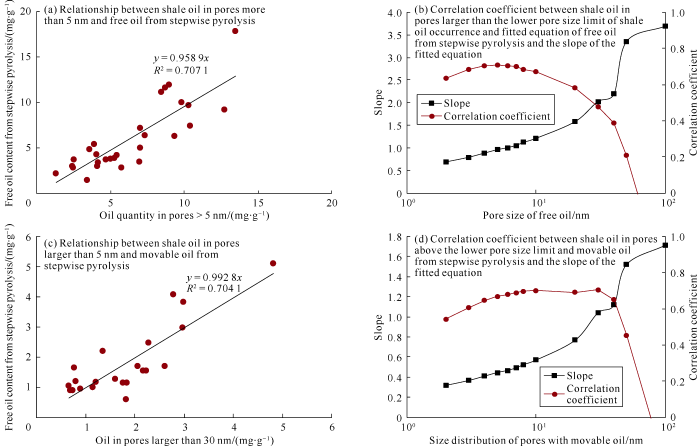

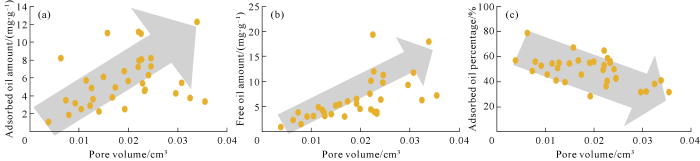

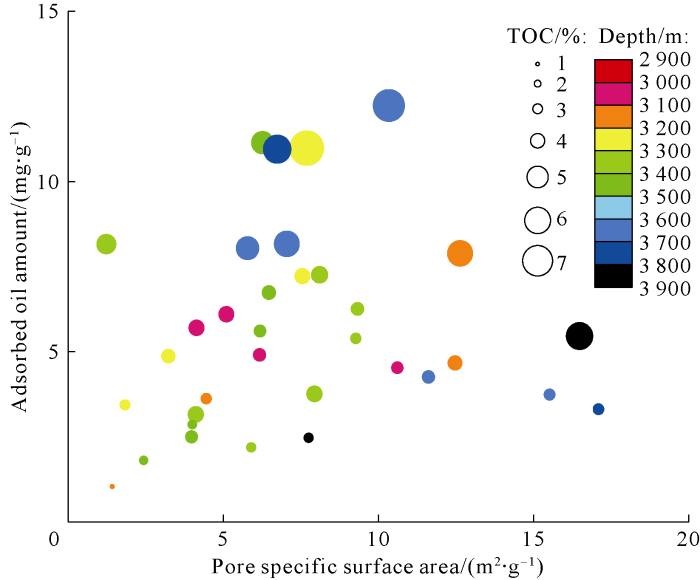

... Besides adsorbed on pore surface, shale oil also exists in free state in pores. With the increase of pore size, the mobility of shale oil increases gradually, that is, free oil/movable oil increases gradually. According to the pore size distribution curve (Fig. 5), the oil-bearing pore volume was gradually accumulated from large to small pores, and the accumulative oil-bearing pore volume curve of each type of shale was plotted (i.e. the oil-bearing volume of a pore size and pores larger than the pore size). Combining with the density of the oil produced (0.83 g/cm3) in the study area, the shale oil quantity in the pores larger than a given pore size was calculated. Taking the free oil content obtained from stepwise pyrolysis as the longitudinal axis, and the oil content in the pores with a given size and larger sizes than the given size as the horizontal axis, a crossplot was made (Fig. 6a). The crossplot shows the linear correlation and slope coefficient at different pore sizes (Fig. 6b). See references [40-41] for detailed description. When the slope coefficient is close to 1 and the correlation is the maximum, the pore size is the lower limit for free oil, and the pore size evaluation method for movable oil distribution is similar to this method. It can be seen that with the pore sizes turning from small to large, the correlation coefficient of free oil obtained by stepwise pyrolysis and shale oil obtained before and after washing increases first and then decreases, and is 0.7071 at maximum (Fig. 6a), and the corresponding slope of fitting equation at this point is about 1 (Fig. 6b), which indicates that the lower pore size limit of free oil may be 5 nm, i.e. the oil in the pores less than 5 nm is in adsorbed state. This conclusion is basically consistent with the result of molecular dynamics simulation that “the oil in pores <4 nm is all in adsorbed state”[40]. The lower pore size limit of movable oil obtained by this method is about 30 nm (Fig. 6c, 6d). ...

Pore characteristics of continental shale and its impact on storage of shale oil in northern Songliao Basin

0

2015

Quantitative evaluation of residual liquid hydrocarbons in shale

1

2015

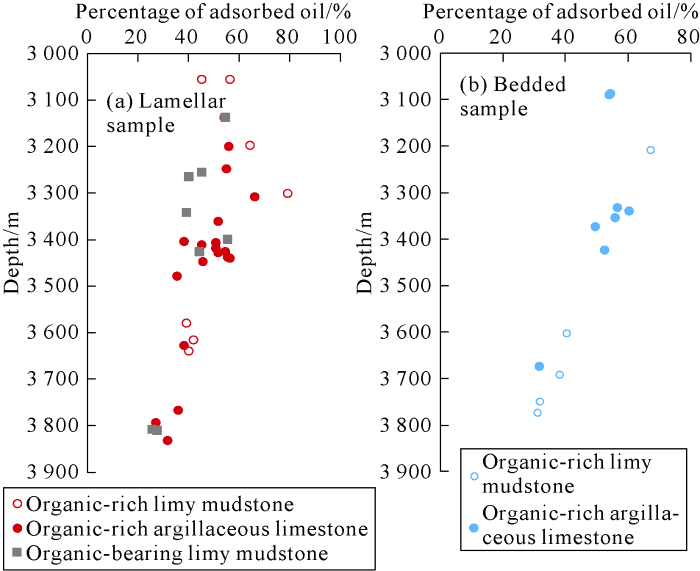

... The crude oil viscosity and density of the Shahejie Formation decrease with the increase of depth, while the saturated hydrocarbon content goes up gradually with the increase of depth[42]. From Fig. 9, it can be seen that the decrease of the percentage of adsorbed oil with the increase of depth is mainly due to the increase of thermal evolution degree, the increase of the percentage of light components (alkanes) in shale oil, the increasing difference of the structure between the remaining hydrocarbon components and the hydrocarbon-generating parent materials, and the gradual decrease of the adsorption and mutual solubility between them. ...

Simple kinetic models of petroleum formation. Part I: Oil and gas generation from kerogen

1

1995

... The amount of adsorbed oil is related not only to the composition of shale oil, but also to the abundance of organic matter and mineral composition of shale. It can be seen from Fig. 10 that there is a good linear positive correlation between the amount of adsorbed oil and TOC: the higher the TOC value, the higher the adsorbed oil amount will be (Fig. 10a). Therefore, for the shales with the same oil content, the lower the TOC, the less the adsorbed oil amount and the higher the movable oil ratio will be. The adsorbed oil obtained from stepwise pyrolysis is mainly from dissolved kerogen. In addition, the pores associated with organic matter are oil-wet, so their surface can adsorb a certain amount of oil. It can be seen from Fig. 10a that the retained oil (dissolved + adsorbed) is about 179 mg/g per unit of TOC. It is noteworthy that the fitting equation in Fig. 10a doesn’t cross the origin, indicating that the residual oil includes not only the oil dissolving organic matter and adsorbed to organic pore surface, but also some oil adsorbed by some inorganic pore surface. The amount of adsorbed oil in inorganic minerals is about 0.2162 mg/g per unit of rock (the intersection with the Y axis). The amount of adsorbed/dissolved oil is related not only to the type of kerogen, the degree of thermal evolution of kerogen and the development of organic pores associated with kerogen, but also to the composition of oil. It can be seen that a consensus hasn’t been reached on the understanding of organic matter adsorption/dissolved oil. Pepper et al. used S1/TOC of 0.1 or “A”/TOC of 0.2 as the boundary of adsorption saturation of marine source rock[43,44]. According to theoretical calculation, Tian Shansi et al.[45] believed that the oil content related to type I and type II1 kerogen (adsorbed + swelled) is 130-150 mg/g organic carbon per unit mass. Wei et al.[46] found through experiments that the amount of adsorbed oil related to kerogen in the Dongying depression was 40-120 mg/g per unit of TOC. Through swelling experiments, Zhang Linye et al.[27] considered that the retained oil amount in Es3 and Es4 was 123.07 mg/g per unit mass of kerogen and 142.29 mg/g kerogen respectively. The oil composition (43.49% of saturated hydrocarbons, 17.78% of aromatic hydrocarbons, 17.46% of non-hydrocarbons and 6.98% of asphaltene) used in Zhang Linye's experiment is similar to that of the sample extracts (49.52% of saturated hydrocarbons, 17.13% of aromatic hydrocarbons, 25.59% of non-hydrocarbons and 7.05% of asphaltene) in this study. Assuming that the conversion coefficient between kerogen and TOC is 0.8, then the conclusion reached by Zhang Linye et al. is consistent with the statistical result of this study. Compared with the conclusion from this study, the adsorption capacity of pure minerals in previous studies is generally higher. The main cause is that the adsorption occurs only on the pore surface related to minerals, not on all surface of pure minerals in the experiment, and the existence of bound water on the surface of some minerals under geologic conditions reduces the adsorption capacity. It can be seen that it is more appropriate to work out the adsorption/dissolution amount of shale oil and the adsorption capacity of minerals by statistical analysis in specific areas. ...

Simple kinetic models of petroleum formation. Part III: Modelling an open system

1

1995