Tight oil remains the leading source of future U.S. crude oil production

1

2018

... Horizontal drilling and hydraulic fracturing can increase the contact area of the reservoir and fractures, and thus making oil production from the tight reservoir efficient and economic. According to the U.S. Energy Information Administration (EIA), 54% of the U.S oil production came from the tight reservoirs in 2017[1]. In contrast, tight oil only accounted for less than 1% of the total oil production in China[2,3], because of complicated geological conditions and poorer fracturing effect of tight oil reservoirs in China. Although the single well production rate of tight oil reservoirs can be enhanced by increasing the horizontal section length, reducing spacing between stages, and increasing dosage of the fracturing fluid and proppants, the ultimate recovery of this kind of reservoir is still less than 10%[4,5,6]. Therefore, more advanced techniques are needed to maximize the oil recovery from these reservoirs with hydraulic fracturing. In this work, through analyzing the challenges in fracturing of tight oil reservoirs, integrated techniques of high effective fracture-network stimulation and EOR are proposed. ...

Exploration and development of continental tight oil in China

1

2018

... Horizontal drilling and hydraulic fracturing can increase the contact area of the reservoir and fractures, and thus making oil production from the tight reservoir efficient and economic. According to the U.S. Energy Information Administration (EIA), 54% of the U.S oil production came from the tight reservoirs in 2017[1]. In contrast, tight oil only accounted for less than 1% of the total oil production in China[2,3], because of complicated geological conditions and poorer fracturing effect of tight oil reservoirs in China. Although the single well production rate of tight oil reservoirs can be enhanced by increasing the horizontal section length, reducing spacing between stages, and increasing dosage of the fracturing fluid and proppants, the ultimate recovery of this kind of reservoir is still less than 10%[4,5,6]. Therefore, more advanced techniques are needed to maximize the oil recovery from these reservoirs with hydraulic fracturing. In this work, through analyzing the challenges in fracturing of tight oil reservoirs, integrated techniques of high effective fracture-network stimulation and EOR are proposed. ...

Breakthrough and significance of unconventional oil and gas to classical petroleum geology theory

1

2017

... Horizontal drilling and hydraulic fracturing can increase the contact area of the reservoir and fractures, and thus making oil production from the tight reservoir efficient and economic. According to the U.S. Energy Information Administration (EIA), 54% of the U.S oil production came from the tight reservoirs in 2017[1]. In contrast, tight oil only accounted for less than 1% of the total oil production in China[2,3], because of complicated geological conditions and poorer fracturing effect of tight oil reservoirs in China. Although the single well production rate of tight oil reservoirs can be enhanced by increasing the horizontal section length, reducing spacing between stages, and increasing dosage of the fracturing fluid and proppants, the ultimate recovery of this kind of reservoir is still less than 10%[4,5,6]. Therefore, more advanced techniques are needed to maximize the oil recovery from these reservoirs with hydraulic fracturing. In this work, through analyzing the challenges in fracturing of tight oil reservoirs, integrated techniques of high effective fracture-network stimulation and EOR are proposed. ...

Trends in U.S. oil and natural gas upstream costs

1

2016

... Horizontal drilling and hydraulic fracturing can increase the contact area of the reservoir and fractures, and thus making oil production from the tight reservoir efficient and economic. According to the U.S. Energy Information Administration (EIA), 54% of the U.S oil production came from the tight reservoirs in 2017[1]. In contrast, tight oil only accounted for less than 1% of the total oil production in China[2,3], because of complicated geological conditions and poorer fracturing effect of tight oil reservoirs in China. Although the single well production rate of tight oil reservoirs can be enhanced by increasing the horizontal section length, reducing spacing between stages, and increasing dosage of the fracturing fluid and proppants, the ultimate recovery of this kind of reservoir is still less than 10%[4,5,6]. Therefore, more advanced techniques are needed to maximize the oil recovery from these reservoirs with hydraulic fracturing. In this work, through analyzing the challenges in fracturing of tight oil reservoirs, integrated techniques of high effective fracture-network stimulation and EOR are proposed. ...

Assessment of global unconventional oil and gas resources

1

2016

... Horizontal drilling and hydraulic fracturing can increase the contact area of the reservoir and fractures, and thus making oil production from the tight reservoir efficient and economic. According to the U.S. Energy Information Administration (EIA), 54% of the U.S oil production came from the tight reservoirs in 2017[1]. In contrast, tight oil only accounted for less than 1% of the total oil production in China[2,3], because of complicated geological conditions and poorer fracturing effect of tight oil reservoirs in China. Although the single well production rate of tight oil reservoirs can be enhanced by increasing the horizontal section length, reducing spacing between stages, and increasing dosage of the fracturing fluid and proppants, the ultimate recovery of this kind of reservoir is still less than 10%[4,5,6]. Therefore, more advanced techniques are needed to maximize the oil recovery from these reservoirs with hydraulic fracturing. In this work, through analyzing the challenges in fracturing of tight oil reservoirs, integrated techniques of high effective fracture-network stimulation and EOR are proposed. ...

Benchmarking EUR estimates for hydraulically fractured wells with and without fracture hits using various DCA methods

1

2018

... Horizontal drilling and hydraulic fracturing can increase the contact area of the reservoir and fractures, and thus making oil production from the tight reservoir efficient and economic. According to the U.S. Energy Information Administration (EIA), 54% of the U.S oil production came from the tight reservoirs in 2017[1]. In contrast, tight oil only accounted for less than 1% of the total oil production in China[2,3], because of complicated geological conditions and poorer fracturing effect of tight oil reservoirs in China. Although the single well production rate of tight oil reservoirs can be enhanced by increasing the horizontal section length, reducing spacing between stages, and increasing dosage of the fracturing fluid and proppants, the ultimate recovery of this kind of reservoir is still less than 10%[4,5,6]. Therefore, more advanced techniques are needed to maximize the oil recovery from these reservoirs with hydraulic fracturing. In this work, through analyzing the challenges in fracturing of tight oil reservoirs, integrated techniques of high effective fracture-network stimulation and EOR are proposed. ...

Modern shale gas development in the United States: A primer

1

2009

... In tight reservoirs, oil accumulates in pore throats of rocks with permeability less than 0.1×10-3 μm2[7], so oil stored in the rock matrix far from the created fractures is hard to be recovered by natural depletion. Previous studies on over 1000 horizontal wells in Barnett and Marcellus gas fields indicated that for a fracture spacing of 15 m, the interference of two neighboring fractures would occur after 4-5 years fracturing, the gas from the matrix in the middle of two parallel fractures can flow to the fractures and be recovered[8,9]. For oil with higher viscosity, the interference time would be longer unless the fracture spacing is reduced further. Therefore, the first challenge in improving fracturing effect is to create an dense and effective fracture network that enlarges the drainage area and ensures a high fracture conductivity. ...

Gas production in the Barnett Shale obeys a simple scaling theory

1

2013

... In tight reservoirs, oil accumulates in pore throats of rocks with permeability less than 0.1×10-3 μm2[7], so oil stored in the rock matrix far from the created fractures is hard to be recovered by natural depletion. Previous studies on over 1000 horizontal wells in Barnett and Marcellus gas fields indicated that for a fracture spacing of 15 m, the interference of two neighboring fractures would occur after 4-5 years fracturing, the gas from the matrix in the middle of two parallel fractures can flow to the fractures and be recovered[8,9]. For oil with higher viscosity, the interference time would be longer unless the fracture spacing is reduced further. Therefore, the first challenge in improving fracturing effect is to create an dense and effective fracture network that enlarges the drainage area and ensures a high fracture conductivity. ...

Marcellus wells’ ultimate production accurately predicted from initial production

1

... In tight reservoirs, oil accumulates in pore throats of rocks with permeability less than 0.1×10-3 μm2[7], so oil stored in the rock matrix far from the created fractures is hard to be recovered by natural depletion. Previous studies on over 1000 horizontal wells in Barnett and Marcellus gas fields indicated that for a fracture spacing of 15 m, the interference of two neighboring fractures would occur after 4-5 years fracturing, the gas from the matrix in the middle of two parallel fractures can flow to the fractures and be recovered[8,9]. For oil with higher viscosity, the interference time would be longer unless the fracture spacing is reduced further. Therefore, the first challenge in improving fracturing effect is to create an dense and effective fracture network that enlarges the drainage area and ensures a high fracture conductivity. ...

Evaluation of production log data from horizontal wells drilled in organic shales

1

... Although different clusters and stages of fractures in tight oil and gas wells are typically designed to have similar scales during hydraulic fracturing, distributed temperature sensing (DTS) and production logging results often show that different clusters of fractures develop quite differently. In most cases, approximately 70% of the production comes from 20% of the fractures[10,11]. Propagation of fractures can change the stress field around, and in turn limits the propagation of neighboring fractures, this interference is known as the “stress shadow” effect[12]. This effect can make the fractures divert or even two neighboring fractures merge gradually during propagation[13,14] when arrangement of fractures becomes denser for larger drainage area, resulting in the reduction of the stimulated volume by fracture network. Moreover, this effect can make the fractures different in width, which affects the filling of the proppants[15]. ...

Using temperature measurements from production logging/downhole sensors to diagnose multistage fractured well flow profile

1

2018

... Although different clusters and stages of fractures in tight oil and gas wells are typically designed to have similar scales during hydraulic fracturing, distributed temperature sensing (DTS) and production logging results often show that different clusters of fractures develop quite differently. In most cases, approximately 70% of the production comes from 20% of the fractures[10,11]. Propagation of fractures can change the stress field around, and in turn limits the propagation of neighboring fractures, this interference is known as the “stress shadow” effect[12]. This effect can make the fractures divert or even two neighboring fractures merge gradually during propagation[13,14] when arrangement of fractures becomes denser for larger drainage area, resulting in the reduction of the stimulated volume by fracture network. Moreover, this effect can make the fractures different in width, which affects the filling of the proppants[15]. ...

Optimizing fracture spacing and sequencing in horizontal-well fracturing

1

2011

... Although different clusters and stages of fractures in tight oil and gas wells are typically designed to have similar scales during hydraulic fracturing, distributed temperature sensing (DTS) and production logging results often show that different clusters of fractures develop quite differently. In most cases, approximately 70% of the production comes from 20% of the fractures[10,11]. Propagation of fractures can change the stress field around, and in turn limits the propagation of neighboring fractures, this interference is known as the “stress shadow” effect[12]. This effect can make the fractures divert or even two neighboring fractures merge gradually during propagation[13,14] when arrangement of fractures becomes denser for larger drainage area, resulting in the reduction of the stimulated volume by fracture network. Moreover, this effect can make the fractures different in width, which affects the filling of the proppants[15]. ...

Impact of completion design on fracture complexity in horizontal shale wells

1

2014

... Although different clusters and stages of fractures in tight oil and gas wells are typically designed to have similar scales during hydraulic fracturing, distributed temperature sensing (DTS) and production logging results often show that different clusters of fractures develop quite differently. In most cases, approximately 70% of the production comes from 20% of the fractures[10,11]. Propagation of fractures can change the stress field around, and in turn limits the propagation of neighboring fractures, this interference is known as the “stress shadow” effect[12]. This effect can make the fractures divert or even two neighboring fractures merge gradually during propagation[13,14] when arrangement of fractures becomes denser for larger drainage area, resulting in the reduction of the stimulated volume by fracture network. Moreover, this effect can make the fractures different in width, which affects the filling of the proppants[15]. ...

Mechanisms of simultaneous hydraulic-fracture propagation from multiple perforation clusters in horizontal wells

1

2016

... Although different clusters and stages of fractures in tight oil and gas wells are typically designed to have similar scales during hydraulic fracturing, distributed temperature sensing (DTS) and production logging results often show that different clusters of fractures develop quite differently. In most cases, approximately 70% of the production comes from 20% of the fractures[10,11]. Propagation of fractures can change the stress field around, and in turn limits the propagation of neighboring fractures, this interference is known as the “stress shadow” effect[12]. This effect can make the fractures divert or even two neighboring fractures merge gradually during propagation[13,14] when arrangement of fractures becomes denser for larger drainage area, resulting in the reduction of the stimulated volume by fracture network. Moreover, this effect can make the fractures different in width, which affects the filling of the proppants[15]. ...

Benefits of engineering fracture design: Lessons learned from underperformers in the Midland Basin

1

... Although different clusters and stages of fractures in tight oil and gas wells are typically designed to have similar scales during hydraulic fracturing, distributed temperature sensing (DTS) and production logging results often show that different clusters of fractures develop quite differently. In most cases, approximately 70% of the production comes from 20% of the fractures[10,11]. Propagation of fractures can change the stress field around, and in turn limits the propagation of neighboring fractures, this interference is known as the “stress shadow” effect[12]. This effect can make the fractures divert or even two neighboring fractures merge gradually during propagation[13,14] when arrangement of fractures becomes denser for larger drainage area, resulting in the reduction of the stimulated volume by fracture network. Moreover, this effect can make the fractures different in width, which affects the filling of the proppants[15]. ...

The role of induced un-propped (IU) fractures in unconventional oil and gas wells

1

... Furthermore, calculation based on the material balance of the injected fracturing fluid, the wellbore volume and the total volume of designed fractures shows that more than 90% of the fracturing fluid flows into the induced unpropped fractures[16]. The width of this type of fractures is typically in microns to sub-microns order, too small for conventional proppants to get in to form effective support, so they can’t provide sufficient conductivity for oil flow[17]. ...

An experimental study on conductivity of unpropped fractures in preserved shales

1

2018

... Furthermore, calculation based on the material balance of the injected fracturing fluid, the wellbore volume and the total volume of designed fractures shows that more than 90% of the fracturing fluid flows into the induced unpropped fractures[16]. The width of this type of fractures is typically in microns to sub-microns order, too small for conventional proppants to get in to form effective support, so they can’t provide sufficient conductivity for oil flow[17]. ...

U.S. crude oil production efficiency continues to improve

1

2018

... Another characteristic of the tight oil reservoir is that the oil production rate declines sharply in the early stage. For most tight oil horizontal wells in the U.S., the oil production rate falls to 30% of the initial peak rate after one year of production[18]. During hydraulic fracturing, a significant amount of fracturing fluid is injected into the reservoir to form artificial fracture network[19,20]. If the fracturing fluid can imbibe into the tight rock and replace the oil, the sweeping volume of the fracturing fluid and the producing degree of oil would be enhanced and the oil production decline would be slowed down effectively. Therefore, the second challenge in the tight oil fracturing is to enhance the imbibition of the fracturing fluid. ...

A new approach to predict field-scale performance of friction reducer based on laboratory measurements

1

2017

... Another characteristic of the tight oil reservoir is that the oil production rate declines sharply in the early stage. For most tight oil horizontal wells in the U.S., the oil production rate falls to 30% of the initial peak rate after one year of production[18]. During hydraulic fracturing, a significant amount of fracturing fluid is injected into the reservoir to form artificial fracture network[19,20]. If the fracturing fluid can imbibe into the tight rock and replace the oil, the sweeping volume of the fracturing fluid and the producing degree of oil would be enhanced and the oil production decline would be slowed down effectively. Therefore, the second challenge in the tight oil fracturing is to enhance the imbibition of the fracturing fluid. ...

Computed-tomography measurements of water block in low-permeability rocks: Scaling and remedying production impairment

1

2018

... Another characteristic of the tight oil reservoir is that the oil production rate declines sharply in the early stage. For most tight oil horizontal wells in the U.S., the oil production rate falls to 30% of the initial peak rate after one year of production[18]. During hydraulic fracturing, a significant amount of fracturing fluid is injected into the reservoir to form artificial fracture network[19,20]. If the fracturing fluid can imbibe into the tight rock and replace the oil, the sweeping volume of the fracturing fluid and the producing degree of oil would be enhanced and the oil production decline would be slowed down effectively. Therefore, the second challenge in the tight oil fracturing is to enhance the imbibition of the fracturing fluid. ...

Wettability literature survey (Part 2): Wettability measurement

1

1986

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

An experimental study of wetting behavior and surfactant EOR in carbonates with model compounds

1

2008

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

Recent advances in surfactant EOR

1

2011

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

Surfactant-mediated spontaneous imbibition in carbonate rocks at harsh reservoir conditions

1

2013

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

Wettability survey in Bakken Shale with surfactant-formulation imbibition

1

2012

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

Multi-scale rock characterization and modeling for surfactant EOR in the Bakken

1

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

Improved hydrocarbon recovery using mixtures of energizing chemicals in unconventional reservoirs

1

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

The impact of surfactant imbibition and adsorption for improving oil recovery in the Wolfcamp and Eagle Ford Reservoirs

1

2018

... In the tight oil reservoir, asphaltene in the crude oil can absorb with the rock surface, changing the original water-wet minerals such as quartz and clay to oil-wet[21]. Meanwhile, the polar compounds in oil, such as naphthenic acids, can adsorb on the carbonate minerals such as calcite and dolomite, also making them oil-wet[22]. Since the small pores and pore throats in the tight rock are oil-wet with strong capillary force, which hinders the fracturing fluid flowing into the pores to displace the oil. To alter the rock wettability and enhance the imbibition effect of fracturing fluid, the surfactant can be added into fracturing fluid. This idea initially came from the chemical flooding of fractured oil-wet carbonate reservoir[23,24]. At present, the similar types of surfactants were chosen and tested in the tight reservoirs[25,26]. But unlike the conventional fractured carbonate reservoir, tight reservoirs have large specific surface area of matrix pores. This requires a large dosage of surfactant to compensate its adsorption loss on the rock surface, which makes this method uneconomic for the tight oil reservoirs. Moreover, adding surfactants would generate ultra-low interfacial tension (IFT) between oil and water, which would slow down the imbibition rate with capillary force, thus limiting the application of this method in oil fields[27,28]. For efficient and economic imbibition and replacement, the chosen surfactant needs to have 3 features: (1) can alter the rock from oil-wet to water-wet, (2) has minimal adsorption loss on the rock surface, and (3) can maintain certain oil-water IFT for driving the imbibition. ...

Application and study of fine-silty sand control technique for unconsolidation Quaternary sand gas reservoir, Sebei Qinghai

1

... A series of temporary plugging agents of different shapes and sizes have been developed for different temperatures and pressures. They are suitable for reservoirs with a temperature up to 200 °C and a pressure up to 140 MPa where the conventional mechanical plugs do not work reliably[29]. These agents can degrade naturally at the reservoir temperature, and the degradation time can be adjusted by tailoring the relative molecular weights of the polymers for synthesizing the agents. After degradation, they can flow back with the fracturing fluid and oil, leaving no solid residue and thus not causing additional formation damage to the reservoir[30,31]. Moreover, the degraded solution of temporary plugging agent is acidic, and thus can also help to mitigate the near-wellbore formation damage caused by drilling and completion fluids[32]. The agents can be made into fibers, particles, and balls with diameters up to 15 mm to meet different operation requirements. By optimizing the combinations, dosage and injection order of temporary plugging agents, the plugging and diversion of previously formed fractures and the perforation holes during the refracturing can be realized. ...

Case study: YM204 obtained high petroleum production by acid fracture treatment combining fluid diversion and fracture reorientation

1

... A series of temporary plugging agents of different shapes and sizes have been developed for different temperatures and pressures. They are suitable for reservoirs with a temperature up to 200 °C and a pressure up to 140 MPa where the conventional mechanical plugs do not work reliably[29]. These agents can degrade naturally at the reservoir temperature, and the degradation time can be adjusted by tailoring the relative molecular weights of the polymers for synthesizing the agents. After degradation, they can flow back with the fracturing fluid and oil, leaving no solid residue and thus not causing additional formation damage to the reservoir[30,31]. Moreover, the degraded solution of temporary plugging agent is acidic, and thus can also help to mitigate the near-wellbore formation damage caused by drilling and completion fluids[32]. The agents can be made into fibers, particles, and balls with diameters up to 15 mm to meet different operation requirements. By optimizing the combinations, dosage and injection order of temporary plugging agents, the plugging and diversion of previously formed fractures and the perforation holes during the refracturing can be realized. ...

Evaluation and optimization of degradable-fiber-assisted slurry for fracturing thick and tight formation with high stress

1

2018

... A series of temporary plugging agents of different shapes and sizes have been developed for different temperatures and pressures. They are suitable for reservoirs with a temperature up to 200 °C and a pressure up to 140 MPa where the conventional mechanical plugs do not work reliably[29]. These agents can degrade naturally at the reservoir temperature, and the degradation time can be adjusted by tailoring the relative molecular weights of the polymers for synthesizing the agents. After degradation, they can flow back with the fracturing fluid and oil, leaving no solid residue and thus not causing additional formation damage to the reservoir[30,31]. Moreover, the degraded solution of temporary plugging agent is acidic, and thus can also help to mitigate the near-wellbore formation damage caused by drilling and completion fluids[32]. The agents can be made into fibers, particles, and balls with diameters up to 15 mm to meet different operation requirements. By optimizing the combinations, dosage and injection order of temporary plugging agents, the plugging and diversion of previously formed fractures and the perforation holes during the refracturing can be realized. ...

Chapter fourteen: Special focus on produced water in oil and gas fields: Origin, management, and reinjection practice: YUAN B, WOOD D A. Formation damage during improved oil recovery

1

2018

... A series of temporary plugging agents of different shapes and sizes have been developed for different temperatures and pressures. They are suitable for reservoirs with a temperature up to 200 °C and a pressure up to 140 MPa where the conventional mechanical plugs do not work reliably[29]. These agents can degrade naturally at the reservoir temperature, and the degradation time can be adjusted by tailoring the relative molecular weights of the polymers for synthesizing the agents. After degradation, they can flow back with the fracturing fluid and oil, leaving no solid residue and thus not causing additional formation damage to the reservoir[30,31]. Moreover, the degraded solution of temporary plugging agent is acidic, and thus can also help to mitigate the near-wellbore formation damage caused by drilling and completion fluids[32]. The agents can be made into fibers, particles, and balls with diameters up to 15 mm to meet different operation requirements. By optimizing the combinations, dosage and injection order of temporary plugging agents, the plugging and diversion of previously formed fractures and the perforation holes during the refracturing can be realized. ...

Plugging mechanism of fibers and particulates in hydraulic fracture

2

2019

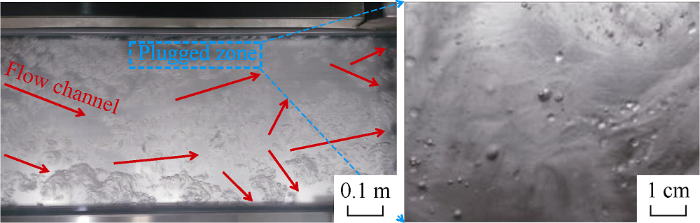

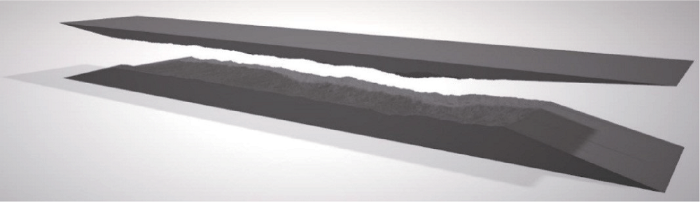

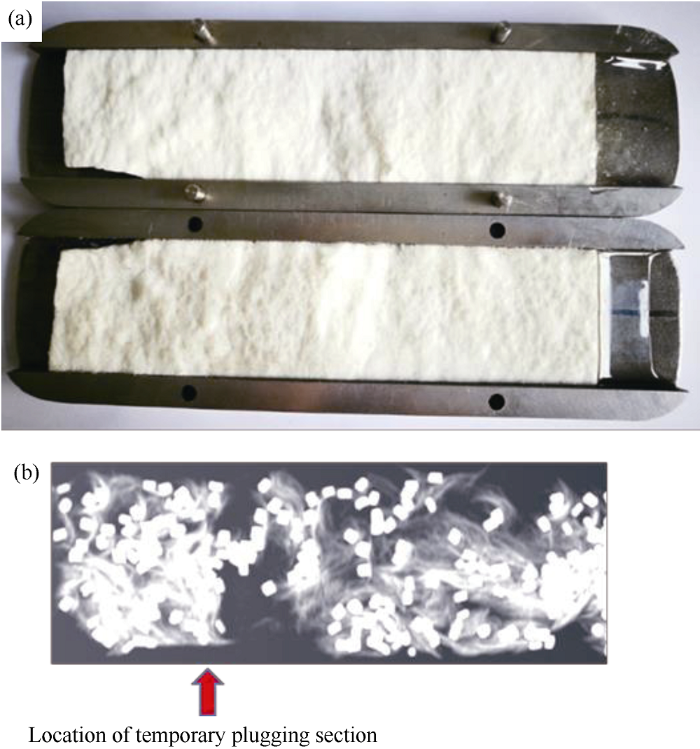

... Through a visual fracture plugging simulation apparatus in the laboratory, the synergy effect of fibers and different-sized particles during the plugging process can be observed. As shown in Fig. 1, when the fibers and particles are injected at the same time, the fibers would attach on rough walls of the fracture first to form a “net”, then the “net” would capture particles injected later, plugging the fracture at last[33]. Meanwhile, the dynamic plugging tests were conducted on a modified fracture-conductivity evaluation system, where the plugging efficiency of the agents inside a rough fracture could be obtained by measuring the pressure difference between upper and lower parts of fractures under simulated confining pressure and formation pressure. The reservoir rock can be used as experiment sample, or its replica from 3D scanning and printing can be used in multiple comparative experiments on fractures with identical wall roughness but different widths (Fig. 2). Once the plugging was formed, the relationship of plugging locations, wall roughness, initial fracture width and different combinations of agents were analyzed through CT scanning. The experimental results indicate that the particles determine the plugging location within the created fracture, while fibers determine both the plugging efficiency and the plugging strength (Fig. 3). Specifically, the sizes of the temporary plugging particles need to be tailored according to the width of created fracture, larger-sized particles are needed for wider fractures, while small-sized particles are needed for tortuous fractures. The experimental results also show that injecting fiber plugging agents first can increase the plugging efficiency and reduce the amount of agents compared with injecting fiber and particle agents together[33]. When the reservoir is poorer in fracability, a higher concentration of fibers is needed to enhance the plugging strength of the temporary blocking section in the fracture to meet the higher fracturing pressure needed to open a new fracture[34,35]. ...

... [33]. When the reservoir is poorer in fracability, a higher concentration of fibers is needed to enhance the plugging strength of the temporary blocking section in the fracture to meet the higher fracturing pressure needed to open a new fracture[34,35]. ...

Fracability evaluation in shale reservoirs: An integrated petrophysics and geomechanics approach

1

2014

... Through a visual fracture plugging simulation apparatus in the laboratory, the synergy effect of fibers and different-sized particles during the plugging process can be observed. As shown in Fig. 1, when the fibers and particles are injected at the same time, the fibers would attach on rough walls of the fracture first to form a “net”, then the “net” would capture particles injected later, plugging the fracture at last[33]. Meanwhile, the dynamic plugging tests were conducted on a modified fracture-conductivity evaluation system, where the plugging efficiency of the agents inside a rough fracture could be obtained by measuring the pressure difference between upper and lower parts of fractures under simulated confining pressure and formation pressure. The reservoir rock can be used as experiment sample, or its replica from 3D scanning and printing can be used in multiple comparative experiments on fractures with identical wall roughness but different widths (Fig. 2). Once the plugging was formed, the relationship of plugging locations, wall roughness, initial fracture width and different combinations of agents were analyzed through CT scanning. The experimental results indicate that the particles determine the plugging location within the created fracture, while fibers determine both the plugging efficiency and the plugging strength (Fig. 3). Specifically, the sizes of the temporary plugging particles need to be tailored according to the width of created fracture, larger-sized particles are needed for wider fractures, while small-sized particles are needed for tortuous fractures. The experimental results also show that injecting fiber plugging agents first can increase the plugging efficiency and reduce the amount of agents compared with injecting fiber and particle agents together[33]. When the reservoir is poorer in fracability, a higher concentration of fibers is needed to enhance the plugging strength of the temporary blocking section in the fracture to meet the higher fracturing pressure needed to open a new fracture[34,35]. ...

An improved fracability-evaluation method for shale reservoirs based on new fracture toughness- prediction models

1

2017

... Through a visual fracture plugging simulation apparatus in the laboratory, the synergy effect of fibers and different-sized particles during the plugging process can be observed. As shown in Fig. 1, when the fibers and particles are injected at the same time, the fibers would attach on rough walls of the fracture first to form a “net”, then the “net” would capture particles injected later, plugging the fracture at last[33]. Meanwhile, the dynamic plugging tests were conducted on a modified fracture-conductivity evaluation system, where the plugging efficiency of the agents inside a rough fracture could be obtained by measuring the pressure difference between upper and lower parts of fractures under simulated confining pressure and formation pressure. The reservoir rock can be used as experiment sample, or its replica from 3D scanning and printing can be used in multiple comparative experiments on fractures with identical wall roughness but different widths (Fig. 2). Once the plugging was formed, the relationship of plugging locations, wall roughness, initial fracture width and different combinations of agents were analyzed through CT scanning. The experimental results indicate that the particles determine the plugging location within the created fracture, while fibers determine both the plugging efficiency and the plugging strength (Fig. 3). Specifically, the sizes of the temporary plugging particles need to be tailored according to the width of created fracture, larger-sized particles are needed for wider fractures, while small-sized particles are needed for tortuous fractures. The experimental results also show that injecting fiber plugging agents first can increase the plugging efficiency and reduce the amount of agents compared with injecting fiber and particle agents together[33]. When the reservoir is poorer in fracability, a higher concentration of fibers is needed to enhance the plugging strength of the temporary blocking section in the fracture to meet the higher fracturing pressure needed to open a new fracture[34,35]. ...

An experimental study on the mechanism of degradable fiber-assisted diverting fracturing and its influencing factors

1

2015

... After studying the plugging efficiency in a single fracture, hydraulic fracturing and refracturing tests were further carried out in larger outcrop of 300 mm×300 mm×300 mm under tri-axial stress conditions. The experimental results show the combination of fibers and particles can realize temporary plugging effectively, inducing the initiation of secondary fracture diverting from the directions of the previously formed fracture[36]. To study the fracture propagation after the temporary plugging in the field scale, a piece of numerical simula-tion software was developed using the cohesive zone model based on the extended finite element method (XFEM-based CZM)[37]. This software can simulate the formation process of temporary plugging section inside or at the mouth of the fracture with different combinations of the temporary plugging agents at different proportions, and the role of the temporary plugging section in triggering the following fracture. The simulated results were compared with outcrop experiment results under tri-axis stress. The software can be used to analyze the impact of rock mechanic parameters and injection program of temporary plugging agents on the multi-cluster fracturing effect, and to optimize the fracturing and temporary plugging scheme. Simulation results show that by optimizing the formula and injection program of temporary plugging agents, the plugging of fracture at the fracture mouth or the fracture diverting inside the fracture can be realized[37,38,39]. Therefore, it is possible to use this technology to do multi- layer fracturing in vertical wells and multi-cluster fracturing in one stage of horizontal well. ...

Numerical simulation on near-wellbore temporary plugging and diverting during refracturing using XFEM-Based CZM

2

2018

... After studying the plugging efficiency in a single fracture, hydraulic fracturing and refracturing tests were further carried out in larger outcrop of 300 mm×300 mm×300 mm under tri-axial stress conditions. The experimental results show the combination of fibers and particles can realize temporary plugging effectively, inducing the initiation of secondary fracture diverting from the directions of the previously formed fracture[36]. To study the fracture propagation after the temporary plugging in the field scale, a piece of numerical simula-tion software was developed using the cohesive zone model based on the extended finite element method (XFEM-based CZM)[37]. This software can simulate the formation process of temporary plugging section inside or at the mouth of the fracture with different combinations of the temporary plugging agents at different proportions, and the role of the temporary plugging section in triggering the following fracture. The simulated results were compared with outcrop experiment results under tri-axis stress. The software can be used to analyze the impact of rock mechanic parameters and injection program of temporary plugging agents on the multi-cluster fracturing effect, and to optimize the fracturing and temporary plugging scheme. Simulation results show that by optimizing the formula and injection program of temporary plugging agents, the plugging of fracture at the fracture mouth or the fracture diverting inside the fracture can be realized[37,38,39]. Therefore, it is possible to use this technology to do multi- layer fracturing in vertical wells and multi-cluster fracturing in one stage of horizontal well. ...

... [37,38,39]. Therefore, it is possible to use this technology to do multi- layer fracturing in vertical wells and multi-cluster fracturing in one stage of horizontal well. ...

Effects of previously created fracture on the initiation and growth of subsequent fracture during TPMSF

1

2018

... After studying the plugging efficiency in a single fracture, hydraulic fracturing and refracturing tests were further carried out in larger outcrop of 300 mm×300 mm×300 mm under tri-axial stress conditions. The experimental results show the combination of fibers and particles can realize temporary plugging effectively, inducing the initiation of secondary fracture diverting from the directions of the previously formed fracture[36]. To study the fracture propagation after the temporary plugging in the field scale, a piece of numerical simula-tion software was developed using the cohesive zone model based on the extended finite element method (XFEM-based CZM)[37]. This software can simulate the formation process of temporary plugging section inside or at the mouth of the fracture with different combinations of the temporary plugging agents at different proportions, and the role of the temporary plugging section in triggering the following fracture. The simulated results were compared with outcrop experiment results under tri-axis stress. The software can be used to analyze the impact of rock mechanic parameters and injection program of temporary plugging agents on the multi-cluster fracturing effect, and to optimize the fracturing and temporary plugging scheme. Simulation results show that by optimizing the formula and injection program of temporary plugging agents, the plugging of fracture at the fracture mouth or the fracture diverting inside the fracture can be realized[37,38,39]. Therefore, it is possible to use this technology to do multi- layer fracturing in vertical wells and multi-cluster fracturing in one stage of horizontal well. ...

Quantitative investigation of fracture interaction by evaluating fracture curvature during temporarily plugging staged fracturing

1

2019

... After studying the plugging efficiency in a single fracture, hydraulic fracturing and refracturing tests were further carried out in larger outcrop of 300 mm×300 mm×300 mm under tri-axial stress conditions. The experimental results show the combination of fibers and particles can realize temporary plugging effectively, inducing the initiation of secondary fracture diverting from the directions of the previously formed fracture[36]. To study the fracture propagation after the temporary plugging in the field scale, a piece of numerical simula-tion software was developed using the cohesive zone model based on the extended finite element method (XFEM-based CZM)[37]. This software can simulate the formation process of temporary plugging section inside or at the mouth of the fracture with different combinations of the temporary plugging agents at different proportions, and the role of the temporary plugging section in triggering the following fracture. The simulated results were compared with outcrop experiment results under tri-axis stress. The software can be used to analyze the impact of rock mechanic parameters and injection program of temporary plugging agents on the multi-cluster fracturing effect, and to optimize the fracturing and temporary plugging scheme. Simulation results show that by optimizing the formula and injection program of temporary plugging agents, the plugging of fracture at the fracture mouth or the fracture diverting inside the fracture can be realized[37,38,39]. Therefore, it is possible to use this technology to do multi- layer fracturing in vertical wells and multi-cluster fracturing in one stage of horizontal well. ...

A practical guide to modern diversion technology

1

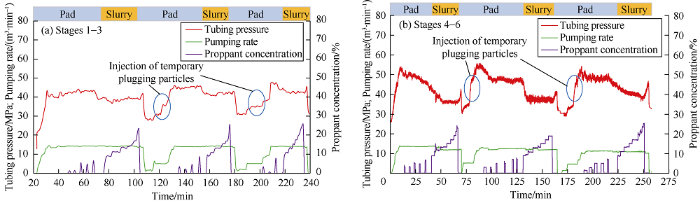

... The horizontal section of Well S-1 is at a depth of around 2300 m, where the reservoir has an average porosity of 18% and average permeability of 0.4×10-3 μm2. At the reservoir temperature of 70 °C, the oil has a viscosity of around 140 mPa•s. During the initial fracturing of this well, the 521 m long horizontal section was divided into 6 stages, with 4 clusters per stage. It was fractured through the perf-and-plug operation. During the refracturing, Stages 1-3 and Stages 4-6 in the first time fracturing were separately by drillable bridge plugs into two stages; eight pumping programs were designed to modify these two stages, detailed steps are: (1) inject the slickwater pad fluid, (2) inject guar gel sand-carrying fluid , (3) inject temporary plugging particles for diverting in stage, (4) inject slickwater pad fluid, (5) inject guar gel sand-carrying fluid, (6) inject temporary plugging particles for diverting in stage, (7) inject slickwater pad fluid, (8) inject guar gel sand-carrying fluid. Table 1 shows the dosage of various fluids, proppants, and temporary plugging particles in the refracturing. Fig. 4 shows the changes of tubing pressure, pumping rate and proppant concentration during refracturing. Pressure increased by 3-10 MPa after the injection of temporary plugging particles, moreover, the injection pressure gradually increased during the injection of pad fluid and sand-carrying fluid in the two stages of refracturing (i.e., tubing pressure increased gradually in the steps 1, 4 and 7, and tubing pressure increased gradually in 2, 5 and 8). These observation results indicate that the injected particles formed plugging within the previously created fractures, thus making the following fracturing fluid stimulate the unstimulated or stimulated regions with low degree of the reservoir[40]. After this refracturing treatment, Well S-1 had an average oil production of 29 t/d in the first month, that is 26% higher than the initial production after the first fracturing. ...

Microproppants unlock potential of secondary fractures.

1

2018

... Previous experimental results indicate that the settling velocity of 0.075 mm (200 mesh) quartz sand is 1/10 of that of 0.800 mm/0.425 mm(20/40 mesh) quartz sand and 1/5 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand, while the settling velocity of 0.044 mm (325 mesh) quartz sand is 1/44 of that of 0.800 mm/0.425 mm (20/40 mesh) quartz sand and 1/22 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand[41]. Micro-size proppants have been applied in a few tight/shale gas or condensate reservoirs, and the reported production could increase by 30%-50% compared to the wells not using this type of proppants[42,43]. However, it remains unclear how micro-sized proppants transport and settle in the complex fracture network, including the induced micro-size fractures as well as the branched fractures formed after refracturing. Moreover, it is also worth studying the surface modification of micro-size proppants to enhance the repelling force between the proppant particles to further reduce the settling velocity[44]. ...

Application of micro-proppant to enhance well production in unconventional reservoirs: Laboratory and field results

1

... Previous experimental results indicate that the settling velocity of 0.075 mm (200 mesh) quartz sand is 1/10 of that of 0.800 mm/0.425 mm(20/40 mesh) quartz sand and 1/5 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand, while the settling velocity of 0.044 mm (325 mesh) quartz sand is 1/44 of that of 0.800 mm/0.425 mm (20/40 mesh) quartz sand and 1/22 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand[41]. Micro-size proppants have been applied in a few tight/shale gas or condensate reservoirs, and the reported production could increase by 30%-50% compared to the wells not using this type of proppants[42,43]. However, it remains unclear how micro-sized proppants transport and settle in the complex fracture network, including the induced micro-size fractures as well as the branched fractures formed after refracturing. Moreover, it is also worth studying the surface modification of micro-size proppants to enhance the repelling force between the proppant particles to further reduce the settling velocity[44]. ...

Post-fracturing production performance of small sized proppant in major unconventional formations

1

... Previous experimental results indicate that the settling velocity of 0.075 mm (200 mesh) quartz sand is 1/10 of that of 0.800 mm/0.425 mm(20/40 mesh) quartz sand and 1/5 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand, while the settling velocity of 0.044 mm (325 mesh) quartz sand is 1/44 of that of 0.800 mm/0.425 mm (20/40 mesh) quartz sand and 1/22 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand[41]. Micro-size proppants have been applied in a few tight/shale gas or condensate reservoirs, and the reported production could increase by 30%-50% compared to the wells not using this type of proppants[42,43]. However, it remains unclear how micro-sized proppants transport and settle in the complex fracture network, including the induced micro-size fractures as well as the branched fractures formed after refracturing. Moreover, it is also worth studying the surface modification of micro-size proppants to enhance the repelling force between the proppant particles to further reduce the settling velocity[44]. ...

First proppant designed to decrease water production

1

... Previous experimental results indicate that the settling velocity of 0.075 mm (200 mesh) quartz sand is 1/10 of that of 0.800 mm/0.425 mm(20/40 mesh) quartz sand and 1/5 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand, while the settling velocity of 0.044 mm (325 mesh) quartz sand is 1/44 of that of 0.800 mm/0.425 mm (20/40 mesh) quartz sand and 1/22 of that of 0.425 mm/0.212 mm (40/70 mesh) quartz sand[41]. Micro-size proppants have been applied in a few tight/shale gas or condensate reservoirs, and the reported production could increase by 30%-50% compared to the wells not using this type of proppants[42,43]. However, it remains unclear how micro-sized proppants transport and settle in the complex fracture network, including the induced micro-size fractures as well as the branched fractures formed after refracturing. Moreover, it is also worth studying the surface modification of micro-size proppants to enhance the repelling force between the proppant particles to further reduce the settling velocity[44]. ...

Novel applications of nanoparticles for future enhanced oil recovery

1

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

A study of wettability-alteration methods with nanomaterials application

1

2015

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

Understanding the mechanism of nanoparticles applications in enhanced oil recovery

1

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

An evaluation of spontaneous imbibition of water into oil-wet carbonate reservoir cores using nanofluid

1

2014

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

Nanoparticle and microparticle flow in porous and fractured media: An experimental study

1

2012

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

Laboratory studies on fluid-recovery enhancement and mitigation of phase trapping by use of microemulsion in gas sandstone formations

1

2016

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

Critical assessment of microemulsion technology for enhancing fluid recovery from tight gas formations and propped fractures

1

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

Nano surfactant system improves post frac oil and gas recovery in hydrocarbon rich gas reservoirs

1

... In recent years, the use of solid nanoparticles to enhance oil recovery from the fractured carbonate reservoirs has been studied extensively[45,46,47]. The study results showed that they could alter the oil-wet carbonate reservoir rock to water-wet, and meanwhile, maintain a moderate oil-water IFT to enhance the imbibition effect[48]. Although these two properties meet the requirements on fracturing fluid additive for enhancing oil recovery after fracturing, the nano-scale pore throats in tight rocks can cause gathering or plugging of the nanoparticles, and thus resulting in permanent reservoir damage[49]. In the meantime, ex-situ microemulsions were studied and proposed as fracturing fluid additives to mitigate the water blockage caused by the invaded fluid, thus enhancing the gas production from shale gas or tight gas reservoirs[50]. In such microemulsion systems, surfactants form thermodynamically stable micelles that can effectively reduce the adsorption loss of surfactants on the rock surface, which enables surfactants to flow deeper and enhance its flowback by reducing the surface tension[51,52]. ...

Evaluation of liquid nanofluid as fracturing fluid additive on enhanced oil recovery from low-permeability reservoirs

1

2018

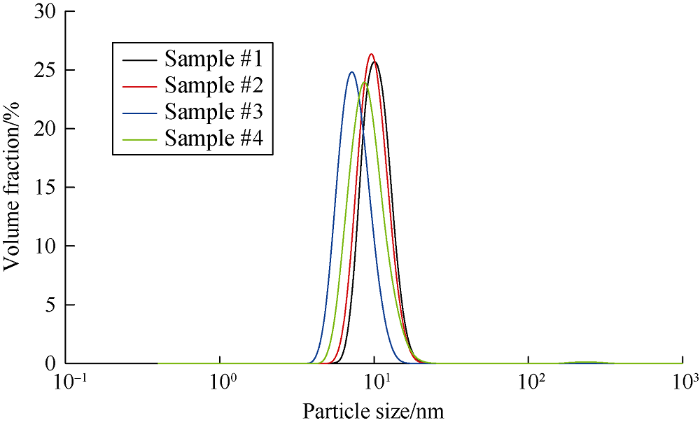

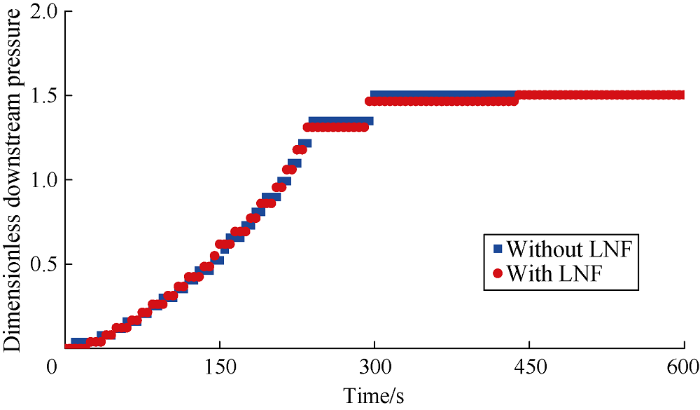

... Based on the above studies, we have developed a series of liquid nanofluid (LNF) systems to enhance the oil recovery with fracturing fluid flowing into the reservoir. They are well-dispersed microemulsions with a uniform micelle molecule size of around 10 nm, the narrow distribution peaks represent uniform properties (Fig. 5). According to the surface charge of the reservoir rock, the types of surfactants (i.e., anionic, cationic, or non-ionic surfactants) forming LNF can further minimize the adsorption loss of microemulsion on the rock surface. Like the solid nanoparticles, LNF can change the oil-wet rock to water-wet, and maintain a moderate water-oil IFT (e.g., an IFT of 1-3 mN/m between kerosene and water)[53]. But unlike the solid nanoparticles, results from the pressure transmission tests indicate LNF with flexible structure can deform and squeeze through the nanoscale pore throats in tight rock[54]. As shown in Fig. 6, when the simulated formation water with and without LNF were injected into the kerosene-saturated tight rock sample with a perme- ability of 0.05×10-3 μm2 at a constant upstream pressure during the pressure transmission test, the downstream pressure of the rock samples reached the equilibrium at the same rate, indicating no extra formation damage was generated by LNF. ...

Experimental study of the membrane behavior of shale during interaction with water-based and oil- based muds. Austin,

1

2005

... Based on the above studies, we have developed a series of liquid nanofluid (LNF) systems to enhance the oil recovery with fracturing fluid flowing into the reservoir. They are well-dispersed microemulsions with a uniform micelle molecule size of around 10 nm, the narrow distribution peaks represent uniform properties (Fig. 5). According to the surface charge of the reservoir rock, the types of surfactants (i.e., anionic, cationic, or non-ionic surfactants) forming LNF can further minimize the adsorption loss of microemulsion on the rock surface. Like the solid nanoparticles, LNF can change the oil-wet rock to water-wet, and maintain a moderate water-oil IFT (e.g., an IFT of 1-3 mN/m between kerosene and water)[53]. But unlike the solid nanoparticles, results from the pressure transmission tests indicate LNF with flexible structure can deform and squeeze through the nanoscale pore throats in tight rock[54]. As shown in Fig. 6, when the simulated formation water with and without LNF were injected into the kerosene-saturated tight rock sample with a perme- ability of 0.05×10-3 μm2 at a constant upstream pressure during the pressure transmission test, the downstream pressure of the rock samples reached the equilibrium at the same rate, indicating no extra formation damage was generated by LNF. ...

Measurement of fluid properties in organic-rich shales

0

2015

Evaluation of wettability alteration and IFT reduction on mitigating water blocking for low-permeability oil-wet rocks after hydraulic fracturing

2

2017

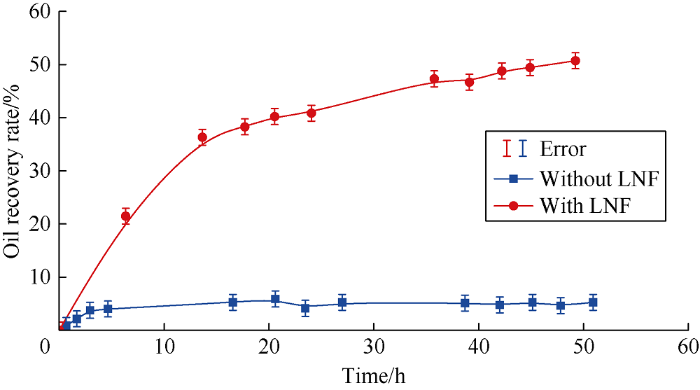

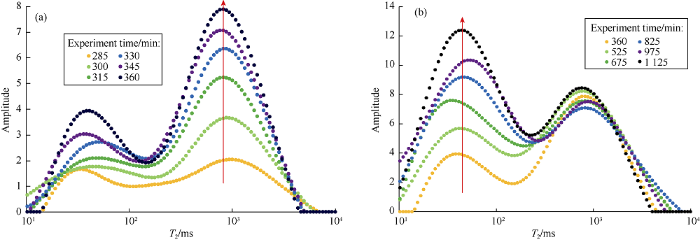

... To evaluate the effect of LNF on enhancing the oil recovery from the oil-wet tight rock, the imbibition cell tests were conducted using the naphthenic-acid-treated oil-wet limestone core samples[56] with a permeability of around 0.7×10-3 μm2. In the tests, core samples of 2.54 cm in diameter and 5 cm in length were firstly saturated with oil, then submerged in the simulated fracturing fluid with and without LNF. The total oil recovery rate of the core sample submerged in the liquid without LNF within 50 h was less than 5%; whereas the total oil recovery rate of core sample submerged in the liquid with LNF was over 50% and rising (Fig. 7). The results show that LNF can alter the oil-wet rock to water-wet and trigger water imbibition to displace the oil. Then, the microscopic oil enhancement mechanism of LNF was further evaluated through the low-field nuclear magnetic resonance (NMR) analyzer. From the T2 spectrum during the CPMG pulse sequence under different time during oil-water displacement, the NMR analyzer can provide the distribution of water and oil in different size pores in tight rock[57]. Before the scanning of the core sample by NMR, the tight core sample, as ones tested in the imbibition cell, was saturated with the fluorocarbon oil in order to shield the NMR signals from the oil and only allow the water signals to show in the T2 spectrum. During the experiment, the simulated fracturing fluid with LNF (i.e., 0.1% LNF+2% KCl) was continuously injected into the core sample at a constant rate of 0.05 mL/min. The experiment was continued for 1290 min until no obvious change was detected in the T2 spectrum. As shown in Fig. 8a, the simulated fracturing fluid with LNF firstly invaded the bigger pores where the capillary pressure was lower; after 360 min in this case, when LNF diffused into the smaller pores and altered their wettability, water started to invade these regions through spontaneous imbibition and displaced the oil (Fig. 8b). The experimental results suggest that the diffusivity and migration speed of LNF can determine the efficiency of LNF in enhancing the oil recovery from tight rock, and shutting-in the well after hydraulic fracturing with LNF can further enhance the oil recovery[58]. Nevertheless, more study is needed to clarify the mechanism of LNF and to establish the optimization criterion of this system for different types of tight oil reservoirs. ...

... In short, LNF can minimize the adsorption loss of surfactants on the rock surface, making it possible for surfactants to go deep with fracturing fluid into the tight reservoir rocks. For the oil-wet regions of reservoir rock, LNF can alter the wettability of pore throats and pore walls and maintain a certain level of oil-water IFT for enhancing the water imbibition to displace the oil. For the water-wet regions of reservoir rock, the reduction of oil-water IFT by LNF can mitigate the water blockage, enhancing relative oil permeability and oil production rate at the same time[56,59-60]. ...

Differences in the fluid characteristics between spontaneous imbibition and drainage in tight sandstone cores from nuclear magnetic resonance

1

2018

... To evaluate the effect of LNF on enhancing the oil recovery from the oil-wet tight rock, the imbibition cell tests were conducted using the naphthenic-acid-treated oil-wet limestone core samples[56] with a permeability of around 0.7×10-3 μm2. In the tests, core samples of 2.54 cm in diameter and 5 cm in length were firstly saturated with oil, then submerged in the simulated fracturing fluid with and without LNF. The total oil recovery rate of the core sample submerged in the liquid without LNF within 50 h was less than 5%; whereas the total oil recovery rate of core sample submerged in the liquid with LNF was over 50% and rising (Fig. 7). The results show that LNF can alter the oil-wet rock to water-wet and trigger water imbibition to displace the oil. Then, the microscopic oil enhancement mechanism of LNF was further evaluated through the low-field nuclear magnetic resonance (NMR) analyzer. From the T2 spectrum during the CPMG pulse sequence under different time during oil-water displacement, the NMR analyzer can provide the distribution of water and oil in different size pores in tight rock[57]. Before the scanning of the core sample by NMR, the tight core sample, as ones tested in the imbibition cell, was saturated with the fluorocarbon oil in order to shield the NMR signals from the oil and only allow the water signals to show in the T2 spectrum. During the experiment, the simulated fracturing fluid with LNF (i.e., 0.1% LNF+2% KCl) was continuously injected into the core sample at a constant rate of 0.05 mL/min. The experiment was continued for 1290 min until no obvious change was detected in the T2 spectrum. As shown in Fig. 8a, the simulated fracturing fluid with LNF firstly invaded the bigger pores where the capillary pressure was lower; after 360 min in this case, when LNF diffused into the smaller pores and altered their wettability, water started to invade these regions through spontaneous imbibition and displaced the oil (Fig. 8b). The experimental results suggest that the diffusivity and migration speed of LNF can determine the efficiency of LNF in enhancing the oil recovery from tight rock, and shutting-in the well after hydraulic fracturing with LNF can further enhance the oil recovery[58]. Nevertheless, more study is needed to clarify the mechanism of LNF and to establish the optimization criterion of this system for different types of tight oil reservoirs. ...

Effect of dispersion on solutal convection in porous media

1

2018