Introduction

Low-permeability reservoirs generally refer to reservoirs with air permeability less than 50.0×10-3 μm2. In recent years, reservoirs with air permeability of (1.0-10.0)×10-3 μm2 are defined as extra-low permeability reservoirs; reservoirs with air permeability of (0.1-1.0)×10-3 μm2 are defined as ultra- low permeability reservoir[1,2]. The formation of low-permeability reservoirs is related to regional diagenesis and the degree of compaction[3].

Generally speaking, the oil and gas output of a reservoir depends on the accumulation scale of the oil and gas, the permeability of the reservoir, and the formation energy. Under certain formation energy, oil and gas production mainly depends on the reservoir permeability. The main reasons for the low production of low-permeability reservoirs with certain reserves are: (1) The total amount of interstitials (matrix and cement) in the pore throat structure of the reservoir is too high; (2) Through compaction, rock particles are packed denser, making pore space reduce and permeability limited (also known as permeability damage). In the deep strong diagenesis-compaction-cementation zone, reservoirs with low porosity and poor permeability are likely to be formed, which often have oil and gas production lower than commercial oil flow standard.

In order to produce the low-permeability and hard-to-develop resources economically, researchers in oil and gas exploration and development fields have been trying to enhance single-well production since the early 1990s[4,5,6,7,8]. Matrix acidi-fication and fracturing are currently the main methods to increase the permeability of low-permeability reservoirs[9]. However, for low-permeability reservoirs cemented by a variety of clay minerals and salt crystals, traditional acidification methods simply aim at removing near-well zone pollution can’t enhance the matrix permeability in large scope and the yield significantly. Conventional fracturing methods can’t stimulate the reservoir due to the damage mechanism of the reservoir interstitial material, so they are low in efficiency usually. Moreover, the mechanical force during the fracturing process pushes the interstitial material to stack locally in the reservoir, leading to decrease of matrix permeability and damage to reservoir permeability.

The clay minerals in the pore throat of low-permeability reservoirs are diverse in type. In order to improve the effect of reservoir stimulation, different types of minerals require different types of acid liquids at proper acid concentrations to achieve the best dissolution effect. The by-products from chemical reactions of acidizing must be separated by complexation and carried away to wider seepage channels far from the well zone to remove the blockage in the near-well zone. In addition, clastic reservoirs often contain some carbonate cements. The choice of acid solution should avoid conflict of chemical schemes. Depending on the types of interstitial minerals, different types and ratios of acid solutions should be used[10]. These are problems that need to be solved to increase the single well production in low permeability oil reservoirs currently.

In this work, factors such as framework grain, interstitial composition, and pore throat structure in the reservoir are collectively referred to as "structural elements". In light of the petrological and mineralogical characteristics of low-permeability sandstone reservoirs, the reasons blocking oil production have been diagnosed comprehensively, the three “structural elements” of rock affecting the production of low-permeability reservoirs are analyzed, and the technology of “stepwise dissolution and separation” of acidification and acid fracturing is proposed to increase production and injection and applied in the field.

1. Mineralogic damage factors of low-permeability sandstone reservoirs

Low-permeability sandstone reservoirs have generally experienced strong compaction and have relatively stable textural maturity and compositional maturity. Chemical cementation, particle embedding and clay filling are the main factors damaging the physical properties of sandstone reservoirs.

1.1. Damage by mud and clay minerals in the reservoir

Sandstone reservoirs contain mud and a variety of clay minerals. The former is mainly composed of extremely fine- grained sedimentary minerals, while the latter consist of kaolinite, montmorillonite or mixed-layered illite/montmorillonite, illite and chlorite etc. Different clay minerals and combinations of clay minerals have different sensitivities to fluid. For example, montmorillonite swells when contacting fresh water. Chlorite produces iron hydroxide precipitate when meeting hydrochloric acid, while illite produces potassium fluorosilicate when meeting hydrofluoric acid. These products will do harm to the permeability of the reservoir and affect the output of oil, and are the key factors for reservoir permeability damage (Fig. 1).

Fig. 1.

Fig. 1.

Clay minerals in the reservoir and types of damage caused by them.

Particle-embedding damage is caused by mud or kaolinite-based euhedral grain clay minerals (products from feldspar alteration) in the reservoir in free and dispersed states moving irregularly with fluid flow. The crystal is in pseudohexagonal "bookpage-like" aggregate with a large specific surface area. Once dispersed by fluid, the crystals are likely to gather in the throat of the reservoir and block the channel, causing reservoir permeability damage and oil output reduction (Fig. 1a, 1d and 1g). The key to control this type of damage is the flow velocity of the formation fluid. The dispersed flow of kaolinite crystals requires a certain starting flow rate. When the fluid flow rate is less than the critical value, kaolinite sticks to the particle surface or partially fills in the pores, having little effect on the original permeability of the reservoir. When the fluid flow velocity is equal to or higher than this critical value, kaolinite particles will move with the fluid in a large range, causing serious damage to the permeability of the reservoir, consequently, oil well will drop rapidly in production, or even stop producing completely. A high proportion of oil can’t be produced due to the large-scale accumulation of kaolinite[11,12,13].

Swelling-prone clay membrane is “film-like” montmorillonite or mixed-layered illite/montmorillonite formed by muddy components in the original sediment that adhere to the surface of the particles during transportation (Fig. 1b, 1e, and 1h). At the early stage of diagenesis, the sedimentary water environment is often neutral, so the clay membrane is mostly composed of montmorillonite. As the burial depth increases, the clay membrane generally experiences a transformation process from montmorillonite to 90% mixing ratio illite/montmorillonite to 10% mixing ratio illite/montmorillonite and to illite. The clay membrane composed of montmorillonite has the strongest swelling ability, and can expand to 5 to 8 times of its original volume in fresh water. As the mixing ratio decreases, the expansion capacity of the "membrane" weakens. But with the increase of densification degree, the reservoir becomes worse and worse in physical properties, and in this circumstance, even weak clay expansion can cause serious reservoir permeability damage. In general, shallow reservoirs or heavy oil reservoirs often have a large amount of associated expansive clay minerals. For example, in the Jiyang Depression, the “red bed” reservoirs of the lower sub-member of the fourth member of the Shahejie Formation, the Kongdian Formation and the Mesozoic are characterized by low porosity and low permeability. These reservoirs have concentrated expansive clays due to their special diagenetic environment, so even weak clay expansion may cause serious blockage of the reservoir seepage channels.

Needle-like and flaky clay "bridging" damage is caused by the "bridging" structure formed by needle-like and flaky illite or illite/montmorillonite mixed layer (sometimes in rolled- sheet or plate-like shape) trussing between two or more particles (Fig. 1c, 1f, and 1i). This structure can block fluid flow through pores and throats, and moving particles may also be blocked and stacked, causing significant reduction of reservoir permeability. This type of blockage is common in deep extra-low-permeability reservoirs. Most low-permeability sandstone layers contain illite, but not all illite appears in "bridging" form, and most illite crystal flakes are irregularly distributed in the reservoir, which will have negative effect on reservoir permeability too.

1.2. Damage by crystalline salt in reservoir fabric

In addition to the framework particles, the species, quantity and sensitivity of the interstitial minerals in pores and throats of reservoir dominate physical properties of the reservoir. Among them, the crystalline salts have nonnegligible impact on the porosity and permeability of the reservoir. They are widely distributed, diverse in type, and uneven in content in reservoirs. The most common species of crystalline salt minerals are calcite (calcium carbonate), dolomite (calcium magnesium carbonate), siderite, sulfate and iron-containing carbonate cement.

The formation water in the Jiyang Depression is mostly salt water or brackish water. Since the shallow burial stage, a large amount of crystalline salt was generated. During deep burial process, the discharged water due to mudstone compaction (abundant hydrocarbon-acid fluids are common in the oil window), deep heat-source water, fracture channeling water and other external water mixed into the formation water[14,15], leading to continuous changes of solubility and salinity, and precipitation of a series of crystals and dissolution of early stage crystalline salts. These reactions all occur in the pores and throats of the reservoir, so they have a significant impact on the sand body reservoir properties.

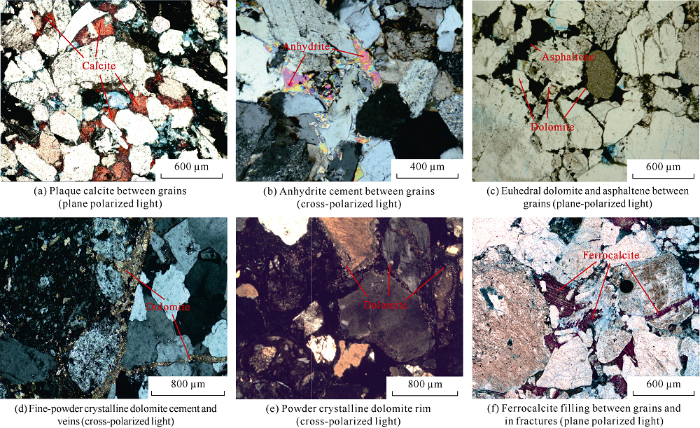

Cementation, filling, replacement, dissolution and re-precipitation of crystalline salt during diagenesis would also cause damage to reservoir permeability. There are mainly 5 types of damage, namely, pore embedding (plaque distribution), throat-fracture vein-like filling, micritization and adhesion of particle edge, iron ion immersion, and acid sensitivity (Fig. 2).

(1) Pore embedding. This mainly occurs between the framework grains of the reservoir. In the early stage of deposition, high-salinity water seeped into the loose high-permeability sand body, as climate changed, evaporation caused further decrease of solubility of the water body in the unconsolidated or weakly consolidated sand body; consequently, the crystalline salt continuously precipitated and remained in the pores of the sand body with high porosity and high permeability. With the ongoing of the compaction, the framework grains and the crystalline salt are compacted together, the pore volume further reduces, and the crystalline salt gradually fills the pores. As a result, the sandstone body becomes tighter and lower in permeability. The crystalline salts formed in this course are mostly free of iron if not affected by diagenesis-fluids in the later stage. The crystal grains are relatively coarse. Generally, they come in coarse grains to giant crystals originally, and may be fractured, deformed or embedded in the later stage due to compaction, and sometimes closely resemble original sedimentary grains (Fig. 2a and 2b).

(2) Throat-fracture vein-like filling. External fluids in the diagenetic stage carry a large amount of cations such as calcium, iron, and magnesium into the sand body. The original fractures or connected throats in the sand body are the main migration paths where the cations crystallization happens. Frequently, vein-like filling of crystalline salts and early oil and gas migration signs (asphaltene superposition) are often observed in the thin sections (Fig. 2c and 2d). This type of damage will cause the reservoir throat and the original channeling fracture to be blocked, greatly reducing permeability of the reservoir.

(3) Micritization and adhesion of particle edge. In addition to debris particles, the sediment contains a large amount of mud. A mud film often develops on the surface of the framework grain. Affected by the fluid environment during the diagenesis, the mud film often has some fine-grained crystals mixed in or crystallizes itself. As a result, the mud film gets more and more adherent to the grain and bigger and bigger in volume, eventually leading to block of the throat, reduction of pore size, and decrease of permeability (Fig. 2e).

(5) Acid sensitivity. The acid sensitivity damage of crystalline salt is mainly caused by the sensitivity to mud acid series. Mud acid is a common and necessary acidizing fluid used in oil fields. The hydrochloric acid in it is used to dissolve carbonate and the hydrofluoric acid in it to dissolve silicate fillings such as clay. However, there is a contradiction when using the acid, that is, when acidizing the reservoir containing both carbonate and clay minerals, the reaction between hydrochloric acid and carbonate happens very quickly, so hydrochloric acid would dissolve calcite and dolomite quickly, releasing a large amount of calcium, magnesium, and iron ions, which are in free state and easily captured by fluoride ions to form a large amount of silicate deposits such as potassium fluorosilicate, causing secondary blockage of the pores and throats and damage to reservoir permeability.

Fig. 2.

Fig. 2.

The formation and filling of crystalline salt in the fabric of reservoir.

1.3. Reservoir damage caused by compaction

The burial and compaction of sediment directly leads to the decrease of porosity[16]. From the unconsolidated-weakly consolidated stage at the beginning of deposition to the consolidated-strongly consolidated stage in the burial process, the porosity of the rock continuously decreases. The continuous formation of diagenetic minerals and blockage by them accelerate the reduction of porosity and permeability, eventually leading to the formation with low-permeability. The main damage of mechanical compaction is to make the reservoir throats turn narrow and reservoir permeability drop gradually. Even if the throat is not completely plugged, when the throat size reduces to a certain level, water lock effect and ‘Jia Min’ effect etc. will occur during the development of the reservoir, affecting fluid flow. Moreover, the compression of the rock can cause deformation, shrinkage, compaction, migration, and dehydration of clay minerals. When contacting with formation water later, even weak clay expansion and minor clay migration can cause sensitive blockage of narrow throats and thus reduction of reservoir permeability.

In addition, due to compaction, the framework grains are no longer in point or line contact with each other, but instead become inlaid or stitched contact. During the compaction process, the oil in the reservoir is separated into isolated "immovable oil", increasing the difficulty of production.

2. Stepwise dissolution and separation and production enhancement technology

2.1. Technical connotation and characteristics of the stepwise dissolution and separation

The matrix acidification and production enhancement of low-permeability sandstone reservoirs that have suffered damage requires formula developed based on the "structural elements" of the reservoir rocks, which can effectively dissolve clay minerals and crystalline salts. In addition to expanding the reservoir pore volume, it can also effectively protect the pore structure of the rock. Due to its variety in species, and the chemical similarity to the frame particles of the rock, the interstitial minerals cannot be completely dissolved and removed[17,18].

The main purpose of acidification (acid fracturing) is to effectively dissolve the main interstitial components that have a significant blocking effect, and to effectively improve the permeability of the reservoir; the reaction residue of the dissolved interstitials must be separated from the rock structure to improve and protect the connectivity between the pores. According to this principle, the "stepwise dissolution and separation" technology for increasing production is developed.

The (acid fracturing) formula developed based on the principle of "stepwise dissolution and separation" uses sustained- release acid as main acidizing fluid, supramolecular solvent instead of hydrochloric acid to dissolve the carbonate, and composite system of ammonium hydrogen fluoride, fluoroboric acid and fluorophosphoric acid to dissolve silicate. The dissolution happens step by step and the measures are implemented step by step, to reach the final goal of increasing pore size and permeability. (1) This method not only avoids the problem of cation crystallization caused by the contradiction between the dissolution of different minerals in using traditional acid, but also solves the problem of precipitation of free iron ions after hydrochloric acid dissolving iron-containing carbonate and chlorite. (2) This method creates favorable conditions for the effective dissolution of kaolinite. Kaolinite has a large specific surface area, and the complex acid in the formula has very strong wettability to kaolinite lamellae. Although weak in acidity, the complex acid has a large contact wetting area with kaolinite lamellae, so that it can quickly occupy the surface of clustered kaolinite lamellae, slowly dissolve and gradually swallow kaolinite residual crystals. This solves the problem that frame grains may be dissolved before kaolinite in the traditional acidification process. (3) The complexing effect of supramolecular solvent is made use to prevent problems caused by-products such as potassium fluorosilicate. The supramolecular solvent is synthesized by integrating organic solvents such as xylene and cationic additives such as nickel, zinc, chromium, copper, and barium. It can not only decompose crystalline salts, but also complex metal cations and inhibit their precipitation. It breaks down the residues into smaller particles, and after being complexed, the micro- particles are pushed into space deep in the reservoir matrix by subsequent acid solution and then dispersed and fixed.

The laboratory experiment and field application (successfully in more than 100 wells) have proved that the method is reliable, and it solves the technical problem that the residual acid must be flown back in time after traditional acidizing. The well treated by this method can be put into production without flowback after shutdown when the acid gets basically neutral.

2.2. Stepwise dissolution and separation experiments

Reservoir interstitials include more than 10 types of clay minerals and their variants, as well as chemical cements such as carbonate and sulfate. These minerals are highly sensitive and are main factors of reservoir permeability damage (especially low permeability reservoir), which would seriously affect the output of oil. The key to increasing reservoir production is to remove the plugging of matrix interstitial material in the drainage zone and improve the permeability of the near-well zone.

Immersion experiments were conducted on reservoir sample thin sections and dip experiments were conducted on the sample transect. The effects of dissolution were repeatedly observed under microscopes (polarizing microscope and stereoscopic microscope, shown in Fig. 3). Before the immersion experiment, the edges of the rock particles were blurred, and a lot of fine-grained interstitials were observed under polarized light (Fig. 3a). After the immersion experiment, the particle edges were clear, the interstitials and minerals adhering to the particles were gradually dissolved, and the porosity of the sample increases (Fig. 3b). The same effect was seen in the acid dip experiment on the rock transect. Before the experiment, the interstitials were mixed in types and high in content (Fig. 3c). After the experiment, the interstitials reduced in content and type, and pores between particles increased (Fig. 3d).

Fig. 3.

Fig. 3.

The effect of dissolution and separation in immersion experiments of thin section samples of Fan 128 well.

The "stepwise dissolution and separation" method was carried out on several groups of samples, and the optimal chemical deblocking schemes for certain minerals were chosen. (1) Kaolinite: compound system of high temperature fluoboric acid-fluorophosphoric acid-ammonium bifluoride, combined with organic cationic clay stabilizer and self-made soft sand control agent. The dissolution ratio can reach 55% (calculated by using the dissolved ratio of original interstitials after the reaction residues drain out). (2) Illite: self-made dissociating acid (a mixture of fluoboric acid, hydrofluoric acid, formic acid and acetic acid), combined with soft sand control agent. The dissolution ratio is 30%. (3) Montmorillonite: Ammonium bifluoride and biquaternary ammonium salt are used alternately, combined with 5% to 15% potassium chloride and ammonium chloride. The dissolution ratio is 45%. (4) Illite/montmorillonite mixed layer: the dissociating acid, biquaternary ammonium salt, ammonium chloride, hydrochloric acid, fluoboric acid, mixing with soft sand control agent. The dissolution ratio is 38%. (5) Chlorite: the dissociated acid and 8% hydrochloric acid, combined with iron salt and supramo- lecular complexing agent. The dissolution ratio is 90%. (6) Iron-containing calcite: 10% hydrochloric acid mixed with iron chelating agent, which can partially dissolve the framework particles and achieve the highest permeability increment, and has a dissolution ratio of 98%. (7) Iron-containing dolo- mite: supramolecular solvent, hydrochloric acid and iron chelating agent combined, which can dissolve framework parti-cles partially and has good effect of permeability increase. The dissolution ratio can reach 78%. (8) Calcium sulfate, barium sulfate, strontium sulfate and other sulfate precipitation: high-concentration supramolecular solvent combined with weak acid. The formula has slow dissolution rate, so when used in the field, time long enough should be left for sufficient reaction, and the maximum dissolution ratio is 24%. (9) Siderite: hydrochloric acid, iron ion stabilizer and organic mud acid combined. The aqua regia had the best effect in the laboratory experiment. But considering the corrosion of the tubing string, high concentration inhibitor is generally used. The dissolution ratio is 88%. (10) Organic scale: composite depolymerizing agent, solvent oil, organic mud acid and superamolecular complexing agent used in combination. The dissolution ratio is 90%. (11) Near-well drilling fluid (non-matrix acidification): high-concentration mud acid series in combination with high-temperature, high-energy corrosion inhibitor. The dissolution rate is 65%.

For reservoirs with multiple types of interstitial materials, acid fracturing should be carried out in the reverse "stepwise dissolution and separation" mode. For example, the reservoir of Well Fan 128-1 shows low-porosity, low-permeability and multi-sensitivity characteristics. The “structural elements” of the rock are: structural grain → illite/montmorillonite mixed layer clay membrane → microcrystalline iron-containing dolomite → later-stage giant-coarse crystal calcite → autogenous vermiculite-like kaolinite. The well can be treated by the following procedure: (1) dissociated acid to remove kaolinite damage; (2) hydrochloric acid to dissolve calcite cement; (3) supramolecular solvent to dissolve dolomite; (4) high temperature fluoboric acid system to remove illite/montmorillonite mixed layer membrane; (5) non-injury replacement fluid to displace residues. The well should be shut down long enough to allow effective dissolution of residues.

2.3. Principle of stepwise dissolution and separation stimulation

The "structural elements" of the rock, that is, the mineral composition and structure, constitute a complex oil storage and accumulation system. The chemical reactions that occur when the acid liquid enters the rock structure are very complicated, often dissolution accompanying with reprecipitation. While dissolution occurs, new minerals often appear in the form of flocculent precipitates. If the volume of space occupied by the new mineral is larger than the volume of the original interstitial space, the permeability of the reservoir will not be improved, but further deteriorate. Therefore, we must fully understand the characteristics of the rock skeleton of the reservoir, identify the composition, type, quantity, and filling form of the interstitial material between the supporting the framework particles, and study the dynamic characteristics of the interstitial material during operation. The scheme to effectively dissolve the interstitial material under the formation conditions and clear the throat of the reservoir and at the same time not to affect the rock skeleton is designed. Optimize the order of dissolution, implement the acidification operation step by step, and finally achieve the purpose of expanding the pore volume, improving reservoir permeability and increasing well production.

The reaction between rock and acid fluids aims to improve the porosity and permeability of the reservoir, which is also the basic requirement for the establishment of acid-rock reaction. Identifying the mineral composition and microstructure of the reservoir is the basis for selecting the acid solution. At the same time, the chemical composition of the minerals, the original physical conditions of the reservoir, and the properties of oil, gas, and water should also be considered. The main principle of "stepwise dissolution and separation" acidification (acid fracturing) to increase production can be summarized as follows: for the limited drainage radius of low permeability reservoirs, the "stepwise dissolution and separation" acidification (acid fracturing) treatment technology is adopted to create a high-permeability drainage zone with a radius of several meters to tens of meters in the near-wellbore zone to increase drainage radius and reach the goal of increasing production and injection.

3. Application cases

In order to verify the effectiveness of the method, deblocking tests were conducted in low-permeability reservoirs according to different situations: (1) In newly developed low- permeability blocks where the permeability of the reservoir matrix is low, and the daily oil production of exploration well testing fails to meet commercial oil flow standard, traditional acidizing uses conventional oilfield chemical agents such as mud acid and hydrochloric acid to remove plugging, which is not pertinent to the specific complex "structural elements" of the reservoir. (2) In old low-permeability blocks developed for many years which are often fractured in the early stages of development, the reserve utilization rate is very low, and the water cut is very high, which makes the later stimulation difficult. (3) In plugging removal and pressurization by water injection, the near-bottom area of the injection well is blocked, and the water injection pressure gradually increases to the pressure limit of the pipe network. The amount of water injection gradually reduces, and the production of surrounding oil wells reduces rapidly.

3.1. Newly-developed low-permeability reservoir

The third member of Shahejie Formation in Fan 128 block of Jiyang Depression is a low-permeability sandstone reservoir. The exploration wells have low oil production in formation testing and early development stage, the main reasons are low porosity and low permeability of the reservoir and damages by acid sensitivity and speed sensitivity etc. The acidizing and deblocking solution designed according to the idea of “stepwise dissolution and separation” was implemented in Well Fan 128-2, and the well obtained a high oil flow of 14 tons per day after treatment.

The permeability of sandstone reservoirs in Xia 463 well in Wawu area of Jiyang Depression was only 0.2×10-3 μm2, and there was no natural productivity. “Stepwise dissolution and separation” acidification measures were implemented. The initial oil production was 8 t/d. Then it stabilized at 3-4 t/d, and the current cumulative production has exceeded 1.0×104 t, which is relatively rare in extra-low permeability oil wells.

3.2. Low-permeability old blocks

After years of development, the low-permeability reservoirs of the Paleogene Sha 3 member turbidite sandstone and Sha 4 member beach bar sandstone in blocks of F151, F16, and C26 in the Chunliang oil area of the Jiyang Depression have seen severe drop of formation energy. Consequently, many wells witnessed decline of liquid production year by year, and most oil wells have no economic benefits anymore. When the formation pressure coefficient is less than 0.7, the oil wells basically stopped production. It is found through study that the reservoirs have a total content of clay minerals of about 12%. Among them, pseudohexagonal “bookpage-like” kaolinite with the highest possible damage to reservoir and chlorite extremely sensitive to acid combined account for 60% of the clay minerals. In addition to clay minerals, patchy carbonate cements also harm reservoir permeability.

According to the principle of "stepwise dissolution and separation", the acidizing scheme adopted in this block is: (1) injecting low-concentration NH4Cl prepad fluid to form an acidic medium environment without side effects and stabilize kaolinite; (2) squeezing in high temperature fluoroboric acid composite system of appropriate concentration postpad fluid to solve kaolinite slowly; (3) injecting hydrochloric acid of moderate concentration with an appropriate amount of organic acid to quickly dissolve the chlorite, and flowing back the residues before the acid solution is exhausted (maintain the pH value less than 3.98) to increase the porosity of the reservoir; (4) injecting iso-ascorbic acid adjuvant to prevent re- precipitation of Fe2+ and Fe3+; (5) using concentrated phosphoric acid or low-concentration hydrochloric acid to deeply and slowly dissolve the small amount of carbonate cement.

Using this scheme, more than 10 wells including F151-8 were stimulated, and all of them obtained commercial oil flow and stable production after treatment. Before treatment, they had a daily oil production of 0-0.90 t, 0.44 t on average, and water content of 20%-100%, 73.6% on average. After treatment, they had a daily oil production of 2.40-3.50 t, 3.02 t on average, and water cut of 20.0%-80.0%, 48.6% on average. The results are satisfactory.

3.3. Plugging removal of water injection wells

The Well CX103 in the Chunliang oil area of the Jiyang Depression was an oil well at the beginning. Later, due to insufficient formation energy, it was converted into a water injector. At the beginning of water injection, the water injection was smooth. After a long time, the near-bottom area of the injection well was blocked, the water injection pressure gradually increased, the amount of daily water injection gradually reduced. Finally, the water injection pressure increased to the pressure limit of the pipe network. There are dozens of such wells in the beach bar sand block of the upper sub-member of the fourth member of Shahejie Formation in Chunliang oil area, which have affected the effect of water injection development seriously.

The "stepwise dissolution and separation" acidification scheme designed for the CX103 well is: (1) the combination of supramolecular solvent and composite acid dissolves the carbonate crystals formed because of the decrease in solubility due to temperature and pressure changes at the wellhead of the injection well; (2) the "point-contact acid" mixed by fluoroboric acid, activated water, and sodium nitrate dissolves various clay minerals in the reservoir and suppresses secondary blockage by the residue. After the deblocking operation was implemented, the designed injection was 30 m3/d, and the actual injection was also 30 m3/d. The amount of water injection has been stable for more than one year. This scheme was adopted in 9 water injection wells in this oil area. The pump pressure before the measures was 26.0-35.0 MPa, with an average of 31.0 MPa. The designed injection volume was 26.0-36.0 m3/d, with an average of 31.4 m3/d. The actual water injection volume was 0-7.0 m3/d, with an average of 1.6 m3/d. The pump pressure after measures was 10.0-30.0 MPa, averaged at 24.0 MPa. The designed injection volume was 12.0-30.0 m3/d, averaged at 21.3 m3/d. The actual water injection volume was 10.0-30.0 m3/d, with an average of 21.3 m3/d. All of these reached the goal of increasing injection.

4. Application prospect and significance

At present, China's dependence on imported crude oil has been close to 70%[19,20], so it is of great significance to effectively produce the low-grade petroleum resources. For the large-scale fracturing popular in the world, China has invested a lot of money in both the old oil areas in the east and the new oil areas in the west, but the returns have fallen short of the expectations. In the past, much attention has been paid on the researches on oil recovery technology, oil field chemistry, and oil recovery auxiliary agent series in the oil and gas industry. The mineral composition and its damage to the reservoir haven’t been analyzed as important factors restricting oil and gas output. The new "stepwise dissolution and separation" acidizing technology mainly focuses on the "structural elements" of the reservoir rock. From a microscopic perspective, a reasonable acidizing (acid fracturing) fluid formulation is designed specifically for the reservoir situation and implemented stepwise. This technology has been used over 100 well/times in Shengli and Jianghan oilfields (with a success rate close to 100%), proving the reliability and applicability of the technology. Apparently, it has broad promotion value.

At present, the low-permeability and difficult to recover reserves in Shengli Oilfield alone amounts to hundreds of millions of tons. As up to the national level, the number will be much larger[21,22]. The old blocks in the eastern oil areas (including medium- and high-permeability reservoirs as well) have very high water cut now, and tapping the remaining resources is currently the main aim. A large amount of crude oil can be produced by stimulating low-yield wells and water injection wells.

Carrying out detailed study on rock mineralogy and closely integrating geology-petrology-chemistry-technical process to form comprehensive technologies and promoting them into practice are main research direction in the next step.

5. Conclusions

There are three main factors affecting the permeability of low-permeability sandstone reservoirs: (1) The muddy fillings between the sandstone framework grains block the seepage channels; (2) The changes of salinity and solubility of the syn-sedimentary formation water during burial and the uneven migration of the formation fluid cause mineral crystal precipitation which occupies the pore throat space; (3) As the rock is gradually buried deeper and deeper under the overburden pressure, the framework debris is compacted more densely, and the seepage channel becomes narrower.

The damage by mud and clay minerals to the permeability of low-permeability sandstone reservoirs includes three types, which are euhedral clay minerals, mostly kaolinite, causing particle embedding during fluid movement, montmorillonite or illite/montmorillonite mixed layer swelling when meeting foreign fluid, and the needle-like or lamellar illite trussing between the particles to form "bridges" structure. The damage by crystalline salt to permeability is mainly manifested in five types, pore embedding (in plaque-like distribution), throat- fracture vein-like filling, micritization and adhesion of particle edge, iron ion impregnation and acid sensitivity.

According to the "structural elements" of low-permeability reservoirs, the "stepwise dissolution and separation" acidification (acidification) formula use sustained-release acid as the main acid fluid, and supramolecular solvents instead of hydrochloric acid to dissolve carbonate, and composite system of ammonium hydrogen fluoride, fluoboric acid and fluorophosphoric acid to dissolve silicate. The process is implemented step by step to reach the final goal of enlarging pores and increasing permeability. "Stepwise dissolution and separation" acidification (acid fracturing) technology can effectively dissolve the main interstitial components that have a significant blocking effect on pores, and can separate the dissolved interstitial reaction residues from the rock structure to expand the effective drainage radius and increase well production and injection. Field tests have proven that this technology is reliable and practical, and can provide technical support for the upgrade and development of low-permeability oil reserves in eastern China.

Reference

Summary of control factors of dense oil reservoir in Chinese continental lake basin

The development situation and future of low permeability oil reservoirs of SINOPEC

Development status and enlightenment of American tight oil

Present situation, experience and inspiration of exploration and development of tight oil in the United States

Petroleum geology of the giant Elm Coulee field, Williston Basin

DOI:10.1306/05280909006 URL [Cited within: 1]

Organic carbon in Bakken Formation, United States portion of Williston Basin

Petroleum source rocks and stratigraphy of Bakken Formation in North Dakota

Reservoir stimulation

ZHANG Hongkui, WENG Jiaxiang, YANG Yilian, et al,

Technical method and application for reservoir damaged identification by microexamination rock construction

Sandstone diagenesis and formation damage prevention in Shengli oildom. Journal of the University of Petroleum,

DOI:10.3406/etchi.2006.891 URL [Cited within: 1]

Optimization experiment of acidizing fluid system in oil well of Niu872 block in Xianhezhuang Oilfield

Cation and proton exchange pH variation and carbonate reactions in a freshening aquifer

DOI:10.1029/94WR01048 URL [Cited within: 1]

Dissociation constants of calcite and CaHCO3+ from 0 to 50 °C

DOI:10.1016/0016-7037(74)90112-4 URL [Cited within: 1]

Characteristics of Chinese non-conventional dense rock oil and gas reservoirs

DOI:10.3787/j.issn.1000-0976.2012.05.001

URL

[Cited within: 1]

Tight oil and gas is one of unconventional hydrocarbon resources and is widely distributed all over the world. Although it is also in wide distribution and with a great exploration prospect in China, its exploration degree is rather low at present. In view of this, this paper discusses and summarizes the main characteristics of Chinese tight oil and gas reservoirs in such compacted rocks as sandstone, marl, mudstone, etc. (1) Under the condition of low porosity and low permeability, the compacted rocks and source rocks are mostly interbeded and gas pools were formed in a large area and overlaid by rocks with multiple time periods and multiple layers. (2) Such tight hydrocarbon reservoir combinations have many different types which are dominated by selfgenerating and selfpreserving reservoirs. (3) Such tight hydrocarbon reservoirs with complex relationship between oil, gas and water often coexisted with shale gas or coalbed methane gas, and the hydrocarbon charging and expulsion occurred at different beds and different points. It is concluded that among those unconventional hydrocarbon resources, the tight oil and gas has the greatest potential for exploration because its recovery is less difficult than dark shale gas or coalbed methane gas, thus it can be one of the most important and most practical alternative energy resources for present and future hydrocarbon resource exploration and development.

Energization and flowback technology through plugging removal and acidization

Development of the theory and technology for low permeability reservoirs in China

DOI:10.1371/journal.pone.0205958

URL

PMID:30403681

[Cited within: 1]

It is generally difficult to predict fractures of low-permeability reservoirs under high confining pressures by data statistical method and simplified strain energy density method. In order to establish a series of geomechanical models for the prediction of multi-scale fractures in brittle tight sandstones, firstly, through a series of rock mechanics experiments and CT scanning, we determined 0.85 σc as the key thresholds for mass release of elastic strain energy and bursting of micro-fractures. A correlation between fracture volume density and strain energy density under uniaxial stress state was developed based on the Theory of Geomechanics. Then using the combined Mohr-Coulomb criterion and Griffith's criterion and considering the effect of filling degree in fractures, we continued to modify and deduce the mechanical models of fracture parameters under complex stress states. Finally, all the geomechanical equations were loaded into the finite element (FE) platform to quantitatively simulate the present-day 3-D distributions of fracture density, aperture, porosity, permeability and occurrence based on paleostructure restoration of the Keshen anticline. Its predictions agreed well with in-situ core observations and formation micro-imaging (FMI) interpretations. The prediction results of permeability were basically consistent with the unobstructed flow distributions before and after the reservoir reformation.

Distribution and potential of global oil and gas resources

Characteristics of tight oil in Triassic Yanchang Formation, Ordos Basin

DOI:10.1016/S1876-3804(13)60018-X URL [Cited within: 1]

Nano-hydrocarbon and the accumulation in coexisting source and reservoir