Introduction

The Sichuan-Chongqing region in China has become one of the fastest growing regions in the world for shale gas production, following the successful development of shale gas in North America. By the end of 2019, the total proved original gas in place (OGIP) of shale gas in China is 17865 × 108 m3, and the shale gas production capacity has reached 200 × 108 m3/a, with an annual shale gas production of 154 × 108 m3 in 2019. The production growth of marine shale gas in the Sichuan Basin will become the main contributor of China's natural gas production growth in the future[1,2,3].

The “Shale Gas Revolution” in the United States has had a huge impact on the world’s energy landscape. Although many scholars have analyzed the experience of successful development of shale gas in U.S. in terms of technology, economy, policy, and management, there are few analyses of the development practices and well productivity dominating factors of individual shale gas play[4]. Take the Fayetteville shale gas play, the second commercial shale gas play in the United States, as an example, its rapid production boom cannot be achieved without a deeper understanding of the geology, the progressive development strategy from sweet area to the inferior area, the continuous improvement of drilling and completion technology, and large number of shale gas wells[4,5,6,7,8]. Compared with shale gas play in North American[9,10,11,12], the marine shale in the Sichuan Basin has low TOC value, low porosity, low gas saturation and smaller thickness of high- quality reservoir, but high degree of thermal evolution. The shale gas accumulation conditions in China are more complex[13,14,15,16,17]. Located on the slope of Sichuan Basin, Weiyuan shale gas play is different from Changning-Zhaotong located in the depression and Fuling located on the box faulted anticline in China[14,18]. The Weiyuan shale gas play is characterized by small thickness (1-7 m and an average of 3.8 m) of high-quality reservoir, large horizontal stress difference (7.7-18.7 MPa), and large variation in well productivity. In order to improve the production rate of shale gas wells, it is of great significance to analyze the dominating factors on well productivity and development strategies optimization for commercial development of shale gas in South Sichuan Basin.

In this paper, based on systematic evaluation of shale gas reservoir geology and well logging interpretation in more than 20 appraisal wells, a correlation has been built between the test production rate and the high-quality reservoir length drilled in the horizontal wells, high-quality reservoir thickness and the stimulation treatment parameters in over 100 horizontal wells. The dominating factors on horizontal well productivity are identified, and the development strategies optimization is proposed. The research results effectively guide the development of shale gas under complex geological conditions.

1. The Weiyuan shale gas play

1.1. Regional geological background

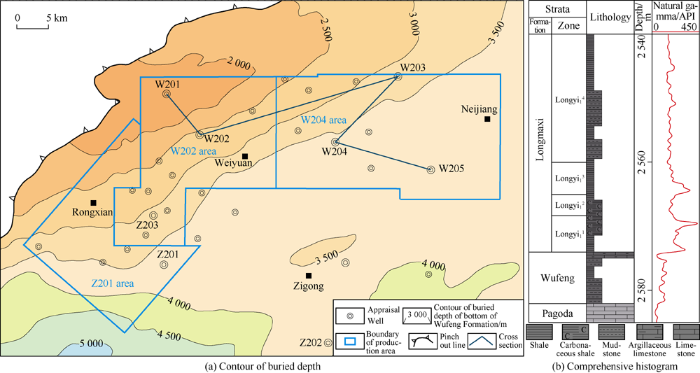

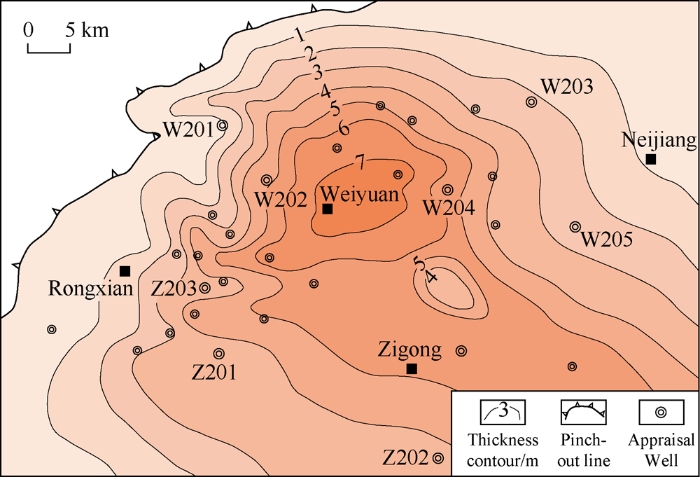

The Weiyuan shale gas play, in the southwest of the Sichuan Basin, is located in the central Sichuan lower uplift structural belt with shale gas area of 1520 km2 (Fig. 1). The organic-rich marine shale in the Wufeng Formation of Ordovician and Longmaxi Formation of Silurian, which was deposited in the deep-water continental shelf, is the favorable reservoir for shale gas exploration and development [19,20]. Controlled by the ancient uplift of Leshan-Longnüsi in Caledonian period, the thickness and burial depth of the shale strata gradually increase from northwest to southeast, with total thickness of 180-600 m and burial depth of 2000-4000 m (Fig. 1a). The favorable shale is located in the Wufeng and Longyi 1 subsection. While the Longyi 1 subsection can be divided into four layers named as Longyi 11, Longyi 12, Longyi13 and Longyi 14 from bottom to top (Fig. 1b).

Fig. 1.

Fig. 1.

Contour map of buried depth at the bottom of the Wufeng Formation and comprehensive histogram of Wufeng-Longmaxi Formation in the Weiyuan shale gas play.

1.2. Geological characteristics

The reservoir properties of shale in Weiyuan are similar to those in the rest area of Sichuan Basin. But faults and fractures are more developed, high-quality reservoirs are thinner and horizontal stress difference is larger in Weiyuan.

1.2.1. Reservoir properties

The reservoir properties in Wufeng-Longyi 1 are generally high, with TOC value of 2.1%-8.1% and average of 3.2%, porosity of 2.1%-9.6% and average of 5.9%, brittle mineral content of 60%-82% and average of 74%, gas content of 3.3-8.5 m3/t and average of 5.5 m3/t.

1.2.2. Characteristics of the study area

(1) The curvature distribution map by three-dimensional seismic (Fig. 2a) shows that the fractures, especially the microfractures, are well developed in Weiyuan shale and a few small faults (with larger curvature) are found locally. Natural fractures are more developed in the north of W202 area and in the middle and east of W204 area, followed by Z201 area. It can also be seen from the imaging logging that the fractures in the shale reservoirs are developed (Fig. 2b).

Fig. 2.

Fig. 2.

3D seismic curvature distribution map of Longyi 1 sub section and imaging logging map of well Wei 202 in the Weiyuan shale gas play.

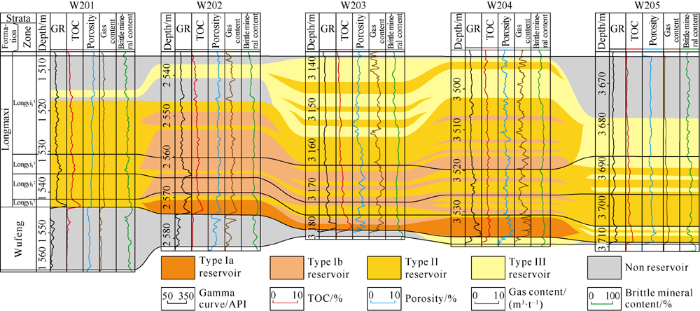

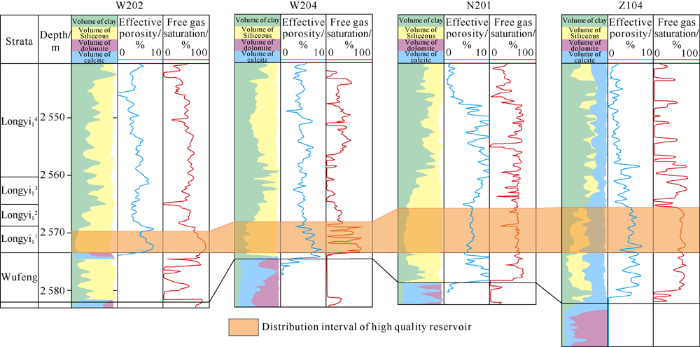

(2) The thickness of high-quality reservoir is smaller and varies greatly in Weiyuan. It can be seen from Fig. 3 that the thickness of type I + II reservoirs is 29-47 m, and the thickness of high-quality reservoir (Type Ia reservoirs, definition see Section 2) is small. The high-quality reservoirs are mainly distributed in Longyi 11. The thickness of high-quality reservoir in W202 area and W204 area is relatively large, but the average thickness is only 3.8 m in Weiyuan, which makes it difficult to improve the drilling length of high-quality reservoir in drilling.

Fig. 3.

Fig. 3.

Reservoir correlation profile of Wufeng-Longyi 1 in the Weiyuan shale gas play (see

(3) The horizontal stress difference is large. The horizontal stress difference in W202 area and W204 area is significantly higher than that in Z201 area. It is more difficult to create complex fracture network by hydraulic fracturing. The maximum horizontal principal stress is 70.0-88.3 MPa, the minimum horizontal principal stress is 54.0-69.6 MPa, and the horizontal stress difference is 16.0-18.7 MPa in W202 area and W204 area. In Z201 area, the maximum principal stress is 84.0 MPa, the minimum principal stress is 76.3 MPa, and the horizontal stress difference is 7.7 MPa (Table 1).

Table 1 Geostress parameter statistics of typical well Wufeng- Longyi 1 sub section in Weiyuan.

| Well | Maximum horizontal principal stress/MPa | Minimum horizontal principal stress/MPa | Horizontal stress difference/MPa |

|---|---|---|---|

| W202 | 70.0 | 54.0 | 16.0 |

| W204 | 88.3 | 69.6 | 18.7 |

| Z201 | 84.0 | 76.3 | 7.7 |

1.3. Development features

By the end of June 2019, 188 horizontal wells have been put into production, with a cumulative gas production of 53.87 × 108 m3. The lateral length of drilled horizontal well is between 816 m and 2200 m with an average of 1595 m, and the well spacing is between 300 m and 400 m.

(1) Test production rate. 173 wells have been tested with a total well test production rate of 3126.85×104 m3/d. The test production rate is 1.81-71.22×104 m3/d, with an average of 18.1×104 m3/d. While the well head pressure is in range of 5.7-36.7 MPa, with an average of 19.0 MPa during the well test.

(2) Average daily production rate in the first year. The average daily production rate in the first year of shale gas wells is used to evaluate the gas productivity, which is similar to that of North America. The average daily production rate of the producing wells in the first year is (1.0-32.0)×104 m3, with an average of 8.2×104 m3.

(3) Decline of the production rate. There are some differences in production decline rate of horizontal wells between W202 area and W204 area. The production decline rate in the first five years is 56%, 34%, 26%, 21% and 18% respectively for W202 area, and 59%, 32%, 23%, 18% and 14% respectively for W204 area.

(4) Estimated Ultimate Recovery (EUR). The EUR is in range of (0.12-2.34)×108 m3, with an average of 0.78×108 m3. The average EUR of Type I wells is 1.21×108 m3, and 0.75×108 m3 for Type II wells and 0.47×108 m3 for Type III wells.

2. Dominating factors on well productivity

It is necessary to obtain industrial gas flow through hydraulic fracturing for shale gas wells due to the shale has extremely low permeability. The well productivity is controlled by reservoir quality, reservoir thickness and the effectiveness of stimulation. Based on the analysis of the reserves in the shale gas reservoir, this paper makes it clear that the deployed reserves of high-quality reservoir is the dominating factor on well productivity through integrated analysis of the geology and engineering in the Weiyuan shale gas play. In other words, the production rate of shale gas horizontal wells is controlled by the thickness of high-quality reservoir, the drilling length of high-quality reservoir and the effectiveness of stimulation.

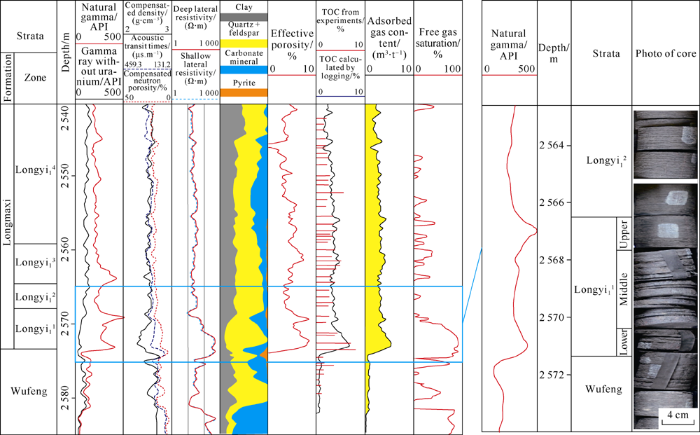

Shale gas reserves are mainly composed of free gas and adsorbed gas[21]. In overpressure areas with best preservation conditions, free gas is the main contributor for shale gas wells. According to the equation (1), free gas reserves are mainly related to effective porosity, gas saturation and gas volume factor. High quality gas reserves refer to the free gas contained in the high-quality reservoirs. Vertically, the high-quality reservoir shale has the characteristics of high effective porosity and high gas saturation. As the organic matter content can reflect the development of pores and brittle mineral content means that the shale is more easy to be fractured in South Sichuan Basin[22,23,24], the TOC content and brittle mineral content are also used to evaluate the high-quality reservoirs. According to Fig. 4, the shale with high TOC (greater than 4%), high effective porosity (greater than 6%), high gas saturation (greater than 70%), high brittle mineral content (greater than 75%) is defined as high-quality reservoir (shale with high-quality gas reserves), also known as Type Ia reservoir. In W202 area, high-quality reservoirs are mainly distributed in the middle and lower part of Longyi 11. In W204 area, high-quality shale is mainly distributed in Longyi11. The high-quality reservoir is characterized by medium-high natural gamma, low density, high resistance and low gamma ray without uranium. The siliceous mineral content is high and the beddings is well developed in high-quality reservoir as well (Fig. 4).

Fig. 4.

Fig. 4.

Comprehensive histogram of well logging interpretation of W202.

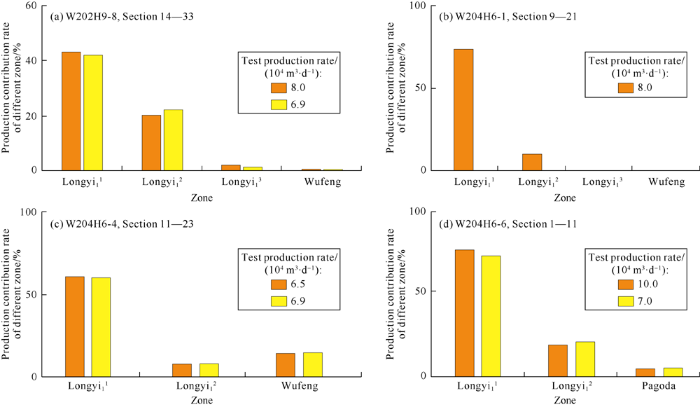

The production logging result is consistent with the above conclusions. The Longyi 11 (high-quality reservoir) has the highest gas production rate, which is usually 2-5 times of Longyi 12 (overlying stratum, thickness no more than 5m), and more than 10 times of Longyi 13 (Fig. 5). Although the thickness of high-quality reservoir is small with an average thickness of only 3.8 m, it is difficult to fully deplete the reserves of high-quality reservoir if another zone such as Longyi 12 is taken as the target of the horizontal well.

Fig. 5.

Fig. 5.

Statistic of production logging data of different gas wells at different intervals in the Weiyuan shale gas play.

In addition, based on the average daily production rate in the first year with the reservoir drilling length of 6 wells in H2 platform of W202 area, it can be seen that the average daily production rate in the first year is positively correlated with the drilling length of the high-quality reservoir of each horizontal well, and the correlation coefficient can reach as high as 0.93 (Fig. 6).

Fig. 6.

Fig. 6.

Relationship between average daily production rate in the first year and drilling length of high quality reservoir of 6 horizontal wells in H2 platform in Wei 202 area.

The high-quality shale gas reservoirs are mainly developed near the Weiyuan County, with a maximum thickness of over 7 m, and gradually thinned outward (Fig. 7). Compared with Changning (N201) and Zhaotong (Z104), the thickness of high-quality reservoirs in Weiyuan is significantly reduced (Fig. 8).

Fig. 7.

Fig. 7.

Thickness contour map of high-quality reservoir in the Weiyuan shale gas play.

Fig. 8.

Fig. 8.

Comparison of high quality reservoirs in typical wells of Weiyuan, Changning and Zhaotong.

2.1. Thickness and drilling length of high-quality reservoirs

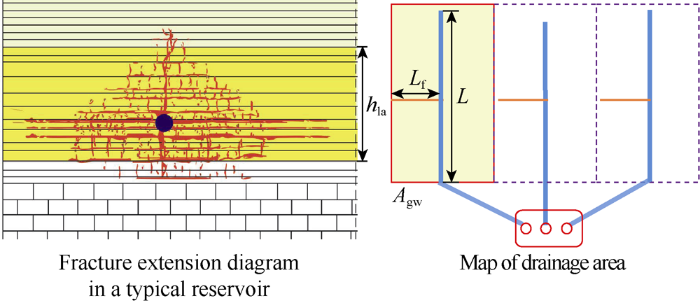

As the developed bedding restricts the longitudinal extension of the hydraulic fracture, temperature logging shows that the proppant fracture height of hydraulic fracture is only 6-7 m, and it is easier to extend upward[25]. The closer the horizontal well target is to the bottom of the high-quality reservoir, the higher the deployed reserves of high-quality reservoir (Fig. 9). According to the combination of equation (1) and Fig. 9, the greater the thickness of high-quality reservoir (h1a), the more free gas reserves there are, and the higher the gas well production rate under a certain fracturing treatment. The drainage area of a shale gas well (Agw) is mainly determined by L and Lf, where L is the drilling length of high-quality reservoir and Lf is the half length of hydraulic fracture in horizontal wells.

Fig. 9.

Fig. 9.

Fracture distribution and drainage area of shale gas horizontal wells.

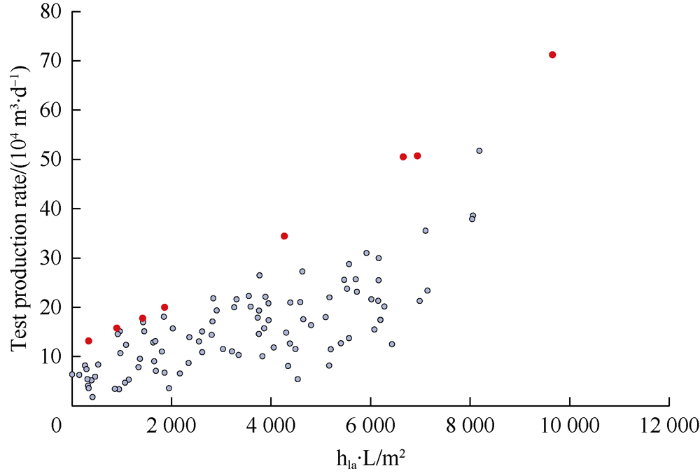

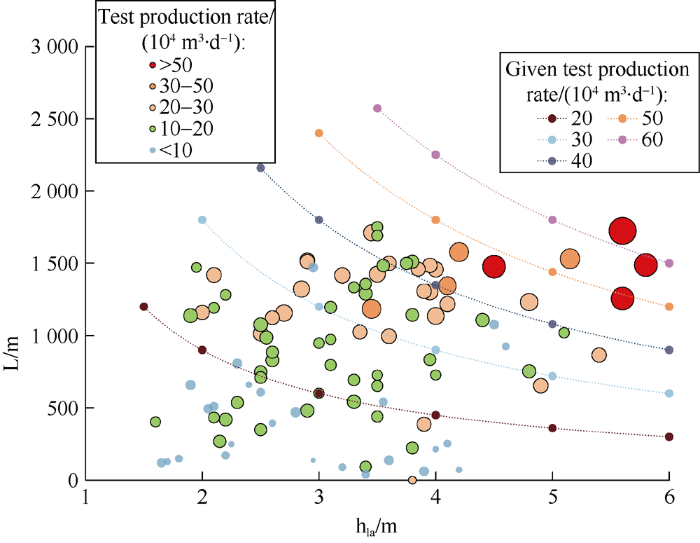

It can be seen from Fig. 10 that the test production rate is positively correlated with hla·L. Under certain stimulation treatment, the thickness and drilling length of high-quality reservoir are the domination to the deployed reserves of high-quality reservoir. In the complex geological conditions, some wells are affected by the casing deformation, and some wells are tested with new technology, so the production rate are not so high. The red dots in Fig. 10 represent the wells with the best productivity under the same geological conditions but eliminating the negative influence of engineering factors. The relationship between the ideal productivity (qgt) of a well and the hla·L under current technical conditions obtained by regression of red dots is shown in equation (2). According to equation (2), if the ideal gas production rate and the thickness of high-quality reservoir are given, the needed drilling length of high-quality reservoir can be estimated, and vice versa (Fig. 11).

Fig. 10

Fig. 10

The relationship between test production rate and hla · L

Fig. 11.

Fig. 11.

Test production rate and target test production rate under different thickness and drilling length of high quality reservoir.

2.2. Natural fractures development and hydraulic fractures

The fracture network, including both natural fractures and hydraulic fractures, is the guarantee of deployed reserves of high-quality reserves.

Natural fracture is the fracture network formed by in-situ stress in shale gas reservoir, which can not only extend the storage space, but also is helpful to connect isolated pores during stimulation. Natural fractures are well developed in Weiyuan, which provides favorable flow path to improve the production rate (Fig. 2).

The effectiveness of hydraulic fracturing is one of the key factors to dominate well productivity[26]. The number of fracturing stage, proppant volume per length, fluid volume per length, pump rate and number of clusters are the key parameters for hydraulic fracturing. In Weiyuan, the average frac length per stage is 68.2 m, the average frac stages are 22.4, the average proppant volume is 1.61 t/m, the average liquid volume is 27.4 m3/m, the average pump rate is 13.5 m3/min, and the number of clusters is mainly 3-4. Since the second half of 2019, 5-7 clusters have been tested in some wells. The geological characteristics of Haynesville shale gas play in the United States are similar to that of the Weiyuan shale gas play. The fracture length in Haynesville is 30-50 m, with proppant volume of 2.36-5.17 t/m and liquid volume of 19.9-43.5 m3/m. On the whole, the fracturing parameters in the Weiyuan shale gas play are much lower than that of Haynesville with similar geological conditions in North America.

Increasing pump rate, high proppant volume per length, shorter frac length and more clusters per stage are the main technical means to improve well performance. It is found that increasing the intensity of fracturing has a significant effect on improving the production rate of shale gas wells in Weiyuan. Through the statistics analysis of fracturing parameters of gas wells with test production rate over 30×104 m3/d, it can be seen that the frac length per stage is 52-77 m, the frac stages is 23-33, the proppant volume is 1.57-2.00 t/m, the liquid volume is 26.4-32.1 m3/m, and the pump rate is 13.1-15.3 m3/min, which all are higher than that of low productivity wells.

3. Development strategies optimization and its effects

3.1. Target of horizontal well

In W202 area, considering the facts such as the high clay content, high calcium content and low physical properties at the top of Longyi 11, the target zone is located in the middle and lower part of Longyi 11 with high TOC, high brittle mineral content, high gas saturation and more bedding developed. In W204 area, the longitudinal variation of Longyi 11 is minor, and the target zone is located in Longyi 11.

3.2. Optimized deployment of horizontal wells

Horizontal wells are preferentially arranged in the surrounding area of Weiyuan County where the thickness of high-quality reservoir is relatively thick, and gradually step out to the surrounding area where the thickness of high-quality reservoir is relatively thin. The continuous progress of technology can make up for the negative influence of thin high-quality reservoir.

3.3. Fracturing treatment parameters

Based on the results of fracturing parameters of high-performance wells in Weiyuan and best practice in Haynesville, aiming at greatly increasing the production rate of shale gas wells, it is recommended that the frac length of the horizontal wells is more than 1800 m, the frac length per stage is less than 60 m, the proppant volume is more than 2.0 t/m, the liquid volume is about 30 m3/m, and the pump rate is more than 14 m3/min.

3.4. Field application effects

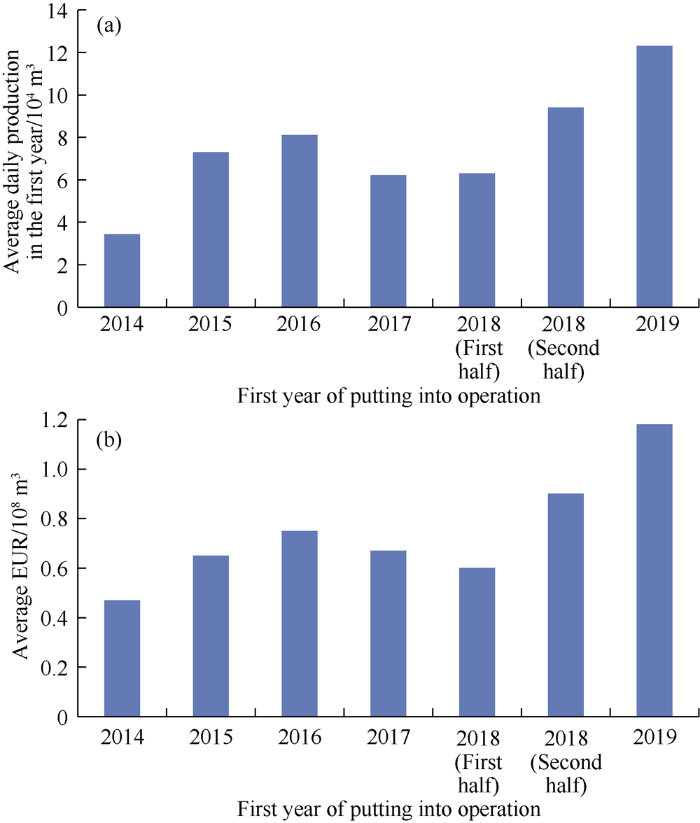

By the end of 2019, many horizontal wells or platforms in the Weiyuan shale gas play have achieved high production rate after the implementation of development strategies optimization in April 2018. For example, the total test production rate of the four- well-platform H15 in W202 area is 192.67× 104 m3/d, the average test production rate per well is 48.17× 104 m3/d, and the maximum well test production rate is exceeded 70×104 m3/d. Since the second half of 2018, the average daily production rate in the first year for new production wells has reached 11.7×104 m3, an increase of 85.7% compared with that of 6.3×104 m3 in the first half of 2018, and an increase of 63.4% compared with that of 7.16×104 m3 of all production wells before the implementation of development strategies optimization (Fig. 12a). The average EUR of new production wells is 1.11×108 m3, 85% higher than that of production wells in the first half of 2018, and 63.2% higher than that of all production wells before the implementation of development strategies optimization (Fig. 12b). It should be noted that the average EUR of Blasingame method and analytical method are taken for all production wells to ensure the reliability of the EUR.

Fig. 12.

Fig. 12.

The histogram of average daily production rate in the first year (a) and EUR (b) of 2014-2019 in the Weiyuan shale gas play.

4. Conclusions

Based on the analysis of the geological characteristics and dynamic performance of the Weiyuan shale gas play, evaluation criteria of high-quality reservoir are built, and the reservoir characteristics and distribution of high-quality reservoir are clarified. High-quality reservoirs are characterized by high TOC value (more than 4%), high effective porosity (more than 6%), high gas saturation (more than 70%) and high brittle mineral content (more than 75%). They are mainly distributed in the middle and lower part of longyi 11 (W202 area) or longyi 11 (W204 area), with high gas production contribution. It is clear that the well productivity of shale gas horizontal wells is mainly controlled by the thickness of high-quality reservoir, drilling length of high-quality reservoir, the development of natural fractures and the effectiveness of stimulation. Suggestions on target zone of horizontal wells, optimized deployment of horizontal wells and fracturing parameters are put forward. After the implementation of development strategies optimization, a breakthrough in well production rate has been achieved, and the average EUR of new wells is 85% higher than that in the first half of 2018. In the future, we should improve the stability of technology and the application of advanced technology, which include improving the effectiveness of stimulation (focus on high proppant volume per length), reducing the casing deformation, and reducing the frac hit.

Nomenclature

Ag—reservoir area, km2;

Agw—drainage area of single well, km2;

Bgi—volume factor of original shale gas;

Gx—total free gas volume, 108 m3;

h—thickness of reservoir, m;

hla—thickness of high-quality reservoir, m;

L—drilling length of high-quality reservoir, m;

Lf—half length of fracture, m;

qgt—test production rate, 104 m3/d;

Sgi—original gas saturation, %;

ϕ—effective porosity, %.

Reference

The progress and prospects of shale gas exploration and exploitation in southern Sichuan Basin, SW China

A golden era for natural gas development in the Sichuan Basin

Shale gas in China: Characteristics, challenges and prospects (II)

The development of Fayetteville shale play and its implications

Deconstructing the Fayetteville: Lessons from a mature shale play

(2015-06-25)[2020-01-20]. http:// kimmeridge.com/wp-content/uploads/2018/12/Kimmeridge- Deconstructing-the-Fayetteville.pdf.

Fayetteville shale-production outlook

The “shale revolution”: Myths and realities

Mississippian Barnett Shale: Lithofacies and depositional setting of a deep-water shale-gas succession in the Fort Worth Basin, Texas

Organic-rich Marcellus Shale lithofacies modeling and distribution pattern analysis in the Appalachian Basin

Geologic analysis of the Upper Jurassic Haynesville Shale in east Texas and west Louisiana

DOI:10.1306/02141110128

URL

[Cited within: 1]

The Upper Jurassic Haynesville Shale is currently regarded as one of the most prolific emerging shale-gas plays in the continental United States. It has estimated play resources of several hundred trillion cubic feet and per-well reserves estimated as much as 7.5 bcf. The reservoir spans more than 16 counties along the boundary of eastern Texas and western Louisiana. Although this basin has a long history of exploration and analysis of its Mesozoic section, a comprehensive subsurface study characterizing the Haynesville Shale has not been conducted. This article is the first to address the structural setting, stratigraphy, depositional environment and facies, fracturing, and production challenges of the Haynesville shale-gas play. Basement structures and salt movement influenced carbonate and siliciclastic sedimentation associated with the opening of the Gulf of Mexico. The Haynesville Shale is an organic- and carbonate-rich mudrock that was deposited in a deep partly euxinic and anoxic basin during the Kimmeridgian to the early Tithonian, related to a second-order transgression that deposited organic-rich black shales worldwide. The Haynesville Basin was surrounded by carbonate shelves of the Smackover and Haynesville lime Louark sequence in the north and west. Several rivers supplied sand and mud from the northwest, north, and northeast into the basin. Haynesville mudrocks contain a spectrum of facies ranging from bioturbated calcareous mudstone, laminated calcareous mudstone, and silty peloidal siliceous mudstone, to unlaminated siliceous organic-rich mudstone. Framboidal to colloidal pyrite is variably present in the form of concretions, laminae, and individual framboids and replaces calcite cement and mollusk shells. Haynesville reservoirs are characterized by overpressuring, porosity averaging 8 to 12%, Sw of 20 to 30%, nanodarcy permeabilities, reservoir thickness of 200 to 300 ft (70 to 100 m), and initial production of as much as 30 mmcf/day. Reservoir depth ranges from 9000 to 14,000 ft (3000 to 4700 m), and lateral drilling distances are 3000 to 5000 ft (1000 to 1700 m). Typical Haynesville wells exhibit a steeper decline curve (similar to 80% in the first year) than other shale-gas plays, which is attributed to a very high overpressure.

Haynesville and Bossier mudrocks: A facies and sequence stratigraphic investigation, East Texas and Louisiana, USA

DOI:10.1016/j.marpetgeo.2011.10.001

URL

[Cited within: 1]

Upper Jurassic Haynesville and Bossier shale-gas plays of the northwestern Gulf of Mexico (GOM) Basin produce from organic-rich, marine transgressive to highstand mudrocks within mixed carbonate-clastic depositional systems. Modern wireline-log suites from similar to 200 deep wells were used for detailed correlations, and 10+ cores throughout the upper Kimmeridgian to lower Tithonian basin were incorporated into detailed fades, stratigraphic, and lithologic analyses. The Haynesville Shale lies within a 2nd-order transgressive systems tract (TST) that encompasses back-stepping ramp carbonates (proximal) and marine shales (distal) below a maximum flooding surface (MFS). This shale onlaps retrogradational carbonates and basement highs and is capped by the 2nd-order MFS. Bossier shales and local sandstones prograde basinward above the Haynesville shale and downlap the 2nd-order MFS. They grade upward and updip into the thick, highstand systems tract (HST), fluvio-deltaic sandstones of the Cotton Valley Group. Distally, organic-rich fades developed in restricted Bossier environments, creating another productive gas-shale opportunity. Several preexisting basement highs in the south and carbonate platforms in the northwest and west restrict and partition the basin, thus influencing deposition of highly organic versus nonorganic and siliciclastic-dominated versus carbonate-dominated lithologies. Haynesville and Bossier shales each compose three upward-coarsening cycles that probably represent 3rd-order sequences within the larger 2nd-order TST and early HST, respectively. Most of the three Bossier 3rd-order cycles are dominated by varying amounts of siliciclastics. Deposition of the Haynesville mudrocks occurred below storm-wave base under mostly dysoxic conditionsm allowing settlement of benthic bivalve communities and bioturbating organisms and oscillating periodically to more anoxic conditions on the seafloor. However, most of the sparse faunae found in these mudrocks are of planktonic origin. Bossier mudrocks exhibited more oxygenated and clastic-rich lithologies related to progradation of the clastic shoreline and sea-level highstand. Knowledge of lithologic, stratigraphic, geochemical, and faunal variations across mudrock basins needs to be detailed so that shale-gas basins might be successfully explored. (C) 2011 Elsevier Ltd.

Shale gas in China: Characteristics, challenges and prospects (I)

Main geological factors controlling high production of horizontal shale gas wells in the Sichuan Basin

Breakthrough and prospect of shale gas exploration and development in China

Shale gas enrichment pattern and exploration significance of Well WuXi-2 in northeast Chongqing, NE Sichuan Basin

Comprehensive evaluation technology for shale gas sweet spots in the complex marine mountains, South China: A case study from Zhaotong national shale gas demonstration zone

Discovery and exploration of Fuling shale gas field

Stratigraphic sequence and sedimentary characteristics of Lower Silurian Longmaxi Formation in the Sichuan Basin and its peripheral areas

A relationship between elemental Geochemical characteristics and organic matter enrichment in marine shale of Wufeng Formation—Longmaxi Formation, Sichuan Basin

Development characteristics of organic pore in shale gas reservoir of Wufeng Formation-Member 1 of Longmaxi Formation in Pingqiao block, Fuling shale gas field

Controlling factors of organic nanopore development: A case study on marine shale in the middle and upper regions, South China

Controlling factors of hydraulic fractures extending into network in shale formations

Research on influence of shale bedding to vertical extension mechanism of hydraulic fracture

Experience of efficient fracturing of shale gas in north America and enlightenment to China