Introduction

Porous sand gas reservoirs play very important role in natural gas reserves and production in China. As of 2018, 64 large gas fields with proven gas reserves of over 30 BCM (billion cubic meter) were discovered in China, with total proven gas reserves of 10.17 TCM (trillion cubic meter), among them, 32 were porous sand gas fields, with proven gas reserves of 5.22 TCM, accounting for 51.3% of the total proven gas reserves. In 2018, the gas production of porous sand gas fields was 62.9 BCM, accounting for 39.8% of the total gas production in China of that year.

Pore-throats are the main flow channels in porous sand gas reservoirs. Influenced by water saturation and overburden pressure, the effective permeability of porous sandstone reservoir at the in-situ conditions has a big difference from the gas permeability measured in laboratory. Previous studies[5,6,7,8,9,10,11,12,13,14,15,16,17] show that sandstone reservoirs with different permeability, especially low permeability and tight sandstone reservoirs have very different seepage features from the results of conventional experimental tests owing to the differences in pore throat size, water saturation and overburden pressure. This difference can affect the evaluation of gas well productivity and producing reserves directly, and then affect the strategy planned for the gas reservoir development.

Based on well test[18], production performance analysis, overburden permeability and porosity test, gas-water core flooding test and high-pressure mercury injection, a quantitative correlations between in-situ permeability and conventional permeability and water saturation of porous sandstone reservoir have been built, the ranges of Main Flow Channel Index (MFCI) in porous sand gas reservoirs of different permeability levels were determined, and a new method has been established to evaluate the in-situ permeability of porous sandstone gas reservoir, which can guide the formulation of reasonable development strategy for this kind of gas reservoir.

1. Main flow channel index of porous sand gas reservoirs

1.1. Definition

To identify the main types of flow channel in complex porous oil and gas reservoirs, Li et al.[19] defined the "main flow channel index (MFCI)" as the ratio of effective permeability to matrix permeability of a reservoir:

Ke represents effective permeability under in-situ conditions, which can be obtained through well test or production performance analysis. Km represents matrix permeability, which can be obtained by conventional core analysis or well logging. It can be seen from the definition that MFCI represents the difference between the macroscopic flow capacity of a reservoir and the microscopic flow capacity of matrix to some extent.

1.2. Features

By establishing a quantitative relationship between the flow rate of large channel and the MFCI, Li et al.[19] set up the quantitative criterion to identify the type of main flow channel. When the MFCI is less than 3, pore-throats are the main flow channels and the reservoir is of single-porosity and single-permeability system. When the MFCI is between 3 and 20, the reservoir has fractures as main flow channels and pore- throats as auxiliary flow channels, and the reservoir is of double-porosity and double-permeability. When the MFCI is greater than 20, the reservoir has fractures only as flow channels, and the reservoir is of double-porosity and single-permeability.

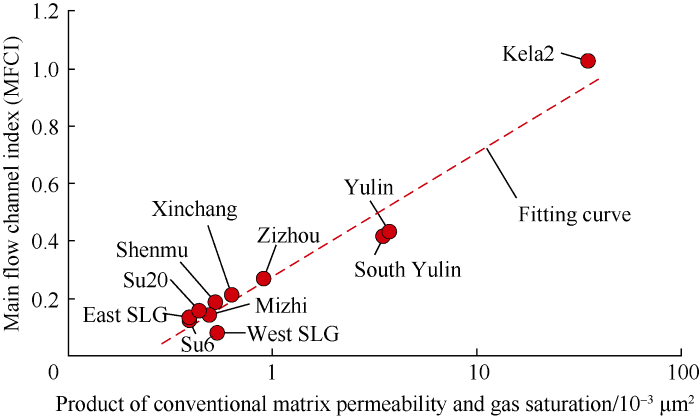

According to Eq. 1, the MFCI of China's main porous sand gas reservoirs (blocks) were calculated and the results are shows in Table 1. The results show that the MFCI of a porous sand gas reservoir (blocks) is closely related to its matrix permeability and water saturation. The lower the matrix permeability and the higher the water saturation, the lower the MFCI will be. When the matrix permeability is greater than 5.0×10-3 μm2, the MFCI is generally greater than 0.5. When the matrix permeability is from 1.0×10-3 to 5.0×10-3 μm2, the MFCI is mainly between 0.2 and 0.5. When the matrix permeability is less than 1.0×10-3 μm2, the MFCI is less than 0.2.

Table 1 MFCIs of China's main porous sand gas reservoirs (blocks).

| Gas reservoir (block) | Number of wells | Average matrix Permeability/mD | Average water saturation/% | MFCI |

|---|---|---|---|---|

| West SLG | 7 | 0.68 | 45 | 0.079 |

| East SLG | 18 | 0.65 | 38 | 0.124 |

| Su6(SLG) | 27 | 0.62 | 35 | 0.125 |

| Su20(SLG) | 26 | 0.77 | 36 | 0.126 |

| Mizhi | 4 | 0.66 | 33 | 0.130 |

| Shenmu | 7 | 0.77 | 39 | 0.140 |

| Xinchang | 10 | 1.09 | 42 | 0.209 |

| Zizhou | 39 | 1.27 | 28 | 0.266 |

| South Yulin | 10 | 4.40 | 20 | 0.416 |

| Yulin | 27 | 4.61 | 19 | 0.431 |

| Kela2 | 11 | 42.08 | 29 | 1.020 |

| Tainan | 12 | 15.61 | 32 | 1.041 |

| Sebei I | 16 | 9.13 | 47 | 1.149 |

| Sebei II | 25 | 10.07 | 48 | 1.285 |

Note: The water-out gas wells in the Kela 2 gas reservoir are excluded.

2. Physical simulation of main flow channel index

The key to evaluating the MFCI is to obtain reliable effective permeability and matrix permeability of the reservoir. The matrix permeability can be measured by conventional core analysis or by well logging. The effective permeability of reservoir is usually obtained by well test or production performance analysis, but it usually takes a long time to acquire the data to obtain a reliable result. Since this type of reservoirs have few fractures and the effective permeability is mainly controlled by overburden pressure and water saturation, actual formation conditions can be simulated in laboratory by physical experiment to test the effective permeability accurately under in-situ conditions.

2.1. Influence of net overburden pressure on effective permeability of reservoir

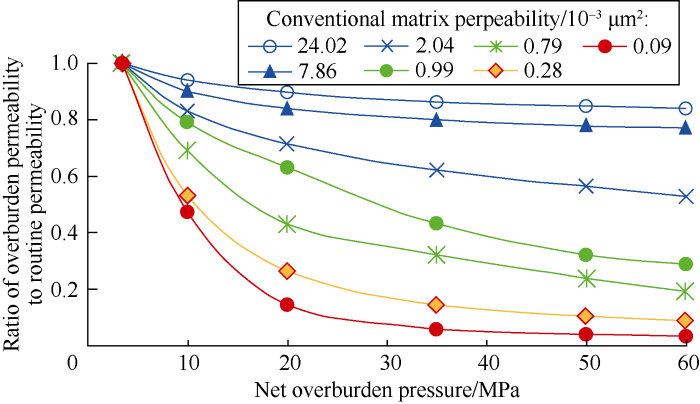

Using titanium alloy material, we developed a core permeability test device under in-situ conditions, which uses nitrogen as test fluid and can work at the maximum pressure of 100 MPa. The effective permeability under pressure and matrix permeability of core plugs from the Sulige gas field (SLG) were measured with this device to find out the effect of overburden pressure on reservoir effective permeability. In the SLG gas field, the reservoir has a burial depth of 3000 m, the formations have a rock density of 2.36 g/cm3 and pore pressure of 30 MPa, and the calculated initial net overburden pressure of the reservoir is 40.8 MPa. The results show that under the initial net overburden pressure, when the conventional matrix permeability is greater than 5.0×10-3 μm2, the ratio of the overburden permeability to the conventional permeability is greater than 0.8. When the conventional permeability is in the range of (1.0-5.0)×10-3 μm2, the ratio of overburden permeability to conventional permeability is 0.4-0.8. When the conventional permeability is less than 1.0×10-3 μm2, the ratio of overburden permeability to conventional permeability is less than 0.4 (Fig. 1).

Fig. 1.

Fig. 1.

Influence of net overburden pressure on ratio of overburden permeability to conventional permeability.

2.2. The effect of water saturation on gas-water relative permeability

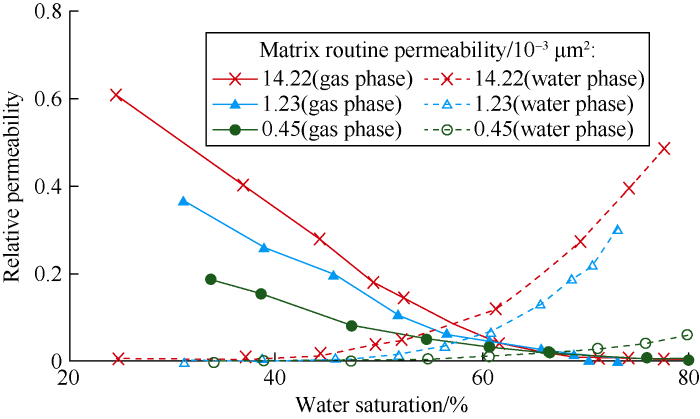

The influence of water saturation on gas-water relative permeability of porous sand gas reservoir was tested by gas-water seepage experiment[20] (Fig. 2). The results show that with the increase of water saturation, the relative permeability of gas decreases gradually, while that of water increases gradually. According to the statistical results in Table 1, the porous sand gas reservoirs have a water saturation of 30%-50% generally. For the core plug with matrix permeability of 14.22×10-3 μm2, the relative permeability of gas is 0.15-0.50, and that of water is 0.007-0.050. For the core plug with matrix permeability of 1.23×10-3 μm2, the relative permeability of gas is 0.11-0.36, and that of water is 0.000 5-0.011 0. For the core plug with matrix permeability of 0.45×10-3 μm2, the relative permeability of gas is 0.05-0.20, and that of water is 0.000 43- 0.007 00.

Fig. 2.

Fig. 2.

Gas-water relative permeability curves of porous sand gas reservoirs.

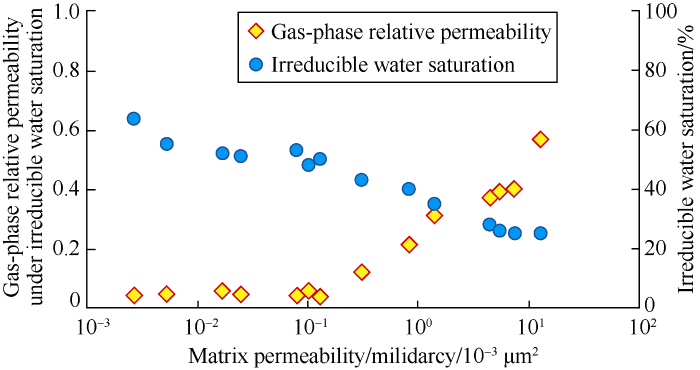

If no formation water is produced during gas production, then the water saturation of the gas reservoir remains constant. It can be considered that the effective permeability of the gas reservoir is only affected by irreducible water saturation. According to the experimental results, the irreducible water saturation and gas-phase relative permeability of sandstone samples with different matrix permeabilities are shown in Fig. 3. The results show that when the matrix permeability is greater than 5.0×10-3 μm2, the irreducible water saturation is less than 30%, and the relative permeability of gas phase is greater than 0.4 in general. Irreducible water saturation has little effect on the relative permeability of gas phase. When the matrix permeability is (1.0-5.0)×10-3 μm2, the irreducible water saturation is 30%-40%, and the relative permeability of gas phase is 0.25-0.4, and irreducible water saturation has significant effect on the relative permeability of gas phase in this kind of reservoir. When the matrix permeability is less than 1.0×10-3 μm2, the irreducible water saturation is often greater than 40%, and the relative permeability of gas phase is less than 0.25, irreducible water saturation has very strong effect on the relative permeability of gas phase of this kind of reservoir.

Fig. 3.

Fig. 3.

Irreducible water saturations and gas-phase relative permeabilities of sandstone samples with different matrix permeabilities.

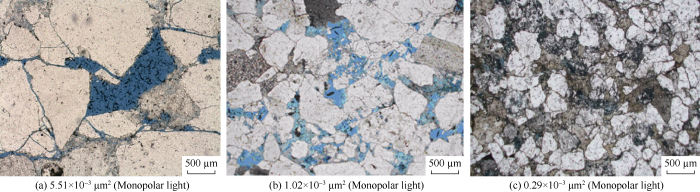

Fig. 4.

Fig. 4.

Thin sections (100×, Monopolar light) of sandstone samples with different conventional permeabilities.

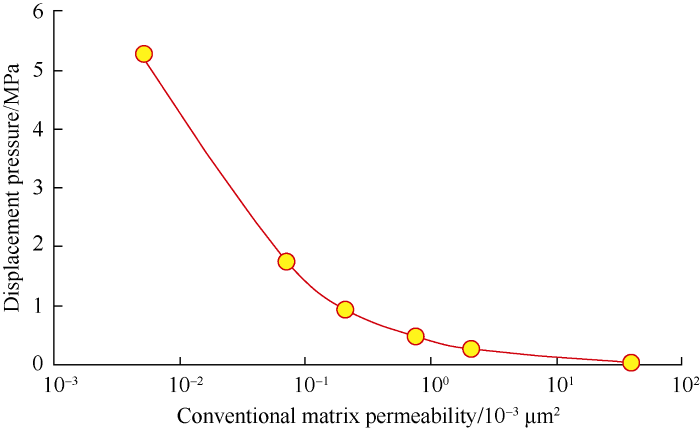

Fig. 5.

Fig. 5.

Displacement pressures of sand reservoirs with different conventional matrix permeabilities.

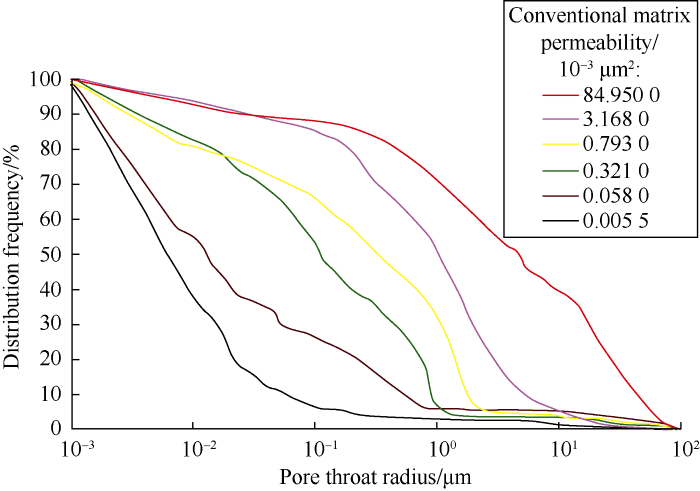

Fig. 6.

Fig. 6.

Distribution of pore throat radius in sandstone cores with different permeabilities.

2.3. Mechanism analysis

By high-pressure mercury injection and cast thin section observation[21,22], the pore throat size, displacement pressure, pore type and connectivity of porous sandstone gas reservoirs with different permeabilities in the Sulige gas field were tested (Figs. 4-6). The results show that: when the matrix permeability is greater than 5.0×10-3 μm2, the rock composition is mainly quartz and rhyolite cuttings, and the reservoir has mainly primary pores and some dissolution intergranular pores, good connectivity between pores, displacement pressure of less than 0.1 MPa, and median throat radius of generally greater than 2 micrometers. In the reservoirs with matrix permeability of (1.0-5.0)×10-3 μm2, the quartz is of single crystal with clean surface and no cleats; associated feldspar is small in quantity; the debris is composed of siliceous rocks, sandstone and phylite; the cement in interstitial material is mostly matrix; the pores are largely primary pores, with medium connectivity, displacement pressure of 0.1-0.5 MPa, and median throat radius of 0.5-2.0 micrometers. The reservoirs with the matrix permeability of less than 1.0×10-3 μm2 are mainly composed of quartz and slate debris, in which the cement in interstitial material is primarily calcium, pores are composed of primary pores and dissolution pores largely, and poor in connectivity, with displacement pressure of greater than 0.5 MPa and median throat radius of less than 0.5 micrometers.

The above results show that sandstone samples with different matrix permeabilities have obvious differences in rock composition, pore type and connectivity. When water exists in the pores of reservoir rocks, as different rock minerals have different sensitivity to water, and different sizes of pore throats have different capillary force on water, reservoirs under in-situ conditions would have different effective permeabilities. This is the fundamental reason for the difference of main channel index of porous sandstone reservoirs with different permeabilities.

3. Application

We can evaluate the effective permeability and producing degree of reserves of gas reservoir conveniently by using MFCI, which can guide the formulation of development strategy.

3.1. Evaluation of gas reservoir effective permeability

According to the definition of MFCI, the evaluation method of effective permeability of porous sand reservoir under in-situ conditions has been established, so we can quickly evaluate newly discovered gas reservoirs or gas reservoirs without well testing data. The equation is as follows:

the MFCI (λ) can be obtained by:

(1) For the gas reservoir that has well testing data and well logging data, the MFCI can be calculated according to its definition

(2) For the newly discovered gas reservoir or block without well testing, the MFCI can be determined according to the empirical method. Based on the parameter list of typical porous sand gas reservoirs (excluding loose sand reservoir) in Table 1, the correlation chart of MFCI with matrix permeability and gas saturation is established (Fig. 7), and the empirical equation of MFCI is fitted (with correlation coefficient of 0.95):

Fig. 7.

Fig. 7.

Relationship of MFCI with the product of matrix conventional permeability and gas saturation.

(3) In addition to the above two methods, the MFCI can also be determined by physical simulation method mentioned above.

3.2. Identification of tight sandstone gas

According to the petroleum industry standard (GB/T 26979—2011: The classification of natural gas pool[23]), when the effective permeability of a reservoir is less than 0.1×10-3 μm2, the reservoir can be identified as tight gas reservoir. In practice, the effective permeability of gas reservoir is generally obtained through well test or production performance analysis. However, for low permeability and tight sandstone gas reservoirs, it usually takes a long time to reach steady state or pseudo steady state, so it is difficult to accurately evaluate and identify whether the reservoir is tight gas reservoir or not in the early stage of development.

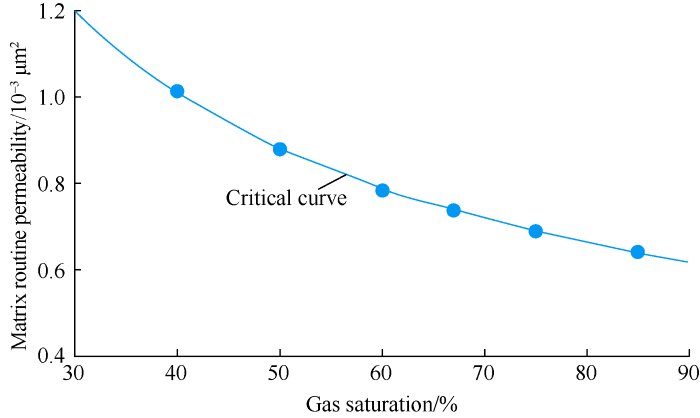

Tight sandstone gas reservoir can be quickly identified by using the exponential relationship of MFCI of typical porous sand gas reservoir. Combining Eq. 2, Eq. 3 and tight sandstone gas standard, we know that tight sandstone gas reservoir parameters should meet the following equation:

According to Eq. 4, the critical curve of tight sand gas identification can be obtained (Fig. 8). If the matrix permeability and gas saturation of a newly developed gas reservoir / block are below the critical curve, the reservoir can be identified as tight sandstone gas reservoir. At the meantime, the matrix permeability and gas saturation meet the following relationship:

Fig. 8.

Fig. 8.

Tight sand gas identification chart.

3.3. Evaluation of recoverable reserves of gas reservoir

As different porous sand reservoirs under in-situ conditions have obvious difference in MFCI, and reservoirs with different permeability under different water saturation conditions differ in producing degree of reserves, how to accurately evaluate the recoverable reserves in the early stage of gas reservoir development is the key to gas reservoir development evaluation and the scientific basis for making gas field development plan.

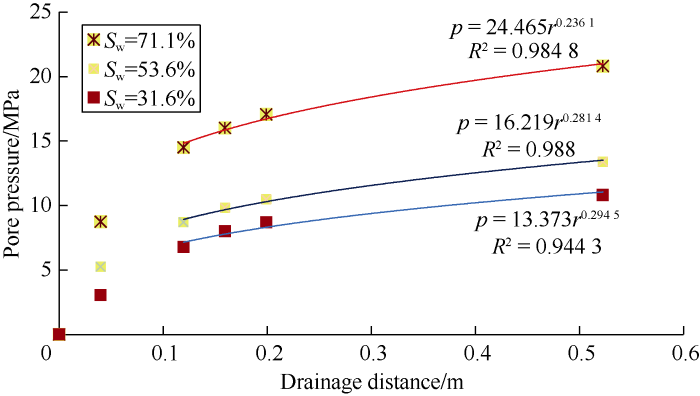

By using the physical simulation experiment method in reference [24], simulation experiments under 3 different water saturations were carried out on a porous sandstone core with a conventional permeability of 0.063×10-3 μm2, to find out the relationship between the corresponding pore pressure and drainage distance when the gas production rate dropped to 10% of the initial production rate, and the results are shown in Fig. 9.

Fig. 9.

Fig. 9.

The relationships between pore pressure and drainage distance under different water saturations.

According to the relationship between pore pressure and drainage distance in Fig. 9, in order to eliminate the influence of end effect on experimental results, data points far from the core end were selected for fitting, and the results show that pore pressure and drainage distance have a power function relationship:

In the Eq. 6, a and b are coefficients related to permeability and water saturation, which can be determined by function fitting of the experimental test results of the reservoirs of different permeabilities under different water saturation conditions.

According to the physical properties and original formation pressure of a gas reservoir, the drainage area of the reservoir can be calculated by Eq. 6, and then the reservoir can be quantitatively evaluated according to the definition of the producing degree of reserves in petroleum industry standard (SY/T 6170-2012: The technical indexes of natural gas production and their calculation methods[25]).

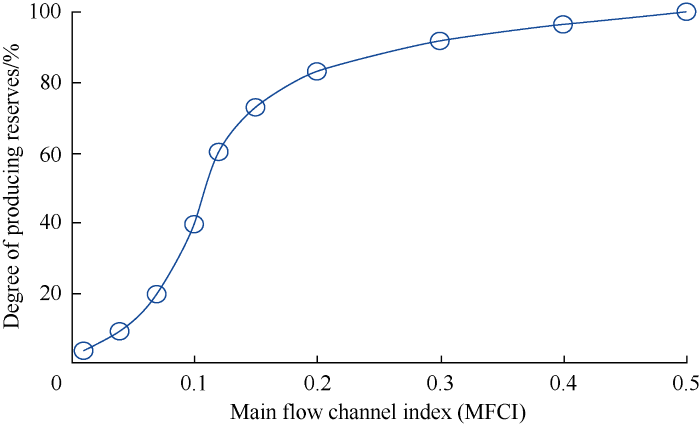

By using the above method, the producing degree of reserves in reservoirs with different permeabilities at different water saturations and well spacing of 400 m were evaluated, and the relationships between the producing degree of reserves and MFCI of sandstone gas reservoirs with different permeabilities at different water saturations were established (Fig. 10). It can be seen that when the MFCI is greater than 0.2, the producing degree of reserves is more than 80%, in other words, the reserves is fully produced, and infilling well is unnecessary. When the MCFI is 0.1-0.2, the producing degree of reserves is 40%-80%, and infill drilling is necessary. When the MFCI is less than 0.1, the producing degree of reserves is less than 40%, it means that the reservoir is tight, the reserves are difficult to be produced. Infill drilling would have little effect in improving the recovery.

Fig. 10.

Fig. 10.

Relationship between producing degree of reserves and MFCI at the well spacing of 400 m.

4. Conclusions

The MFCI of porous sand reservoir has strong correlation with the matrix permeability and water saturation. The lower the matrix permeability and the higher the water saturation, the lower the MFCI will be.

In general, when the matrix permeability is greater than 5.0×10-3 μm2, the MFCI is greater than 0.5. When the matrix permeability is in the range of 1.0-5.0×10-3 μm2, the MFCI is 0.2-0.5. When the matrix permeability is less than 1.0×10-3 μm2, the MFCI is less than 0.2.

When the matrix permeability and gas saturation of a porous sand gas reservoir meet the condition of$K_{m}S_{g}^{0.60}\le 0.58$, the reservoir can be identified as a tight gas reservoir.

The effective permeability evaluation method under in-situ conditions of porous sand gas reservoir allow quick evaluation of newly discovered gas reservoirs or gas reservoirs without well testing data. The relationship chart between the producing degree of reserves and MFCI can provide a basis for the evaluation of recoverable reserves and infill drilling potential in porous sand gas reservoir.

Nomenclature

a, b—coefficient related to reservoir permeability and water saturation, dimensionless;

Ke—effective permeability of reservoir (obtained by well test or production performance analysis), μm2;

Km—conventional permeability of matrix (obtained by core analysis or well logging), μm2;

p—pore pressure at a certain location within the producing range, MPa;

r—drainage distance, m;

R—correlation coefficient, dimensionless;

Sg—gas saturation, %;

Sw—water saturation, %;

λ—main flow channel index (MFCI), dimensionless.

Reference

Travis peak core permeability and porosity relationships at reservoir stress

Effect of overburden pressure on some properties of sandstones

DOI:10.2118/461-PA URL [Cited within: 1]

Effective compressibility of reservoir rock and its effects on permeability

Effect of fluid, confining pressure and temperature on absolute permeabilities of low permeability sandstones

A new method to determine the relationship between permeability of low permeability core and effective overburden pressure

Theory of rock deformation and stress sensitivity of tight sandstone reservoir

Comprehensive study on stress sensitivity of tight sand stone reservoir in Daniu gas field of Ordos basin

The analysis about rock stress sensitivity considering in situ stress

Influence of water saturation and effective stress on permeability of tight sandstone

Evolution of gas from liquids flowing through porous media

Incorporating capillary pressure, pore throat aperture radii, height above free-water table, and Winland r35 values on Pickett plots

Effect of pressure and water saturation on the permeability of western tight sandstones. Tulsa,

Reservoir characteristics of low-permeability sandstones in the Rocky Mountains

Aspects of permeability, capillary pressure, and relative permeability properties and distribution in low-permeability rocks important to evaluation, damage, and stimulation

Capillary behavior in porous solids

Similarities and differences between natural gas accumulations in Sulige gas field in Ordos Basin and Xujiahe gas field in central Sichuan Basin

Quantitative criteria for identifying main flow channels in complex porous media

Varying law of water saturation in the depletion-drive development of sandstone gas reservoirs

Research on percolation mechanism of tight sandstone gas reservoir

Physical simulation on gas percolation in tight sandstone