Introduction

The Ordovician carbonate reservoir of Tahe oilfield is a typical fractured-vuggy reservoir, with lots of fractures and caves developed. Differing from a clastic rock reservoir, a fractured-vuggy reservoir has strong heterogeneity, storage and flow spaces made up of karst caves, fractures and pores in different sizes, shapes in scatter distribution, and complex fluid flow law and oil displacement mechanisms, which makes the development and study of fractured-vuggy reservoir more difficult[1,2,3,4]. At present, the karst cave is usually regarded as the target during drilling of such a reservoir, and depletion development is generally adopted in the initial stage of production. Wells drilling into karst-caves often have high initial production but rapid decline of formation energy. Moreover, most of the karst caves are located in the inter-well zone, and have low recovery if developed by depletion, so water flooding is needed. In recent years, waterflooding has been implemented in more than 120 fractured-vuggy units in the Tahe Oilfield[5]. Due to the strong heterogeneity of reservoir connectivity and spatial distribution, the injection water may advance in widely different speeds in different directions of the same injection well, which affects the development effect negatively. Performance analysis of injection-production units shows that injection wells displacing in one direction and production wells affected in one direction are over 70%; the water sweep coefficient is relatively low; and the inter-well interference inside well group is severe. In recent years, physical modeling technology of fractured-vuggy reservoir has been advancing continuously, but the research conclusions have no universality while the experimental models pursue refinement and complexity due to the complexity of fractured-vuggy reservoirs. Therefore, properly ignoring some individual features of the fractured-vuggy structure in the design of the experimental model is helpful to obtain relatively universal understandings which can effectively guide the development of waterflooding in the fractured-vuggy units. In this study, considering the main macroscopic characteristics of the fractured-vuggy reservoir and the oil displacement mechanisms, a simplified physical experiment model with universal features is designed to conduct the inter-well interference experiments during waterflooding. Based on the percolation theory and water-flooding mechanisms of such reservoir, an inversion model simulating waterflood interference is built to study the influences of different factors on interference characteristics based on experimental results. An optimization strategy of injection-production well patterns is proposed to enhance water flooding effect. The study results can provide technical ideas for the analysis of production performance in fractured-vuggy reservoirs, adjustment of injection-production well patterns, and reservoir stimulation.

1. Physical modeling experiments of inter-well interference characteristics in fractured-vuggy reservoirs

The fractured-vuggy reservoir is not in layered distribution[1,2] and has strong heterogeneity and discretion. The differences in fracture connectivity and volume of karst caves connected by fracture zone lead to the uneven effect on production wells during waterflooding. Based on the concept of interlayer interference of waterflooding in sandstone reservoir, the inter-well interference is defined as the interference of injected water distribution proportions along different injection-production directions due to the differences in physical properties and well spacing when water is injected in one injection well to two or more production wells. In order to study the inter-well interference characteristics of waterflooding in fractured-vuggy reservoirs, physical modeling experiments of inter-well interference were conducted according to the simplified geological characteristics.

1.1. Experimental scheme design

1.1.1. Geological characterization model of fractured-vuggy reservoir

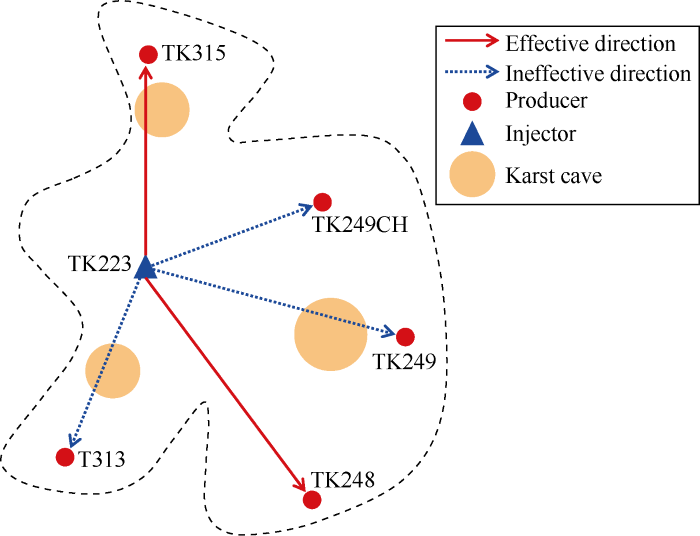

Due to the discrete spatial distribution of storage bodies, it is difficult to establish a relatively complete injection-production well pattern in a fractured-vuggy reservoir. Generally, injection-production unit is taken as the research object. Fig. 1 shows the water flooding effect diagram of T313 injection- production unit in Tahe Oilfield, in which Well TK223 is injection well, and wells T313, TK315, TK248, TK249CH and TK249 are production wells. Some lines connecting the injection well and production wells pass through karst caves. After water injection started in Well TK223, only Well TK315 and TK248 had significant effect due to the inter-well interference caused by the differences in injection-production direction connectivity, flow resistance, and reservoir body distribution.

Fig. 1.

Fig. 1.

Water flooding effect diagram of T313 injection-production unit.

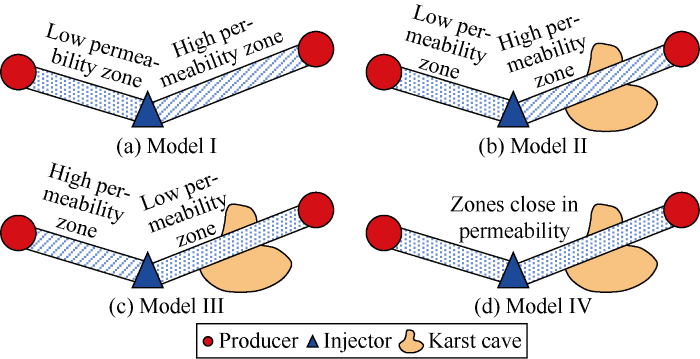

In fractured-vuggy reservoirs, karst caves are mainly connected by complex fracture network[1,2] which have strong heterogeneity. Based on analysis of connection characteristics between the injection and production wells in fractured-vuggy units of the Tahe Oilfield, while ignoring the inter-well individual structural characteristics, the universal features of " difference in inter-well fractures or fracture zone connectivity and in karst cave volume connected by fractures" were extracted to classify the injection-production well connection into 4 models, as shown in Fig. 2.

Fig. 2.

Fig. 2.

Simplified connection models between injection well and production well.

In Model I, there is a high permeability fracture zone and a low permeability fracture zone between the injection well and production wells, and both two fracture zones don’t connect with karst caves. In Model Ⅱ, there is also a high permeability fracture zone and a low permeability fracture zone between the injection well and production wells, but the high permeability fracture zone connects with karst caves (or the high permeability fracture zone connects with larger caves, the low permeability fracture zones connect with smaller ones). In Model Ⅲ, there is also a high permeability fracture zone and a low permeability fracture zone between the injection well and production wells, but the low permeability zone connects with karst caves (or the low permeability fracture zone connects with larger caves, while the high permeability fracture zone connects with smaller cave). In Model Ⅳ, the fracture zones between the injection well and production wells have similar permeability, but one of them connects with a karst cave.

1.1.2. Model parameters and experimental procedures

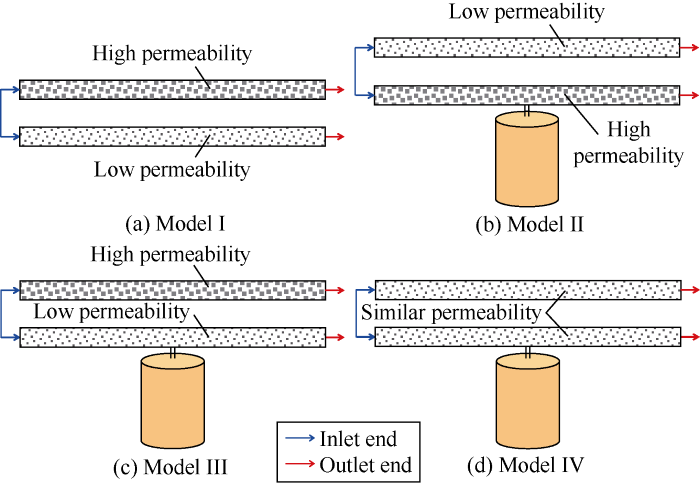

To further analyze the inter-well interference characteristics, according to the inter-well interference models mentioned above, simplified visual physical fracture-vug models of were designed (Fig. 3). In these models, both the injection end and the production end were connected with a thin tube. Since the fracture zone consists of many complex natural fractures with continuity, the fracture zone was simulated by filling quartz sand into the thin tube. A cylindrical vessel with a certain volume was connected to the thin tube to represent the cave.

Fig. 3.

Fig. 3.

Schematic diagrams of the visual injection-production in fracture-vug models.

The main mechanism of water displacing oil in karst cave is gravity displacement[6,7], In order to ensure the similarity between the reservoir and the experimental model, according to the Bond number (the ratio of gravity to capillary pressure)[8,9] and the researh results of Prey[10] and Schechter et al.[11], the fracture opening at the junction of the fracture and cave should meet:

According to the Froude number (the ratio of inertial force to gravity)[3], the injection velocity should satisfy:

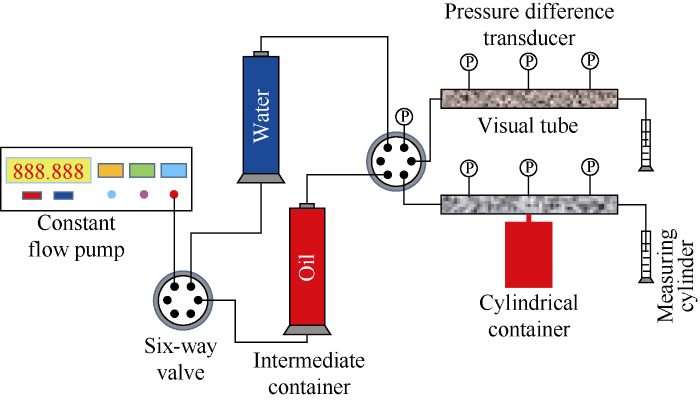

The experimental system mainly included injection, measurement, data acquisition and model units (Fig. 4). The injection unit consists of an ISCO pump and intermediate container. The measurement unit was mainly a measuring cylinder. The data acquisition unit was mainly a micro differential pressure transducer, which adopts the single crystal silicon resonant sensor technology with no lag in the pressure change. The differential pressure transducer has the advantages of high accuracy and good stability, and was used to measure the pressure variations in the displacement process. According to the variation range of experimental pressure, two kinds of micro differential pressure transducers with ranges of 0-10 kPa and 0-40 kPa were selected, with measuring accuracy of 0.01 kPa and 0.04 kPa, respectively, which meets requirements of the measurement. The model system was mainly visual fractured-vuggy model. The visualized tubes in each model were filled with quartz sand of different sizes to simulate fracture zones with different conductivities. The tubes were 100 mm long and 20 mm in inner diameter. The pore volume in the tube measured by the volume balance method was about 100 mL. The cylindrical containers represented karst caves of 50, 100, and 200 mL respectively, and the corresponding cave- fracture reserve ratios were about 1:2, 1:1, 2:1, which represent relatively small caves, medium caves and large caves in the oilfield. The connection position of karst cave and visual tube could be adjusted according to the experimental scheme. Based on the calculation result of equation (1), the value of b at the junction was set at 16 mm.

Fig. 4.

Fig. 4.

Experimental process of inter-well interference of fracture-vug models.

1.1.3. Experimental schemes and procedures

The experiments mainly tested inter-well interference characteristics during waterflooding under different fracture-vug models, cave locations, cave volumes, and permeability ratios of fracture zones. 9 sets of experimental schemes at the injection rate of 2 mL/min were designed (Table 1). Experiments 1, 2, 3, and 4 tested interference characteristics of the cases with different fracture-vug models. Experiments 2, 5, 6 studied interference characteristics of cases that karst caves at different locations of the high-permeability fracture zone. Experiments 2, 7, 8 studied interference characteristics of cases that karst caves with different volumes located in the middle of the high permeability fracture zone. Experiments 2, 4 and 9 studied interference characteristics of cases that two fracture zones with different permeability ratios (3:1, 1:1, and 10:1). In addition, the percolation resistance difference is the root cause of inter-well interference, so the percolation resistance ratio (the ratio of percolation resistance in low permeability fracture zone to high permeability fracture zone) was introduced to analyze the characteristics of water flooding.

Table 1 Experimental schemes for inter-well interference characteristics of fractured-vuggy reservoirs.

| No. | Quartz sand size/mm | Cave location | Cave volume/mL |

|---|---|---|---|

| 1 | 0.850-1.700 (High permeability) | No cave | |

| 0.425-0.850 (Low permeability) | No cave | ||

| 2 | 0.850-1.700 (High permeability) | Middle | 200 |

| 0.425-0.850 (Low permeability) | No cave | ||

| 3 | 0.850-1.700 (High permeability) | No cave | |

| 0.425-0.850 (Low permeability) | Middle | 200 | |

| 4 | 0.850-1.700 | Middle | 200 |

| 0.850-1.700 | No cave | ||

| 5 | 0.850-1.700 (High permeability) | Close to the injection side | 200 |

| 0.425-0.850 (Low permeability) | No cave | ||

| 6 | 0.850-1.700 (High permeability) | Close to the exit side | 200 |

| 0.425-0.850 (Low permeability) | No cave | ||

| 7 | 0.850-1.700 (High permeability) | Middle | 100 |

| 0.425-0.850 (Low permeability) | No cave | ||

| 8 | 0.850-1.700 (High permeability) | Middle | 50 |

| 0.425-0.850 (Low permeability) | No cave | ||

| 9 | 0.850-1.700 (High permeability) | Middle | 200 |

| 0.180-0.425 (Low permeability) | No cave |

According to the above schemes, the experiment procedures are: (1) The quartz sand was washed and dried in a thermostat; (2) the quartz sands of corresponding sizes were used to fill the fractured-vuggy reservoir models; (3) the cylinder vessel with corresponding volume representing the karst cave was connected to the designed location; (4) the experimental device was connected, nitrogen was injected to the pressure of 0.5 MPa to check the air tightness of the model; (5) the simulated oil was injected at the injection rate of 1 mL/min to saturate the model, and the volume and permeability of the fracture zones were calculated; (6) according to the calculation result of equation (2), the water displacement was started at the displacement rate of 2 mL/min, the liquid production at the outlet and the pressure variation along the way were recorded, and the real-time ratio of percolation resistance of the fracture zones was calculated.

1.2. Experimental results and analysis

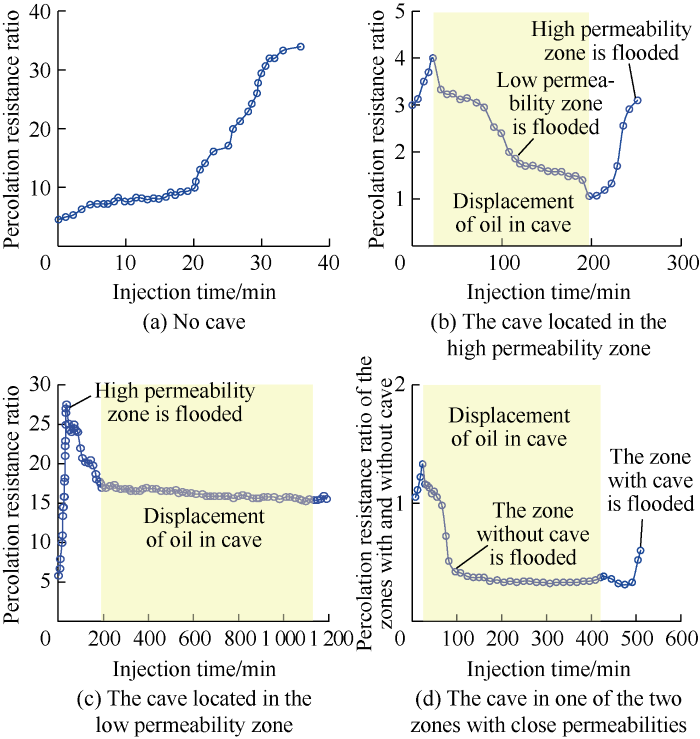

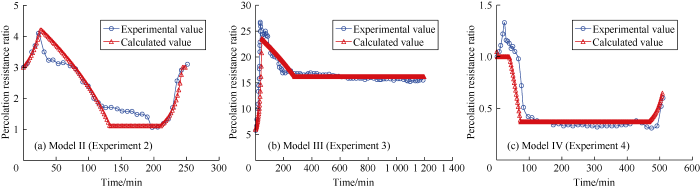

1.2.1. Interference characteristics of waterflooding in different fracture-vug modelsThe distribution pattern of caves in fractured-vuggy reservoirs directly affects the fluid distribution during waterflooding. Experiments 1, 2, 3, and 4 represented no cave model and models with a cave located in the middle of the high-permeability fracture zone, low-permeability fracture zone, and one of the two similar permeability fracture zones. The interference characteristics of them are shown in Fig. 5. When there was no karst cave, the percolation resistance ratio gradually increased during the displacement process, which is consistent with sandstone reservoir (Fig. 5a). When the karst cave was in the high-permeability fracture zone, the percolation resistance ratio increased with time and then decreased and then increased again (Fig. 5b). 20 mins into the displacement, the water front in the high-permeability fracture zone reached the cave and replaced the crude oil, while the water in the low-permeability fracture zone continued to advance, and the percolation resistance ratio decreased rapidly; 120 min into displacement, the low-permeability fracture zone was flooded, and then the percolation resistance ratio was basically stable; 200 min into displacement, the oil in the cave was completely displaced out, the crude oil in the rear fractures started to be displaced, and the percolation resistance ratio increased; 250 min into displacement, both the high permeability and low permeability fractures were completely flooded, and the percolation resistance ratio returned to the initial value. When the cave was located in the low-permeability fracture zone, the percolation resistance increased rapidly during the initial stage of displacement. 35 mins into the displacement, the high-permeability fracture zone was flooded and the percolation resistance ratio gradually decreased; 200 mins into the displacement, the water drive front reached the cave, and the oil in the cave was displaced out completely until 1200 mins into the displacement (Fig. 5c). When the two fracture zones were close in permeability, the ratio of percolation resistance in the directions without and with cave were basically stable at the initial stage of displacement; 25 mins into the displacement, the water drive front reached the cave, and then the percolation resistance ratio decreased slowly and then decreased rapidly; 100 mins into the displacement, the fracture zone without cave was flooded, the time kept for 400 min to displace the oil completely; 500 mins into the displacement, the fracture zone with cave was flooded. It can be seen that when the cave is located in the high permeability fracture zone, the time it took to displace the oil in the cave and that in the whole process were shorter than those when the cave was in the low permeability and homogeneous fracture zone, which indicates that the effect of waterflooding is much better when the cave is located in the high permeability fracture zone of the injection-production unit or the well group has certain heterogeneity.

Fig. 5.

Fig. 5.

Interference characteristics of cases with different fracture-vug models.

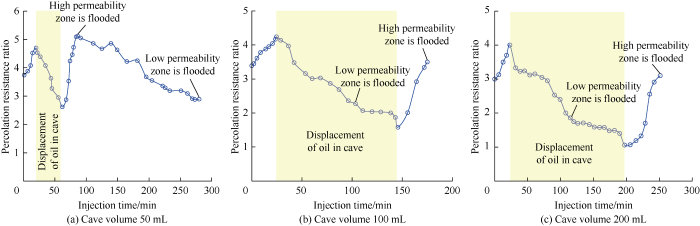

1.2.2. Interference characteristics of waterflooding at different karst cave volumesFrom the above analysis, we can see the karst cave has a great influence on percolation resistance during waterflooding. According to the experimental results of experiments 2, 7, 8, the interference characteristics of cases of different volume caves located in the high-permeability fracture zone were obtained (Fig. 6). It can be seen that the percolation resistance ratio reversed when the water drive front in high-permeability fracture zone reached the cave; the percolation resistance ratio gradually decreased during the displacement of oil in the cave; the displacement of oil in the cave was completed within 40 min when the cave volume was small, and the percolation resistance ratio reversed again; the high permeability fracture zone was quickly flooded and the low permeability fracture zone was flooded 280 min into displacement (Fig. 6a). When the caves were larger, the low permeability zone was flooded first; the oil in the caves took 120 min and 180 min to be completely displaced respectively (Fig. 6b and 6c). The total displacement times were shorter than the case with small cave. It can be seen that, as the volume of the karst cave increases, the waterflooding time decreases first and then increases.

Fig. 6.

Fig. 6.

Interference characteristics of cases with different cave volumes (cave in the middle of the high permeability fracture zone).

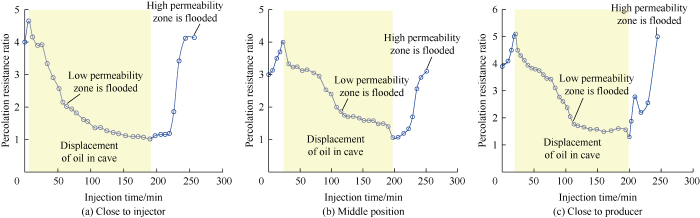

1.2.3. Interference characteristics of waterflooding at different karst cave locationsThe distribution of karst caves in fracture zones in fractured-vuggy reservoir is random. According to the results of experiments 2, 5, 6, the interference characteristics of cases of caves at different locations on the high-permeability fracture zone were obtained (Fig. 7). It can be seen that, when the cave was close to the injection well, the time it took to displace the oil in the cave was longer, the low permeability zone was flooded early, and the total displacement time was longer. Therefore, when the well pattern is constructed or reorganized, the wells closer to the cave should be production wells, which is consistent with the understanding of injection in fractures and production from caves obtained by previous studies.

Fig. 7.

Fig. 7.

Interference characteristics of cases at different cave locations (with the cave located in high permeability fracture zone).

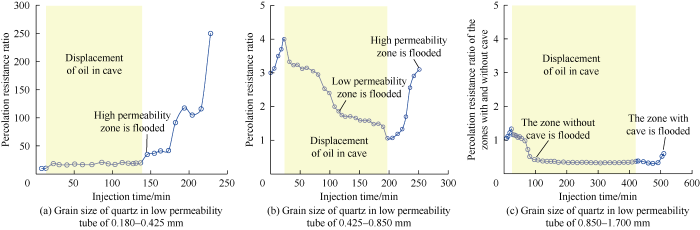

1.2.4. Interference characteristics of waterflooding at different permeability differences of the fracture zonesTo study the influence of the permeability difference on water displacement characteristics of fractured-vuggy reservoir, the results of experiments 2, 4, 9 were compared (Fig. 8a-8c, the quartz sands used in the low permeability pipe represented 3 experiments). It can be seen that when the permeability difference was big, the high permeability zone was flooded first even if the karst cave was in the high permeability fracture zone. When the permeability difference was small, the low permeability zone was flooded first in the displacement of oil in the cave. The greater the difference in permeability, the shorter the time displacing oil in the cave was.

Fig. 8.

Fig. 8.

Interference characteristics of cases at different permeability differences of the fracture zones (with the karst cave located in the middle of high permeability fracture zone).

2. Numerical inversion model of inter-well interference characteristics of fractured-vuggy reservoir

2.1. Establishment of inversion model of waterflooding interference in fractured-vuggy reservoir

To better study the interference characteristics of waterflooding, based on percolation theory, the numerical inversion model simulating waterflooding interference was built. The basic assumptions are as follows: (1) The rock-fluid compressibility is negligible due to the small injection-production pressure; (2) the oil-water replacement is completed instantly after the injected water reaches the cave; (3) the oil displacement by water in fracture is based on the piston displacement theory[12], and the oil water viscosity ratio is low; (4) the capillary force and gravity in the fracture are ignored. Based on the assumptions above, the percolation resistance between the injection and production wells can be approximated as:

The production ratio between different flow channels is:

For the same group of injection-production wells or different groups of injection-production wells with the same injection-production differential pressure, the ratio of split flow rates of high and low permeability fracture zones is:

In the case of one fracture zone connected to several karst caves, when the water drive front reaches the cave, the oil in the cave under the fracture zone will be displaced first due to gravity. Then, the water front will continue to advance to the production well after the oil in the cave was displaced completely. Therefore, for the connected line of injection-production well with arbitrary fracture and vug distribution, the position of the water drive front at a certain moment is expressed as follows:

2.2. Verification of inversion model of waterflooding interference in fractured-vuggy reservoir

Fig. 9.

Fig. 9.

Fitting results of experimental data of injection-production interference for different fracture-vug models.

Fig. 10.

Fig. 10.

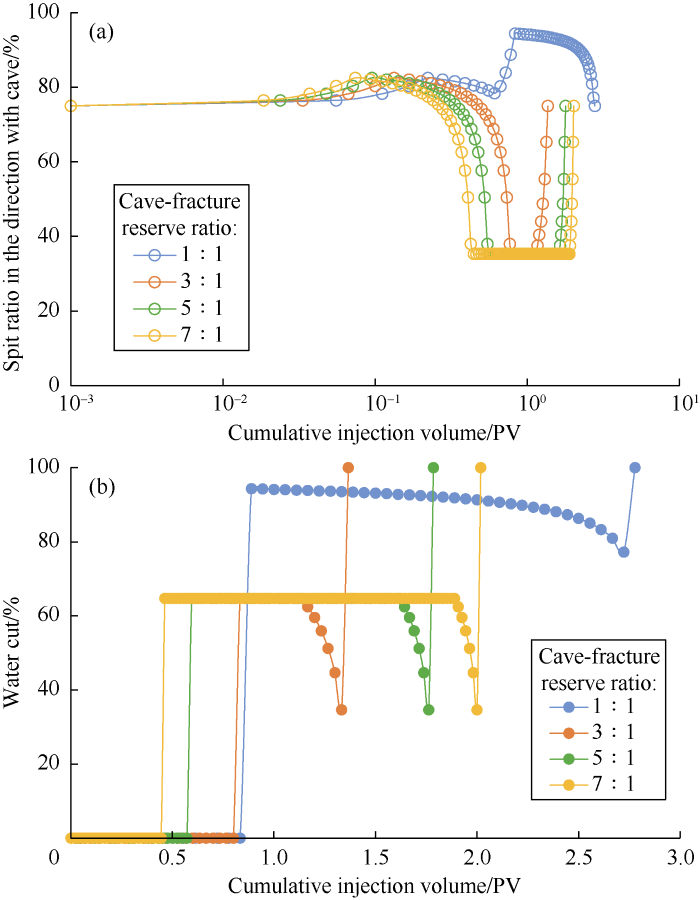

Variations of split flow ratio (a) and water cut (b) at different ratios of cave and fracture reserves in the case with the karst cave located in the high permeability fracture zone.

Fig. 11.

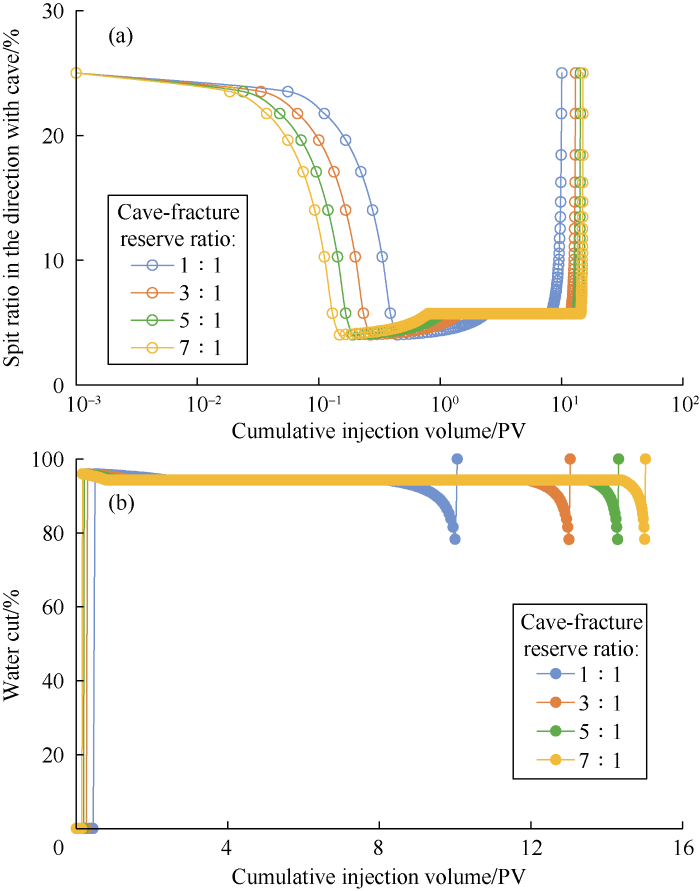

Fig. 11.

Variation characteristics of split flow ratio (a) and water cut (b) at different ratios of cave and fracture reserves when the cave is in the low permeability fracture zone.

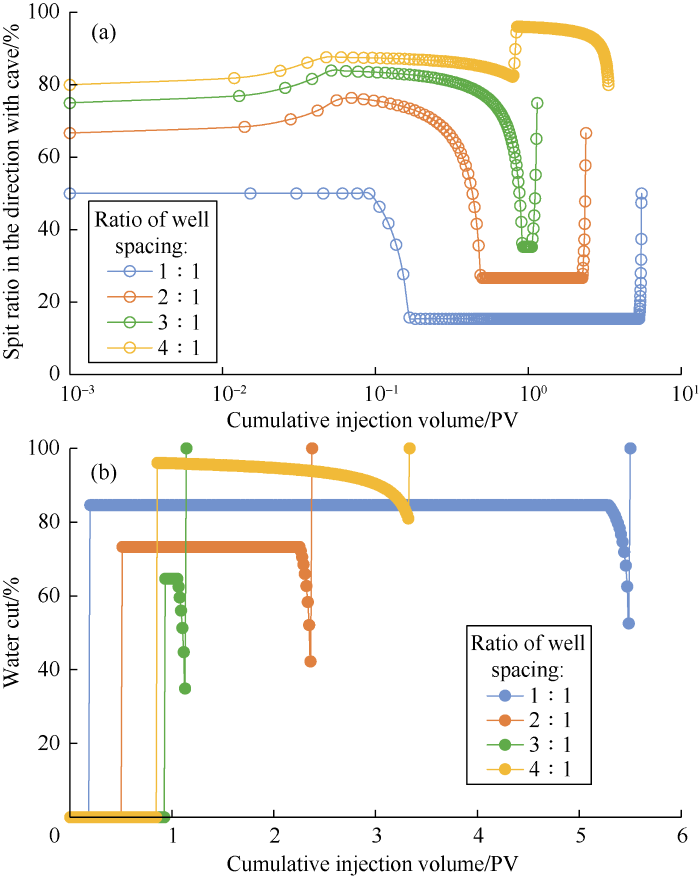

Fig. 12.

Fig. 12.

Variation characteristics of split flow ratio (a) and water cut (b) at different well spacing ratios when the cave is on the side with small well spacing.

Fig. 13.

Fig. 13.

Variation characteristics of split flow ratio (a) and water cut (b) at different well spacing ratios when the cave is on the side with large well spacing.

Fig. 14.

Fig. 14.

Variation characteristics of split flow ratio (a) and water cut (b) at different permeability ratios with cave located in the high permeability direction.

Fig. 15.

Fig. 15.

Variation characteristics of split flow ratio (a) and water cut (b) at different permeability ratios with the cave located in the low permeability fracture zone.

Table 2 Values of fitting parameters.

| Fracture-vug models | Qw/(mL·min-1) | KH/KL | μo/(mPa·s) | μw/(mPa·s) | ϕL/% | ϕH/% | V/mL | r/cm | Lp/cm |

|---|---|---|---|---|---|---|---|---|---|

| Model Ⅱ (Experiment 2) | 2.0 | 3 | 4.4 | 1.0 | 22 | 26 | 240 | 1.0 | 100 |

| ModelⅢ (Experiment 3) | 2.0 | 6 | 4.4 | 1.0 | 20 | 25 | 240 | 1.0 | 100 |

| Model Ⅳ (Experiment 4) | 2.0 | 1 | 4.4 | 1.0 | 25 | 25 | 240 | 1.0 | 100 |

Note: The volume of the cave includes the volume of the cavity at the junction

Because the numerical inversion model ignores the capillary force and gravity, there are small amount of sand migration in the sand filling model, and the pressure sensor and liquid measure have errors, the experimental results have non-mechanical fluctuations in local parts, which differ slightly from the calculated values. The overall fitting result of the inversion model is good, which can reflect the change trend of the percolation resistance and the mechanism characteristic points, and can be used for the analysis of interference characteristics of subsequent waterflooding.

3. Influencing factors and characteristics of inter-well interference in fractured-vuggy reservoirs

To fully understand the characteristics and influencing factors of inter-well interference in fractured-vuggy reservoir during waterflooding, the inversion model was used to study the effects of cave-fracture reserve ratio, injection-production well spacing, permeability ratio of fracture zones, and oil- water viscosity ratio on waterflooding, and simulate the optimal values of well spacing and permeability ratio under the joint effects of multiple factors, which can provide guidance for the construction or reorganization of well pattern and reservoir stimulation. Split flow ratio is the most direct and effective parameter to reflect the inter-well interference during waterflooding. It indicates the percentage of water driven to a certain production well in the total injected water of the injection well per unit time. Therefore, the split flow ratio of the zone with cave is higher, and more injected water is used to displace the oil in the cave. Hence, that the amount of water consumed in this stage is small is good for oil displacement, the split flow ratio of water in the direction with cave is taken as an important parameter for analyzing the characteristics of inter-well interference and waterflooding effect, in addition, water cut is used as the parameter to analyze water flooding performance.

3.1. Ratio of cave and fracture reserves

The characteristics of waterflooding interference and waterflooding performance at different ratios of cave and fracture reserves were simulated in this study. The variations of split flow ratio and water cut are shown in Figs. 10 and 11. In the simulations, the well spacing ratio (in the case with one injection well and two production wells, the ratio of the larger well spacing between the injection well and production well to the smaller well spacing between the injection well and the other production well) was 1:1, the permeability ratio was 3:1, the oil-water viscosity ratio was 5:1, and the karst cave was located in the middle of the injection well and production well. When the karst cave is in the high permeability zone, the split proportion at the initial stage in the direction with cave was 75%, and then slowly increased; after the water drive front reached the cave, the split ratio in the high permeability zone decreased rapidly because more water was diverted to the low permeability zone during the oil displacement in the cave. When the ratio of cave and fracture reserves was large (greater than 3:1), the split ratio in the high-permeability zone was stable. This is because when the cave is large, the low-permeability zone was flooded first during oil displacement by water, and the percolation resistance no longer changed, so the split ratio kept constant, and the cumulative injection volume was less than 2 PV (pore volume multiple). When the ratio of cave and fracture reserves was relatively small (1:1), the split ratio decreased slightly and then increased (the oil in the cave was displaced completely); the split ratio in the high permeability zone was always high, which was unfavorable for the oil displacement in the low permeability zone; and the cumulative injection volume was 3 PV. When the cave is located in the low permeability zone, the split ratio in the zone with cave was always less than 25%, and was less than 10% during the displacement of oil in the cave, which resulted in an invalid circulation of more than 90% of the injected water in the high permeability zone. In terms of variations in water cut, when the cave was in the high permeability zone, the periods of water-free and medium water cut were long most of the time; only when the cave was small, the well entered high water cut period directly. When the karst cave was located in the low permeability zone, the water-free production period was very short, and the production well was water flooded rapidly soon after water breakthrough, which is commonly seen in the injection-production units of Tahe oilfield. Therefore, when constructing injection-production well pattern in the initial stage or reorganizing injection-production well pattern after depletion development, the cave should be located in the relatively high permeability zone as far as possible, and the reserves controlled by injection-production wells should be proportional to the permeability in different injection-production directions, that is, large reserves should be in the side of high permeability fractures.

3.2. Injection-production well spacing

The injection-production well spacing is a key controllable parameter in the construction or reorganization of injection- production well patterns. Optimizing well spacing is of great significance for improving the effect of waterflooding development. Therefore, the characteristics of waterflooding inference and water driving performance when the cave was located on the side of the large well spacing side and small well spacing side (at permeability ratio 1:1, oil-water viscosity ratio 5:1, and cave-fracture reserve ratio 5:1, karst cave located in the middle of the injection and production wells) were studied. The split flow ratio and water cut variations are shown in Figs. 12 and 13, respectively. It can be seen that when the karst cave was on the side with small well spacing, the percolation resistance in this side was small; the split ratio in this side was higher than 50% and gradually increased until the water drive front reached the karst cave. When the well spacing ratio was 4:1, the split ratio in the direction with cave decreased slightly and then increased rapidly. This is because the split ratio on the side with large well spacing was always low, the oil in the cave on the side with small well spacing had been displaced completely before the water broke through in the well on this side. Under the low split ratio, lots of water was consumed to displace the oil in the long well-spacing side. When the well spacing ratio is lower than 3:1, the split ratio in the side with cave decreased greatly, and more injected water displaced along the side with large well spacing until the water broke through; then the split ratio remained stable, and after the oil in the cave was all displaced, the side with small well spacing was quickly flooded. It can be seen that, as the well spacing ratio increases, the total water consumption decreases first and then increases. When the cave was on the side with large well spacing, as the well spacing ratio increased, the split ratio in the side with cave decreased until the water injection from the side with small well spacing broke through, and then increased slightly; after the water drive front reached the cave, the split ratio entered a longer stable stage; the injected water broke through after the oil in the cave was displaced completely for a period of time. The water consumption of the entire displacement process reached 10 PV or even higher. In terms of water cut, when the cave was on the side with small well spacing and the well spacing ratio was 3:1, the water free oil production period and medium water cut period were longer and the water consumption during the displacement process was lower. When the cave was on the side with large well spacing, the period of water free production was short, and the side with small well spacing was quickly flooded. Therefore, in the initial construction or reorganization of injection-production well pattern, the side where the cave is located should be the small well spacing direction as far as possible, the reserves in different injection-production directions should be inversely proportional to well spacing, that is, the large reserve should be in the side with small well spacing.

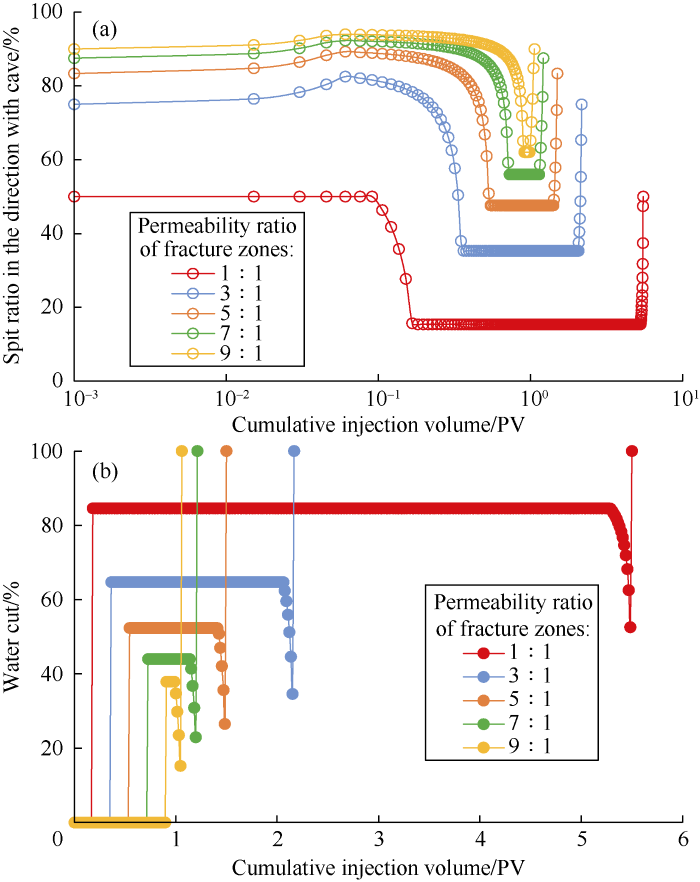

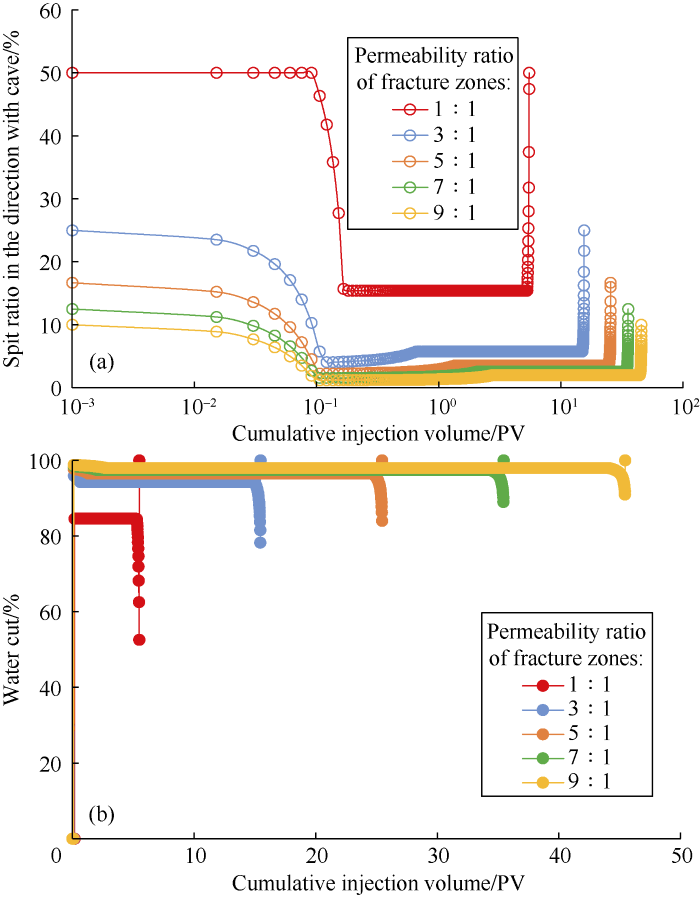

3.3. Permeability ratio of fracture zones

When the cave was located in high permeability and low permeability fracture zones respectively, the influences of permeability ratio of the fracture zones on interference characteristics and waterflooding dynamic characteristics (at well spacing ratio of 1:1, the ratio of oil-water viscosity of 5:1, the ratio of cave and fracture reserves of 5:1, with the karst cave located in the middle of the injection and production well) are shown in Figs. 14 and 15. When the cave was in the high permeability direction, the greater the permeability ratio, the higher the split rate in the direction with cave, the shorter the displacement time of oil in the cave, and the less the total water consumption for displacement were; on the contrary, when the cave was in the low permeability direction, the larger the permeability ratio, the lower the split ratio in the direction with cave, the slower the displacement of oil in the cave were; and the total water consumption of displacement was up to 10-100 PV. Comparing the curves of water cut, when the cave was in the direction of high permeability, the greater the permeability ratio, the longer the period of water-free oil production, and the lower the water cut in the medium water cut period were. Therefore, when the cave is in the high permeability direction and the reserve difference between the injection and production well is large, the difference in conductivity of different injection-production directions is beneficial to water flooding development. On the contrary, when the cave is in the low permeability direction, the closer the conductivities in different injection-production directions are, the better the water flooding effect is. If the cave is in the direction of low permeability, the oil well in the direction of high permeability should be shut down after sudden flooding, and the well on the low permeability side should be treated by acid-fracturing.

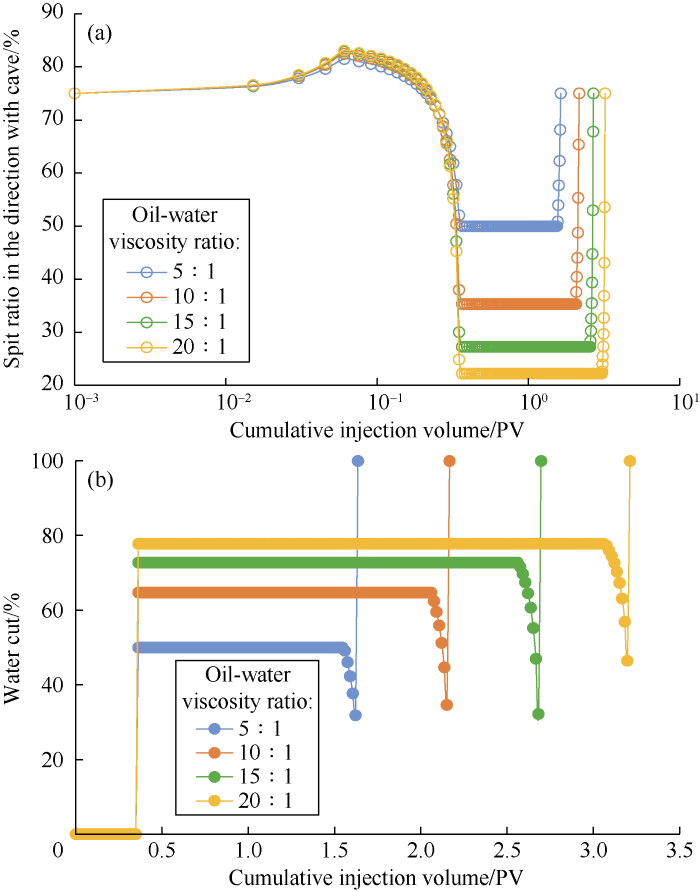

3.4. Oil-water viscosity ratio

Fig. 16 shows the effect of oil-water viscosity ratio on the inter-well interference and dynamic characteristics during waterflooding when the cave was in the high-permeability fracture zone (at the permeability ratio of 3:1, well spacing ratio of 1:1, the ratio of cave and fracture reserves of 5:1, with the karst cave located in the middle of the injection and production wells). It can be seen that, at different oil-water viscosity ratios, the time needed for the water drive front to reach the cave are the same, and the water-free oil production periods are the same. The greater the oil-water viscosity ratio, the lower the split ratio in the direction with cave during the cave oil displacement, the higher the water cut in the medium-high water cut period, the greater the total water consumption during the displacement process is.

Fig. 16.

Fig. 16.

Variation characteristics of split flow ratio (a) and water cut (b) at different oil-water viscosity ratios with the cave located in the high permeability fracture zone.

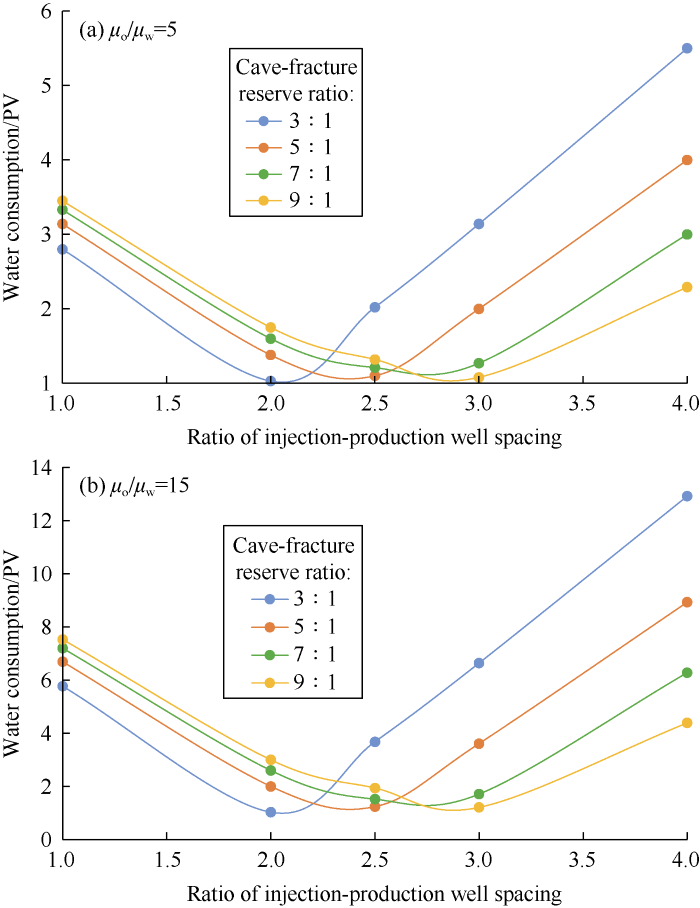

3.5. Optimization of injection-production well spacing under the combined influence of cave-fracture reserve ratio and oil-water viscosity ratio

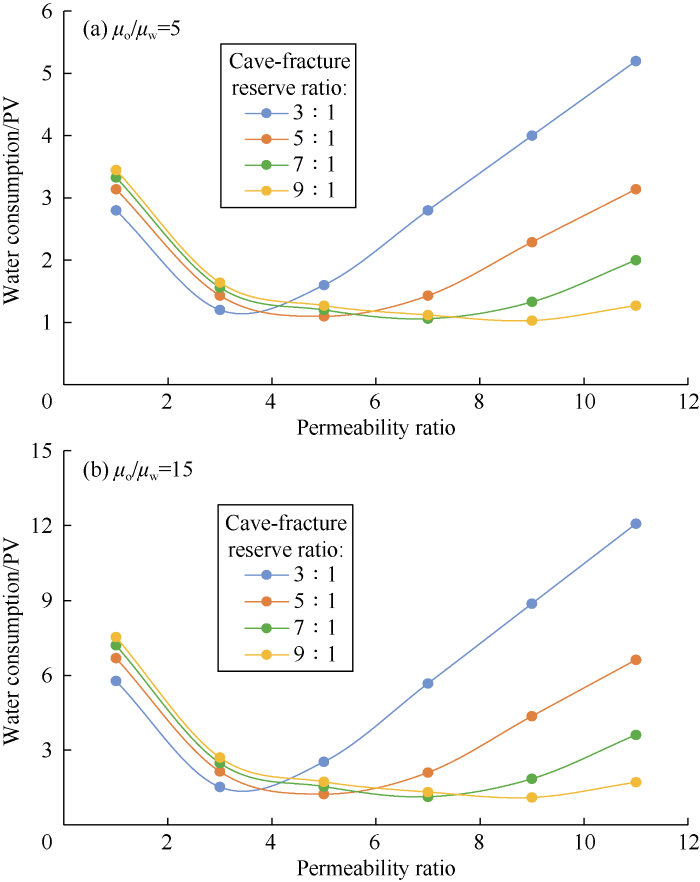

The injection-production well spacing under the combined effect of cave-fracture reserve ratio and oil-water viscosity ratio was optimized (at the permeability ratio of 1:1, with the cave located in the middle of the injection and production wells). In the optimization process, water consumption was taken as a comparative indicator. The variations of water consumption with injection-production well spacing at different cave-fracture reserve ratios are shown in Fig. 17. It can be seen that no matter the oil-water viscosity ratio is 5 or 15, the water consumption at the same cave-fracture reserve ratio decreased first and then increased with the increase of the injection-production well spacing ratio. Apparently, there is an optimal well spacing ratio at which the water consumption is the lowest, and this ratio increases with the increase of the cave-fracture reserve ratio. As the oil-water viscosity ratio increases, the water consumption of non-optimal well spacing greatly increases during waterflooding. Therefore, it is more necessary to optimize the well spacing when the crude oil has high viscosity.

Fig. 17.

Fig. 17.

Variation of water consumption with injection-production well spacing at different ratios of cave-fracture reserves.

3.6. Optimization of permeability ratio under the combined influence of cave-fracture reserve ratio and oil-water viscosity ratio

In order to better guide acid-fracturing, the optimal perme- ability ratio under the combined effect of the cave-fracture reserve ratio and the oil-water viscosity ratio was studied (at the well spacing ratio of 1:1, with the cave located in the middle of the injection well and production well). Fig. 18 shows the variation of water consumption with permeability ratio at different cave-fracture reservoir ratios. It can be seen that no matter the oil-water viscosity ratio is 5 or 15, the water consumption at the same cave-fracture reserve ratio decreased first and then increased with the increase of the permeability ratio. Hence, there is an optimal permeability ratio at which the water consumption is the lowest, and this optimal permeability ratio increases with the increase of the cave-fracture reserve ratio linearly. Therefore, the fracturing target should be determined according to the difference in reserves between one injection and different production wells. The greater the difference in reserves, the stronger the strength of fracturing is needed.

Fig. 18.

Fig. 18.

Variation of water consumption with permeability ratio at different cave-fracture reserve ratios.

4. Conclusions

Aiming at fractured-vuggy reservoirs, inter-well interference characteristics of waterflooding and influencing factors were studied through physical modeling and numerical inversion simulation, which can provide theoretical guidance for the construction and reorganization of injection-production well patterns and reservoir stimulation.

During waterflooding of fractured-vuggy reservoirs, the cave should be located in the high permeability fracture zone with relatively small well spacing in the injection-production unit. The closer the cave to the production well, the longer the water-free oil production period, and the lower the water cut after water breakthrough will be. When constructing or reorganizing the injection-production well pattern, if the cave is located on the side with relatively low permeability or relatively large well spacing, the water-free oil production period will be short and the well will be flooded quickly after water injection. When the karst cave location, well spacing and oil-water viscosity ratio are similar, and the larger cave is located in the high-permeability fracture zone, the production well in the direction of the low-permeability fracture zone would have water breakthrough first. If the larger cave is located in the direction of small well spacing, the production well in the direction of larger well spacing would see water breakthrough first. When the permeability ratio is similar, as the volume of the cave in the direction of high permeability increases, the water consumption decreases first and then increases. When the cave is in the high permeability direction and the reserve difference between the injection and production wells is large, conductivity differences in different injection-production directions are beneficial to waterflooding development. When the cave is in the direction of low permeability zone, the more similar the conductivities in different directions, the better the development effect will be.

When constructing or reorganizing injection-production well pattern, the reserves of cave should be proportional to permeability in the different injection-production directions, and inversely proportional to the well spacing, but excessive well spacing ratio would result in increase of water consumption. The well close to the cave should be producer, and the well far from the cave should be water injector. Each cave-fracture reserve ratio corresponds to an optimal well spacing and optimal permeability ratio, and both the optimal well spacing and optimal permeability ratio increase with the increase of the reserve ratio. The acid-fracturing scheme should be formulated according to the difference in reserves between injection and production wells.

Nomenclature

A—visual tube cross-sectional area, m2;

Af—fracture section area, m2;

b—fracture opening at the junction of the fracture and cave, m;

c—constant, depending on the nature of the reservoir, generally 0.02;

g—acceleration of gravity, m/s2;

h—fracture height at the joint of the fracture and karst cave in injection-production model, m;

KH and KL—permeability in high and low permeability directions, m2;

Ko—oil permeability, m2;

Kw—water permeability, m2;

Lp—tube length, cm;

L—injection-production well spacing, m;

li—interval between the (i-1)th and ith cave, m;

LH and LL—well spacing in high and low permeability directions, m;

LHw(t) and LLw(t)—position of water drive front in high and low permeability directions at time t, m;

Lw(t)—position of the water drive front in the fracture zone at time t, m;

m—number of caves;

Qw—injection speed, m3/s;

Qw(t)—injection speed at time t, m3/s;

QH(t) and QL(t)—fluid production at high and low permeability directions at time t, m3/s;

R—percolation resistance, (Pa•s)/m3;

RH(t) and RL(t)—percolation resistance at high and low permeability directions at time t, (Pa•s)/m3;

r—tube radius, m;

t—time, s;

V—cave volume, m3;

Vi—volume of the ith cave, m3;

ΔpH and ΔpL—pressure difference between injection and production wells in high and low permeability directions, Pa;

Δρow—oil-water density difference, kg/m3;

θ—contact angle, (°);

μo—oil viscosity, Pa•s;

μw—water viscosity, Pa•s;

σow—oil-water interfacial tension, N/m;

ϕH—porosity of high permeability tube, %;

ϕL—porosity of low permeability tube, %;

ω(Sw)—proportion of water phase, dimensionless.

Reference

Features and hierarchical modeling of carbonate fracture-cavity reservoirs

Experiments on water flooding in fractured-vuggy cells in fractured- vuggy reservoirs

Practice and knowledge of volumetric development of deep fractured-vuggy carbonate reservoirs in Tarim Basin, NW China

Formation mechanism and distribution law of remaining oil in fracture-cavity reservoirs

Technological policy research of cyclic waterflooding in fracture-cavity carbonate reservoir in Tahe Oilfield

Investigation of the microvisual flow and relative permeability law of condensate oil and gas

Mechanism simulation of oil displacement by imbibition in fractured reservoirs

An analytical method for fracture distribution and water production regularity in a buried-hill reservoir