Introduction

In recent years, the deep-ultra-deep reservoirs have become a major exploration frontier worldwide, and major discoveries have been made in exploration in onshore and offshore deep-ultra-deep reservoirs[1]. China has abundant deep-ultra-deep oil and gas resources, which are widely distributed in various types of reservoirs. Significant breakthroughs have also been made in the deep- ultra-deep oil and gas resources in China in recent years. As of 2018, proven oil reserves of more than 40×108 t and gas reserves of nearly 5×1012 m3 have been discovered in china, more than 5.7×108 t crude oil and 4300×108 m3 nature gas have been produced[2]. The typical reservoirs include the buried hills around the Bohai Bay Basin in East China, and Kuqa Piedmont in the Tarim Basin, NW China, and the Sinian in the Sichuan Basin in SW China[2]. With low proven rate and low production proportion, the deep/ultra-deep reservoirs have large room left for increasing reserves and production. The ultra-deep reservoirs have special geological conditions such as deep burial (6500-8882 m), high temperature (HT) (150- 200°C), and high pressure (HP) (105-155 MPa), etc, posing challenge to the development and application of reservoir stimulation technologies[3].

The development of ultra-deep reservoir stimulation technology is reviewed, and the features of ultra-deep reservoir stimulation in China and abroad are described. It is made clear that the ultra-deep reservoir stimulation technology has been in transition from the conventional method by vertical well general stimulation to the multi- layer stimulation by vertical wells and the horizontal well multi-stage fracture control stimulation guided by modern stimulation theory. The overseas stimulation focuses on supporting technologies such as the HT and HP resistant equipment and tools, wellbore integrity, safe operation, etc. Compared with other countries, China takes the leading position in the weighting technology of fluids and materials, but is relatively backward in equipment and tools for ultra-deep reservoir stimulation. The trend of deep reservoir stimulation technology in China is pointed out through comprehensive analysis of the geological characteristics of deep reservoirs, major difficulties in reservoir stimulation technology, and future technical demand.

1. Present situation of stimulation

1.1. Development history of overseas ultra-deep reservoir stimulation technology

The drilling test in ultra-deep reservoirs was initiated in North America in the 1960s. Ultra-deep reservoirs have been developed economically in Mississippi, the Gulf of Mexico, the North Sea, etc., where the maximum well depth reaches 10 960 m. The ultra-deep reservoir stimulation technology has been in progress along with the development of this type of reservoirs, and its development history can be divided into three stages.

(1) Conventional acidizing and plug-removal in vertical wells (before 2000): The stimulation was to remove the pollution by completion fluids by acidizing and small- scale sand fracturing. In some massively thick layers, mechanical methods were used to separate layers simply during stimulation. In this stage, the stimulation operations focused on the reservoirs with good physical properties and high pressure coefficients. Acidizing and small-scale sand fracturing worked well in removing the near-well bore pollution and enhancing productivity[4].

(2) Vertical well sand fracturing (2000-2010): rapid progress was made in vertical well multi-layer sand fracturing technology after breakthroughs were made in HT resistant fracturing fluid, weighted fracturing fluid and HT and HP resistant mechanical layering tools. At this stage, ultra-deep safe completion technology, new materials with HT and pressure resistance, packers and perforation tools, downhole safety valves, intelligent monitoring and production systems were researched and developed, and the fracturing and completion, and safe operation technology series which can ensure the wellbore integrity were formed[5].

(3) Diverse stimulation technologies (2010 to present): As the ultra-deep reservoirs became more and more complex, diverse stimulation technologies were required, and the ultra-deep reservoir stimulation technologies showed a diversified trend. International oilfield service corporations developed a series of new tools, new materials and new equipment such as the packer and fast drilling/soluble bridge plug able to work at high temperature of 180 °C and high pressure, the fracturing fluid with a temperature resistance of 220 °C, the corrosion inhibitor system with a temperature resistance over 160°C matching with the acid solution, the HT resistant temporary plugging diversion materials, coiled tubing equipment with 7000 m deep operation capability, and the HP resistant wellhead and pumping equipment, etc., promoting the progress of ultra-deep reservoir stimulation technology, and meeting the needs of stimulating ultra-deep clastic, carbonate and volcanic reservoirs[6,7].

1.2. Development history of the ultra-deep reservoir stimulation technology in China

China drilled its first 6000 m ultra-deep well (Well Nüji 1) in 1976, and then the ultra-deep reservoir stimulation technology developed along side and progressed from technology for VD 6000 m deep reservoirs to that for reservoirs more than VD 800 m deep. By the end of January, 2020, the deepest ultra-deep reservoir stimulated in China was 8882 m. Major breakthroughs have been made in the stimulation technologies for ultra-deep onshore reservoirs. In contrast, restricted by drilling platform technology, the offshore oil development is limited to the coastal region. The development history of the ultra-deep reservoir stimulation technology in China is also divided into three stages.

(1) Breakthrough in sand fracturing in wells more than 6000 m deep (before 2000): Restricted by the performance of HT and HP equipment, tools and stimulation fluid materials, the stimulation in ultra-deep wells was dominated by general stimulation of vertical wells in the early stage. In the 1970s, in order to study deep in-situ stress, the State Seismological Administration carried out deep formation fracturing experiments in 4000 m wells around Dagang Oilfield in North China[8]. In the mid-1990s, sand fracturing was implemented in some water injectors 6000 m deep in the Donghe Oilfield of the Tarim Basin, breaking the bottleneck of sand fracturing in ultra-deep wells.

(2) Breakthrough in sand fracturing in wells more than 7000 m deep (2000-2010): rapid progress was made in the ultra-deep reservoir stimulation technology, including stimulation theory, process, fluid materials, especially in sand fracturing in vertical wells of the ultra-deep clastic rock reservoirs in the Kuqa piedmont and the deep-ultra-deep horizontal well staged fracturing in deep-ultra- deep carbonate reservoir in the Tarim Basin in this period. Significant progress was also made in the materials for weighted stimulation fluids. Well Keshen 101 (depth of 6389 m) in the Tarim Oilfield was the first well treated by bromide weighting acid (1.35 g/cm3) acidizing in China, marking the start of exploration of stimulation of abnormally high stress deep reservoir. Well Yeyun 2 in the Tarim Oilfield was the first well stimulated with weighted fracturing fluid, during the fracturing, 28.5 m3 of proppant was added. Well Dabei 3 over 7000 m deep in Tarim Oilfield was treated by sand fracturing successfully[9]. Multi-stage large-scale acid fracturing were implemented in vertical wells more than 7000 m deep in the CNPC Southwest Oil and Gas Field Company and Tahe Oilfield, Tarim Basin[10,11]; and breakthroughs have been made in stimulation technology for deep volcanic reservoirs[12].

(3) Successful stimulation in wells more than 8000 m deep (2010 to present): rapid progress has been made in ultra-deep stimulation technology in the past 10 years, realizing multi- stage layered stimulation of clastic rock reservoirs in vertical wells up to 7000 m deep and acid fracturing in wells up to 8000 m deep. Composite acid fracturing and horizontal well staged acid fracturing technology have been developed for stimulating ultra- deep carbonate reservoirs. In the Tarim Oilfield, ultra- deep network fracture sand fracturing was firstly implemented in Well Keshen 2-2-8, by using the fracturing fluid system of linear gel+gel+diversion agent, the stimulation realized multiple-stage intra-fracture diversion and downhole microseismic monitoring[13].

Around the world, the deepest reservoir stimulated reaches the depth of 10 960 m, the formation pressure of over 150 MPa, and the temperature of above 200 °C. Correspondingly, the stimulation fluids have developed from conventional fracturing fluid to weighted fracturing fluid, and the pressure resistance of tools and equipment have upgraded from 105 MPa to 140 MPa. Major breakthroughs have been made in HT and HP resistant equipment development, wellbore integrity technology, and mature safe operation technology overseas, while China takes the lead in the development of fluid weighting technology and materials for ultra-deep reservoir stimulation[14,15].

1.3. Major progress in China's ultra-deep reservoir stimulation technology

The ultra-deep reservoirs lead to complicated operation conditions, and the researches are focused on the ultra-deep reservoir stimulation theory, laboratory physical simulation experiments, HT resistance and materials for weighted fracturing fluids, HT and HP resistant downhole layer isolation tools, and HP resistant equipment, and optimized design to improve the production rate of ultra-deep reservoirs. These technologies have seen rapid development through years of research.

1.3.1. Theoretical research and laboratory physical simulation on ultra-deep reservoir stimulation

The mechanisms of hydraulic fracture (HF) propagation, fluid flow and proppant conductivity have been studied. Ultra-deep reservoirs are characterized by high stress and large horizontal principal stress difference. By adopting proper perforation technologies, such as single-stage perforation or dual-stage perforation + fiber temporary plugging technology and directional perforation, the vertical stimulation degree of ultra-deep and hugely thick reservoirs can be improved. For the stimulation of ultra-deep carbonate reservoirs, cross- linked acid sand-carrying technology has been developed by studying viscous fingering, acid-rock reaction, liquid rheological properties and sand transport morphology through large transparent parallel plate experiments and analyzing characteristics of acid fracturing and sand fracturing, in combination with principles of loss control of the cross-linking acid fluids and deep penetration[16].

Volume stimulation of ultra-deep reservoirs needs to harness natural fractures (NF). The analysis suggests that when the angle between HF and NF is less than 30°, the NF may open anyway regardless of the horizontal stress difference. When the angle between HF and NF is 30°-60°, the NF may opened when the horizontal stress ratio (the ratio of the horizontal maximum principal stress to the horizontal minimum principal stress) is 1.0-1.3, making it possible to form a fracture network. When the horizontal stress ratio ≥ 1.5, the NF wouldn’t open and the HF directly passes through the NF and propagates on, making it impossible to form a fracture network. When the angle > 60°, the NF wouldn’t open no matter how much the horizontal stress ratio is, and the HF would pass directly through the NF and extend on, making it impossible to form a fracture network[17]. Based on this theory, a theoretical chart can be established to judge if fracture network can be formed in ultra-deep reservoirs in different areas. For example, Table 1 is such a chart for the ultra-deep clastic reservoirs with NFs in Kuqa pediment. According to the angle between the in-situ stress direction and the NF strike, as well as the NF density and the number of intersecting fractures, it is possible to judge the possibility of forming a fracture network and the scale of the fracture network.

Table 1 Judgment for forming fracture network in ultra-deep wells in Kuqa pediment and application in typical wells.

| Fracture type | Typical well | Fracture density/m | Number of crossed fractures | Stress direction | NF strike | NF inclination/ (°) |

|---|---|---|---|---|---|---|

| Complex network fracture | KS8-1 | 9.93 | 171 | NE15° | Complex and various | 80 |

| Medium network fracture | KS8 | 5.85 | 81 | NE45° | Complex and various | 83 |

| Slight network fracture | KS11 | 6.20 | 42 | NW20° | NE45° | 83 |

| Simple fracture | KS505 | 7.80 | NW30° | NW5° | 81 | |

| Simple fracture | KS10 | 2.35 | NW10° | NW75° | 60 |

In order to observe the HF propagation morphology in the rock, RIPED introduced a Terretak full 3D stress- loading hydraulic fracturing experimental equipment for the 1 m×1 m×1 m rock sample, with the maximum loading stress of 69 MPa, the maximum stress difference of 14 MPa, the maximum loaded pore pressure of 20 MPa. It is equipped with 24 acoustic signal sensors, allowing real-time monitoring and interpreting HF propagation pattern in the rock sample. It has been confirmed by experiments that the complex fracture network can still be formed in carbonate rocks with relatively developed NFs under the horizontal stress difference of only 15 MPa, and the HF can communicate with more NFs to form the fracture network when the product of discharge and viscosity of fracturing fluid is at the order of 1×10-8 N•m. Injecting temporary plugging agents to tight sandstone reservoirs with micro-fractures can increase the net pressure within the fractures to achieve the purpose of opening micro-fractures. Under these conditions, experiments were carried out to find highly efficient stimulation technology for ultra-deep reservoirs and formation mechanisms of ultra-deep fracture network[18,19].

1.3.2. Weighted fracturing fluid with tolerance to high temperature, and various acid materials

The performance of stimulation fluid material is very important for ultra-deep reservoir stimulation and can determine the success or failure of the stimulation. The fracturing fluid requires low viscosity and low friction of base fluid, and HT tolerance, good sand carrying performance, low damage to the reservoir and weighting capability of gel. The acid should have low acid-rock reaction rate and controllable corrosion to the pipe string at HT.

In the past 10 years, China have developed three types of the ultra-high temperature fracturing fluids according to the thickeners[20]. The first type is the HT tolerance weighted fracturing fluid systems with guar gum as thickener, including HPG and CMHPG fracturing fluids[21]. The displacement in fracturing of ultra-high temperature wells would be limited if this type of HT tolerance fracturing fluid is used, as high concentration of guar gum thickener would cause excessively high viscosity of base fluid and increase additional friction of fracturing fluid. In medium-high temperature wells, the CMHPG fracturing fluid developed by the RIPED showed low friction[22], with friction reducing by 40% compared with other types of fracturing fluids. After successful test in an ultra-deep well (TVD of 5130 m) of Jilin Oilfield, this fracturing fluid has been applied more than one thousand well-times in 9 oilfields including Changqing, Jilin, Daqing, and North China, etc. The second type is the HT tolerance fracturing fluid with modified guar gum and polymer as thickener. The base fluid of this fracturing fluid has high viscosity, and is difficult to prepare and apply. There is no report on its field application[23]. The third type is the polymer HT tolerance fracturing fluid, and the polymer is a mixture of polyacrylamide. This fracturing fluid is characterized by high thickener concentration and fast cross-linking, adding difficulty to field application[24,25].

The weighted fracturing fluid is an effective measure to overcome the ultra-high fracturing pressure of ultra-deep wells[26,27]. In recent years, some researchers developed 1.20- 1.55 g/cm3 weighted fracturing fluid systems, with a temperature tolerance of 150-160 °C based on guar gum fracturing fluid by combining sodium bromide and sodium nitrate as a weighting agent and boron compounds or organic zirconium as crosslinker[28,29]. Compared with non-weighted fracturing fluids, the weighted fracturing fluids make the treatment displacement increase by 1.0-1.5 m3/min and the wellhead pressure decrease by 10-20 MPa, and thus lower the risks in ultra-deep well stimulation.

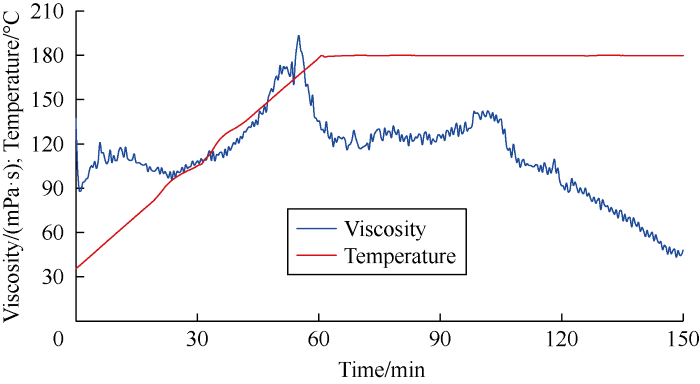

In 2018, the Tarim Oilfield Company and RIPED developed two weighted fracturing fluid systems: One is guar gum calcium chloride weighted fracturing fluid, with 0.45% guar gum, and high-quality calcium chloride; the cross-linked gel of this system can tolerate high temperature of up to 140 °C. The other is the polymer/calcium chloride weighted fracturing fluid prepared with additives of industrial calcium chloride, novel polymers, cross-linker, etc., and the formula is 40% calcium chloride + 0.6% thickener + 0.2% temperature stabilizer + 0.5% cross-linker, and the fluid has a density of 1.35 g/cm3, can tolerate temperature up to 180 °C, and the fluid has a viscosity above 90 mPa·s after shearing at 170 s-1 for 120 min (Fig. 1). Moreover, they developed a salt-resistant corrosion inhibitor, which solves the problem of corrosion of saline solutions to the completion string at HT.

Fig. 1.

Fig. 1.

Rheologic curve of polymer/calcium chloride weighted fracturing fluid.

In recent years, a series of novel acid fluids such as autogenous acid, variable viscosity acid, and diversion acid have been developed[30]. Mao Jincheng et al.[31] used erucamide propyl dimethyl tertiary amine and epichlorohydrin to synthesize a viscoelastic surfactant. Using this viscoelastic surfactant as a diversion agent, they came up with a clean diversion acid system, solving the difficulty of uniform acid distribution in heterogeneous reservoirs. However, progress in the key additive (HT resistant corrosion inhibitors) that affects the performance of the acid fluid system in the ultra-deep reservoir has been slow, and there are few reports on HT resistant corrosion inhibitors that can meet the requirements of the stimulation of carbonate reservoirs at above 160 °C.

1.3.3. High temperature and high pressure resistant downhole tools and high pressure resistant operation equipment

The downhole tools for ultra-deep reservoir stimulation mainly refer to various packers. Tarim Oilfield Company adopts the three-stage rubber cylinder design model and combines software simulation with experiment to get the optimal design. (1) The packers with the maximum outer diameter of 108.2 mm can work under the pressure difference of 91 MPa, and have the minimum setting pressure of 31.2 MPa, can tolerate maximum temperature of 232 °C and long-term temperature of 177°C. (2) The fracturing sliding sleeves include conventional ball drop sleeves and fixed-point multi-cluster sliding sleeves, and can work at the temperature of up to 150°C and pressure of up to 70 MPa, and in combination with low-density composite ball and soluble ball. (3) The open-hole packers include single-cylinder compression, double-cylinder compression and self-expanding types, and can work at the temperature of up to 120 °C and pressure up to 70 MPa. (4) The fixed string hydraulic sand blasting staged/layered fracturing packer can work at the maximum pressure of 70 MPa and maximum temperature of 120 °C[32]. The HT resistant packers have been widely used in stimulations in the Kuqa piedmont of Tarim, CNPC Southwest Oil and Gas Field Company and the deep carbonate reservoirs in the Huabei Oilfield Company. Up to now, the deepest layered stimulation well with packers is Well Luntan 1 (TVD of 8,882 m), and the highest temperature well stimulated with the packers is Well Niudong 1 (with formation temperature 205 °C). Other deep downhole operation tools include HT and HP resistant perforating guns, hangers, running tools, joint assembly, etc. In China, the fracturing vehicle equipment technology has been in rapid progress, and 4500 turbine type and 6000 type electric drive fracturing pump vehicles have been tested and developed. The HP pump head and wellhead equipment can work at the pressure of up to 140 MPa, meeting the needs of deep HP treatment.

1.3.4. Design optimization technology to improve the producing degree of ultra-deep reservoirs

The ultra-deep reservoir stimulation technology has developed from the vertical well acidizing and general stimulation to composite acid fracturing, temporary plugging fracturing, and sand fracturing in naturally fractured reservoirs. Ultra-deep horizontal wells are mainly treated by staged acid fracturing with open hole packers, hydraulic jet staged acid fracturing, and sand fracturing, which meet the demand for stimulation of ultra-deep clastic rock, carbonate rock and volcanic rock reservoirs.

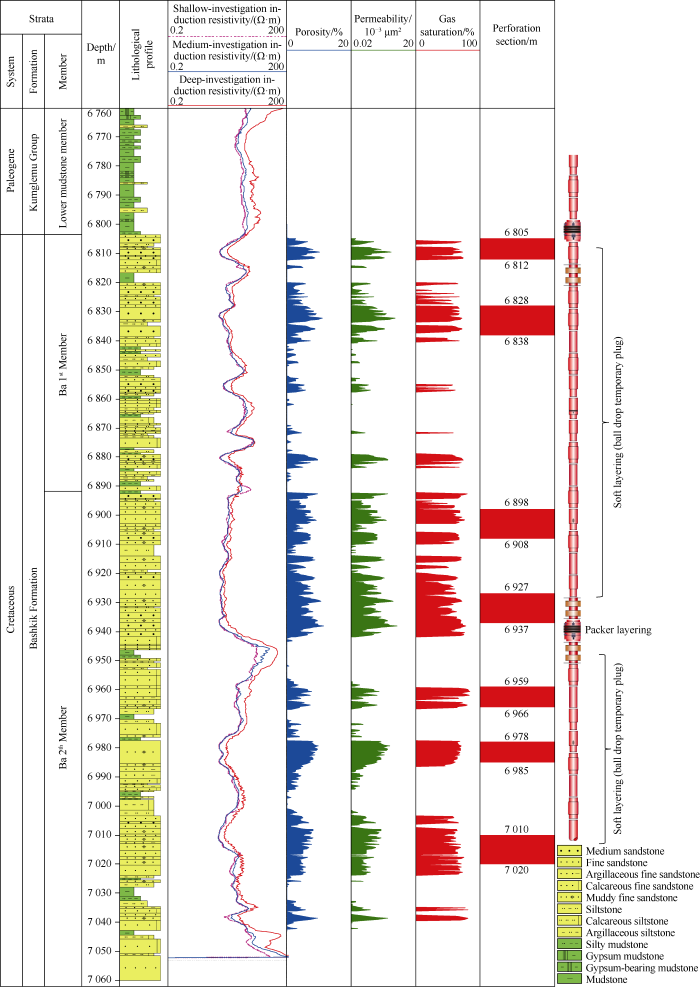

The ultra-deep temporary plugging layered stimulation technologies include "linear gel + gel" composite fracturing, "temporary plugging ball + fiber" combination, prepad viscous fingering acid fracturing, multi-stage acid fracturing of prepad + acid fracturing + prepad + acid fracturing, etc. The sand fracturing technologies for naturally fractured reservoirs include "fiber + ceramsite" and "different sizes of temporary plugging ball + fiber" soft layering, "linear gel+ gel" composite sand fracturing, and "linear gel+ acids of different functions" acid fracturing (acidizing)[33,34]. For example, Well A in the Keshen block of the Kuqa Depression, the Tarim Basin was treated with the combined layered fracturing technology (Fig. 2) in the interval of 6805.0-7020.0 m (thickness of 215 m). Two sections were separated by the ball drop sliding sleeve, and each section was treated in multiple layers by ball drop temporary plugging. The well was stimulated in 7 layers in total. The fracturing used 2560 m3 of fracturing fluid and 150 m3 0.425 mm/0.212 mm (40/70 mesh) high-strength ceramsite proppant. After fracturing, the well produced 74×104 m3 gas daily with 9 mm nozzle at the tubing pressure of 77 MPa.

Fig. 2.

Fig. 2.

Multi-stage layering stimulation of Well A in Keshen block, Kuqa Depression, Tarim Basin.

The horizontal well open hole packer sliding sleeve staged fracturing technology is an ultra-deep horizontal well fracturing technology developed in recent years, and it is mainly applied in stimulating ultra-deep carbonate reservoirs by oil-expansion open-hole packer and mechanical open-hole packer[35]. The CNPC Southwest Oil and Gas Field Company and Tarim Oil Field Company have developed the large inner diameter tool assemblage for the horizontal well to meet the demand of large-scale stimulation in highly inclined wells and horizontal wells in ultra-deep carbonate reservoirs. The key tools can tolerate temperature of up to 200 °C and pressure difference up to 70 MPa[36,37]. This technology is an effective method to solve the difficulties of discontinuous fractures and caves and low producing degree of reserves in carbonate reservoirs and has been applied in nearly 200 wells in Tarim Oilfields and Southwest Oil and Gas Fields. For example, the interval of 5210-6410 m in Well Gaoshi 001-H11 was acid fractured at the displacement of 2.0-7.1 m3/min with 1,358.7 m³ acid in total; and the well had a production of 103.3×104 m3/d after acid fracturing.

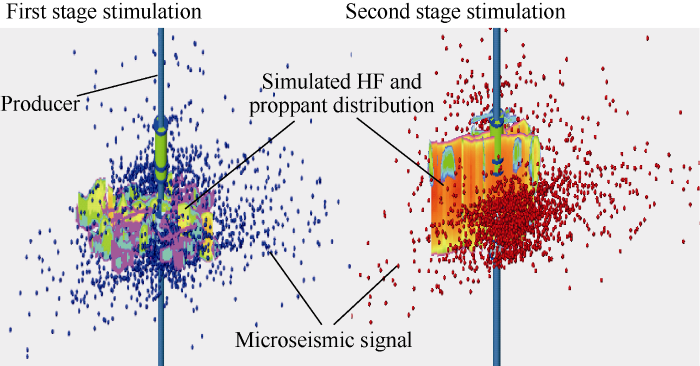

1.3.5. Monitoring and evaluation technology for ultra-deep reservoir stimulation

Reservoir stimulation monitoring technologies, micro- seismic monitoring, micro-deformation inclinometer monitoring, production logging, etc. have been developed rapidly with the advancement of unconventional reservoir stimulation technologies. Meanwhile, new hydraulic fracture monitoring technologies, such as distributed optical fiber monitoring, liquid tracing, and proppant tracing have also been tested and applied[38]. Limited by stimulation conditions, tested monitoring and evaluation technologies for ultra-deep reservoir stimulations in China are mainly ultra-deep downhole microseismic monitoring, tracer testing, and liquid production profile logging[39,40]. For example, in the Kelasu structural belt in the Tarim Basin, the microseismic monitoring (HFM) evaluation was implemented during sand fracturing of an ultra-deep Well B. With a vertical depth of 6761 m (Fig. 3), this well is the deepest well with downhole seismic monitoring implemented. The evaluation showed the well has SRV of 1506× 104 m3. The CNPC Southwest Oil and Gas Field Company used tracer and gas production profile logging techniques to evaluate the stimulation effect of each layer in Sinian carbonate reservoir[41]. The CNPC Southwest Oil and Gas Field Company and Chuanqing Downhole Operation Company jointly developed a wireless real-time data transmission system for downhole test. The system was tested in the stimulation of ultra- deep horizontal wells (Wells Moxi 008-H26, Moxi 008-H27, Moxi 022-H21) in Southwest Oil and Gas Field, during which effective data signals were obtained. The system was applied in a maximum depth of nearly 6000 m at the temperature of 136 °C, and had a signal transmission rate of 1 set/min, data packet dropout rate of ≤ 0.4%, and data accuracy rate of 99.5%.

Fig. 3.

Fig. 3.

Microseismic monitoring and evaluation of stimulation volume of the ultra-deep Well B in the Kelasu structural belt.

1.4. Effects of ultra-deep reservoir stimulation

In recent years, 246 wells more than 6000 m ultra-deep were drilled on average each year in China. As the deep reservoirs get poorer in quality, efficient ultra-deep stimulation technology plays an increasingly important role in the exploration and development of ultra-deep oil and gas pools (Table 2). (1) This technology supports breakthroughs in exploration of ultra-deep reservoirs. Wells targeting ultra-deep reservoirs need large investment and long well construction period, and are small in number, so the test results of key exploration wells have a great impact on the geological understanding of the block and production capacity deployment. For example, Well Moxi 8 in the Southwest Oil and Gas Field, the well was treated with pre-pad acid fracturing, multi-stage acid fracturing, and acidizing for plugging removal in different layers in 2012. The test production of Longwangmiao Fm in this well was 107×104 m3/d, on this basis, the proven reserves of the block were estimated at 4403×108 m3, marking a major exploration breakthrough. (2) The technology has propelled the production capacity construction of large ultra-deep oil and gas fields represented by Tarim and Sichuan oilfields. For example, 92% of ultra-deep wells in Kuqa pediment belt of Tarim Basin have been stimulated, and have an annual production capacity of 220×108 m3.

Table 2 Technical indicators of ultra-deep reservoir stimulation and typical wells in China.

| Stimulation parameter | Value | Typical well |

|---|---|---|

| Maximum depth of acidizing in vertical well | 8 882 m | Lutang 1 |

| Maximum depth of fracturing in vertical well | 7 620 m | Keshen 13 |

| Maximum temperature | 205 °C | Niudong 1 |

| Maximum stage number in vertical well (highly deviated well) | 6 layers | Gaoshi 001-X25 |

| Maximum depth of horizontal well | 8 008 m | Tazhong 862H |

| Maximum horizontal section length | 1 561 m | Tazhong 721-8H |

| Maximum stage number of horizontal section | 12 stages | Tazhong 541-H1 |

| Maximum treatment pressure in the case with non-weighted fracturing fluid | 122 MPa | Keshen 902 |

| Maximum treatment pressure in the case with weighted fracturing fluid | 136 MPa | Dabei 301 |

| Maximum fluid volume | 8 588 m3 | Tazhong 862H |

| Maximum proppant volume | 159 m3 | Keshen 1002 |

| Maximum displacement | 11.2 m3/min | Dabei 101-1H |

2. Technological trend

2.1. Technical difficulties

China has made breakthroughs successively in deep oil and gas exploration, pushing exploration frontier towards ultra-deep reservoirs. The deepest well tested in the Tarim Oilfield reached the depth of 8882 m (Well Luntan 1). The risk exploration well deployed in the southern margin of the Junggar Basin in Xinjiang is planned to drilled to the depth of 8700 m. An ultra-deep exploratory well targeting Permian in western Sichuan Basin reaches the depth of 8029 m (Well Hongxing 1). The latest risk exploratory wells in Qinghai and Tuha oilfields reach the depth of over 7000 m. With deeper burial depth in ultra-deep reservoir, high temperature and pressure, and complex conditions, the reservoirs will inevitably pose more challenges to stimulation technology.

(1) More difficulties in research and application of the geological engineering integration technology: The geology-engineering integration in reservoir stimulation follows the concept of reverse thinking and forward implementation. Reservoir stimulation operators have to put forward specific requirements on drilling and completion, stimulation layer selection, local well pattern deployment, and development geology from the perspective of stimulation implementation. The integration requires them to have good understanding of other disciplines. Therefore, for ultra-deep reservoirs, it is more difficult to implement stimulation following the geology-engineering integration idea.

(2) Higher requirements on materials injected into the well: The fracturing fluid must tolerate high temperature of above 200 °C, and must be shear resistant, have stable sand carrying performance and low friction (friction reduction greater than 60%), be able to be prepared on site, and have good pumping performance (with base fluid viscosity of less than 90 mPa·s). The proppant particles must be as small as possible in size (< 0.150 mm (100 mesh)), in order to improve the transportability of ceramsite and reduce the risk of sand plugging in the case of insufficient ultra-deep fracture width. The acid system must be able to work at higher temperature, and with corrosion inhibitor added, the acid system must have a corrosion rate of less than 60 g/(m2·h) below 200 °C.

(3) Great difficulty in further improving the vertical producing degree of ultra-deep and thick reservoirs: Currently, the ultra-deep reservoirs can be stimulated by packers in 3 layers at most. For gas wells with wellhead pressures of more than 90 MPa, perforation, drill grinding, and live coiled tubing operation would have high well control risks, making the bridge plug staged stimulation unable to be implemented. Extreme limited entry multi-cluster layering would have limited pressure increase (less than 3 MPa) in the case with small displacement (less than 6 m3/min) and dozens of perforations (more than 60 holes), and thus unable to realize multi-cluster layering stimulation.

(4) Higher requirements on downhole tools and supporting high-pressure equipment at the surface: The ultra-deep reservoir stimulation tools must can tolerate high temperature and pressure, and stable performance, and have stable performance, so it is urgent to research and develop high-temperature and high-pressure resistant materials, fracturing equipment and tools to facilitate the implementation of efficient stimulation. High displacement is a guarantee for reservoir stimulation effect, and it is difficult to achieve the expected stimulation effect at low displacement. High displacement would accompany with extremely high treatment pressure, and large liquid volume requires high-pressure pumps and wellhead high-pressure equipment work stably and economically for a quite long time.

(5) Difficulties in stimulation of ultra-deep, HT and HP wells: Currently, implementing at relatively low displacements (less than 6 m3/min), ultra-deep reservoir stimulations are limited in scale and fall short of the expected effect. How to further reduce the treatment pressure and increase the displacement is the key to achieving efficient stimulation. With short horizontal section, stimulations in ultra-deep horizontal wells are few in stages, low in displacement and fracturing fluid volume, making it difficult to create complex fracture network. Therefore, it is urgent to upgrade high-efficiency stimulation and supporting technologies for horizontal wells.

(6) More difficulties in direct monitoring of and accurate evaluation after reservoir stimulation: The direct monitoring technology for ultra-deep reservoir stimulation is still immature. It is difficult to identify microseismic signals in wells more than 6000 m deep. Various kinds of direct physical detection equipment can’t work at temperatures above 180 °C and pressures over 120 MPa. As exploration goes to deeper reservoirs, limitations of direct monitoring technologies will further stand out.

2.2. Major technological trend

In 2030, it is expected that the CNPC’s gas production will reach 1600×108 m3/year, of which more than 40% is from deep-ultra-deep reservoirs. Stimulation will inevitably play a more important role in the economic exploration and exploitation of ultra-deep reservoirs. In light of future technical requirements of ultra-deep reservoir stimulation, the development history, gaps, requirements and difficulties of domestic ultra-deep reservoir stimulation technologies, it is believed that the development of China's ultra-deep reservoir stimulation technology should draw on the successful experience of unconventional reservoir stimulation, and focus on the following aspects.

(1) Systematically establish basic research methods and new evaluation experiments. In line with HT and HP ultra-deep reservoirs, rock mechanics characteristics, in-situ stress field distribution, fracture propagation and characterization technology under HT and HP should be researched; studies on mechanisms of the matching of fracture network and conductivity under high closure stress, proppant transportation and settlement law should be strengthened; the research on mechanisms of fracture initiation and propagation under complex geological and extreme operation conditions in ultra-deep layers should be deepened; new theories, new methods and new materials for ultra-deep reservoir stimulation should be investigated.

(2) Deepen geological understanding and improve the operation mechanism of geological-engineering integration. We should deepen understanding on the connotation of geological-engineering integration, improving stimulation effect of complex exploration objects, and build four integrated platforms, namely integrated evaluation platform, integrated design platform, integrated sharing platform, and integrated analysis platform. The integrated evaluation platform makes full use of evaluation techniques such as geology, sweet spot, in-situ stress, and completion quality to evaluate reservoir quality. The integrated design platform integrates the geological model, reservoir model, fracture model, and economic model, etc. The integrated sharing platform realizes sharing of experimental results, optimized plans, and treatment design. The integrated analysis platform mainly fulfills the functions of post-fracturing tracking, measure evaluation, effect evaluation, and model modification. In a word, the geology and engineering integration is to fuse multiple disciplines to improve the pertinence of design of ultra-deep reservoir stimulation.

(3) Develop more directed materials for highly efficient stimulation of ultra-deep reservoirs, including fracturing fluids, acid fluids, proppants, and temporary plugging materials. The fracturing fluids for ultra-deep reservoir stimulation should develop in the direction of high temperature tolerance, low friction, stable sand carrying performance, and low damage to reservoir, and with capability to be weighted; moreover, low cost and environmental friendliness are the basic requirements for large-scale application. For the acid liquid, the focus should be put on development of acid corrosion inhibitors with high-temperature tolerance to form acid systems for ultra-deep and high-temperature reservoir stimulation; meanwhile, additives to reduce the corrosion rate of high-temperature acid fluid should be developed to increase the distance of acid etching. For proppants, ceramsite proppant with small particle size, and high strength is the development trend; moreover, replacing ceramsite with quartz sand in ultra-deep reservoir stimulation should be attempted. For temporary plugging layering materials, ball drop temporary plugging to achieve layered stimulation is an ideal technology for stimulation of ultra-deep and hugely thick reservoirs currently, and this technology requires the temporary plugging material to be able to withstand high pressure and high temperature, controllable in dissolution and economically feasible.

(4) Tackle the problems in fine layered stimulation technology for ultra-deep and huge-thick reservoirs. Fine layer division is a key in the research of ultra-deep and hugely thick reservoir stimulation technology. For reservoirs with relatively developed natural fractures vertically, fine layer division makes it possible to communicate all thick layers through vertically local stimulation. As the reservoir goes deeper, nature fractures become less. Production logging, fracture height dynamic monitoring after shale reservoir stimulation, and proppant tracer monitoring have confirmed that the effective fracture height supported by proppant formed by injecting gel or low viscosity gel with sand at large displacement fall far short of expectation. Therefore, it is necessary to strengthen the research of temporary plugging multi-stage layering technology, implement fine layering with the help of layering tools to effectively expand the volume of fracture network, and improve the effectiveness and economy of the fracture process.

(5) Investigate fracture controlled stimulation technology for ultra-deep horizontal wells. The "fracture-controlled reserves" stimulation technology fully integrates and optimizes the parameters such as length, spacing, and height of HF in line with the reservoir physical properties and stress, and well-controlled reserves. With the development of drilling and completion technologies, drilling and stimulation of ultra-deep horizontal wells become more common. The research on the stimulation technology for horizontal wells should be strengthened to realize fracture controlled stimulation at low displacement. The focus of fracture control in the ultra-deep horizontal well is to maximize and rationalize the controlled reserves of individual HF, optimize the ultra-deep fracture controlled stimulation technology, and achieve the best input- output ratio.

(6) Develop direct HF monitoring technology for ultra-deep reservoir stimulation: The research on tools and materials for direct monitoring of HF and ultra-deep HF monitoring and evaluation methods should be strengthened, to fully excavate the down hole HP information contained in the basic data during the treatment process. The recognition and interpretation level of HF monitoring instruments to remote signals need to be improved further. The temperature and pressure monitoring gauges with HT and HP tolerance are commonly used to monitor the bottom hole data during ultra-deep fracturing, and the recorded pressure, temperature, etc. are relatively reliable. Strengthening the analysis of these data is currently an economical and feasible method.

(7) Develop downhole HT and HP resistant stimulation tools and HP resistant supporting wellhead equipment: More efforts should be put in the development of downhole layering tools to meet the needs of ultra-deep reservoir stimulation at above 220 °C. Large inner diameter stimulation tools should be developed to reduce throttling friction, increase treatment displacement, and improve downhole operation capability comprehensively. Soluble bridge plug and supporting assembly tools with reliable performance and simple maneuver suitable for ultra-deep well stimulation should be researched. The surface equipment with HP resistance, high-power fracturing trucks, supporting HP wellhead equipment, and economic and environmentally friendly fracturing equipment and low-cost green energy fracturing pump trucks should be developed.

3. Conclusions

Ultra-deep reservoir stimulation technologies have played an important role in breaking exploration and increasing reserves and production in ultra-deep reservoirs. After years of research, China’s ultra-deep reservoir stimulation technologies basically meet the needs of ultra-deep reservoir stimulation in different periods, and have supported the production capacity construction in several large ultra-deep oil and gas fields such as Tarim Oilfield, Southwest Oilfield. As China made breakthroughs in exploration in deeper reservoirs in a wider range, the ultra-deep reservoir stimulation technology is increasing in demand and raising in function and status. It is of great significance to put more efforts in research on the basic theories, operating mechanisms, materials and equipment, tools and equipment for the ultra-deep reservoir stimulation for supporting stable oil production and rapid development of gas business in ultra-deep reservoirs of China.

Acknowledgements

This is the achievement of the research team from RIPED, PetroChina. We thank Gao Ying, Han Xiuling and Wang Liao for their participation, the management of CNPC for their guidance, and the Tarim Oilfield Company and Southwest Oil and Gasfield Company for their support in the technical tests.

Reference

Characteristics of oil and gas discoveries in recent 20 years and future exploration in the world

Progress and development directions of deep oil and gas exploration and development in China

Integrated techniques for rapid and highly-efficient development and production of ultra-deep tight sand gas reservoirs of Keshen 8 Block in the Tarim Basin

Stress measurements at depth in North China by hydraulic fracturing

Application of new testing tech in well Yeyun2

Significance and prospect of ultra-deep carbonate fault-karst reservoirs in Shunbei Area, Tarim Basin

The developing trend of acid fracturing technique in Tahe Oilfield

Volume fracturing technology based on geo-engineering integration for ultra-high temperature and ultra-deep heterogeneous carbonate reservoir

“Fracture network” fracturing technique for improving post-fracturing performance of low and ultra-low permeability reservoirs

A criterion for identifying hydraulic fractures crossing natural fractures in 3D space

Progress and development of volume stimulation techniques

Laboratory study on hydraulic fracture geometry of Longmaxi Formation shale in Yibin area of Sichuan Province

Research on acid fracturing system with improving stimulated reservoir volume

Research of new ultra high temperature synthetic polymer fracturing fluid

Domestic progress of ultrahigh-temperature fracturing fluids in the last decade

Preparation and performance evaluation of fracturing fluid with low friction, high density and high temperature resistance

Performance and application of weighted GHPG fracturing fluid with low cost

Application of aggravating acidification of high density acid in stimulation of deep well with surpressure gas reservoir of West Sichuan

Development and performance evaluation of cationic VES diverting acid system

Technological challenges and countermeasures in well control of ultra-deep ultra-high temperature and ultra-high pressure oil and gas wells

Technological process and prospect of reservoir stimulation

Stress interference calculation model and its application in volume stimulation of horizontal wells

Research and application of hydraulic jetting and acid fracturing technology in horizontal well of Lunnan carbonate formation

The “fracture- controlled reserves” based stimulation technology for unconventional oil and gas reservoirs

Study on microseismic monitoring of synchronous fracturing and its application