Introduction

Gulong shale oil in the Daqing Oilfield is a typical continental shale oil with oil flowing from the edge to the center of the Gulong sag of Songliao Basin. high yield was obtained from interlayer-type, sandwich-type to pure shale type reservoirs. The whole section from the lower part of the second member of Lower Cretaceous Qingshankou Formation to the first member of Qingshankou Formation contained oil, so the Gulong shale oil resource has great potential[1⇓-3].

Compared with domestic and international marine or saline lacustrine basin sedimentary shale, the shale in Gulong has a big difference in rock fabric, physical property, oil-bearing property, and shale oil mobility. The north American mature geological theory and engineering technology are difficult to be directly applied, due to a series of challenges such as high investment cost per well, low initial production, and estimated ultimate recovery (EUR) being lower than the economic utilization threshold[4⇓⇓⇓⇓⇓-10], so it has become the most urgent task to realize the development theory and technological innovation of Gulong shale oil. For this reason, this article preliminary analyzes six scientific problems of the Gulong shale, including the source of organic matter, the mechanism of hydrocarbon generation, structure and type of reservoir space, mineralogical evolution characteristics, mechanical properties, production stimulation mechanism, shale oil production and phase, and evaluation of shale oil properties and recovery enhancement. At the same time, three key technologies are put forward in the future research direction for the Gulong shale oil, including geological sweet spot selection, engineering optimization design, development technology policy optimization, and recovery enhancement.

1. The strategic significance, exploration and development history of Gulong shale oil

The Songliao Basin is one of the continental sandstone petroliferous basins with the most abundant riches oil and gas resources discovered in the world, which has made great contributions to the development of China's petroleum industry and still plays an important role[3,11 -12]. After more than half a century of exploration and development, the accumulated proved reserves of Daqing Oilfield have been 63.7×108 t, with a proven rate of 62.3%. In recent years, the grade of newly proved reserves has decreased. From 1990 to 2019, the newly proved reserves have been 31×108 t, among which the low and ultra-low permeability reserves have been 26×108 t, accounting for 83.8%. At the same time, it is more difficult to stabilize the production of the main oil fields. For example, the average water content of the Sazhong development zone has reached 96%, and its production and operation costs are increasing year by year, and the comprehensive decline rate is constantly rising. Strengthening oil and gas exploration and delaying production decline in the Songliao Basin are of great strategic significance to the stability of crude oil production and energy security in China[11,13⇓ -15].

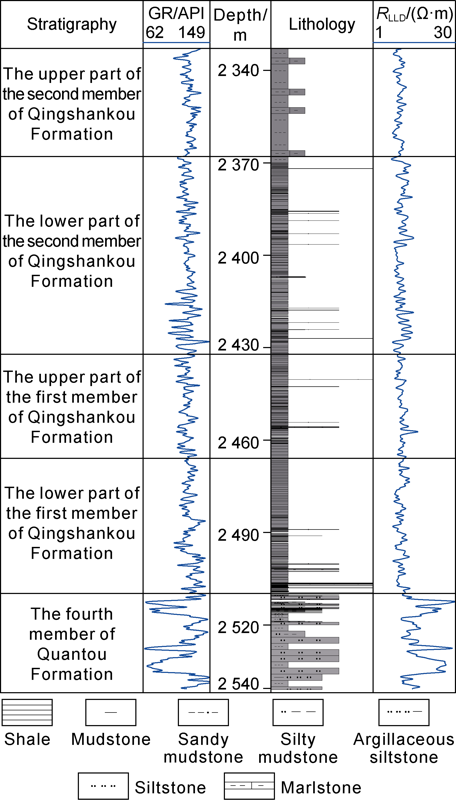

Qingshankou Formation of the Lower Cretaceous in the northern Songliao Basin is the largest lake pan period deposit, where it's organic-rich dark shale is widely distributed, and has relatively high maturity, reaching 1.20%-1.67% in Qijia-Gulong sag (Fig. 1). Controlled by sedimentary conditions, three different types of shale oil developed in interlayer-type, sandwich-type, and pure shale type (Fig. 2), in which the pure shale oil can be divided into lamellation-type and lamination-type (Fig. 3)[3,6,12,16⇓⇓ -19]. The interlayer-type shale oil is the crude oil occurring in interbedded shale and sandstone, the shale accounts for 60%-80%, the single-layer thickness of sandstone is 2-4 m, and the resource amount is 1.56×108 t. The sandwich-type shale oil is the crude oil occurring in thick shale interbedded with thin siltstone, the shale accounts for 80%-95%, the single layer of sandstone interlayer is 0.2-1.5 m, and the resource amount is 8.71×108 t; the pure shale type oil is the crude oil occurring in thick shale, in which the shale accounting for more than 95%, with siliceous, dolomitic (shelly limestone) laminae, which are mostly less than 0.01 m thick. The source and reservoir are integrated and can be further subdivided into lamellation-type shale oil in the lower part of the first member of Qingshankou Formation, and lamination-type shale oil in the upper part of the first member of Qingshankou Formation and the second member of Qingshankou Formation (Fig. 4). The lamellation-type shale oil refers to the crude oil in the shale developed in the lower part of the first member of Qingshankou Formation with lamellation, and the lamination-type shale oil refers to the crude oil in the shale developed in the upper part of the first member of Qingshankou Forma- tion and the second member of Qingshankou Formation with silty calcareous (dolomitic) laminae, and the resource amount is 89.31×108 t[20]. Currrently, interlayer- type shale oil in the Songliao Basin has been partially developed for commercial use, and sandwich-type, lamination-type, and lamellation-type shale oil has huge resource potential. Once a breakthrough is made, it will become an important resource for the large-scale increase of oil and gas reserves and production in the Songliao Basin in the future, which will effectively guarantee the sustainable development of the petroleum industry in the Daqing Oilfield and support the construction of oil fields for hundreds of years.

Fig. 1.

Fig. 1.

Shale oil exploration result of Qingshankou Formation in northern Songliao Basin.

Fig. 2.

Fig. 2.

The distribution pattern of shale reservoir types of Qingshankou Formation in Ao 34 well-Jin 281 well in the northern Songliao Basin. GR—natural gamma ray; RLLD—deep lateral resistivity.

Fig. 3.

Fig. 3.

Pure shale profile in Guye 3HC.

Fig. 4.

Fig. 4.

Core and thin section photos of lamellation-type and lamination-type shale oil reservoirs in Guye 1 well.

Shale oil exploration in the Daqing Oilfield has lasted for a long time with a history of nearly 40 years, experiencing three stages of discovery, exploration, research and understanding, and experimental breakthrough[14,21]. In 1981, the first discovery well (Ying 12 well) was drilled with the conventional oil exploration concept and development technology, aiming at the fractured mudstone reservoir in Gulong sag. The industrial oil-gas flow of 3.8 t/d and 441 m3/d was obtained in the first and second members of the Qingshankou Formation. From 1983 to 1991, the experimental mudstone reservoir area of Ying 12 well was further established, and five wells were drilled successively, among which Ying 18 and Ha 16 wells obtained industrial oil flow. A preliminary exploration of horizontal shale oil well development was carried out in 1998, and the screen completion of Guping 1 well achieved a low oil production rate of 1.5 t/d.

In 2011, tight oil exploration concept and development technology to develop shale oil in interlayer-type and sandwich-type shale oil fields was adapted and applied, and the development objects were thin sandstone layers in shale layers. The interlayer-type shale oil in Qiping 2 well had a production of 31.9 t per day, and the four development experimental areas had an accumulated oil production of 92.95× 104 t, which has realized large-scale development. Sandwich-type shale oil in Qiping 1 well had a production of 10.2 t per day and 14.3 t of oil flow per day in Qiping 1-1 well.

In 2018, Daqing Oilfield entered the experimental breakthrough stage, and continued to strengthen the exploration of shale oil, exploring the exploration concept and development technology of shale oil. It optimized the deployment of 18 vertical wells, such as Guye 1, Ying X57, and Chao 21, with a daily oil production of 1.36-6.72 t, which confirmed the overall oil bearing formation from the lower part of the second member to the first member of the Qingshankou Formation, with the thickness of 100-140 m. The lower part of the first member of Qingshankou in Gulong sag is a light oil belt with a thickness of 50-60 m and stable lateral distribution, covering an area of 2326 km2. Four horizontal wells, namely Songye You 1HF, Songye You 2HF, Guye Youping 1, and Yingye 1H, were deployed and implemented in the sweet-spot layers of the first member of Qingshankou Formation shale (Fig 1). Guye Youping 1 well is located in the deep part of Gulong sag in the central sag of Songliao Basin. After taking the shale in the lower part lamellation-type shale of the first member of Qingshankou as the sweet-spot target, it obtained a high-yielding industrial oil-gas flow of 30.5 t/d and 13 032 m3/d. The high yield of Guye Youping 1 well marks an important breakthrough of pure shale oil, which shows a broad prospect of continental shale oil resources, and has a significant strategic turning meaning.

2. The particularity of Gulong shale oil in Daqing Oilfield

The Gulong shale oil is mainly pure shale type oil, which is different from other type shale oil abroad, and there havent been any successful large-scale commercial development. Its has got peculiar resource endowment conditions and reservoir characteristics, which overturns the traditional concept and understanding of shale oil exploration and development, including the four aspects.

2.1. Special geochemical characteristics and oil properties of Gulong shale oil

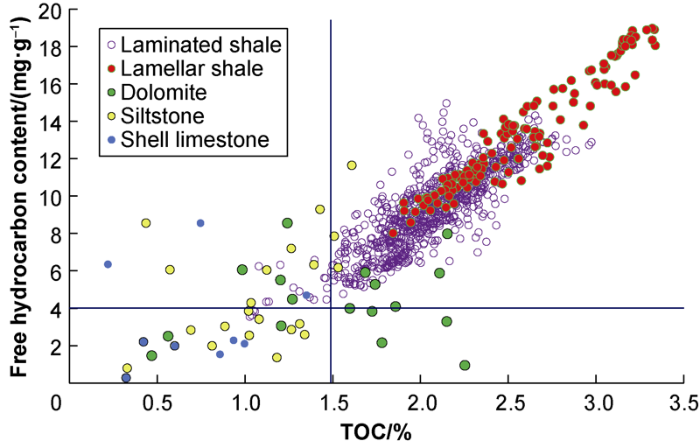

The Gulong shale has a good organic matter type, the planktonic algae erupted during the first and second members of the Qingshankou Formation sedimentary period, organic matter was given priority to lamellar algae, the sedimentary environment was mainly anaerobic-anoxic, organic matter type was mainly type I, with high hydrogen index of 600-800 mg/g and high hydrocarbon generation potential. The TOC of the first member of the Qingshankou Formation is 1.8%-4.5% in the semi-deep to deep lacustrine facies area, and the TOC of the second member of Qingshankou Formation is 1.4%-2.2%. The free hydrocarbon content of the lower part of the first member of Qingshankou Formation is the highest, generally more than 8 mg/g, followed by the upper part of the first member of Qingshankou Formation and the second member of Qingshankou Formation, generally more than 6 mg/g.

According to the traditional understanding, compared with the marine shale oil in North America, the thermal evolution degree of continental shale oil in China is generally lower, with high crude oil density, high viscosity, low gas-oil ratio, and poor mobility[22⇓-24]. The formation pressure coefficient in the Qijia-Gulong area is generally 1.20, with the highest pressure coefficient of 1.58. The high pressure area in the first member of Qingshankou Formation with the pressure coefficient greater than 1.20 is 4550 km2, and the high pressure area in the second member of the Qingshankou Formation with the pressure coefficient greater than 1.20 is 2617 km2. The oil test data of Guye 1 well, Guye Youping 1 well and Yingye 1H well show that the surface oil density is generally less than 0.84 g/cm3, and the viscosity of formation oil is generally less than 0.8 mPa•s, with colloid content of 8.0%-18.6%, the asphaltene content is 0-0.4%, the average saturated hydrocarbon content is 84.2%, and the aromatic hydrocarbon content is 9.7%. The gas-oil ratio gradually increases with the increase of maturity, and the gas-oil ratio of Youping 1 well located in the deep sag reaches more than 400 m3/m3. The movable oil index (OSI, the ratio of free hydrocarbon content to total organic carbon content) from the lower part of the second member of Qingshankou Formation to the first member of Qingshankou Formation is of 100-400 mg/g (Fig. 5), and it is higher than that of the Eagle Ford shale oil (OSIof 100-200 mg/g), which has been successfully developed on a large scale in North America[25], indicating that Gulong shale oil has great mobility potential. The above characteristics indicate that the Gulong shale oil is not only superior to other shale oil resources found in China but also superior to major shale oil resources reported in North America, changing the traditional understanding that continental shale oil is characterized by high density, high viscosity, and low gas-oil ratio.

Fig. 5.

Fig. 5.

Data of transcendence effect of Gulong continental shale oil.

2.2. Special reservoir space of Gulong shale

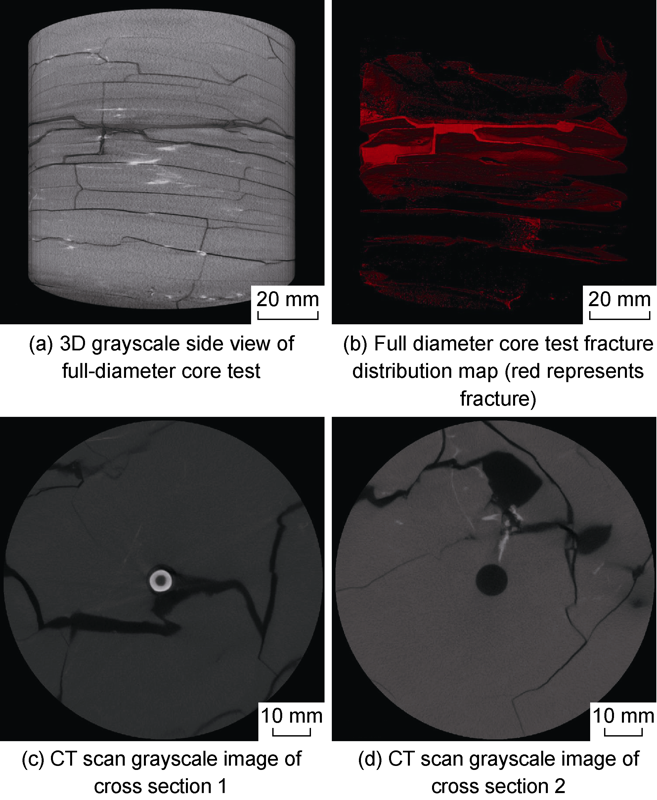

Gulong shale in Songliao Basin is different from other shales in the world. The reservoir system has both organic and inorganic origins and is mainly composed of matrix pores and bedding fractures. Different from conventional reservoirs, the pore types of Qingshankou Formation shale are dominated by organic pores and fractures, dissolved pores, and clay mineral intercrystalline pores (Fig. 6), accounting for more than 80% of the total surface porosity. A detailed description of the core shows that organic and inorganic horizontal bedding fractures are extremely developed (1000-3000 per meter) (Fig. 6), with a total surface porosity of 22%-79%. The nano-scale pore-fracture system controlled by horizontal beddings has improved the reservoir physical property. Under overpressure conditions, the horizontal permeability is (0.011-1.620)×10-3 μm2, the average permeability is 0.580×10-3 μm2, whereas for the vertical permeability being less than 1×10-7 μm2. Therefore, the high porosity and permeability zone in the horizontal direction is formed. Due to the development of pre-existing horizontal bedding, the tip effect of the organic matter and other clastic minerals arranged along the bedding promotes the lateral expansion of fractures, forming a large number of bedding fractures, which can expand the volume of shale reservoir space by 1.0-1.2 times, equivalent to an increase in porosity of about 2%-3%[26].

Fig. 6.

Fig. 6.

Field emission scanning electron microscope images of Gulong shale.

2.3. Special evaluation criteria for the compressibility of Gulong shale

The Gulong shale oil has changed the standard of judging shale reservoir compressibility by clay content. The Gulong shale is mainly argillaceous felsic shale with an average clay mineral content of 35.6%. According to the traditional reservoir reconstruction theory, high clay mineral content is the key factor affecting the fracturing effect. However, the study found that Gulong shale is in the late stage of middle diagenesis phase, with a high degree of clay mineral evolution. A large amount of montmorillonite disappeared and transformed to illite, and siliceous precipitates in the transformation process, which increases the rigid component and brittleness of the shale (Fig. 7)[27]. The illite in the shale is oriented by diagenetic compaction, which makes the rock easy to denude and fracture along the bedding surface. During the fracturing process, vertical fractures along the prin-cipal stress direction and multiple horizontal fractures along the bedding surface are opened at the same time, forming a complex network of fractures in the shape of the Chinese character of "Feng" (Fig. 8), which significantly improves the reservoir compressibility.

Fig. 7.

Fig. 7.

Diagenetic evolution of clay minerals resulted in quartz precipitation.

Fig. 8.

Fig. 8.

Gulong shale fracture morphology with the Chinese character shape of "Feng".

2.4. Special engineering sweet spots of Gulong shale oil

The breakthrough in Gulong oil has changed the traditional practice of choosing tight interlayers in shale formations as engineering sweet spots. The development of North American marine tight oil/shale oil is usually carried out by selecting a tight interlayer as the target layer in the shale system and using the long-horizontal well volume fracturing model for commercial development[8,28⇓⇓ -31]. The shale oil of Lucaogou Formation in Jimsar sag and Chang 71+2 members in Ordos basin, which have been developed on a large scale in China, also learns from the experience of North America[32-33]. However, the thickness of lamellation-type and lamination-type shales in the Qijia-Gulong area accounts for more than 95%. Although there are dolomite, shell limestone, and siltstone laminated, the thickness is very thin with a single layer ranges between 0.05 to 0.15 m. At the same time, due to the significant improvement of shale physical properties by bedding fractures, the average total porosity is 9.8%, and the average effective porosity is 6.2%. The good reservoir property and connectivity make it used as high-quality engineering sweet-spot layers.

Thanks to the engineering concept and technological innovation of unconventional oil and gas, the establishment of the key technology system of shale oil exploration and development will contribute to the large-scale industrial breakthrough of Gulong shale oil[24,34⇓ -36]. However, the exploration and development of Gulong shale oil is still in its initial stage, and its uniqueness makes it impossible to directly apply the exploration and development technology route of shale oil in North America (Table 1). The unique resource endowment characteristics and key parameters of reservoir evaluation need to be further implemented, while the main development parameters are not clear yet. The technical system of drilling and completing wells and stimulation is still to be perfected. The law of development decline is not clear; well pattern, well spacing, and production system needs to be optimized; EOR technology has not been researched; early production wells generally have the problems of high investment cost per well and low initial production, and EUR below the economic production threshold. Therefore, it is still necessary to innovate theories and develop technologies in practice to support rapid and efficient development.

Table 1. Comparison table of main characteristic parameters of shale oil in China and abroad.

| Shale oil | Reservoir type | Reservoir depth/m | Effective thickness/m | Porosity/% | Permeability/10-3 μm2 | Gas-oil ratio/(m3•m-3) | Pressure factor | Crude oil viscosity/(mPa•s) | Brittle mineral content/% |

|---|---|---|---|---|---|---|---|---|---|

| Eagle Ford | Black calcareous shale (brittle) | 1200-4300 | 15-100 | 5.0-14.0 | 0.001-0.002 | 240 | 1.4-1.7 | >80 | |

| Dongying sag of Shengli Oilfield | Argillaceous shale | 3300-3600 | 10.0-19.4 | 0.000 85-177 | 1.2-1.8 | ||||

| Dagang Cangdong (Guan 1702H) | Laminated shale (with beddings and fractures) | 3900 | 10-40 | 6.0-9.0 | 0.11-4.00 | 82-103 | 0.96-1.27 | 19 | >80 |

| Jimusar | Dolomitic siltstone, limestone, and dolomite | 2300-4300 | 4-33 | 6.0-14.0 | 0.01 | 17 | 1.2-1.6 | >50 | 28-45 |

| Gulong sandwich-type shale oil | Thin sand-mud interbeds | 1978-2000 | 0.2-1.5 | 2.5-6.5 | 0.01-0.02 | 30.13 | 1.13 | 3.65 | >35 |

| Gulong pure shale type shale oil | Mudstone, argillaceous shale (with beddings) | 2000-2500 | 4.4-22.8 | 4.0-15.0 | <0.01 | 70-800 | 1.30-1.57 | 2.70-10.74 | >30 |

3. Scientific problems of Gulong shale oil

Gulong shale oil is a new resource type, and there are no existing geological theories and development technologies that can be directly copied and applied domestically and abroad. Although the exploration and development practice has made an important breakthrough, it still faces a series of problems, such as the lag of basic research, the unmatched engineering technology, the high construction cost, and the benefits without a breakthrough. According to the resource characteristics and exploration and development status of Gulong shale oil, the following six key scientific issues are sorted out.

3.1. Organic matter source, hydrocarbon generation and expulsion mechanism, and key factors affecting shale oil abundance of Qingshankou Formation shale

Current studies have shown that: (1) Body and molecular fossil evidence of lacustrine algae, marine algae, prokaryotes, and advanced plants have been found in the Qingshankou Formation shale[37⇓⇓-40], indicating the complexity of the mother source of sedimentary organic matter in Gulong shale. (2) Due to the significant differences in paleoclimate and palaeowater environment in which different types of organisms occurred, the hydrocarbon generation capacity and product composition of formed kerogen were also significantly different[41], which affected the formation and enrichment of Gulong shale oil. (3) Based on the study of Songke 1 well, it is revealed that transgression events may occur during the sedimentary period of the first member of the Qingshankou Formation[39,42], and the astronomical orbital force of the earth profoundly affects the climate change and sedimentary process of the palaeolake[43], which may be the main controlling factor for the cyclicity of organic matter enrichment in Gulong Shale. (4) In this area, the overpressure gas-oil ratio has a good correspondence with Ro, and the generated oil and gas density is lighter than that of kerogen, resulting in volume expansion and overpressure in the source, which is the main driving force of oil and gas expulsion. However, at present there are still some problems: (1) The parent material source of Gulong shale organic matter is still not to carry out the quantitative evaluation, whether the transgression of the first member of Qingshankou Formation of depositional period reached Gulong sag remains controversial, the main control factors of multi-scale frequent alternation between organic laminae and felsic detritus or carbonate are still unclear, and because of this it directly affects the accurate understanding of high quality Gulong shale oil formation mechanism and the resource potential. (2) The formation of overpressure and the mechanism of hydrocarbon generation and expulsion still need to be further studied.

3.2. Types and structural characteristics of effective reservoir spaces in Gulong shale and their contribution to porosity and permeability

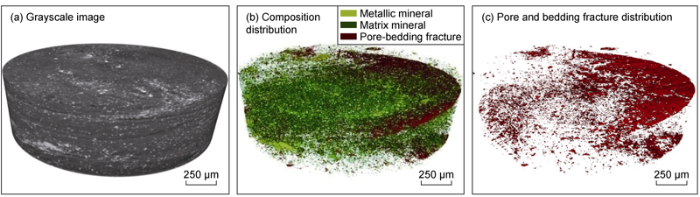

At present, the differences of reservoir properties of lamination-type, lamellation-type, and sandwich-type shales have been preliminarily defined, and the development characteristics of bedding fractures and their effects on reservoir properties have been discussed. However, the pore types of Gulong shale are different from conventional reservoirs. The pores and fractures are related to organic matter, clay minerals, and dissolution. The pore types are mainly organic pores and fractures, dissolved pores, and intercrystalline pores of clay minerals, which account for more than 80% of the total surface porosity. Meanwhile, nano-scale pore and fracture systems controlled by beddings further improve the reservoir's physical properties (Fig. 9).

Fig. 9.

Fig. 9.

Pore-fracture-matrix mineral micrometer CT 3D model of Gulong shale (Ao 34 well, the first member of Qingshankou Formation, laminated shale, 2231.2 m).

Due to peculiar properties of pore types in Gulong shale, there are some problems that still exist, such as: (1) The study on the fusion characterization of pore structures at different scales has not been carried out yet; (2) The effectiveness of bedding fractures, the contribution ratio of effective fractures to pores under formation conditions are not clear. (3) Due to the differences in reservoir properties of the three types of shale, there is a lack of effective characterization methods for whether shrinkage fractures, diagenetic fractures, organic pores, and bedding surfaces are effective reservoir space. (4) Reserves estimation and prediction are still lacking basis.

3.3. Genesis and evolution of Gulong shale minerals and their control on reservoir availability, sensitivity and compressibility

According to the previous study: (1) The Gulong shale is argillaceous felsic shale with an average content of clay minerals of 35.6% and a low content of carbonate. (2) The diagenetic evolution sequence of clay minerals is preliminarily identified, that is, the whole is in the late stage of middle diagenesis, and the clay minerals have a high degree of evolution. When the burial depth is more than 1650 m, a large amount of montmorillonite is transformed into illite, and the clay minerals tend to be stable, quartz precipitates during the transformation process, and the brittleness increases. (3) The relationship between clay minerals and the formation of bedding is put forward, that is, the orienting arrangement of illite by diagenetic compaction, which makes the rock have fissile beddings, and it is easy to be eroded and fractured into thin beds along the bedding plane. However, there are still some shortcomings in the current research. (1) The sources of clay minerals have not been distinguished, and the types, proportions, and occurrence of sedimentary and diagenetic clay minerals have not been understood. (2) The understanding of the influence of different clay minerals on the reservoir property, sensitivity and compressibility of shale still needs to be deepened. (3) The horizontal distribution of the vanishing line of montmorillonite in the Gulong area is still unclear.

3.4. Rock mechanics and fracture propagation law of Gulong shale

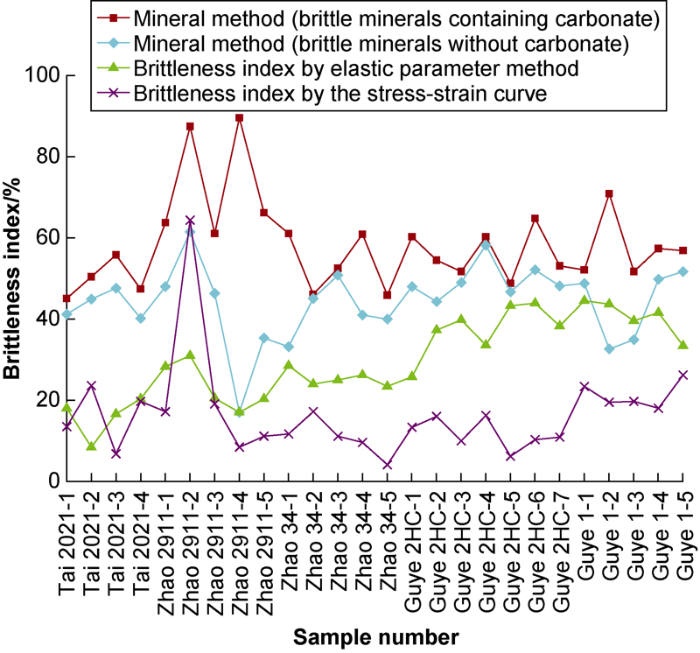

The comparative study of rock mechanics in the directions vertical and parallel to the bedding has been carried out. The results show that: (1) The fracture toughness and tensile strength of samples taken with parallel bedding are 38.6% and 71.7% lower than those taken with vertical bedding, respectively, and the rock mechanics anisotropy is significant. (2) In Gulong shale, clay minerals are mainly illite with bedding laminae developed. Its compressibility is jointly controlled by complex mineral fabric, organic matter content, and distribution of bedding laminae. (3) Based on the full-diameter core physical simulation, the dynamic equilibrium process of hydraulic fracturing fracture propagation (longitudinal propagation under the control of vertical stress, horizontal expansion under the control of bedding laminae) is defined, and the artificial fracture presents the complex shape of the Chinese character "Feng". (4) Low viscosity fluid is conducive to the opening of bedding, and high viscosity fluid is conducive to the longitudinal extension of fractures, thus forming the main volume fracturing technology of pre-CO2, alternating injection of gelatine, and slickwater, which improves the volume of fracturing and the complexity of fractures. However, there are still many problems to be solved. (1) In the process of conventional rock mechanics testing, the mechanical properties are distorted due to the stress release after the core is taken out, and the understanding of the mechanical properties of bedding laminae and the anisotropy of shale mechanics under the in-situ environment is not clear. (2) The correlation of shale brittleness index calculated by mineral method (including two models of brittle minerals containing carbonate and without carbonate), elastic parameter method, and stress-strain curve method is very poor, and it is difficult for the existing evaluation methods to comprehensively consider various control factors (Fig. 10). (3) Fracturing physical modeling experiments differ greatly from real fracturing conditions in stress environment, specimen size, and rock mechanical properties. The existing numerical fracturing models are difficult to consider the effects of multi-scale heterogeneity of shale itself, which greatly limits the application range and prediction ability of the models. (4) Fracturing monitoring results show that under the current fracturing process, the fractures extend towards the horizontal component, the longitudinal extension of fractures is limited, the fracture height is generally less than 10 m, and the stimulation volume is limited. Therefore, multiple horizontal wells need to be arranged vertically to achieve the overall control of the sweet-spot sections.

Fig. 10.

Fig. 10.

Analysis results of different compressibility evaluation methods.

3.5. Changes of oil products and phase states and main controlling factors of adsorption-desorption transformation of Gulong shale oil

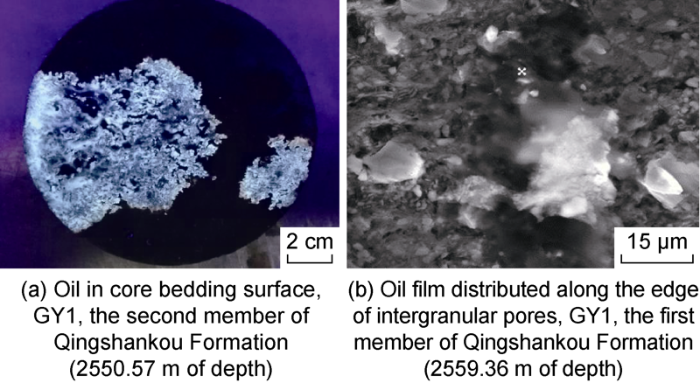

The existing test data show that the Gulong shale oil has the characteristics of low density (less than 0.84 g/cm3), low viscosity (less than 0.8 mPa•s), a high proportion of light hydrocarbon (average content of saturated hydrocarbon is 84.2%), and the positive correlation between gas-oil ratio and maturity. The oil content of Gulong shale oil is generally good. The measured oil saturation of the first member of the Qingshankou Formation is 26.1%-73.2%, with an average of 44.8%. Nuclear magnetic resonance (NMR) analysis shows movable oil saturation of 37.3%-50.6%, and the field 1D NMR oil saturation is 40.3%-80.2%, with an average of 58.0%. The microscopic observation of the environmental scanning electron microscope shows that the crude oil presents two forms of free state and adsorbed state, occurring in the two regions of matrix pores and bedding fractures, with high oil saturation and free state proportion (Fig. 11). However, current phase state studies cannot determine the impact of drastic temperature and pressure changes during pre-CO2 injection and sampling, and the characteristics of phase state in nano-scale porous media under reservoir conditions and the lateral distribution of phase state in shale oil production areas are not clear. At the same time, the research on the occurrence form and state of shale oil is still mainly based on static qualitative research, while the quantitative evaluation of the ratio of free hydrocarbon and adsorbed hydrocarbon and the study on the dynamic conversion law needs to be strengthened urgently.

Fig. 11.

Fig. 11.

Electron microscope analysis of oil occurrence state.

3.6. Liquid-solid and liquid-gas processes mechanism and enhanced oil recovery mechanism of Gulong shale oil

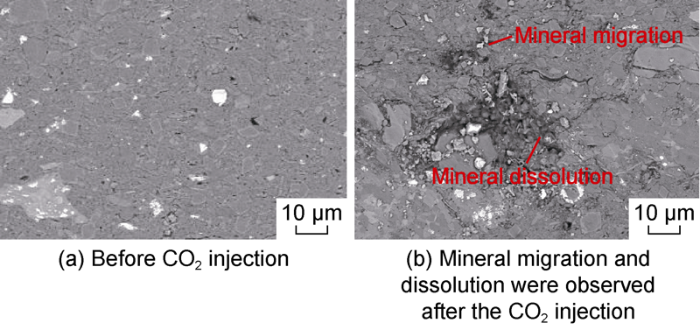

Recent work: (1) By revising the classical Kelvin equation, a new theory of nano-scale confined capillary condensation is preliminarily established, and the important role of solid-liquid interface mechanics in nano-scale/ submicron scale capillary condensation is expounded, and the latest experimental results and mechanical mechanism of this limit scale are reasonably explained[44-45]. (2) The microscopic origin of capillary force at the solid-liquid interface was studied, and the mechanism of force equilibrium at the droplet contact line was revealed. The reasonable explanation of Young's equation in the field of solid-liquid interface wetting was given from the perspective of mechanics, which provided a new understanding of interface wetting phenomena such as rock-oil interface wettability, erosion and fracture of oil droplets/oil film on the rock surface[46]. (3) Based on the study of multiphase seepage, the spatial distribution of gas and its changing relationship with time were explored, and the influence of degassing on the production process was clarified, that is, when the degassing formed a continuous gas path, the gas left the oil retained, and the pressure supplement efficiency was low. When the gas was expelled to form a bubble group, the gas retained and the oil left, and the pressure supplement efficiency was high. (4) The mechanism of EOR by pre-CO2 injection is preliminarily defined, that is, the extraction of organic matter by CO2and the dissolution of minerals such as K-feldspar, albite, calcite, generate new organic pore and dissolved inorganic pore effectively improve reservoir physical properties, but the accompanying migration of kaolinite particles and siderite precipitation can also cause damage to the seepage channels[47] (Fig. 12). The pore permeability test results show that under the soaking in 7 d, shale porosity increased from 5.37% to 7.81%, but the horizontal permeability decreased from 0.019× 10-3 μm2 to 0.002 × 10-3 μm2. However, on the whole, (1) There are relatively few studies on the basic theory of Gulong shale oil flow, and the effects of phase transformation, occurrence transformation, solid-liquid interaction, and other factors on the flow are not involved. (2) The influence mechanism and technical adaptability of pre-CO2 injection on enhancing energy and assisting drainage, artificial fracture morphology, porosity and permeability parameters in Gulong shale oil are not clear, and there is no basis for CO2 usage amount optimization.

Fig. 12.

Fig. 12.

Changes of microscopic morphology before and after CO2 injection in Gulong shale.

4. Research direction

Based on the understanding of the uniqueness of Gulong continental facies shale oil and the analysis of scientific problems, three research directions are sorted out, which are shale oil geological sweet-spot selection, engineering sweet-spot selection, and development plan selection.

4.1. Optimal selection of shale oil geological sweet spot

The genetic mechanism and distribution law of Gulong shale oil are complex, so it is necessary to further study the mechanism of hydrocarbon generation, displacement, storage, migration, and accumulation to guide the optimization of shale oil geological sweet spot.

4.1.1. Isochronous geologic framework and high-resolution chronograph

The technical advantages of the high-precision U-Pb isotopic age and astronomical chronology of volcanic ash zircons should be fully used. Based on the previous research results of Songke 1 well, the data of volcanic ash composition, horizon, and age of cores at different positions in the sag should be taken as isochronous geological events "anchor point". Combined with the analysis of cyclostratigraphy, the high-precision isochronous age framework of Qingshankou Formation in the sag with a resolution of 100 000 years is established, and the sedimentary time, geological events and sedimentary characteristics of each sequence and interval of Qingshankou Formation in the sag are defined, which are the "three-stage" and "nine-stage" types (Q1-Q9) of oil layers of Qingshankou Formation in the sag. The division provides a high-precision chronological scale to guide reservoir division and sweet-spot identification.

4.1.2. Transgression/lake flooding geological events and organic matter enrichment mechanism

High-resolution sampling and multi-index comprehensive analysis should be carried out for the possible horizon of transgression/lake flooding, and the occurrence of transgression should be determined by microfossils (such as marine foraminifera), special minerals (such as glauconite), and special biomarkers (such as 24-n-propylcholestane, 24-isopropylcholestane). Determine the variable depth of ancient lakes and sulphate supply source by pyrite sulfur isotope, determine the water salinity by B isotopes, determine the hypoxia degree of the water body and openness of the basin through Mo isotope, determine the oxidation-reduction environment of water body through the major and trace elements and iron composition, combined with basic organic geochemical characteristics, the time limit, stage, intensity and influence range of transgression of Qingshankou Formation in the sag were comprehensively determined, and the model of organic matter enrichment, water environment change, and hydrocarbon source rock development under transgression/lake flooding was established.

4.1.3. Periodic parameters and main controlling factors of shale laminae

High-resolution in-situ imaging scanning of magnetic susceptibility, grayscale, minerals, and elements of the selected core segment should be carried out by using the means of multi-dimensional and multi-scale quantitative description of laminar characteristics. At the same time, through the spectrum analysis and the deposition rate constraint, we identified the cycle period and the climate influencing factors and further defined the climate cycle of different scales (such as the Earth's rotation axis slope period of 17.3×104 years and 4×104 years, the Earth's orbital precession period of 2×104 years, the sunspot activity period of 10-50 years, the El Nino cycle of atmospheric circulation in 2-7 years, etc.) on the supply of debris, the enrichment of organic matter and the formation of laminae were further defined. The periodic parameters and main controlling factors for the formation of organic-rich layers, effective reservoirs, shale oil sweet-spot layers are put forward.

4.1.4. Evaluation and prediction of shale reservoir space and reserves

The sealing and pressure-holding technology for coring scheme should be implemented to effectively ensure that the pressure is not lost, the bedding surface is not damaged, and the natural gas is not escaping, and the technologies should be innovated to meet the requirements of multi-scale characterization of organic pore-inorganic pore, and the characteristics and effectiveness of the reservoir space of lamination-type, bedding-type and sandwich-type shale should be defined. Three-dimensional characterization of the occurrence, distribution, and connectivity of pores and fractures under near-formation conditions was carried out to identify the effectiveness and main influencing factors of bedding fractures, and quantitatively evaluate their contribution to reservoir space. On this basis, geological models were established for three types of shale respectively. Combined with the technologies of "iron pillar" well comprehensive analysis, well logging acquisition, experimental analysis, and so on, the reserves of Gulong shale were evaluated and predicted respectively based on volume method.

4.1.5. Formation overpressure law and shale oil migration and accumulation mechanism

It is necessary to determine the time limit for the generation and displacement of large amounts of oil and gas, and to clarify the time sequence relationship between the formation of conventional oil and Gulong shale oil in Daqing Changyuan. Also, it is necessary to establish a reliable residual hydrocarbon testing and recovery technology, accurately determine the content and composition of hydrocarbon in rocks, determine the hydrocarbon expulsion efficiency of source rocks, and further study the secondary cracking mechanism of residual hydrocarbon, and study its influence on the content and composition of residual hydrocarbon and formation of overpressure. Based on the analysis methods of tectonic stress field, temperature and pressure field, fluid field and so on, the integrated evaluation model of multi-type oil and gas formation model should be established, and the spatial distribution law of multi-type oil and gas should be defined. Based on the evolution process of shale hydrocarbon generation and expulsion, shale oil composition characteristics, pore characteristics and phase evolution rule of the reservoir, and dynamic evolution process, the sweet-spot evaluation index system was established to predict the geological sweet-spot intervals and sweet-spot area of Gulong shale oil.

4.2. Shale oil engineering sweet-spot selection

The controlling factors of clay mineral transformation and lamination structure in the Qingshankou Formation are complex, and there is no systematic understanding of compressibility and fracture-forming mechanism. Therefore, further research is needed to support the selection of engineering sweet spot and optimization of engineering design.

4.2.1. Mineralogical evolution and characteristics

We should comprehensively use XRD (X-ray diffraction), QEMSCAN (Quantitative mineral evaluation with scanning electron microscopy), in-situ Raman, and other analytical methods to study the types and contents of clay minerals, clarify the origin of clay minerals, and quantitatively evaluate the content of authigenic and sedimentary clay minerals. The types and contents of typical shale clay minerals at different depths and locations were studied to clarify the diagenetic evolution sequence of clay minerals and determine the disappearance line of montmorillonite and I/S mixed layers, to provide a reference for the evaluation of shale reservoir effectiveness, sensitivity, and compressibility.

4.2.2. Mechanical characteristics and damage mechanism of shale under in-situ environment

We should focus on the research and development of in-situ formation environment restoration and reconstruction experimental technology suitable for Gulong shale. By analyzing the mechanical properties differences of shale under in-situ environment, distinguish the anisotropic deformation intensity characteristic parameters and routine mechanical performance test parameters, analyzing the effect of in-situ environment and beddings on the mechanical characteristics of shale anisotropy mechanism, building a Gulong shale anisotropic gradual failure model considering the effects of mineral fabric and bedding weak surface for the borehole stability analysis, inversion of in-situ stress and construction of numerical fracturing model to provide experimental and theoretical support.

4.2.3. Fine evaluation of fracturing ability

The spatial distribution and microscopic mechanical parameters of lamination, organic matter, and various minerals should be obtained based on the multi-scale fine characterization and nano-indentation experiment method. Through multi-scale characterization from point (considering single point minerals, pores, and fractures) to surface (considering mineral fabric and heterogeneity) and then to volume (considering bedding and laminae), a fine evaluation method suitable for the fracturing ability of Gulong shale was established.

4.2.4. Fracture propagation mechanism and process optimization

In micro-scale, we should strive to develop shale fracture dynamic growth in-situ characterization method, realize the micro-CT in-situ fracturing, synchronous scanning, simulate the whole process of dynamic fracture growth in laminated shale, make clear about the action of micro-scale bedding laminae, mineral components, and spatial distribution of organic matter on the control of fracture growth and verify with the fracturing numerical model based on the digital core; on a macroscopic scale, we should explore the Gulong bedding-type, laminated shale fracture simulation model, analyze the process and fracture morphology of hydraulic fracturing under the real formation stress environment and engineering conditions, clarify the main controlling geological and engineering factors, and explore the new fracturing technology to effectively improve the longitudinal producing degree of reconstruction, so as to provide theoretical support for engineering design.

4.3. Optimization of shale oil development plan

Fluid phase characteristics and distribution, occurrence state, mobility, liquid-solid and liquid-gas interaction mechanism under formation conditions are complex, and needs to be further studied to guide the optimization of the development scheme and the selection of enhanced oil recovery technology.

4.3.1. Micromechanical effect and mobility evaluation of shale oil

Nano-scale pore model should be constructed and nanomechanical analysis should be carried out, and the applicability of classical theories such as Young's equation describing the wettability of solid-liquid interface and Kelvin equation describing the capillary condensation phenomenon in the complex environment under nano-scale of Gulong shale should be studied. The mechanical mechanism of the micro-interface is deeply analyzed to provide theoretical support for the experimental technology and characterization methods of the phase state and occurrence state of oil and gas in nano-scale pores; based on fine characterization testing technique, molecular simulation, and nanomechanics, quantitatively distinguish free oil from adsorbed oil, clear the occurrence status of shale oil and the distribution law, explore the interaction types and mechanisms between minerals, solid organic matter and crude oil, and clarify the influence of solid/liquid micro-interface interaction on the adsorption-free transition of crude oil. On this basis, to carry out study of the interface effect on shale with different components migrating in nano-scale channel, build a theory system of nano-scale limited domain mass transfer and correlation between molecular scale and the micro-nano scale material transport, which provides molecular simulation details and a new theoretical basis of micro-scale and nano-scale for the establishment of shale oil mobility evaluation method.

4.3.2. CO2 effect mechanism and adaptability evaluation

The study of Gulong shale CO2 fracturing and soaking experiments should be carried out. We should explore the fracture formation mechanism of Gulong shale with CO2 composite fracturing, clarify the change characteristics of minerals and physical properties before and after the action, explore the influence of bedding laminae on enhanced oil recovery, and define the effective scope of CO2 in the matrix-fracture network through macroscopic physical model and microscopic visual simulation. In the process of shale oil development, it is necessary to explore the non-equilibrium gas-liquid phase variation law and its influence on oil and gas flow under different pore structures, fluid characteristics and dynamic pressure conditions, clarify the influence of pressure change on the system phase transition and oil flow, and guide the optimization of CO2 consumption and production system. Also, pay attention to the effect of CO2 pre-injection on the phase state of Gulong shale oil.

4.3.3. Well pattern, well spacing optimization, and production decline law

Gulong shale is characterized by development of bedding fractures, poor vertical perforation ability of fracturing, and great difference in vertical and horizontal flow ability. The flow law of oil, gas and water multi- phase fluid in different scale pores and fractures is complex, there is a lack of mature experience and practice for reference in well pattern and well spacing design, and the adaptability of traditional productivity evaluation and EUR prediction methods is poor. Firstly, the geological model of the test area should be established to quantitatively characterize the heterogeneity of the sweet spot and the cross-scale flow model considering the complex flow mechanism. Combined with the geological and engineering integration method, the reasonable well pattern and well spacing in the test area should be determined to optimize the reasonable production system. Secondly, the production decline model of shale oil should be improved according to the complex phase transition, special occurrence law and multi-phase and multi-component flow characteristics of Gulong shale oil, and the effect of well pattern and well spacing should be comprehensively considered to further improve the decline analysis method, to improve the reliability of EUR prediction. Thirdly, the complex flow mechanism of Gulong shale oil should be considered, and a characteristic well test model and interpretation method should be established to quantitatively evaluate formation pressure, effective fracture length, flow capacity and other parameters, so as to predict future production performance and EUR.

5. Conclusions

For more than 50 years, Daqing oil field relied on two theories which are “on contradiction” and “on practice”, and formed an oilfield exploration and development theory and technical system based on Daqing characteristics. Engineering technology needs to find out the main contradictions that restrict the efficient development of oilfields, and solve key scientific problems. At the same time, forming corresponding characteristic technologies support the stable production of oilfields in different development stages, which provides a strong technical guarantee for oilfield development project.

Currently, Gulong shale oil has superior geological conditions and a huge resource base and broad prospect for exploration and development, which is an important replacement field for Daqing Oilfield. Through recent years' research and breakthrough, we have initially achieved key understanding and important achievements. However, it should be clearly understood that Gulong shale oil is a new type of resource, with distinctive characteristics in reservoir property, oil bearing property, mobility, and compression, and there is no precedent for large-scale commercial development in the world. Facing the new field, we should adhere to the cognitive development law of "practice, understanding, re-practice, re-understanding" and the principle of "unity of opposites" to reveal the development of the movement. We should start with discovering and finding solutions to scientific problems and then solve engineering problems through technological innovation. First of all, in the complicated continental shale oil exploration and development process, many contradictions have been gradually discovered, among which the main contradiction is the scientific problem. Only by summarizing the rules and finding a better way to explain the contradictions and difficult problems, the solution and development of technical and engineering problems can be significantly affected. Secondly, technical problems are the continuous iteration of the cognition of scientific problems and are all kinds of process methods and skills developed according to production practice or scientific principles. Only by constantly developing new methods, means, measures, or approaches, the project implementation can be effectively supported. Finally, engineering problems are complex problems encountered in the production process, which need the form of "practice, understanding, re-practice, re-understanding" to meet the needs of oilfield development step by step. In continuous practice, problems can be found, ideas can be adjusted, and problems can be finally solved. If we focus on solving major engineering problems at the very beginning, even the basic scientific problems cannot be solved well, it will not be able to effectively support the large-scale and efficient development of Gulong shale oil in the long term.

The success of the Gulong shale oil study must highlight the guiding and promoting role of theory and technological innovation. Therefore, we sincerely invite global talents to contribute wisdom and strength to the scale development and benefits of Gulong shale oil and put forward some forward-looking, strategic, and overall suggestions for the development of the Daqing oilfield. The core competitiveness, sustainable and high-quality development ability should be constantly enhanced, making new contributions to the sustainable development of Daqing oilfield.

During the process of researching and writing this paper, we have received guidance and help from experts and researchers in “the Gulong Shale Oil Major Geological Basis and Engineering Practice Collaborative Research” project team of Daqing Oilfield Exploration and Development Research Institute and PetroChina Research Institute of Petroleum Exploration & Development, and other relevant experts and researchers. We express thanks to them.

Acknowledgments

During the process of researching and writing this paper, we have received guidance and help from experts and researchers in “the Gulong Shale Oil Major Geological Basis and Engineering Practice Collaborative Research” project team of Daqing Oilfield Exploration and Development Research Institute and PetroChina Research Institute of Petroleum Exploration & Development, and other relevant experts and researchers. We express thanks to them.

Reference

Gulong shale oil preface

Production test analysis and productivity prediction of horizontal wells in Gulong shale oil reservoirs, Songliao Basin

Resource potential and exploration direction of Gulong shale oil in Songliao Basin

Development characteristics and orientation of tight oil and gas in China

Types and resource potential of continental shale oil in China and its boundary with tight oil

DOI:10.1016/S1876-3804(20)60001-5 URL [Cited within: 1]

Analyses of the mudstone(shale) oil exploration potential in North Sondiao Basin

Progress, challenges and key issues of unconventional oil and gas development of CNPCI

Shale oil exploration and production in the U. S.: Status and outlook

Nanoscale pore structure characterization of the Bakken shale in the USA

DOI:10.1016/j.fuel.2017.08.034 URL [Cited within: 1]

Rock characterization in unconventional reservoirs: A comparative study of Bakken, Eagle Ford, and Niobrara formations

Revitalization and development strategy of Daqing oilfield

Geological conditions and exploration potential of shale oil in Qingshankou Formation, Northern Songliao Basin

Experimental study on surface-active polymer flooding for enhanced oil recovery: A case study of Daqing placanticline oilfield, NE China

Strategic significance and research direction for Gulong shale oil

Thoughts on the development life of oilfield

Petrological characteristics and shale oil enrichment of lacustrine fine-grained sedimentary system: A case study of organic-rich shale in first member of Cretaceous Qingshankou Formation in Gulong Sag, Songliao Basin, NE China

Microscale comprehensive evaluation of continental shale oil recoverability

Geological theory and exploration & development practice of hydrocarbon accumulation inside continental source kitchens

Pore characteristics of continental shale and its impact on storage of shale oil in northern Songliao Basin

Characteristics and distribution of sweet spots in Gulong shale oil reserviors of Songliao Basin

Characteristics of petroleum generation and expulsion in abnormal pressure shale zones and the formation of fractured shale reservoirs

Development potential and technical strategy of continental shale oil in China

“Exploring petroleum inside source kitchen”: Connotation and prospects of source rock oil and gas

DOI:10.1016/S1876-3804(19)30017-5 URL [Cited within: 1]

Enlightenment from formation conditions and enrichment characteristics of marine shale oil in North America

Geochemical assessment and characterization of petroleum source rocks and oils, and petroleum systems, Permian Basin, US

Reservoir space and enrichment model of shale oil in the first member of Cretaceous Qingshankou Formation in the Changling sag, southern Songliao Basin, NE China

The diagenesis evolution and accumulating performance of the mud shale in Qingshankou Formation in Gulong area, Songliao Basin

Global shale oil development and prospects

A big data study: Correlation between EUR and petrophysics/engineering/production parameters in shale formations by data regression and interpolation analysis

Rock characterization in unconventional reservoirs: A comparative study of Bakken, Eagle Ford, and Niobrara formations

Rock typing in Eagle Ford, Barnett, and Woodford Formations

Geological characteristics, resource potential and exploration direction of shale oil in middle-lower Permian, Junggar Basin

The geological characteristics and the progress on exploration and development of shale oil in Chang 7 Member of Mesozoic Yanchang Formation, Ordos Basin

Enlightenments of American shale oil research towards China

Technological progress in re-fracturing of US shale oil and gas wells for higher production factor

Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China

Characteristics of the continental Cretaceous in the Songliao Basin

Microfossils and molecular records in oil shales of the Songliao Basin and implications for paleo-depositional environment

DOI:10.1007/s11430-009-0121-0 URL [Cited within: 1]

Seawater incursion events in a Cretaceous paleo-lake revealed by specific marine biological markers

Organic matter characteristics and shale oil formation of Gulong shale in Songliao Basin

Organic geochemical characteristics and paleosedimentary environments of the source rocks in member 1 of the Qingshankou Formation

The floating astronomical time scale for the terrestrial Late Cretaceous Qingshankou Formation from the Songliao Basin of Northeast China and its stratigraphic and paleoclimate implications

DOI:10.1016/j.epsl.2008.12.016 URL [Cited within: 1]

Capillary condensation under atomic-scale confinement

DOI:10.1038/s41586-020-2978-1 URL [Cited within: 1]

Do shale pore throats have a threshold diameter for oil storage?

Microscopic origin of capillary force balance at contact line

DOI:10.1103/PhysRevLett.124.125502 URL [Cited within: 1]

Evolution characteristics of mechanical properties under supercritical carbon dioxide treatment in shale reservoirs

DOI:10.1021/acsomega.0c05136 URL [Cited within: 1]