Introduction

Shale oil production in North America has shown a rapid growth trend. Industrial oil flows have been successively discovered in shale strata of the Changqing, Daqing, Dagang and Xinjiang oilfields, China, showing good prospects for exploration and development of shale oil and gas. Shale oil and gas exploration and development in China started late but developed rapidly, which is expected to become a new growth point of oil and gas reserves. Shale oil exists in micro and nano pores of shale and can only be produced by artificial fracturing[1⇓⇓⇓⇓⇓⇓⇓⇓⇓-11]. The elastic production energy of shale oil decreases rapidly and the production declines rapidly. After the staged fracturing of horizontal wells in shale oil reservoirs, the initial oil production rate is high, but the production decreases rapidly. A large amount of crude oil is trapped in the pores of shale reservoir, and the water injection effect is poor, making it difficult to replenish energy and connect matrix and fractures in the shale oil reservoir. It is urgent to develop shale oil EOR technology. CO2 is one of the most commonly used oil displacement agents. When pressure is higher than 7.39 MPa, the temperature is higher than 31.06 °C, CO2 is in supercritical condition. Supercritical CO2 can seep into micro and nano pores and interact with crude oil, to reduce the interfacial tension and viscosity of crude oil, expand the volume of crude oil and extract light components of crude oil. Therefore, CO2 injection is one of the effective methods to improve oil and gas recovery. At present, it has been widely used in conventional oil and gas development at home and abroad, but its application in unconventional oil and gas development is still in the exploratory stage[12⇓⇓⇓⇓⇓⇓⇓⇓⇓-22]. It is of great significance to study the influencing factors of CO2 injection into shale reservoirs for exploring development and recovery technology of shale oil[23⇓-25]. At present, some basic researches in this field have been carried out at home and abroad: (1) Study on the mechanisms of CO2 huff and puff on shale core[26⇓-28]; (2) Study on the influence of miscible CO2flooding on shale core oil displacement efficiency[29-30]; (3) Experimental study on comparison of CO2 huff and puff displacement efficiency of shale cores and conventional oil and gas reservoir cores[31]; (4) Comparative experimental study on oil displacement efficiency of CO2flooding and mixed gas flooding in shale cores[32]. These basic studies are mainly carried out on the basis of CT technology and conventional experimental equipment, but there are few reports on the experimental studies on EOR by CO2 injection of shale cores under high temperature and high pressure using NMR technology. Compared with CT and conventional experimental equipment, NMR technology can more effectively identify fluid changes and remaining oil distribution in the pores of shale cores.

In this study, NMR was used to test the factors affecting CO2injection in shale oil reservoir online, observing the crude oil recovery process and remaining oil distribution in real time, and analyze the effects of pressure, temperature, acting time, fracture development degree on CO2flooding, in the hope to provide technical support for evaluating CO2flooding effect in shale oil reservoirs.

1. Experiment

1.1. Principle

The oil-bearing (or water-bearing) shale cores were measured by NMR equipment to get T2 spectra. The fluid in large pores is less affected by the force of the solid surface, and thus has slow relaxation rate and large T2value. On the contrary, the fluid in small pores is greatly affected by the force of the solid surface, and thus has fast relaxation rate and small T2 value. The physical meaning of T2value in the reservoir is the proportion of pores of different sizes in the core to total pores. The relationship between T2 value of fluid and pore size in rock can be expressed as[33-34]:

where

The surface relaxation rate ρ and the pore shape factor F in the core can be approximately regarded as constants, so the conversion coefficient C is also a constant value. After obtaining the value of C, the NMR T2 spectrum can be converted into pore radius distribution map.

Since pores in shale cores are nanoscale, the molecular sieve with the known pore sizes ranging from 4 nm to 11 nm was used as standard sample to conduct experiments to determine the conversion coefficient C. The experimental steps are as follows: firstly, the molecular sieve sample was vacuumed with a molecular vacuum pump and saturated with water under pressure, and then the NMR T2spectrum of the molecular sieve sample was tested.

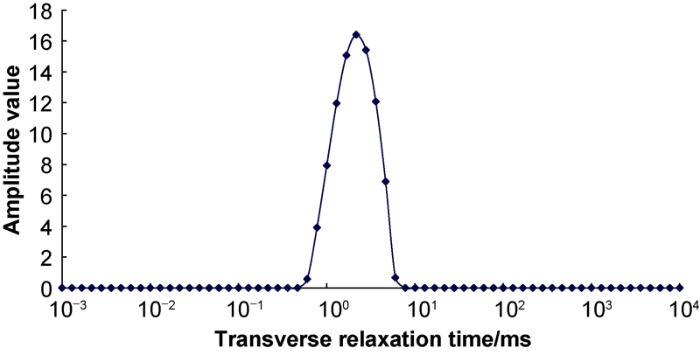

The mean T2value of the molecular sieve sample was calculated as 2.45 ms by the abscissa of the NMR T2 spectrum (Fig. 1). The pore size range of the molecular sieve sample is known as 4-11 nm. Taking 1 nm as a unit, the average pore size was increased by 1 nm evenly at 8 points, and the average pore size was 7.5 nm. The C value was calculated by Eq. (1) as 0.327 ms/μm. After obtaining the value ofC, the transverse relaxation time of the NMR T2 spectrum of the shale core tested in the experiment can be converted into pore size, and the shale reservoir rock samples can be analyzed by NMR T2spectrum.

Fig. 1.

Fig. 1.

NMR T2spectrum of the molecular sieve sample.

Nuclear magnetic resonance imaging is to superpose a gradient magnetic field on the static magnetic field, so as to establish the relationship between the resonance frequency of the magnetic resonance signal and the location of the nuclear, then fast Fourier transform, image reconstruction and other technologies are used to obtain the nuclear magnetic resonance image. Nuclear magnetic resonance imaging can obtain 2D and 3D images of rock samples at any slicing direction and slicing thickness. The gray signal of the image, that is brightness, indicate the distribution of oil and water in the core, the brighter the gray scale, the more oil and water content in the core is. On the contrary, the darker the gray scale, the more tight the core, and the fewer the oil and water are in the pores.

1.2. Method

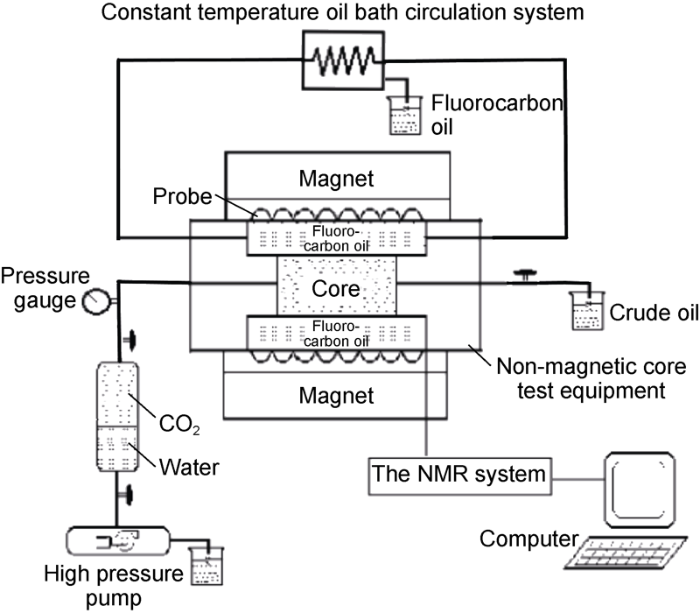

1.2.1. Effect of action time on EOR by CO2 flooding

The experimental system of high-temperature and high-pressure CO2 flooding monitored by NMR online (Fig. 2) consists of three subsystems: (1) The non-magnetic core experimental device. In this device, fluorocarbon oil, as a circulating fluid, is heated and controlled through the constant temperature oil bath circulation system. The maximum pressure of the experimental device is 55 MPa and the maximum temperature is 90 °C, which can simulate supercritical CO2 flooding. (2) Fluid displacement system, in which high pressure pump is used to inject CO2 to displace oil in shale core online. (3) The NMR system, with the shortest echo time of 0.06 ms, can detect signals of the fluid in nanopore pores of the shale core, and can obtain NMR image and T2 spectrum online.

Fig. 2.

Fig. 2.

Schematic diagram of high-temperature and high- pressure CO2 flooding monitored by NMR online in shale core.

The experiment on the effect of action time on CO2flooding was carried out on 2 shale cores from Well Liye 1, Jiyang Depression, Bohai Bay Basin. The basic physical property parameters of the cores are shown in Table 1. The experimental steps are as follows: (1) The simulated oil was prepared with the viscosity of 3.8 MPa·s at 45 °C; (2) The crude oil in the shale core was washed with organic solvent and then dried. The shale core was vacuumed by molecular vacuum pump, and then heated to 110 °C in a thermostatic chamber. (3) After the oil sample was injected into the shale core with an injection pump, the pressure was slowly increased to 65 MPa, and the shale core was saturated with oil at 65 MPa for 1 week to achieve the saturation and aging as far as possible; (4) The core saturated with oil was put in the middle of the non-magnetic core experimental device, with clearance left between the device wall and the core, which was simulated as fracture. All surfaces of the core were in contact with CO2, and then the non-magnetic core experimental device was put into the probe of the nuclear magnetic resonance equipment. (5) The core was heated to 40 °C, and scanned after the temperature of the core was stabilized to obtain T2 spectrum of the core saturated with oil in the initial state, and then CO2 was injected into the core by a high pressure pump. (6) When the CO2 injection pressure reached 8 MPa, the injection was stopped, the inlet and outlet of the experimental device were closed, the temperature and pressure were kept constant, and the NMR T2spectra were tested at the operating time (simulated CO2soaking time) of 0.5, 4.0, 20.0, 30.0, 40.0 h.

Table 1. Physical parameters of experimental samples at different action times.

| Sample No. | Diameter/cm | Length/cm | Porosity/% | Permeability/10-3 μm2 |

|---|---|---|---|---|

| 5-18-27-1 | 2.49 | 6.31 | 7.1 | 0.08 |

| 5-18-27-4 | 2.48 | 6.43 | 7.4 | 0.07 |

The minimum miscibility pressure between CO2 and the simulated oil was measured at 25.6 MPa by long and thin tube experiment. The experimental pressure and temperature were higher than the critical CO2 pressure of 7.39 MPa and temperature of 31.06 °C. Therefore, CO2 in the experiment was in a supercritical state and immiscible condition. The soaking time of domestic and foreign CO2huff and puff oil production is 0.5-30.0 d for vertical wells and 2-60 d for horizontal wells. According to the scale of producing oil reserves, the soaking time converted for the core is 0.5-120.0 h, so the soaking time of the experiment was designed at 0.5-40.0 h.

1.2.2. Effect of injection pressure on EOR by CO2 flooding

Four oil-saturated shale cores of Well Liye 1 in Jiyang depression with similar properties were selected to carry out experiments for the effect of injection pressure on CO2injection to enhance oil recovery. Basic physical property parameters of the cores are shown in Table 2. The experimental steps are as follows: (1) Put the oil-saturated core in the non-magnetic core experimental device, and then the non-magnetic core experimental device was put in the probe of the nuclear magnetic resonance equipment. (2) The core was heated to 40 °C and scanned after the core temperature was stabilized to obtain the T2 spectrum of the oil-saturated core in the initial state. (3) CO2 was injected into the core by a high pressure pump, the injection was stopped when CO2 reached supercritical state at the pressures of 8, 12, 15 and 18 MPa, respectively. Closing the experimental device inlet and outlet at each CO2 injection pressure, keep the temperature and pressure unchanged, and the NMR T2 spectrum was tested at the action time of 30 h at each pressure.

Table 2. Physical parameters of the samples under different pressures.

| Sample No. | Diameter/cm | Length/cm | Porosity/% | Permeability/10-3 μm2 |

|---|---|---|---|---|

| 5-18-27-4 | 2.48 | 6.43 | 7.4 | 0.070 |

| 5-18-27-5 | 2.49 | 6.51 | 7.2 | 0.068 |

| 5-18-27-6 | 2.48 | 6.45 | 7.1 | 0.071 |

| 5-18-27-2 | 2.49 | 6.53 | 7.0 | 0.072 |

The test results show that the starting pressure gradient of the core was in the range of 0.1 MPa/m to 0.8 MPa/m, the pressure at the injection end of the core was 4-32 MPa, and the critical CO2 pressure was 7.39 MPa. In order to reveal the effect of injection pressure on EOR by supercritical CO2flooding, the injection pressure was designed at 8-18 MPa.

1.2.3. Effect of temperature on EOR by CO2 flooding

Four oil-saturated shale cores of Well Liye 1 in Jiyang depression with similar properties were selected to carry out experiments on the influence of temperature on CO2 flooding to enhance oil recovery. Basic physical property parameters of the cores are shown in Table 3. The experimental steps are as follows: (1) Put the oil-saturated core in the non-magnetic core experimental device, and then put the non-magnetic core experimental device in the probe of the nuclear magnetic resonance equipment; (2) The core was heated to 35 °C (CO2 supercritical temperature condition). After the temperature was stabilized, scanning the core to obtain the T2spectrum of the oil-saturated core in the initial state. Then a high-pressure pump was used to inject CO2into the core. When the injection pressure of CO2 reached 9.5 MPa, the injection was stopped, the inlet and outlet of the experimental device were closed, the temperature and pressure were kept unchanged, and NMR T2 spectrum was tested at 30 h of flooding. (3) The core was heated to 40, 50, 60 °C respectively (reaching CO2supercritical state temperature condition), NMR T2 spectrum was tested at each temperature.

Table 3. Physical parameters of the experimental samples at different temperatures.

| Sample No. | Diameter/cm | Length/cm | Porosity/% | Permeability/10-3 μm2 |

|---|---|---|---|---|

| 5-20-27-3 | 2.48 | 6.8 | 6.2 | 0.056 |

| 5-20-27-4 | 2.49 | 6.2 | 6.8 | 0.051 |

| 5-20-27-5 | 2.49 | 6.5 | 6.7 | 0.054 |

| 5-20-27-6 | 2.48 | 6.6 | 6.1 | 0.053 |

During the CO2 injection process, the formation temperature changed little and could be ignored. However, considering the cold damage that might occur near the bottom of the well, the bottom temperature was between 60 and 90 °C. The numerical simulation results show that the maximum temperature change range after CO2 injection was 10-30 °C, so according to the formation temperature of 80 °C (calculated based on the buried depth), considering the temperature resistance index of the experimental equipment, the design temperature range was 35-60 °C.

1.2.4. Effect of fracture development degree on EOR by CO2 flooding

Fractures are the key to shale oil enrichment and production. Based on the observation of outcrops and drilling cores, combined with imaging logging data, it is found that there are mainly structural fractures, interbedded lamination fractures, plane slip fractures, diagenetic shrinkage microfractures, and abnormal pressure fractures from organic matter evolution in the shale. To some extent, the existence of microfractures improves the effectiveness of reservoir, improves the flow ability of shale, and provides migration channels for shale oil to move from matrix pores to wells. Because shale reservoirs are very low in permeability, they usually need to be artificially fractured to produce. The artificial fractures and natural fractures together form a complex fracture network. Fractures not only provide flow channels for CO2, but also promote the material exchange between fractures and matrix. The length, combination and morphology of fractures have great influences on shale oil development.

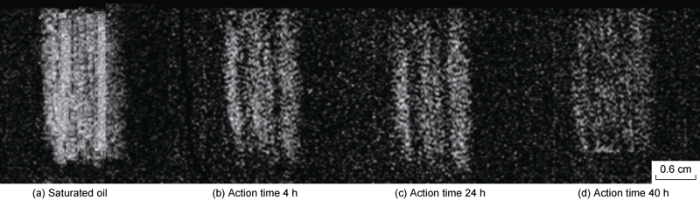

Two oil-saturated shale cores from Well Liye 1, Jiyang Depression were selected to carry out CO2 flooding experiment in matrix cores. Basic physical parameters of the cores are shown in Table 4. The experimental steps are as follows: (1) Put the oil-saturated core in the non-magnetic core experimental device, and then put the non-magnetic core experimental device in the probe of the nuclear magnetic resonance equipment. (2) The core was heated to 40 °C. After the core temperature was stabilized, scanning the core to obtain the NMR image of the oil-saturated core in the initial state. Then CO2 was injected into the core by a high-pressure pump, and the injection stopped when the CO2pressure reached 9.5 MPa. (3) The inlet and outlet of the experimental device were closed, and keep the temperature and pressure constant, the NMR images were tested at 4, 24 and 40 h. The images were 256×256 in matrix, and taken at FOV (field of view) of 80 mm with slice thickness of 30 mm. The images contain the distribution information of oil in the whole core.

Table 4. Physical parameters of the matrix core samples.

| Sample No. | Diameter/cm | Length/cm | Porosity/% | Permeability/10-3 μm2 |

|---|---|---|---|---|

| 5-1-26 | 2.49 | 6.71 | 6.2 | 0.03 |

| 5-20-27 | 2.48 | 6.83 | 6.6 | 0.05 |

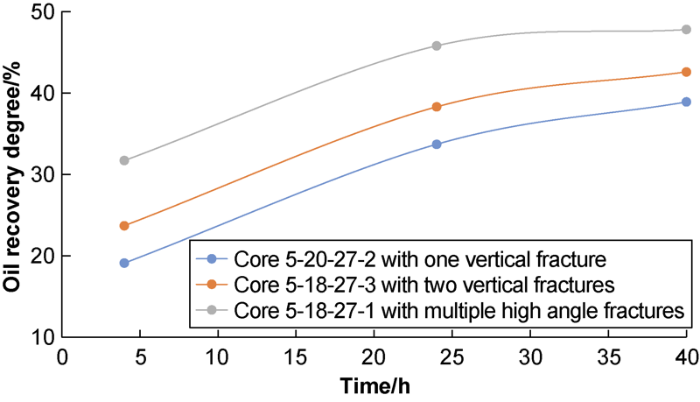

Three shale cores from Well Liye 1, Jiyang Depression were selected to carry out CO2 injection experiment on fracture-matrix cores. The basic physical parameters of the cores are shown in Table 5. The experiment procedure is the same as the CO2 injection experiment on matrix cores. Fractures mainly increase the contact area between CO2 and matrix, and the ratio of the increased contact area to the initial area of the core is defined as the evaluation index of experimental fracture. Three fracture shapes were designed, which were vertical single fracture, vertical double fractures and high angle multiple fractures (three or more fractures in the core were defined as multiple fractures). The specific parameters of fractures are shown in Table 6.

Table 5. Physical parameters of the fracture-matrix core samples.

| Sample No. | Diameter/cm | Length/cm | Porosity/% | Permeability/10-3 μm2 |

|---|---|---|---|---|

| 5-18-27-1 | 2.49 | 6.3 | 7.1 | 0.080 |

| 5-18-27-3 | 2.49 | 6.5 | 7.1 | 0.071 |

| 5-20-27-2 | 2.48 | 6.8 | 6.7 | 0.050 |

Table 6. Specific parameters of fractures with different shapes.

| Sample No. | Fracture shape | Core length/cm | Evaluation index |

|---|---|---|---|

| 5-20-27-2 | Vertical single fracture | 6.8 | 1.53 |

| 5-18-27-3 | Vertical double fractures | 6.5 | 1.95 |

| 5-18-27-1 | Multiple high angle fractures | 6.3 | 2.68 |

2. Results and analysis

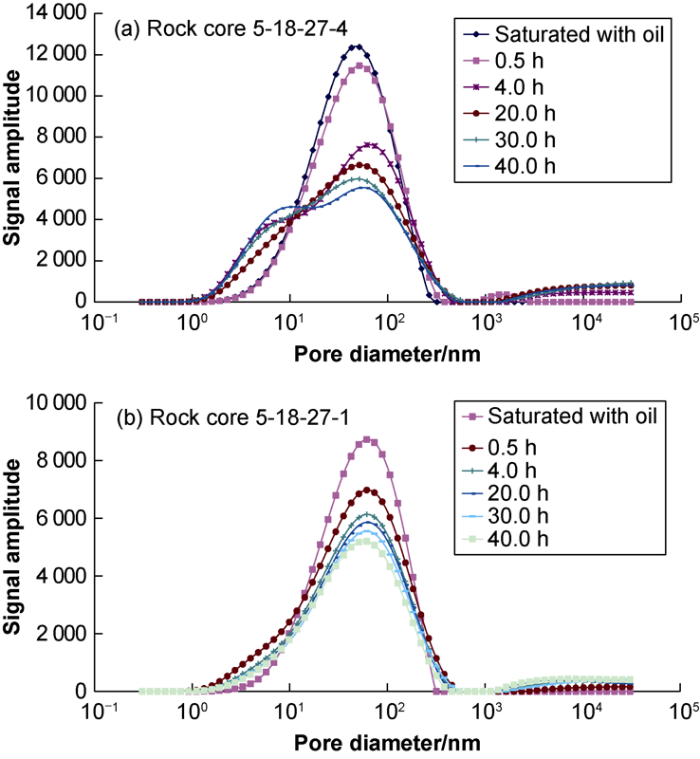

2.1. Effect of CO2action time on EOR

The principle of studying CO2 flooding in shale oil reservoir by NMR test is as follows: CO2has no signal in the NMR T2 spectrum, while oil has signal. The signal volume of NMR T2spectrum reflects the distribution characteristics of oil in pores of different sizes. By comparing the signal volume and distribution characteristics of NMR T2 spectrum at different action times, the quantitative results of oil displaced by CO2 in pores and the distribution position and retained amount of oil in the cores can be obtained. It can be seen from Fig. 3 that shale oil mainly occurs in pores of 3-664 nm in diameter, with the extension of action time, the amplitude of T2 spectrum decreases continuously, indicating that oil in pores of different sizes (mainly 14-664 nm) of the shale core is extracted continuously under the action of CO2, and the oil in pores less than 14 nm in diameter has no contribution to the recovery degree. While the oil is displaced, the T2spectrum amplitude of the pores below 14 nm increases slightly, indicating that the CO2 diffusion process would carry a small part of light oil into the pores below 14 nm to increase the oil saturation in the micro-pores. The T2 spectral amplitude of pores above 664 nm also increases slightly, because some crude oil is expelled from these pores and then attached to the surface of the core, and the amount of crude oil discharged increases with the increase of action time.

Fig. 3.

Fig. 3.

NMR T2 spectra of cores at different CO2 action times.

In order to evaluate the recovery degree of shale oil by CO2 injection, the oil recovery degree was calculated according to the NMR T2 spectrum area as:

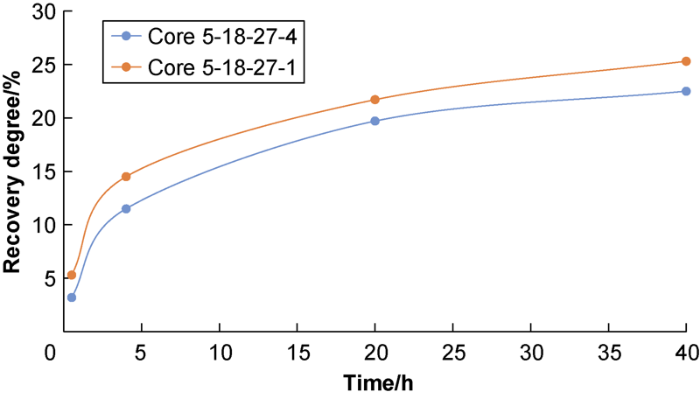

The calculated total recovery degrees at different action times are shown in Fig. 4. It can be seen that with the extension of CO2 injection time and extraction of the oil in the pores of the core, the recovery degree gradually increases. When the action time is 30-40 h, the recovery degree tends stable. The recovery degrees of Core 5-18-27-4 and 5-18-27-1 at 40 h were 22.5% and 25.3%, respectively, indicating that appropriately prolong the CO2 action time is beneficial to oil recovery.

Fig. 4.

Fig. 4.

Influence of action time on recovery degree.

Table 7. The proportions of oil recovered from pores of different sizes to the total oil recovered at the action time of 40 h.

| Sample No. | Total recovery degree/% | The proportions of oil recovered from pores of different sizes to the total oil recovered/% | ||

|---|---|---|---|---|

| 14-100 nm | 100-664 nm | Above 664 nm | ||

| 5-18-27-4 | 22.5 | 60.0 | 11.5 | 28.5 |

| 5-18-27-1 | 25.3 | 55.0 | 23.3 | 21.7 |

2.2. Effect of CO2 injection pressure on EOR

Pressure is a key influencing factor in the process of CO2 injection in shale oil reservoir, which has an important influence on the degree of oil recovery. Under a constant temperature, the higher the pressure of the supercritical CO2, the higher the density of the fluid, the stronger the solvation ability and diffusion ability of the solvent will be. At the same time, with the gradual rise of pressure, the solubility of solute in supercritical CO2 fluid will increase sharply.

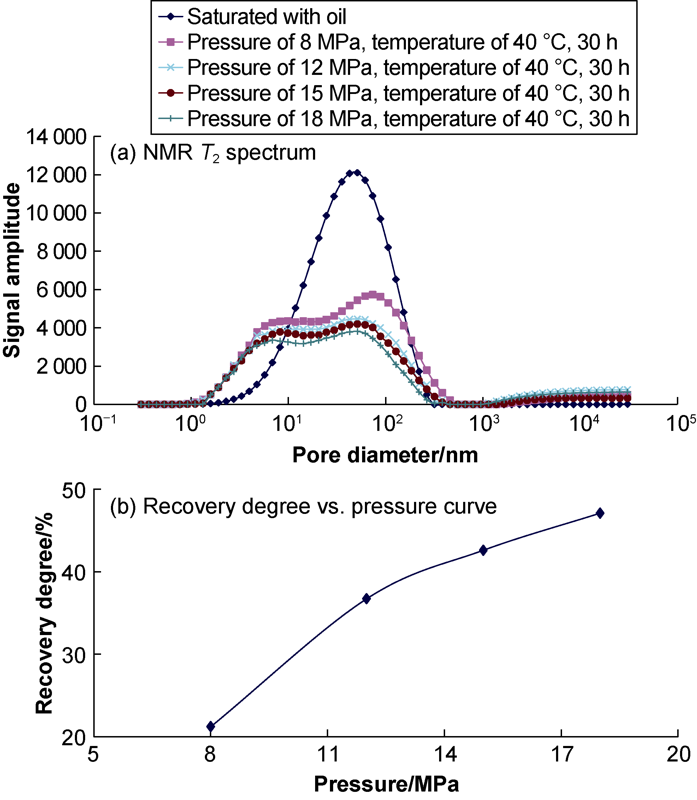

The NMR T2 spectral test results of Core 5-18-27-5 among the four shale cores with similar properties are shown in Fig. 5a. It can be seen that with the increase of pressure, T2 spectrum amplitude value declines gradually, indicating that oil recovery degree increases constantly. At the pressure of 8, 12, 15 and 18 MPa, the oil in the pores of 11-384 nm, 9-384 nm, 8-384 nm and 6-384 nm in size were recovered respectively, indicating that the oil in the pores of smaller sizes was recovered with the increase of pressure. At the pressure of 8, 12, 15 and 18 MPa, the T2 spectrum amplitudes of the pores below 11, 9, 8, 6 nm respectively increase slightly, which is caused by the CO2carrying a small part of oil diffusing into micro-pores with smaller size, making the remaining oil in the core redistribute. The T2 spectrum amplitude of pores above 384 nm in size increases because a portion of crude oil is expelled from these pores and attached to the core surface as pressure increases.

Fig. 5.

Fig. 5.

Influence of pressure on recovery degree of Core 5-18-27-5.

Based on the area of T2spectrum shown in Fig. 5a, the variation curve of oil recovery degree with pressure is obtained, as shown in Fig. 5b. The oil recovery degrees at the injection pressure of 8, 12, 15 and 18 MPa are 21.2%, 36.7%, 42.6% and 47.1%, respectively. With the rise of pressure, the oil recovery degree gradually increases, because with the increase of pressure, the density of CO2 gradually increases, the mass transfer distance is changed, and the dissolving capacity of CO2 to crude oil is enhanced. Moreover, with the increase of pressure, the action energy inside CO2 is close to that inside crude oil. According to the principle of similar phase dissolution, the solubility of crude oil in CO2 also increases correspondingly, and then the recovery degree increases.

The results of the other 3 cores are similar to Core 5-18-27-5, so the details are not nessacery here.

2.3. Effect of temperature on EOR by CO2 flooding

Temperature has complex effect on shale oil recovery in CO2 flooding. Generally, with the increase of temperature, the lowest value of solubility of the material in supercritical CO2 fluid often appears. Temperature has two effects on the solubility of substances in supercritical CO2 fluid: one is the effect of temperature on the density of supercritical CO2 fluid; the other is the effect of temperature on the vapor pressure of the substance.

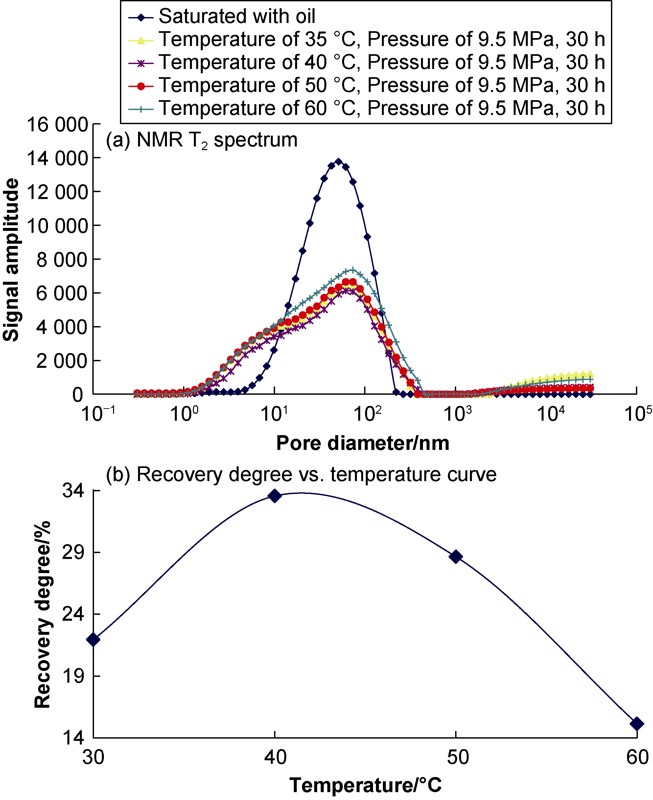

The NMR T2spectrum test results of Core 5-20-27-3 among the four shale cores with similar properties are shown in Fig. 6a. It can be seen that at 35, 40, 50 and 60 °C, oil is recovered from pores of 14-266, 11-266, 14-266 and 17-266 nm in size respectively. At the temperatures of 35, 40, 50 and 60 °C, a small part of oil enters the micro-pores below 14, 11, 14, 17 nm, respectively, making the remaining oil in the core redistribute. A proportion of the crude oil in the pores above 266 nm is expelled from the pores and attached to the core surface.

Fig. 6.

Fig. 6.

Effect of temperature of Core 5-20-27-3 on EOR.

Based on the area of T2 spectrum shown in Fig. 6a, the variation curves of oil recovery degree with temperature are obtained, as shown in Fig. 6b. The oil recovery degrees at 35, 40, 50 and 60 °C are 21.7%, 33.3%, 28.4% and 14.9%, respectively. With the rise of temperature, the recovery degree increases first and then decreases gradually. This is because as the temperature increases the density of CO2decreases, although the rise of temperature will increase the volatility and diffusion coefficient of crude oil, this can't make up for the decrease of solubility caused by the drop of CO2 density; moreover when the extraction temperature increases, the CO2 as an extraction agent will increase in molecular spacing, and thus decrease in intermolecular force, so the density of CO2 will reduce, eventually leading to the decline of its dissolution capacity.

The experimental results of the other three cores are similar to Core 5-20-27-3, and the details are not nessacery here.

2.4. Influence of fracture development degree on EOR by CO2 flooding

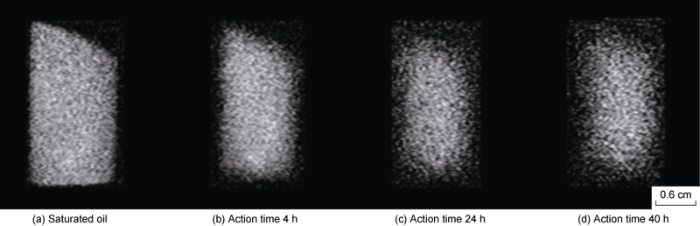

2.4.1. The matrix cores

The NMR images of the two matrix cores are shown in Figs. 7 and 8. The gray signal in the images, namely the brightness, represents the distribution of oil in the cores. In Fig. 7, the image of the oil-saturated core has relatively uniform distribution of gray value. Compared with the image of the oil-saturated core, it can be seen that the image of the core after 4 h has darker gray value at the edge, indicating that CO2 begins to diffuse into the core to displace the oil in the core edge. The images of the core after 24 and 40 h show more extension of darker gray part to the inside of the core, that means CO2gradually diffuses to the inside of the core and the oil inside the core is produced. In Fig. 8, the images of the oil-saturated core also show uniform gray value distribution. Compared with the images in Fig. 7, the image of the core after 4 h of action time in Fig. 8 has darker edge than, and the images of the core after 24 and 40 h of action time in Fig. 8 have larger and darker edges, indicating that more crude oil is produced from the Core 5-20-27 by CO2 flooding.

Fig. 7.

Fig. 7.

NMR images of matrix core 5-1-26 at different times of CO2 injection.

Fig. 8.

Fig. 8.

NMR images of matrix core 5-20-27 at different times of CO2 injection.

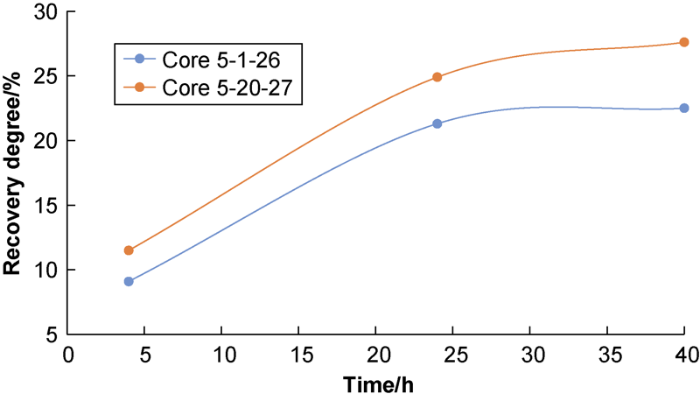

Nuclear magnetic resonance images can be used to evaluate the shale oil recovery degree by CO2 flooding. The oil recovery degree can be calculated by subtracting the gray values of images of the core after different action times from the gray value of the image of oil-saturated core and then divided by the gray value of the image of the oil-saturated core. The calculation results of oil recovery degrees of the two cores are shown in Fig. 9. It can be seen that CO2 gradually diffuses into the core in the initial stage to displace the crude oil in the edge of the core, and the oil recovery degree increases greatly. With the extension of action time, CO2diffuses into the core and contacts with the crude oil in the pores inside the core, the oil inside the core is produced, the oil recovery degree increase continuously but in smaller amplitude. The oil recovery degree of Core 5-1-26 is lower than that of Core 5-20-27, the main reason is that Core 5-1-26 is more tight than Core 5-20-27, so the injected CO2 is easier to diffuse into Core 5-20-27.

Fig. 9.

Fig. 9.

Oil recovery degree curves of the two matrix cores.

The interaction between CO2 and crude oil in the matrix has pseudo miscible characteristics, and this process is a relatively slow diffusion process, so it needs as long time as possible to improve the oil recovery of the matrix. The laboratory test results show that the interaction time between CO2 and crude oil should exceed 48 h as far as possible, and the CO2 injection should be kept at high pressure.

2.4.2. Fracture-matrix cores

The test results of nuclear magnetic resonance images of the three matrix-fracture cores are shown in Fig. 10, Figs. 11 and 12. The bottom and top of the images are the input and output ends of the experimental device respectively, and the gray scale signal, that is the brightness, in the image indicates the distribution of oil in the core. In Fig. 10, the single bright white gray band in the oil-saturated core image is the single fracture in the core, and the gray signals in the rest part represent the oil in the core matrix. The fracture was measured at 0.7 mm wide and 6.5 cm long. Compared with the image of the oil-saturated core, the image of the core after action time for 4 h has the bright white gray band turning to black band, indicating that the injected CO2first enters the fracture and produces the oil, so the oil saturation in the fracture decreases. The gray signals of the matrix gradually darkened in the images after 24 and 40 h of action time, and the gray signals of the matrix around the fracture and on the core surface turned black, indicating that with the increase of action time, CO2 diffused from the single fracture and core surface into the core matrix to displace the oil in the matrix, as a result, the oil saturation in the matrix decreased.

Fig. 10.

Fig. 10.

Magnetic resonance images of the matrix core 5-20-27-2 with one vertical single fracture at different times of CO2 flooding.

Fig. 11.

Fig. 11.

Magnetic resonance images of the matrix core 5-18-27-3 with two vertical fractures at different time of CO2 injection.

Fig. 12.

Fig. 12.

Magnetic resonance images of matrix core 5-18-27-1 with multiple high angle fractures at different time of CO2 injection.

The two bright white gray bands in the oil-saturated core image in Fig. 11 are the double fractures in the core. The left and right fractures are 0.6 and 0.5 mm wide and 4.5 and 6.5 cm long respectively.By comparing the image of the oil-saturated core with the image of the core after 4 h action, the two bright white gray bands have turned black, indicating that the injected CO2 first entered the fractures and produced the oil. In the images of core after 24 and 40 h of action, the gray signals of the matrix gradually darkened, and the gray signals around the fracture and on the core surface have turned black, indicating that with the increase of action time, CO2 diffused from double fractures and core surface to the matrix, displacing out more oil in the matrix.

Multiple oblique bright white gray bands in the oil-saturated core image in Fig. 12 are multiple fractures in the core. From left to right, the three fractures are 0.6, 0.6 and 0.5 mm wide, and 3.5, 6.0 and 3.5 cm long, respectively. Compared with the image of the oil-saturated core, in the image of the core after 4 h action, the multiple bright white gray bands have turned black, indicating that the injected CO2 first entered the fractures and produced the oil. In the images of the core after 24 and 40 h of action, the gray signals around the fractures and on the core surface have turned black, indicating that with the increase of action time, CO2 diffused from fractures and core surface to the matrix, displacing out more oil in the matrix.

Nuclear magnetic resonance image grey value is used to calculate the recovery degree of as shown in Fig. 13. It can be seen that the oil in and around the fractures was recovered first and the oil recovery degree increased fast in the initial stage. With the extension of action time, CO2 diffused from the fractures and core surface into the core and contacted with crude oil in the pores inside the cores to displace the oil inside the cores, as a result, the oil recovery degree further increased, but in slower pace. Fractures expand the contact area between the injected fluid and crude oil. The more the fractures, and the larger the evaluation index of fractures, and the greater the recovery degree of shale oil will be.

Fig. 13.

Fig. 13.

Oil recovery degree curves of the three matrix- fracture cores.

3. Conclusions

In the shale oil EOR experiment by CO2injection, with the extension of CO2 injection time, the oil recovery degree gradually increased, and the oil recovery degrees of the experimental cores were 22.5% and 25.3%, respectively at the action time of 40 h. With the increase of pressure, the density of CO2 increases, and the solubility of crude oil in CO2 increases, thus the recovery degree of shale oil increases. The shale oil recovery degree of the experimental core at 18 MPa is 47.1%. With the increase of temperature, the density and solubility of CO2decrease, and the oil recovery degree increases first and then decreases gradually. The T2signal of crude oil on the core surface was observed first in the CO2 injection experiment, with the increase of action time and pressure, the signal amplitude of crude oil increases, the main reason is that the injected CO2diffuses and dissolves in the crude oil, making the crude oil expand in volume and reduce in viscosity, and the crude oil is discharged from the pores of the core and adheres to the surface of the core.

The experiment of CO2 injection in matrix core shows that CO2 gradually enters and diffuse in the core under the action of pressure difference in the initial stage, reducing the viscosity and interfacial tension of crude oil and improving the oil recovery degree. With the extension of CO2 injection time, CO2 diffuses into the core to displace the oil inside the core, and the increase of oil recovery degree becomes slower. The nuclear magnetic resonance imaging experiments of CO2 injection on matrix cores with fractures show that the oil in and around fractures is extracted first and the oil recovery degree increases fast in the initial stage. With the extension of CO2injection time, CO2 diffuses from the fractures and core surface into the core, and the oil inside the core is produced, and the increase of oil recovery degree gradually slows down. Fractures increase the contact area between injected CO2 and crude oil. The more fractures, the larger the evaluation index of fractures, the greater the recovery degree of shale oil will be.

Nomenclature

F—pore shape factor, dimensionless;

G—oil recovery degree, %;

r—pore diameter, μm;

S1—area ofT2 spectrum of the core at a given action time, m2;

S2—area ofT2 spectrum of oil-saturated core, m2;

T2—transverse relaxation time, ms;

ρ—surface relaxation rate, μm/ms.

Reference

Enlightenment of American shale oil research on China

Research progress of North American shale oil and gas and reflections on China's continental shale oil and gas exploration

Distribution law and accumulation characteristics of shale oil in the United States

Current situation of shale oil development in the United States and its huge impact

Several key issues and research trends in evaluation of shale oil

Characteristics and evaluation elements of shale oil reservoir

Classification of microscopic pore-throats and the grading evaluation on shale oil reservoirs

Quantitative characterization of shale oil in different occurrence states and its application

Evaluation index system of shale oil reservoirs

Occurrence state and mobility analysis of shale oil in Jiyang depression

The first discovery of nanopores in oil and gas reservoirs in China and its scientific value

Status and feasibility analysis on improved shale-oil recovery by gas injection

Research on enhanced oil recovery with CO2 injection in shale gas reservoir

Experimental study on the transmission behaviors of supercritical CO2 and CH4 in shale nanopores

Present situation and development trend of CO2 injection enhanced oil recovery technology

Application of CO2 stimulation in fault-block reservoir

CO2 stimulation test in low permeability reservoir

Study on several factors affecting the effects of CO2 stimulation and oil recovery

Research progress on enhanced oil recovery by CO2 injection

Study on enhanced oil recovery by CO2 injection

Evaluation of enhanced oil recovery by CO2 flooding in low permeability reservoirs

A review of the current progress of CO2 injection EOR and carbon storage in shale oil reservoirs

DOI:10.1016/j.fuel.2018.08.103 URL [Cited within: 1]

Improving oil recovery from shale oil reservoirs using cyclic cold carbon dioxide injection: An experimental study

DOI:10.1016/j.fuel.2019.115716 URL [Cited within: 1]

Investigation of properties alternation during super-critical CO2 injection in shale

DOI:10.3390/app9081686 URL [Cited within: 1]

Effect of injection pressure on enhancing oil recovery in shale cores during the CO2 huff-n-puff process when it is above and below MMP

DOI:10.1021/acs.energyfuels.7b00031 URL [Cited within: 1]

An experimental study of cyclic CO2 injection to improve shale oil recovery

Experimental investigation of enhanced recovery in unconventional liquid reservoirs using CO2: A look ahead to the future of unconventional EOR

Experimental investigation of oil recovery from siliceous shale by CO2 injection

Experimental investigation of oil recovery from siliceous shale by miscible CO2 injection

Hydrocarbon mobilization mechanisms from upper middle and lower Bakken reservoir rocks exposed to CO2

Enhanced oil recovery in liquid-rich shale reservoirs: Laboratory to field

Methods for calculating pore radius distribution in rock from NMR T2 spectra

Methods for calculating pore radius distribution in shale reservoirs from NMR T2 spectra