Introduction

The Ordovician Ma 51 sub-member of the Lower Paleozoic in the Yan'an gas field is a typical tight carbonate reservoir[1-2]. Currently, the reservoir is mainly treated by conventional acid fracturing. Due to high temperature of the reservoir, the acid rock reaction rate is too fast, and the effective action distance of acid is limited[3-4]. Because of low pressure coefficient of the reservoir, flowback of fracturing fluid is difficult. It is difficult to increase the production from this reservoir by conventional acid fracturing[5⇓-7]. By drawing lessons from the successful experience of acid fracturing of tight carbonate reservoirs with CO2 injection[8-10]and pad supercritical CO2 fracturing in shale formation[11-12], the concept of pad CO2 acid fracturing has been proposed in this work to improve the fracturing effect of tight carbonate reservoir with unsatisfactory fracturing effect by conventional acid fracturing, which is to firstly use liquid or supercritical CO2 instead of fracturing fluid or acid to break formation, and then inject acid to non-uniformly etch fractures to make a breakthrough in single well production.

The mechanism of increasing production by the pad CO2 acid fracturing is not clear. The previous fracturing experiments by water, liquid CO2 and supercritical CO2 were largely conducted on granite, coal, shale, and tight sandstone samples. Ishida et al.[13] conducted the true triaxial experiment on granite with water, oil, liquid CO2 and supercritical CO2, the results show that granite, fractured by supercritical CO2, is more likely to produce microfracture, and the breakdown pressure also is reduced significantly. Liu Guojun[14]has carried out a study on fracture propagation in shale with supercritical CO2, and found that the shale with abundant weak planes was easy to form a complex fracture network. Many researchers have carried out studies on the differences between coal, shale and sandstone after fracturing with water, liquid CO2 and supercritical CO2 from the three aspects of breakdown pressure, fracture morphology and fracture surface roughness[15⇓⇓⇓-19], and have obtained clear understandings on fracture propagation laws in coal, shale and sandstone. Although a small number of researchers have carried out studies on fracture propagation laws in carbonate with different acid fluids[20⇓⇓-23], there are few reports on the study of fracture propagation in carbonate in liquid CO2 and supercritical CO2 fracturing, and the laws of fracture initiation and propagation in carbonate remain is unclear at present.

This study took the Lower Paleozoic Ma 51 sub-member in Yan'an gas field as the research object. Large-scale true triaxial fracturing experiments were conducted on natural outcrop samples with the size of 100 mm×100 mm×100 mm by water and liquid CO2, supercritical CO2, then industrial CT was used to obtain the morphology of three-dimensional fractures after fracturing to study the influence of different fracturing fluid on the fracture initiation and propagation in carbonate, and provide technical reference for design of pad CO2 acid fracturing in tight carbonate reservoirs.

1. Experiments

1.1. Samples

The rock samples for true triaxial fracturing experiments are large in volume, and downhole cores can’t meet the requirements. Hence, samples were taken from Lower Paleozoic Ma 51 sub-member on a natural outcrop in Yan'an gas field[24].

The thickness of the formation in the Mawu member of Yan’an gas field ranges from 80 m to 120 m. The Ma 51 sub-member is the major gas pay, with an average burial depth of 3470 m. The reservoir is largely tight dolomite. With mainly intergranular dissolution pores and micro- cracks as storage space, and the average porosity is 2.13%, the average permeability is 0.144×10-3 μm2. Reservoir temperature ranges from 100 °C to 120 °C, and the pressure coefficient ranges from 0.7 to 0.9. The reservoir has maximum horizontal principal stress in nearly east-west, maximum horizontal principal stress greater than the vertical principal stress, vertical principal stress greater than the minimum horizontal principal stress, and horizontal stress difference coefficients from 0.15 to 0.20.

In order to ensure that the selected natural outcrop samples are representative, the natural outcrop samples and downhole cores were compared from four aspects: mineral composition, porosity, permeability, and rock mechanical properties (Table 1). It can be seen that except higher porosity and permeability, the natural outcrop samples are similar with the downhole cores in other parameters. That is to say the natural outcrop samples match with the downhole cores quite well, so the natural outcrop samples can be used to carry out the experiments.

Table 1. Comparison of parameters of natural outcrop samples and downhole cores.

| Rock type | Dolomite/% | Porosity/% | Permeability/10-3 μm2 | Young's Modulus/GPa | Poisson's Ratio | Compressive Strength/MPa |

|---|---|---|---|---|---|---|

| Natural outcrop | 93.60 | 2.08 | 6.44 | 48.70 | 0.233 | 434.00 |

| Downhole core | 94.20 | 1.51 | 3.25 | 45.30 | 0.245 | 401.00 |

| Relative error/% | 0.64 | -27.40 | -49.53 | -6.98 | 5.150 | -7.60 |

Open-hole completion of vertical well is the main completion method of Ma 51 formation, therefore, the experimental samples in this study were designed with open hole vertical well (Fig. 1). Natural outcrops were cut into cubes with the size of 100 mm ×100 mm×100 mm. A hole with a diameter of 6 mm and a length of 50 mm was drilled in each cube to simulate wellbore. The wellbore had a casing section of 40 mm and an open hole section of 10 mm. The casing is stainless steel pipe with an inner diameter of 2 mm and an outer diameter of 3 mm. The casing and the borehole wall were adhered together by glue for 24 h before the experiment[17-18].

Fig. 1.

Fig. 1.

Schematic diagram of experimental sample.

1.2. Apparatus

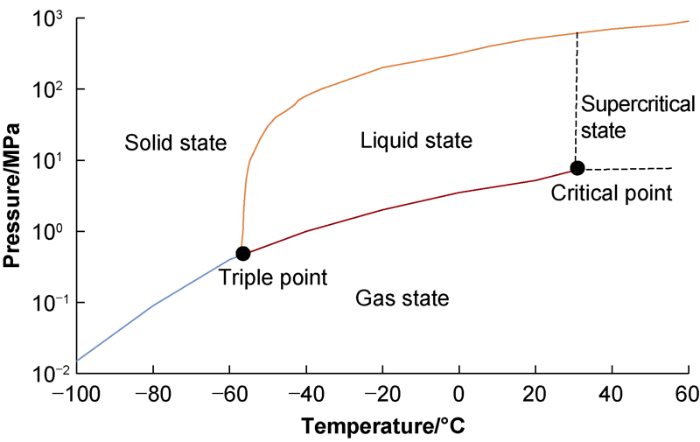

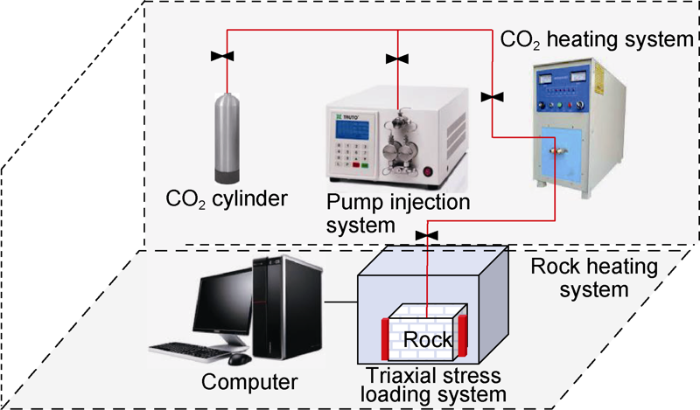

With low viscosity and surface tension, liquid CO2 and supercritical CO2 are[25] likely to escape from the junction of wellbore and borehole, leading to failure of the experiment. Meanwhile, when fracturing with supercritical CO2, rock and CO2 need to be heated above 31.1 °C at the same time (Fig. 2), it can be seen that the experiments have very strict requirements on experimental apparatus. The TCHSFM-I type large-size true triaxial fracturing seepage simulation apparatus (Fig. 3) can meet the experimental requirements. The experimental apparatus is mainly composed of a pump injection system, a heating system, and a triaxial stress loading system. The pump injection system can record the injection rate and pressure during the fracturing process in real time. The maximum injection rate of water is up to 1000 mL/min, the maximum injection rate of CO2 is 40 mL/min and the maximum pressure is 60 MPa. The heating system mainly includes a CO2 heating system and a rock heating system, and the temperature can reach over 60 °C, the maximum uniaxial loading stress of the triaxial stress loading system can exceed 100 MPa. The apparatus parameters fully meet the experimental requirements.

Fig. 2.

Fig. 2.

Phase change diagram of CO2.

Fig. 3.

Fig. 3.

The apparatus.

1.3. Scheme

The parameters: (1) As the rock samples were large, according to the in-situ stress gradient of Ma 51 reservoir (Table 2), the in-situ stress gradient ratio method was used to calculate the triaxial stress required for the experiment, the result shows that the maximum horizontal principal stress of the experiment is 9 MPa, the minimum horizontal principal stress is 7 MPa, and the vertical stress is 8 MPa. In the experiment, the vertical stress was applied along the wellbore direction, the maximum horizontal principal stress was applied parallel to the discontinuities, and the minimum horizontal principal stress was applied perpendicular to the discontinuities. (2) With low viscosity, liquid CO2 and supercritical CO2 would leak fast during the fracturing process, so if the injection rate is too small, it is hard to establish wellbore pressure. Meanwhile, in consideration of the maximum pumping capacity of the pumping system, the injection rate was designed at 40 mL/min. (3) Fracturing experiments with water and liquid CO2 were carried out at room temperature (25 °C), and supercritical CO2 fracturing experiments were carried out at 60 °C.

Table 2. In-situ stress characteristics of Ma 51reservoirs.

| Well | Member | Vertical depth/m | In-situ stress gradient/(MPa•m-1) | ||

|---|---|---|---|---|---|

| σH | σh | σv | |||

| A | Ma51 | 3 721-3 733 | 0.027 9 | 0.024 1 | 0.025 3 |

| B | Ma51 | 3 597-3 606 | 0.028 2 | 0.023 5 | 0.025 4 |

| C | Ma51 | 3 339-3 347 | 0.028 8 | 0.023 9 | 0.025 5 |

According to this parameter sequence, a total of 8 schemes were designed, according to the fracture characteristics of the rock samples and the types of fracturing fluid (Table 3).

Table 3. Parameters of experimental schemes.

| No. | Natural fracture | In-situ stress/MPa | Fracturing fluid | Injection rate/(mL•min-1) | ||

|---|---|---|---|---|---|---|

| σH | σh | σv | ||||

| 1 | Yes | 9 | 7 | 8 | Water | 40 |

| 2 | No | 9 | 7 | 8 | Water | 40 |

| 3 | No | 9 | 7 | 8 | Liquid CO2 | 40 |

| 4 | Yes | 9 | 7 | 8 | Liquid CO2 | 40 |

| 5 | Yes | 9 | 7 | 8 | Liquid CO2 | 40 |

| 6 | No | 9 | 7 | 8 | Supercritical CO2 | 40 |

| 7 | No | 9 | 7 | 8 | Supercritical CO2 | 40 |

| 8 | No | 19 | 15 | 17 | Supercritical CO2 | 40 |

2. Results and analysis

2.1. Analysis of breakdown pressure and its influencing factors

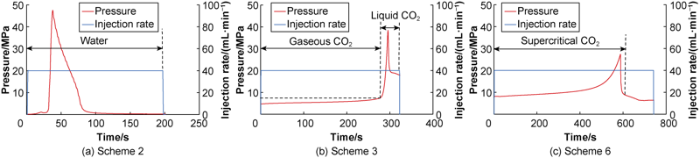

Fig. 4 shows the pumping pressure curves of the second, third and sixth experimental schemes. For carbonate with few natural fractures under the same experimental conditions: (1) When experiments were conducted with water (Fig. 4a), the bottom hole pressure rises quickly, the fracturing progresses to 37 s, the bottom hole pressure reaches at 47 MPa, and the rock was fractured, the cumulative consumption of water in this process was 24.6 mL. (2) When fracturing with liquid CO2 (Fig. 4b), at the beginning, CO2 was mainly gaseous in the wellbore. The viscosity of gaseous CO2is low and filtration rate is fast so the bottom hole pressure rises slowly. When fracturing goes on for 280 s, the bottom hole pressure is greater than 7 MPa, CO2 changes from gaseous to liquid, so the density and viscosity of CO2 increase greatly[25-26], and the bottom hole pressure rises rapidly. At 296 s into fracturing, the bottom hole pressure reaches at 37 MPa and the rock was fractured, the cumulative consumption of liquid CO2 in this process is 197.3 mL. (3) In the fracturing with supercritical CO2 (Fig. 4c), supercritical CO2 with low viscosity and small surface tension[25-26] was directly injected into the wellbore, the supercritical CO2 filtrated seriously, and the bottom hole pressure rise very slowly. At 590 s into fracturing, the bottom hole pressure reaches at 27 MPa, the cumulative consumption of supercritical CO2in this process is 393.3 mL.

Fig. 4.

Fig. 4.

Pump injection pressure curves during fracturing experiments with different fluids.

Comparing the above results, we can see that: (1) Compared with water and liquid CO2, supercritical CO2is much lower in viscosity and surface tension, and thus the filtration rate during fracturing is soon, and it is hard to build up pressure in wellbore. Under the same experimental conditions, the volume of supercritical CO2 required for fracturing carbonate is 16 times that of water. (2) Under the same experimental conditions, supercritical CO2can reduce the breakdown pressure of carbonate significantly, the breakdown pressure required by supercritical CO2 to break carbonate is 57.4% that of water and 72.9% that of liquid CO2.

The research results of Chen[27]show that the pore pressure around the wellbore is equal to the original formation pressure if not considering fluid filtration; if fluid filtration is considered, the pore pressure around the wellbore is equal to the fluid pressure in the porous media; and the filtration of fluid would significantly reduce the breakdown pressure. According to the prediction model of rock breakdown pressure considering infiltration effect established by Zeng[28], it can be seen that with the decrease of fracturing fluid viscosity, the pore pressure of rocks around the wellbore increases, so the breakdown pressure of the rocks decreases. Compared with water and liquid CO2, supercritical CO2 is the lowest in viscosity, so the pore pressure around wellbore increases the largest during fracturing with supercritical CO2. Therefore, supercritical CO2 can significantly reduce the breakdown pressure of rock.

2.2. Influence of fracturing fluid on fracture morphology

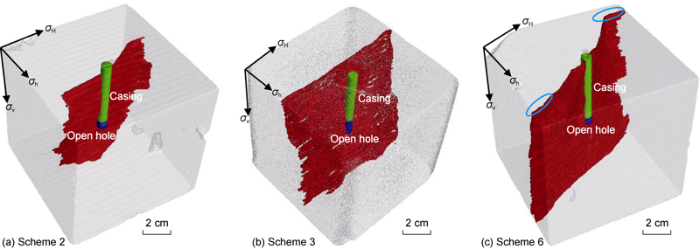

Fig. 5 shows the CT scan results of fractures after fracturing in the second, third, and sixth experimental schemes. For carbonate with few natural fractures, when other experimental conditions are the same: (1) After fracturing with liquid CO2, the fractures propagate along the direction of maximum horizontal principal stress, a symmetrical double wing fracture parallel to the wellbore direction was formed (Fig. 5a). (2) After fracturing with liquid CO2, the fractures also propagate along the direction of the maximum horizontal principal stress, a symmetrical double wing fracture parallel to the wellbore direction was formed (Fig. 5b). (3) With low viscosity, supercritical CO2 greatly makes the pore pressure of the rock around the wellbore increase greatly and the shear strength of the rock reduce, and the rock is prone to shear failure in fracturing with supercritical CO2[13]. It can be seen from Fig. 5c that the angle between the propagation direction of these shear fractures near the wellbore with the maximum horizontal stress is 45°, and the fractures gradually turn to propagate along the direction of the maximum horizontal stress when extending to a certain distance from the wellbore (the blue oval), leading to an increase of fracture tortuosity compared with the other cases.

Fig. 5.

Fig. 5.

CT scan results of fracture morphology in schemes 2, 3 and 6.

The experimental results show that fracturing with low viscosity fluid is still difficult to create a complex fracture network in carbonate with few natural fractures. This is consistent with the experimental research results of homogeneous sandstone fracturing carried out by Lu et al.[29]. In contrast, the experimental results of coal and shale fractured by liquid CO2 and supercritical CO2 showed that[14⇓⇓⇓⇓-19], compared with water, liquid CO2 and supercritical CO2with low viscosity and surface tension and stronger penetrability would cause connection of discontinuities such as bedding and natural fractures, and thus formation of complex fracture networks in coal and shale. This means that the existence of discontinuities such as natural fractures and bedding is the geological basis for the formation of complex fracture networks in fracturing with liquid CO2and supercritical CO2.

2.3. Influence of horizontal stress difference on fracture morphology

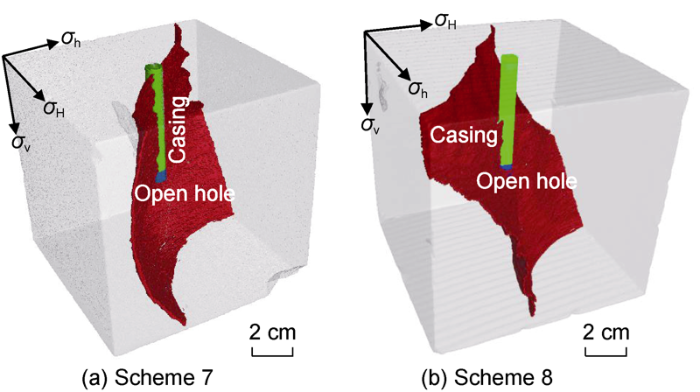

Fig. 6 shows the CT scan results of fracture morphology after completing fracturing of the seventh and eighth experimental schemes. It can be seen that for carbonate with few natural fractures, horizontal stress difference has little effect on the fracture morphology after fracturing with supercritical CO2. Even under the condition of low horizontal stress difference, complex fractures still cannot be formed after fracturing (the horizontal stress difference of the seventh scheme was 2 MPa, and that of the eighth scheme was 4 MPa). Combined with Fig. 5, it can be seen that for carbonate with few natural fractures, compared with water fracturing, supercritical CO2fracturing can change the fracture initiation mode of rock. Water fracturing causes tensile failure, while supercritical CO2 fracturing causes shear failure, and the latter can increase the tortuosity of fractures.

Fig. 6.

Fig. 6.

CT scan results of fracture morphology in schemes 7 and 8.

2.4. Influence of approaching angle of natural fracture on fracture morphology

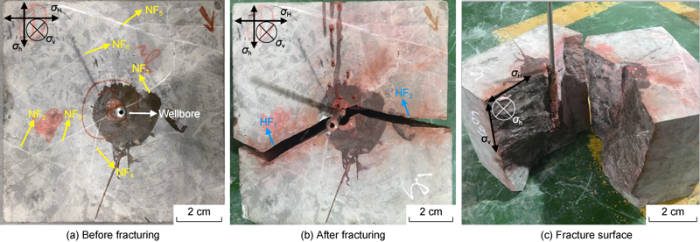

There are a total of six natural fractures on the surface of the rock sample in Scheme 1, including low approaching angle natural fractures NF1, NF2, NF3, high approaching angle natural fractures NF4, and natural fractures far away from the wellbore NF5 and NF6 (Fig. 7a). After fracturing with water, a symmetrical double wing fracture parallel to wellbore direction was formed (Fig. 7b, 7c). the fracture initiated from the open hole, the HF1 in the left wing propagated along the NF3 with a low approaching angle and directly passed through the NF4 with a high approaching angle in the process of propagation. As HF1 continues to propagate, another low approaching angle natural fracture NF2, was connected and HF1 further propagates along NF2. In the right wing, the fracture HF2, propagates firstly along the NF1, then turn to propagate along the direction of maximum horizontal principal stress. It can be seen that when water is used to break the carbonate, the fractures are more likely to communicate with natural fractures with low approaching angles near the wellbore, but natural fractures with high approaching angles are difficult to be communicated, and staircase fractures will be formed after fracturing.

Fig. 7.

Fig. 7.

Fracture morphology before and after fracturing in scheme 1.

In scheme 4, the rock sample has a natural fracture NF1 with high approaching angle near the wellbore (Fig. 8a). After fracturing with liquid CO2, the fracture HF2 initials from the open hole and then propagates along the direction of the maximum horizontal principal stress. Then it connects with the natural fracture NF1 with high approaching angle near the wellbore. Hereafter, the HF2 fracture propagates along both directions of maximum horizontal principal stress and NF1, multi-directional fracture was formed (Fig. 8b, 8c). Combined with the fracturing experiment results of the sample in scheme 1, it can be seen that the key to the formation of complex fractures after carbonate fracturing is to connect natural fractures with high approaching angle.

Fig. 8.

Fig. 8.

Fracture morphology before and after fracturing in scheme 4.

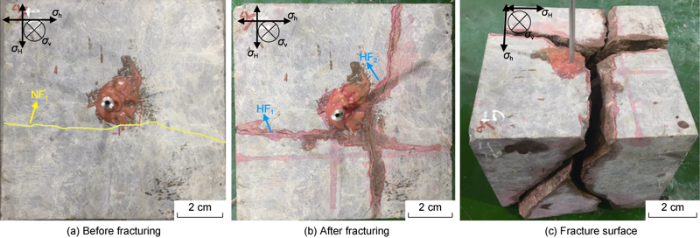

In scheme 5, the rock sample has a total of 3 natural fractures, among which NF1 is close to the wellbore with high approaching angle, NF2 and NF3 are far away from the wellbore (Fig. 9a). After fracturing with liquid CO2, the natural fracture, NF1, was communicated, and the hydraulic fracture, HF1, in the left wing propagates along NF1. The HF2 in the right wing propagates in the direction of the maximum horizontal principal stress, forming a “L-shaped” fracture (Fig. 9b, 9c). Comparing the experimental results of scheme 1 (water fracturing) with scheme 4 (liquid CO2 fracturing) and scheme 5 (liquid CO2 fracturing), it can be seen that liquid CO2 with low viscosity and stronger penetrability is more likely to communicate with high approaching angle natural fractures near wellbore.

Fig. 9.

Fig. 9.

Fracture morphology before and after fracturing in scheme 5.

3. Conclusions

Supercritical CO2, with low viscosity, strong diffusivity, and large filtration loss, is likely to increase the pore pressure of rocks around the wellbore and reduce the breakdown pressure of the rocks significantly. However, the wellbore pressure rises slowly during fracturing, and supercritical CO2 consumed to break rock is much larger than water in volume.

For carbonate with few natural fractures, tensile failure is more likely to occur when fracturing with water or liquid CO2, and fractures formed propagate mainly along the direction of maximum horizontal principal stress. In contrast, in fracturing with supercritical CO2, shear fractures are likely to be created, and horizontal stress difference has little effect on the shape of fracture. Besides, the angle between propagation direction of these shear fractures near the wellbore and the maximum horizontal stress is 45°, and the fractures would gradually turn to propagate along the direction of maximum horizontal stress when extending to a certain distance from the wellbore, leading to an increase of fracture tortuosity than the other fracturing schemes.

For carbonate with many natural fractures, fracturing with water is likely to connect low approaching angle natural fractures and form staircase fractures with simple morphology. The key to form complex fractures after fracturing of carbonate rocks is to connect the high approaching angle natural fractures; fracturing with liquid CO2 with low viscosity is likely to connect high approaching angle natural fractures and form multi-directional fractures with complex morphology. Connecting high approaching angle natural fractures is the key to form complex fractures in carbonate after fracturing.

Nomenclature

σH—maximum horizontal principal stress, MPa;

σh—minimum horizontal principal stress, MPa;

σv—vertical principal stress, MPa.

Reference

Gas exploration potential of tight carbonate reservoirs: A case study of Ordovician Majiagou Formation in the eastern Yi-Shan slope, Ordos Basin, NW China

Accumulation and potential analysis of self-sourced natural gas in the Ordovician Majiagou Formation of Ordos Basin, NW China

Experimental study of influence factors about acid-rock reaction rate in carbonate reservoir of Majiagou Formation

An experimental study on acid-rock reaction kinetics using dolomite in carbonate acidizing

DOI:10.1016/j.petrol.2018.05.041 URL [Cited within: 1]

A theoretical study of acid-fracture conductivity under closure stress

DOI:10.2118/124755-PA URL [Cited within: 1]

Application of CO2 fracturing technology for terrestrial shale gas reservoirs

Research status and prospects of supercritical CO2 fracturing technology

Features of CO2 fracturing deduced from acoustic emission and microscopy in laboratory experiments

DOI:10.1002/jgrb.v121.11 URL [Cited within: 2]

Experimental study on the supercritical CO2 fracturing of shale

Experimental study on fracture initiation and growth in coal using hydraulic fracturing with supercritical CO2 and normal water

Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing

DOI:10.1016/j.fuel.2016.10.120 URL [Cited within: 2]

Supercritical carbon dioxide fracturing in shale and the coupled effects on the permeability of fractured shale: An experimental study

DOI:10.1016/j.jngse.2016.10.005 URL [Cited within: 3]

Liquid CO2 fracturing: Effect of fluid permeation on the breakdown pressure and cracking behavior

DOI:10.1007/s00603-018-1542-x URL [Cited within: 3]

Experimental study on the growth behavior of supercritical CO2-induced fractures in a layered tight sandstone formation

DOI:10.1016/j.jngse.2017.11.005 URL [Cited within: 2]

Experimental investigation of shear slippage behavior in naturally fractured carbonate reservoirs using X-ray CT

DOI:10.1016/j.ijrmms.2019.104066 URL [Cited within: 1]

Characteristics of fracture propagation in compact limestone formation by hydraulic fracturing in central Sichuan, China

DOI:10.1016/j.jngse.2018.06.035 URL [Cited within: 1]

Investigation on acid fracturing treatment in limestone formation based on true tri-axial experiment

DOI:10.1016/j.fuel.2018.08.057 URL [Cited within: 1]

Effect of different types of stimulation fluids on fracture propagation behavior in naturally fractured carbonate rock through CT scan

Hydraulic fracture propagation geometry and acoustic emission interpretation: A case study of Silurian Longmaxi Formation shale in Sichuan Basin, SW China

Wellbore temperature and pressure coupling calculation of drilling with supercritical carbon dioxide

W-shaped permeability evolution of coal with supercritical CO2 phase transition

DOI:10.1016/j.coal.2019.103221 URL [Cited within: 2]

Initiation pressure models for supercritical CO2 fracturing and sensitivity analysis

Experimental and modeling investigation of fracture initiation from open-hole horizontal wells in permeable formations

DOI:10.1007/s00603-018-1623-x URL [Cited within: 1]

Experimental and theoretical analysis of hydraulic fracturing and gas fracturing of rock under true triaxial compressions

DOI:10.1016/j.engfracmech.2020.107100 URL [Cited within: 1]