Introduction

Geothermal energy is a kind of green, low-carbon, and recyclable clean energy characterized by large reserves, wide distribution, high stability, reliability, and environmental-friendliness[1⇓⇓-4]. Geothermal resources abound in China[5⇓⇓⇓-9] will support a considerable potential heating market. As stated the National “13th Five-Year Plan for the Development and Exploitation of Geothermal Energy”[2], China will increase geothermal energy heating area by 11×108 m2 during the “13th Five-Year Plan” period. As of 2015, the geothermal heating area in China was only 3.92×108 m2, the shallow geothermal heating had been primarily developed by ground source heat pump[10-11], and the medium and deep hydrothermal geothermal heating had not reached scale development. In the development of hydrothermal geothermal energy from the Guantao Formation of the Neogene in the plain of Hebei Province, groundwater has been produced without supplementing, thereby making the groundwater level decline continuously and the utilization of geothermal resources hard to sustain[12]. A large-scale karst geothermal reservoir in the Wumishan Formation of Jixian System in Xiongxian County has been mined. Subsequently, the groundwater level had been dropping by 5 m annually from 2004 to 2012. Over the past few years, the development mode of hydrothermal geothermal resource has progressively shifted from the extensively “random mining and discharge” to a sustainable model of “taking heat without water” based on the balanced production and injection[3]. The karst fissure thermal reservoir re-injection technology has been applied at a large scale in the Xiong'an area of North China, whereas large-scale productive re-injection in sandstone porous thermal reservoir has no precedent in China[3,13], and there are no successful cases of large-scale heating with this kind of resource so far. One of the key issues in the future development and exploitation of geothermal energy in the Beijing-Tianjin-Hebei region is to design the balanced production and re-injection development and exploitation technology for geothermal resource[3,14]. In this study, by making use of the geological data and technology accumulated over years of oil and gas exploration, the Gaoshangpu-Liuzan thermal field is selected to perform a large-scale heating test by the sandstone pore-type thermal reservoir based on the local heating market demand. Besides, the heating development and exploitation supporting technologies for large-scale sandstone thermal reservoir, including the geothermal field resource evaluation, development target selection, porous sandstone thermal reservoir simulation and evaluation, balanced production and re-injection in the same sandstone thermal reservoir, and decentralized mining and re-injection plan optimization, are investigated, in the hope to provide reference for the sustainable development and exploitation of medium-deep geothermal energy.

1. Geological background

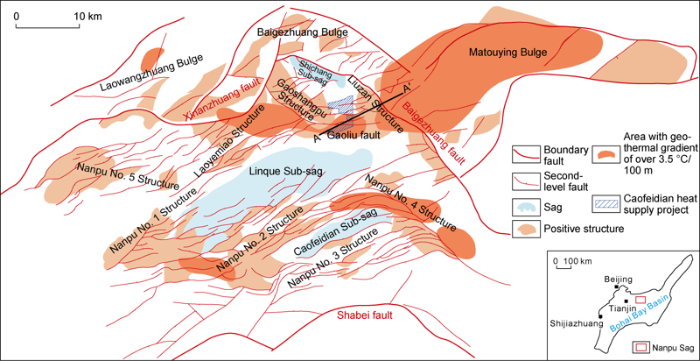

The Nanpu sag is in the northern part of the North China Plain geographically, and in the central-north of the Bohai Bay Rift Basin tectonically. Lying against the southern margin of the Yanshan platform fold belt to the north, it is a single-faulted ridge sag with fault in the north and overlap in the south formed by Mesozoic and Cenozoic rifts on the base of the North China platform, covering an area of nearly 2000 km2. The Nanpu sag and the surrounding areas include three sub-sags (i.e., Shichang sub-sag, Linque sub-sag and Caofeidian sub-sag) and three bulges (i.e., Baigezhuang bulge, Matouying bulge and Laowangzhuang bulge) (Fig. 1). During the late Yanshan Movement-Early Himalayan Movement, as the tectonic stress field in east China shifted from NW compression to NW extension, the structural deformations in Nanpu sag and its surrounding areas were affected by the Tanlu strike-slip fault zone and Zhangjiakou-Penglai strike-slip fault zone, where multiple periods of geological activities resulted in a series of north-east-trending faults, which played an effective role in geothermal conduction. Moreover, the well-developed sedimentary caprock in the Tertiary of the Nanpu sag provide good conditions for the formation of the geothermal field[5,15-16].

Fig. 1.

Fig. 1.

The division of structural units and distribution of geothermal anomalous zones in the Nanpu sag.

1.1. Regional thermal background

Anomalous geothermal zones appear on the edges of major plates in general. Heat sources show a significant correlation with the expansion or extinction of the plates, and different tectonic evolutions give rise to differences of various sedimentary basins in geothermal background[17-18]. The Bohai Bay Basin belongs to the Western Pacific back-arc rift basin[19-20], in which the mantle material upwelled[21], and deep hot magma and hydrothermal fluids spilled out onto the shallow surface of the earth along large faults, leading to high heat flow. Hence, the zone near the rift boundary fault has more significant high heat flow anomaly. The Bohai Bay Basin is located in the upper mantle uplift area with thinner crust in eastern China, and is a complex geothermal field on the whole. The Nanpu sag has undergone four stages of rifting since the Cenozoic, and each stage of rifting was accompanied with a magmatic thermal event[12-13]. Although the thermal activity ended at the end of the Neogene, the higher thermal background in the previous period remains[22]. The current land heat flow in the Nanpu sag reaches 93.8-100.1 mW/m2, basically comparable with that of Xiongxian County, Hebei (113.9 mW/m2) and Dagang, Tianjin (105.9 mW/m2). The Matouying bulge has a higher heat flow value of 148.9 mW/m2[23-24]. The heat flow is "high in the bulges and low in the sub-sags". The water temperature of the Guantao Formation in Gaoshangpu- Liuzan, Nanpu and other heat fields is largely lower than 90 °C, so these fields are middle-low temperature geothermal fields. A medium-high temperature thermal field over 100 °C has been found in the Guantao Formation of the Baigezhuang and Matouying uplift areas close to the sag boundary fault.

1.2. Stratigraphic characteristics

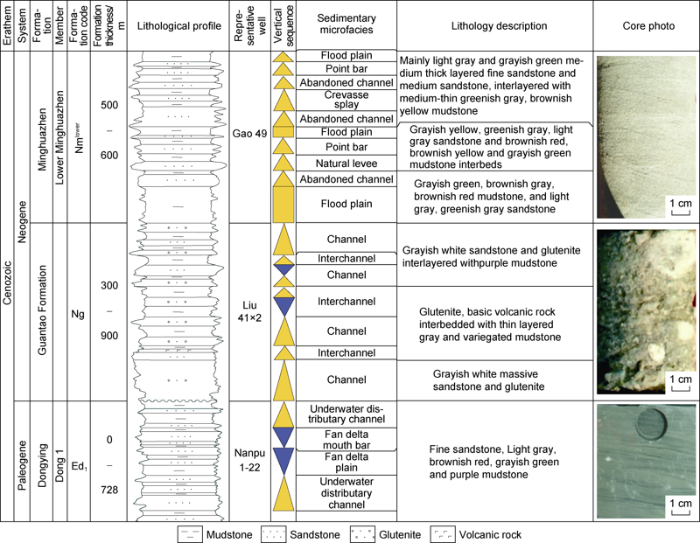

The Nanpu sag is a Tertiary sedimentary lake basin developing on the basement of the Middle Paleozoic. Sedimentary formations there include the Pre-Tertiary (Palaeozoic and Mesozoic), the Paleogene Shahejie Formation, the Dongying Formation, and the Neogene Minghuazhen Formation and Guantao Formation. The Tertiary has the maximum thickness of 8000 m. Since the Neogene, the Bohai Bay Basin has subsided into a unified basin. The Neogene in Nanpu sag has sedimentary characteristics similar to other areas in the Bohai Bay Basin, the Guantao Formation gets thicker from the surrounding bulges to the sub-sags gradually, and is thickest from the Linqueci sub-sag to the Caofeidian sub-sag. The Guantao Formation is dominated by braided river deposits and interchannel deposits, with sand contents of 60%-70%. The Guantao Formation has an average thickness of 300-900 m, and cumulative thermal reservoir thickness of 120-300 m. The Guantao Formation consists of gray-white massive sandstone, glutenite, basic volcanic rock, and thin layers of gray and variegated mudstone[5] (Fig. 2).

Fig. 2.

Fig. 2.

Composite columnar section of the Gaoshangpu-Liuzan heat field.

2. Distribution and influencing factors of geothermal field

2.1. Distribution of geothermal field

The sedimentary basin geothermal resources are largely medium- low temperature conduction geothermal resources[8]. The special geographical location and thermal events undergone since the Tertiary of Nanpu sag determine its special geothermal field background. Corresponding to the geological structure of alternate subsags and bulges in this sag, the geothermal field is characterized by "alternate high and low temperature belts"[25⇓-27]. The high ground temperature and high ground temperature gradient areas tally with the basement uplift and bulge areas[28]. Moreover, the extension directions of the high-temperature fields are basically identical to the strikes of the main structural belts and deep faults, namely, east-west and north-east, respectively. The basement uplift areas have higher geothermal gradients. As confirmed by drilling data, the geothermal gradient at the bottom of the Cenozoic caprock is over 5.0 °C/100 m, and 8.3 °C/100 m at maximum. In the sag area, the geothermal gradient at the bottom of the Cenozoic caprock is lower (3.0-4.0 °C/100 m in general). According to the standard of geothermal gradient of over 3.0 °C/100 m, 5 geothermal anomalous zones have been found in the Nanpu sag and its surrounding areas (Fig. 3 and Table 1), with a total area of nearly 2160 km2.

Fig. 3.

Fig. 3.

Overlay map of geothermal gradient contours and geothermal anomalies in the Nanpu sag and its surrounding areas.

Table 1. Parameters of geothermal anomaly zones in the Nanpu sag and its surrounding areas.

| No. | Geothermal anomaly zone | Thermal reservoir | Area/km2 | Buried depth/m | Thermal reservoir thickness/m | Thermal reservoir temperature/°C | Geothermal gradient/(°C·(100 m)-1) |

|---|---|---|---|---|---|---|---|

| I | Laowangzhuang- Xinanzhuang-Bagezhuang | Nm | 310 | 1000-1300 | 140-160 | 45-55 | 3.2-4.2 |

| Ng | 1100-1700 | 100-300 | 55-75 | ||||

| O, —C | 190 | 1400-2500 | 50-200 | 60-90 | 2.5-3.5 | ||

| II | Laoyemiao- Gaoshangpu -Liuzan | Nm Ng | 290 | 1700-2200 2100-2700 | 200-260 120-300 | 60-90 70-110 | 3.5-5.0 |

| III | Nanpu | Nm Ng | 667 | 1600-2400 2400-3 300 | 200-300 150-400 | 65-75 65-95 | 2.3-3.9 |

| O, —C | 101 | >4000 | 100-200 | 150-200 | 3.0-4.0 | ||

| IV | Matouying | Nm | 174 | 1150-1400 | 150-160 | 70-105 | 4.0-7.0 |

| Ng | 1350-1650 | 120-150 | 75-110 | ||||

| Ar | 145 | 1300-3000 | 1 500 | 150 | 1.8-2.5 | ||

| V | Jiang Gezhuang | Nm | 600 | 710-950 | 150-240 | 60-100 | 3.5-6.3 |

| Ng | 950-1200 | 200-250 | 70-110 |

Note: Nm—Minghuazhen Formation; Ng—Guantao Formation; Ar—Archean; O—Ordovician; —C—Cambrian.

The Gaoshangpu-Liuzan heat field is located between the Shichang sub-sag and the Matouying bedrock uplift area, and is adjacent to the second-level Gaoliu fault in the sag, with geothermal gradients of 3.5-4.0 °C/100 m. This field is characterized by superior geothermal resources and considerable reserves. Its corresponding ground area is Caofeidian New City, which has a concentrated heating demand and a huge heat consumption.

2.2. Factors affecting geothermal field

Affected by factors such as geological structure, fault activity, magmatic activity, stratum characteristics, groundwater movement, and lithology[24,29], the distribution of geothermal field in the Nanpu sag is closely related to regional thermal background, rifting faults, and caprock lithology and thickness.

2.2.1. Regional thermal background

The formation and evolution of the Mesozoic and Cenozoic basins in eastern China, and the thinning of the lithosphere determined the regional thermal background of the geothermal fields in eastern China[24,30-31]. The Bohai Bay Rift System is a typical back-arc rift basin in the Western Pacific. Although the Bohai Bay Basin has undergone sophisticated tectonic-thermal evolution in the Mesozoic and Cenozoic, geophysical data shows it has Moho remaining relatively flat thus far and an average crustal thickness of 34-36 km[32⇓-34]. Traces of magmatic thermal activity in the rift period in the Nanpu sag show that the sag has followed the evolution model of internal rift basin, where the thinning of lithosphere[12-13,27,30] controls the distribution of the geothermal field. At the early stage of the rift, the crust thinned, the mantle material upwelled, and the deep heat energy spurted along deep faults to the surface or was brought onto the shallow surface, leading to high heat flow on the surface and high abnormality of heat flow close to the boundary faults in the rift zone. At the late stage of the rift, the upwelling of magma weakened and then stopped, and the surface heat flow value of the basin gradually dropped; but the higher thermal background in the earlier period remained[27,30]. As a result, the current surface heat flow in the basin remains relatively high[21-22,24,30]. The average heat flow value of the Bohai Bay Basin reaches (64.4±8.1) mW/m2[28], higher than the average heat flow value of mainland China (60 mW/m2). The Jiyang, Bozhong and Liaohe depressions in the east have higher heat flow values from 60 to 80 mW/m2; westward, heat flow comes down gradually, for example, the central Huanghua Depression has a heat flow value of mainly 60-70 mW/m2; the Jizhong and Linqing depressions in the west have low heat flow values of 55-65 mW/m2[20,35]. Under the structural framework of alternate bulges and sub-sags in the basin, the buried hill low uplifts and bulges in the sag show high geothermal anomalies since the thermal conductivity of the bedrock is higher than that of the sedimentary caprock[36].

2.2.2. Faults in rifting stage

Deep faults are a vital path for the transmission of deep thermal energy onto the shallow surface. Boundary faults or secondary faults in sags developed in the rifting period act as main channels for deep thermal energy migration to the shallow formation. Since faults as channels are conducive to heat conduction and convection, thereby making the ground temperature rise, geothermal anomaly zones often are close to faults in the rifting period, and local geothermal anomaly zones may come up in the sag area with low geothermal gradient.

2.2.3. Lithology and thickness of caprock

The Cenozoic covers the bedrock, and the sandstone and mudstone have lower thermal conductivity than the bedrock[37]. Therefore, the greater the thickness of the sandstone and mudstone, the stronger the ability of them to prevent the upward conduction of geothermal heat will be. Accordingly, the shallow geothermal high abnormal zones are mainly distributed in the areas where the Tertiary caprock is thinner[38⇓-40]. The geothermal gradient of the caprock is related to the depth of the top surface of the bedrock.

2.3. Formation model of the Gaoshangpu-Liuzan geothermal field

The Gaoshangpu-Liuzan heat field is located in the Shichang sub-sag in the Nanpu sag, where the geothermal high abnormal zones are distributed on both sides of the second-level Gaoliu fault. The overlying Tertiary is 4000-4800 m thick. The Quaternary and Neogene Minghuazhen Formation overlying the Guantao Formation, the main thermal reservoir, are 1800-2200 m thick in total.

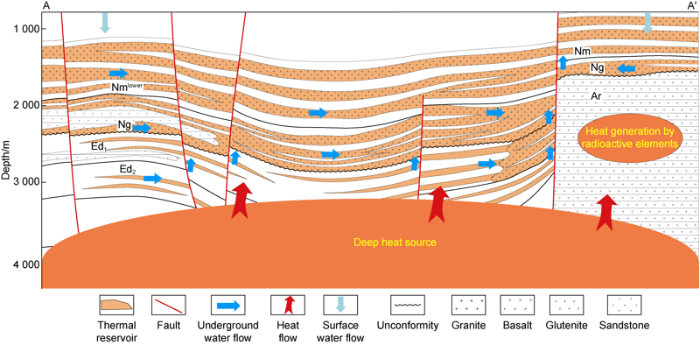

The Gaoshangpu-Liuzan thermal field is a hydrothermal thermal field in a sedimentary sag. Its thermal genetic model can be summarized as the normal earth warming superimposed with heat generation of radioactive elements[25,36] (Fig. 4). Vertically, the deep underground heat energy conducts upward via the overlying sedimentary stratum or deep faults to heat the stratum. The meteoric water absorbed the heat of the surrounding rock via a deep cycle and reacted with the surrounding rock, forming hot water with higher temperatures. The Xinanzhuang fault, the Baigezhuang fault and the Gaoliu fault are all groundwater migration channels. Laterally, the Neogene heat reservoir in Matouying Uplift directly overlies on the Archaean granite, and the heat generated by radioactive elements in the granite rock acts as an additional heat source, giving rise to a high-temperature anomaly zone[41]. The granite contains abundant radioactive elements (e.g., U, Th and K). Through radioactive transformation, the mass of the radioactive elements converted into radiant energy and then into heat energy in the adjacent environment[42], which is also one of the reasons for the formation of the Laoyemiao-Gaoshangpu- Liuzan geothermal anomaly zone and the Matouying geothermal anomaly zone.

Fig. 4.

Fig. 4.

Genetic model of the Gaoshangpu-Liuzan geothermal field (see

3. Thermal reservoirs

3.1. Petrological characteristics

During the oil and gas exploration, the Guantao Formation is divided into 4 members. The I to III members with large thickness and good connectivity are selected as the heat supply layer. Core observation and thin slice identification show the thermal reservoir in the Guantao Formation of the Gaoshangpu-Liuzan heat field is braided river facies deposits. The deposits are mainly gravel channel ones with coarser lithology, medium-good sorting, sub-angular sub-rounding shape, grain support and point contact. Detrital feldspar sandstone takes dominance, followed by feldspar detrital sandstone. In terrigenous clastic particles, quartz accounts for 23% to 32%, 30% on average; feldspar 30% to 35%, 32% on average; and debris 33% to 46%, 41% on average. The feldspar and debris make up for over 70%, and the reservoir sandstone is low in composition maturity.

3.2. Pore structures

The thermal reservoirs in the study area have a porosity of 28%-35%, 30% on average; and permeability of (600-2000)×10-3 μm2, 1500×10-3 μm2 on average, representing high to extra high porosity and high to extra high permeability reservoirs. Under natural production capacity, the reservoirs have a liquid production capacity per meter of over 100 m3/d.

The Guantao Formation has primarily intergranular dissolved pores, intragranular dissolved pores, granular fractures, and moldic pores. Intergranular pores act as the major storage space, taking up nearly 70%. In contact-pore cementation, the reservoirs have a cement content from 1% to 3%, matrix mud content of less than 1%, clay content of less than 1%, and contents of clay minerals from 2.0% to 4.7%. Among the clay minerals, kaolinite, chlorite, illite and smectite account for 17% to 25%, 29% to 54%, 6% to 16%, and 25% to 36%, respectively. The reservoir rocks have low structural maturity, no-weak speed sensitivity, no acid sensitivity, strong salt sensitivity, and weak-very strong water sensitivity.

3.3. Chemical properties of geothermal water

In the Neogene Minghuazhen Formation and the Guantao Formation, the water-bearing system of fine sandstone and glutenite is characterized by regional continuity and stable distribution. Affected by the sedimentary characteristics, the syngenetic water is basically freshwater with low salinity. Due to the sedimentation hiatus between the Tertiary and the Quaternary, the aquifer system was affected by leaching water, thus, the groundwater alternated strongly, and thus has low-salinity and strong-alternate hydrochemical characteristics. With a salinity of 1.1-2.8 g/L and a German degree lower than 8.4, the groundwater is extremely soft water-soft water, which is good for the exploitation of geothermal resources. The water of the Guantao Formation is good in quality, with no peculiar smell. With a Na+ content of 324.36-394.23 mg/L, HCO3- content of 502.28-608.54 mg/L, and Cl-content of 99.25-152.22 mg/L, the water is HCO3•Cl-Na type according to Shukarev's classification (Table 2).

Table 2. Salinity and ion concentration of the Guantao Formation water in the Gaoshangpu-Liuzan geothermal field.

| No. | Well No. | Salinity /(g·L-1) | Na+/(mg·L-1) | K+/(mg·L-1) | Mg2+/(mg·L-1) | Ca2+/(mg·L-1) | F-/(mg·L-1) | Cl-/(mg·L-1) | SO42-/(mg·L-1) | CO32-/(mg·L-1) | HCO3-/(mg·L-1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | High-thermal 4-1 | 1.1 | 345.58 | 6.63 | 2.90 | 14.10 | 8.91 | 146.06 | 29.21 | 507.56 | |

| 2 | High-thermal 4-2 | 1.2 | 333.56 | 4.97 | 1.26 | 8.25 | 10.93 | 126.83 | 31.16 | 502.28 | |

| 3 | High-thermal 4-3 | 1.5 | 341.39 | 5.75 | 1.42 | 10.10 | 11.12 | 133.26 | 30.51 | 506.90 | |

| 4 | High-thermal 4-4 | 2.4 | 344.03 | 5.94 | 1.50 | 12.72 | 11.32 | 130.07 | 27.27 | 510.20 | |

| 5 | High-thermal 4-5 | 1.5 | 388.09 | 8.82 | 1.55 | 20.44 | 11.42 | 152.22 | 29.21 | 514.16 | |

| 6 | High-thermal 5-2 | 1.3 | 394.23 | 9.05 | 2.26 | 22.56 | 11.74 | 143.97 | 0.68 | 32.46 | 549.14 |

| 7 | High-thermal 5-4 | 1.1 | 391.52 | 7.73 | 3.18 | 20.98 | 11.96 | 148.71 | 1.12 | 29.21 | 549.14 |

| 8 | High-thermal 5-6 | 2.1 | 324.36 | 3.31 | 1.01 | 10.05 | 12.20 | 113.87 | 29.21 | 548.48 | |

| 9 | High-thermal 6-1 | 2.3 | 335.98 | 6.87 | 0.98 | 12.67 | 13.98 | 99.25 | 38.95 | 587.42 | |

| 10 | High-thermal 6-3 | 2.0 | 348.22 | 11.24 | 2.34 | 13.98 | 15.15 | 110.04 | 38.30 | 534.62 | |

| 11 | High-thermal 6-5 | 2.5 | 332.47 | 4.89 | 0.87 | 8.28 | 15.21 | 103.11 | 34.41 | 608.54 | |

| 12 | High-thermal 7-1 | 2.2 | 329.47 | 11.74 | 0.85 | 8.24 | 16.09 | 101.47 | 35.71 | 559.04 | |

| 13 | High-thermal 7-2 | 1.9 | 359.64 | 13.52 | 1.94 | 14.18 | 16.39 | 125.67 | 37.00 | 550.46 | |

| 14 | High-thermal 7-4 | 2.8 | 345.58 | 6.63 | 2.90 | 14.10 | 8.91 | 146.06 | 35.06 | 571.58 |

4. Geothermal resource evaluation

According to the "Specifications for Geothermal Resources Geological Prospecting" GB/T 11615-2010, geothermal resource evaluation should take the geothermal geological survey data as basis, and be based on comprehensive analysis of the spatial distribution, boundary conditions, and permeability characteristics of thermal reservoirs, the study of replenishment and migration of geothermal fluid, cause of geothermal formation, heat conduction method, and the characteristics of the geothermal field, and the building of conceptual model of the geothermal system.

4.1. 3D geological model

The three-dimensional geological model can show intuitively the topography and geomorphology, stratum lithology, spatial distribution of geological structures, and the relationship between them. Based on geophysical and drilling data, by considering the regional tectonic background of the study area, the cause and evolution of faults in the study area were figured out, and the characteristics of fault systems and combination patterns of faults were sorted anew, to make clear the plane and vertical combinations of faults. Subsequently, a stratigraphic framework was built based on the interpreted horizon interfaces and fault model and then a three-dimensional geological structure model in the time domain.

After the structure was fully described, the distribution of reservoir properties was described, and a sedimentary facies model was constructed. In this study, a deterministic and random "dual" modeling + data-constrained modeling program was used to establish the reservoir lithofacies model.

4.2. Calculation of geothermal resources

According to characteristics of the thermal reservoir medium in the study area, the traditional thermal reservoir volume method was used to evaluate the geothermal resources of the sandstone thermal reservoir in the Guantao Formation of the Gaoshangpu-Liuzan heat field. The total amount of heat contained in the rock mass and water in a certain area is determined, i.e., the accumulation of geothermal energy. The formula is below:

The formula of the thermal water resources is below:

The parameters required to calculate geothermal resources and thermal water resources are shown in Table 3. According to the "Geothermal Resources Geological Prospecting Specification" GB/T 11615-2010, the sandstone pore-type thermal reservoir of the Guantao Formation has a thermal energy recovery rate of 25% and hot water recovery rate of 20%. The geothermal resources of the sandstone thermal reservoir in the Guantao Formation of Gaoshangpu-Liuzan heat field are 13.79×1018 J, equivalent to 4.70×108 t of standard coal. Calculated at the recovery rate of 25%, the recoverable geothermal resources are 3.45×1018 J, the thermal water resources are 231.6×108m3, and the recoverable hot water resources are 46.3×108 m3 (Table 4).

Table 3. Parameters required to calculate geothermal re-sources and thermal water resources.

| Horizon | Surface area of the calculated area/106 m2 | Thermal reservoir thickness/m | Average temperature of rocks and water/°C | Reference tempera- ture/°C | Density of rock/(kg·m-3) | Density of water/(kg·m-3) | Specific heat capacity of rock/(J·(kg·K)-1) | Specific heat capacity of water/(J·(kg·K)-1) | Porosity of rock/% | Head height/m | Elastic water release coefficient |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Member I | 328 | 81 | 76 | 13.5 | 2 200 | 990 | 878 | 4 180 | 27 | 80 | 8.56×10-5 |

| Member II | 328 | 78 | 79 | 13.5 | 2 200 | 990 | 878 | 4 180 | 29 | 80 | 8.56×10-5 |

| Member III | 328 | 90 | 83 | 13.5 | 2 200 | 990 | 878 | 4 180 | 29 | 80 | 8.56×10-5 |

Table 4. Statistics on thermal reservoir resources of Guantao Formation in Gaoshangpu-Liuzan heat field.

| Horizon | Geothermal resources | Thermal water resources | ||||

|---|---|---|---|---|---|---|

| Geothermal resources/1018 J | Standard coal equivalent/108 t | Recoverable resources/1018 J | Thermal water resources/109 m3 | Standard coal equivalent/108 t | Recoverable hot water resources/108 m3 | |

| Member I | 4.20 | 1.43 | 1.05 | 71.8 | 3.56 | 14.4 |

| Member II | 4.31 | 1.47 | 1.08 | 74.2 | 3.68 | 14.8 |

| Member III | 5.28 | 1.80 | 1.32 | 85.6 | 4.50 | 17.1 |

| Total | 13.79 | 4.70 | 3.45 | 231.6 | 11.74 | 46.3 |

5. Caofeidian geothermal heating

5.1. Balanced production and re-injection in the same layer

The development of geothermal resource by balanced production and re-injection technology can "extract heat without water". The balanced production and re-injection technology in the same layer extracts calorific value of the underground hot water and reinjects the water back into the same layer. In this process, groundwater as a carrier of geothermal energy is repeatedly used in the process of continuous circulation. Adopting this technology can keep the balance and stability of the groundwater system, the pressure and water volume in the mining well, and thus is conducive to the long-term sustainable and stable development of geothermal resources. At present, domestic technical tests in China have been conducted in the sandstone thermal reservoirs of Liaohe Oilfield and Xianyang in Shaanxi, but there is no large-scale productive re-injection[3]. There are two main factors limiting the re-injection. First, there are issues in production and re-injection engineering, including: (1) the particle debris contained in the re-injection water accumulates at the hole of the filter pipe and blocks the filter pipe, causing physical blockage of the thermal reservoir; (2) the organic matter or dissolved matter in the re-injection water easily interacts with the formation water, rock skeleton, and clay minerals during the re-injection, resulting in blockage and making it impossible to implement long-term continuous re-injection; the closer to the well axis, the more severe the degree of blockage will be, the smaller the permeability coefficient will be, and the more difficult it will be to re-inject; (3) the temperature of the tail water after the heat exchange treatment changes, causing changes in chemical composition of the water, thereby chemical blockage of the thermal reservoir. In the actual heating project construction process, not only the problem of produced water re-injection back to sandstone thermal reservoir must be solved, but also the requirement of non-pressure re-injection must be met to lower the construction costs. Second, the re-injection scheme must be optimized, and these questions need to be answered: (1) whether the underground geological conditions are suitable for simultaneous production and re-injection in the same layer; (2) the dynamic variations and development sustainability of the groundwater system and geothermal field under local production and re-injection.

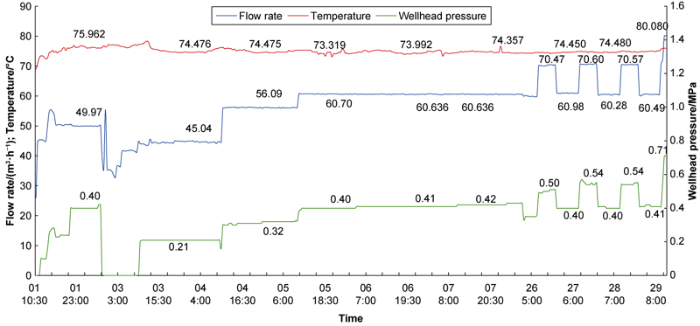

To find out the feasibility of the technology in geology and engineering, two abandoned oil wells were transformed into water producing and water re-injection wells to perform the production and re-injection test in the same layer. The two wells are located nearly 1 km southwest of the Caofeidian heating project, and are approximately 250 m apart in wellhead and 380 m apart in well bottom. The water taking and re-injection horizons are in the Guantao Formation, at the burial depth of 2 050-2 150 m. Well G129×2, the main water production well, has a casing inner diameter of 224.44 mm, 6 thermal reservoirs of 91.6 m thick perforated, stable pumping flow of 95 m3/h, wellhead temperature of 75 °C, and bottom hole temperature of 78 °C. Well G149×1, the re-injection well, has a casing inner diameter of 121.36 mm, 7 thermal reservoirs in Guantao Formation of 90.4 m thick perforated (corresponding to the horizons of Well G129×2). A step-up displacement re-injection test was performed. The maximum re-injection rate was 80.08 m3/h, the cumulative re-injection rate was 14 250 m3, and the wellhead pressure was 0.71 MPa (Fig. 5).

Fig. 5.

Fig. 5.

Curves of flow rate, wellhead pressure, and temperature in the re-injection test of Well G149×1.

Nitrogen was adopted to seal the water production well and re-injection well during the reinjection, and reinjection filtration equipment was introduced to the re-injection system to effectively eliminate the iron and calcium salts, iron bacteria, sulfate-reducing bacteria, thiobacillus, and thiobacillus denitrificans generated due to oxidation from blocking the re-injection system and reservoir. Once the surrounding thermal reservoir is blocked during the re-injection process, the re-injection rate would continuously drop over time under the same re-injection pressure, and the efficiency of re-injection would decrease and even unable to implement. In the actual production process, back pumping should be adopted according to the situation to eliminate or alleviate blockage. The practice of production and re-injection has proved that the amount of re-injection is directly proportional to the permeability coefficient and pressure difference and inversely proportional to the length of the water passage. The early test of production and re-injection with the abandoned oil wells laid technical foundation for the subsequent centralized heating. The Caofeidian geothermal heating project adopts the balanced production and re-injection technology in the same layer. After two heating seasons of 2018-2019 and 2019-2020, the dynamic liquid level has been maintained stable. Fig. 6a shows the re-injection curves of Well GR1-1. It can be seen the re-injection rate is stable at 55-65 m3/h, and the dynamic water level is stable at around -60 m. Fig. 6b shows the water production curves of Well GR1-2. In the 2019-2020 heating season from November 15, 2019 to March 24, 2020, the water production was stable at 110-120 m3/h, the temperature was stable at 80 °C, and the dynamic water level was stable at appoximately -80 m. The successful application of balanced production and re-injection in the same layer can keep the groundwater level relatively stable and ensure the continuous running of the project.

Fig. 6.

Fig. 6.

Re-injection curves of Well GR1-1 (a) and water production curves of Well GR1-2 (b) in the heating season from 2019 to 2020.

5.2. Layout plan

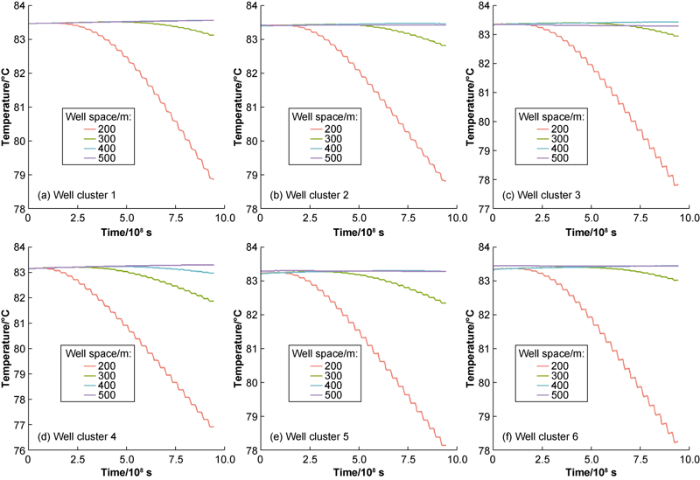

In this study, based on the distribution of well pads in Caofeidian area, temperature changes of water production wells and re-injection wells at the well space of 200, 300, 400, 500 m were simulated numerically (Fig. 7).

Fig. 7.

Fig. 7.

Temperature change trends of production wells of different well clusters at different well spaces.

For the well cluster 1, 2, 3, 5, and 6, at the well space of 200 m, the simulation showed that the temperature of the production wells would drop from the 6th year, and drop significantly in the 10th year. At the well space of 300 m, the temperature would drop from the 18th year, and drop significantly after 25 years. At the well space of 400 m, the temperature would remain basically unchanged, and only the temperature of well cluster 4 would drop slightly. Thus, for the well cluster 1, 2, 3, 5, and 6, the reasonable well space is no less than 400 m; for the well cluster 4, the reasonable well space is no less than 450 m. Finally, the well space of the Caofeidian geothermal heating project was determined at 450 m.

5.3. Construction and operation

In total, 40 geothermal wells were drilled on 7 new well pads, including 16 water production wells, 20 re-injection wells, and 4 backup wells. Completed with screen pipe, the water productions wells have an average drilled thermal reservoir thickness of 158 m in GuanⅠto GuanⅢ Member, water temperature at the wellhead of 78-82 °C, water temperature at the well bottom of 86-92 °C, and average water production rate of 96.0 m3/h. The re-injection wells have an average water injection rate of 76.6 m3/h, dynamic water level of 75-92 m, and static water level of 32-45 m (close to the regional static water level). The produced water is 100% re-injected, at a production to re-injection ratio of 1:1.2.

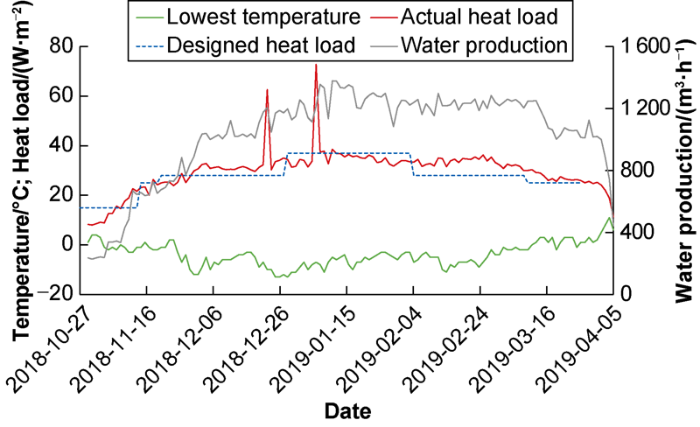

The heating area is 230×104 m2, and the average heat load of geothermal heating is 31.5 W/m2 (Fig. 8), 16.8% higher than the average heating load of coal-fired boilers (the average heating load of coal-fired heating in this area is 26.2 W/m2). The indoor temperature is 3-5 °C higher than the average. All the parameters meet the design requirements and national standards.

Fig. 8.

Fig. 8.

Thermal operation curves of Caofeidian new city geothermal heating during 2018-2019.

After put into operation, the project saved 6.06×104 t of standard coal and reduced carbon dioxide emission of 15.87× 104t annually, achieving good social and economic benefits.

6. Conclusions

The Neogene Guantao Formation in the Nanpu sag has extensive hydrothermal geothermal resources, and several geothermal anomalous zones near the basement paleo-uplift and deep fault zones (with geothermal gradient of greater than 3.0 °C/100 m). The Gaoshangpu-Liuzan thermal field with an area of 200 km2 has geothermal resources of 13.79×1018 J, equivalent to 4.70×108t of standard coal. With high resource abundance and moderate burial depth, the field can support large-scale heating.

The thermal reservoirs of the Guantao Formation in Gaoshangpu-Liuzan heat field consist of sandstone and glutenite. With an average thickness of 120-300 m, a porosity of 28%-35%, and a permeability of generally (600-2000)×10-3 μm2, the reservoirs are high-ultra-high porosity, high-ultra-high permeability ones, and have the characteristics of good storage properties, high water production, and high wellhead water temperature. The balanced production and re-injection in the same layer can be used to extract the heat without water to realize sustainable development.

In the operation of the 230×104 m2 geothermal heating test project in Caofeidian New Town, geothermal heating supporting technologies such as the thermal field resource evaluation, the thermal reservoir distribution prediction, the balanced production and re-injection in the same pore-type sandstone thermal reservoir, and the optimization of decentralized well layout schemes have been tested. The pilot project has run two heating seasons, with operating parameters all up to or better than the design plan. The project can save 6.06×104 t of standard coal and reduce carbon dioxide emission of 15.87× 104 t a year. It has proved that the hydrothermal geothermal resource of the Guantao Formation of the Neogene in the Beijing-Tianjin-Hebei region has broad prospects for geothermal heating.

Under the background of energy structure adjustment and air pollution prevention, geothermal resource with the advantages of significant emission reduction and sustainable supply has become a novel industrial growth point. Oil and gas field companies have accumulated a considerable amount of first-hand information in the oil and gas exploration and development, and strong drilling and production technology and engineering construction capabilities, so they have a leading edge in the development of geothermal resource. Moreover, the breakthrough in the scale balanced production and re-injection in the same layer technology can technically ensure the sustainable large-scale development of medium and deep geothermal energy.

This study was supported and helped by Professor Yan Jiahong with China Petroleum Exploration and Development Research Institute, Yao Yanhua, Chief Geologist of the Hydrology Institute of PetroChina Liaohe Oilfield Company, and Dr. Kong Yanlong with the Institute of Geology and Geophysics, Chinese Academy of Sciences. Thank you all.

Nomenclature

A—the surface area of the calculated area, m2;

Cr, Cw—specific heat capacity of rock and water, J/(kg·K);

d—thermal reservoir thickness, m;

Hw—head height, m;

Q—all the heat contained in the rock mass and water of the calculation area, J;

Tr—the average temperature of rocks and water in the specified volume, K;

T0—reference temperature, K;

W—thermal water resources, m3;

ϕ—porosity of rock, %;

μe—elastic water release coefficient;

ρr, ρw—density of rock and water, kg/m3.

Acknowledgments

This study was supported and helped by Professor Yan Jiahong with China Petroleum Exploration and De-velopment Research Institute, Yao Yanhua, Chief Geologist of the Hydrology Institute of PetroChina Liaohe Oilfield Company, and Dr. Kong Yanlong with the Institute of Geology and Geophysics, Chinese Academy of Sciences. Thank you all.

Reference

Current status and enlightenments of geothermal development in Europe

Review of hot spots of geothermal exploration and development in 2018

Relationship between Tertiary sequence stratigraphy and oil reservoiring in Nanpu depression

Assessment and development of geothermal resources in Jizhong Depression

Evaluation and efficient development of geothermal resource associated with oilfield

Advancement and developmental trend in the geothermics of oil fields in China

Current situation, problems and prospects of geothermal energy development and utilization in China

Status quo and problems of geothermal resource development and utilization in plain area of Hebei province

Volcanic activities and rift-subsidence cycles in Nanpu sag

Evolvement sequence of Tertiary volcanic rocks in the Nanpu sag, Eastern China

Control of strike-slip faulting on reservoir formation of oil and gas in Nanpu sag

DOI:10.1016/S1876-3804(08)60090-7 URL [Cited within: 1]

Terrestrial heat flow pattern and thermo-tectonic domains in the continental area of China

Geothermal structure and evolution of Bohai Bay Basin in eastern China

Thermal evolution models for different types of basin

The map of geothermal system types in China and its brief explanation

The Cenozoic tectono-thermal evolution of depressions along both sides of mid-segment of Tancheng-Lujiang Fault Zone, East China

Compilation of heat flow data in the continental area of China. 2nd ed

Classification of geothermal systems and their formation key factors

The characteristics of the geothermal field and its formation mechanism in the north China down-faulted basin

A tentative discussion on an evaluation system of geothermal unit ranking and classification in China

Geothermal evidence of Meso-Cenozoic lithosphere thinning in the Jiyang sub-basin, Bohai Bay Basin, eastern North China Craton

Thermal status profile in terrestrial sedimentary basins in China

Meso-Cenozoic thermal regime in the Bohai Bay Basin, eastern North China Craton

DOI:10.1080/00206814.2014.1002818 URL [Cited within: 1]

Meso-Cenozoic lithosphere thinning in the eastern North China Craton: Evidence from thermal history of the Bohai Bay Basin, North China

Thermal regime and hydrocarbon kitchen evolution of the offshore Bohai Bay Basin, North China Craton

Heat flow in the continental area of China: A new data set

DOI:10.1016/S0012-821X(00)00126-6 URL [Cited within: 1]

Evolution of Meso-Cenozoic thermal structure and thermal-rheological structure of the lithosphere in the Bohai Bay Basin, eastern North China Craton

Thermal structure of the lithosphere in north China

Characteristics of geothermal resources in Jizhong depression (Hebei region)

The assessment of geothermal resources potential of China

Diagenetic evolution and formation mechanisms of middle to deep clastic reservoirs in the Nanpu sag, Bohai Bay Basin, East China

Characteristics and classification of the geothermal gradient in the Beijing-Tianjin-Hebei Plain, China

DOI:10.1007/s11004-019-09814-8 URL [Cited within: 1]

Exploitation and utilization of oilfield geothermal resources in China

DOI:10.3390/en9010001 URL [Cited within: 1]

Estimate of influence of U-Th-K radiogenic heat on cooling process of granitic melt and its geological implications

DOI:10.1007/s11430-007-0004-1 URL [Cited within: 1]