Introduction

Covering a wide variety, unconventional oil and gas differ in concept and extension greatly in China and abroad[1,2,3,4]. In order to make the discourse well-directed, the unconventional oil and gas mentioned in this paper only include tight oil, tight gas, shale oil and shale gas. More specifically, the shale oil in this context is limited to medium to high maturity shale oil in source-reservoir integration[2]. These four types of unconventional oil and gas are the most important domains in unconventional oil and gas exploration and development in China.

After more than a decade of continuous exploration appraising and technical preparation, China’s unconventional oil and gas exploration has made a breakthrough from small to large and from quantitative to qualitative changes. As of the end of 2019, the cumulative proven geological reserves[5] were 7.37×108 t for tight oil and shale oil, 5.1×1012 m3 for tight gas, and 1.06×1012 m3 for shale gas. In the annual oil and gas production of 2019, tight oil and shale oil contributed 175×104 t, tight gas more than 300×108 m3, and shale gas more than 80×108 m3. Unconventional oil and gas have become one of the most important major resources for increasing oil and gas reserves and production in China. Many large oil and gas basins in China, such as Ordos, Bohai Bay, Songliao, Junggar and Sichuan, have stepped in or are about to enter the era of unconventional oil and gas exploration and development.

The overall resource grade of unconventional oil and gas is low. The reservoirs are tight, complex in lithology, mostly with thin interbeds, strong in heterogeneity and anisotropy. Those geological and reservoir characteristics make the exploration and development of unconventional oil and gas have special requirements on logging technology compared with that in conventional oil and gas. Logging technology is a technical integration consisting of four separate parts, i.e. data acquisition, processing, experiments, and interpretation and evaluation. These four are interlocked and indispensable to form a complete technical chain. In the era of unconventional oil and gas, unconventional logging technology is required. Driven by the technical demand of unconventional oil and gas, it is urgent to develop advanced logging technologies in terms of acquisition equipment, processing and evaluation methods, and petrophysical experimental research, and establish a highly applicable, advanced and complete technology chain to actively respond to the technical challenges faced in unconventional oil and gas exploration and development.

At present, the development of unconventional oil and gas logging technology is mostly aimed at evaluation methods of tight oil and medium to shallow shale gas, including "seven properties" evaluation (lithology, physical properties, electrical properties, oil and gas bearing property, brittleness, hydrocarbon generation characteristics and stress anisotropy) and “three qualities” evaluation (source rock quality, reservoir quality, and engineering quality) etc.[1, 4, 6]. For example, in the Ordos Basin, parameters such as shale content, sand body structure, ratio between sandstone and stratum thickness, and interbed density were established to evaluate the macro-heterogeneity of the tight reservoirs of the Triassic Yanchang Formation, and to study the distribution of sand bodies[7]; in the northern Songliao Basin, tight oil “sweet spots” of the Cretaceous Quantou Formation were identified by an oil production intensity based on the parameters including sand volume used for fracturing, reservoir physical properties and oil-bearing properties[8]; and in southern Sichuan Basin, four parameters were selected to evaluate the horizontal well reservoir quality, i.e. porosity, organic carbon content, brittleness index and total gas in place for medium to shallow marine shale gas reservoirs[9]. However, there are few literatures on the technical requirements and development of unconventional oil and gas logging data processing and experimental analysis, as well as of evaluation methods of shale oil and deep shale gas published so far. We systematically analyze the main technical challenges and requirements encountered in logging data processing, experiments, and evaluation in unconventional oil and gas exploration and development. Based on the development status of logging technology in China and the development trend of logging technology in the world, and in view of the geological and reservoir characteristics of unconventional oil and gas, we put forward corresponding technical measures and development priorities, so that the logging technology will play a better role in improving the quality and efficiency of unconventional oil and gas exploration and development.

1. Role of logging in unconventional oil and gas

In the life cycle of efficient exploration and effective development of unconventional oil and gas reservoirs, logging technology can play many key technical roles, among which the role of logging evaluation technology is mainly reflected in the following three aspects.

1.1. Selection of oil and gas sweet spots and their distribution

For low-grade poor-quality resources such as unconventional oil and gas, the first issue to be solved is how to find the "oil and gas sweet spots", namely the most favorable intervals on the profile and the most favorable area on the plane. "Oil and gas sweet spot" refers to a reservoir that is relatively rich in oil and gas which can be easily and effectively produced. It is an integration of reservoir sweet spot and engineering sweet spot.

Generally, key parameters describing the static characteristics of reservoir, such as effective porosity, saturation, effective thickness, permeability, and oil and gas mobility, are used to characterize the reservoir quality; and key parameters describing the rock mechanics characteristics of reservoir, such as static brittleness index, stress distribution and pore pressure, are used to characterize the engineering quality. Considering the source rock controlling accumulation characteristic of unconventional oil and gas, key parameters describing the source rock's hydrocarbon generation and expulsion ability, such as the total organic carbon content, effective thickness and hydrocarbon expulsion efficiency, are used to characterize the source rock quality. Aiming at specific types of unconventional oil and gas, methods and standards for selecting oil and gas sweet spots can be established based on a combination of these three types of quality.

Obviously, logging plays an important role in the selection of oil and gas sweet spots. For example, the "seven properties" can be analyzed in continuous depth by using electrical, nuclear, acoustic and mechanical logging information, to finely evaluate and classify the source rock quality, reservoir quality and engineering quality, and to eventually select sweet spot intervals. Through comprehensive multi-well logging evaluation and well-seismic integrated analysis, the oil and gas sweet spot areas can be defined from a two dimensional to a three-dimensional space.

1.2. Calculation of reserve parameters

In the calculation of unconventional oil and gas reserves, well logging should provide at least reserve parameters such as porosity, saturation, effective thickness, and area of oil and gas zone, etc. This is similar to conventional oil and gas. But its calculation methods and technologies need to be developed and innovated to suit the geological and characteristics of unconventional oil and gas reservoir.

1.2.1. Porosity calculation

Porosity is one of the four basic parameters for reserve calculation. Considering the diverse pore types and complex pore structure of unconventional oil and gas reservoirs, not only the total porosity, but also the effective porosity and movable fluid porosity should be calculated (the difference between the two is the capillary porosity). In typical unconventional oil and gas reservoir, there is generally no movable water, and movable fluid porosity is the storage space of movable oil and gas, which is the key parameter for sweet spot evaluation. For shale gas and higher maturity shale oil, organic porosity should also be calculated.

The current national reserve specifications require that the relative error of calculated porosity should not be greater than 8%. This accuracy requirement is formulated for conventional oil and gas reservoirs. Obviously, for unconventional oil and gas reservoirs with a main porosity range of 3% to 10%, it is not easy to meet this requirement, limited by factors such as the accuracy of basic logging data and core experiment analysis technology, and this problem needs to be solved with high- precision logging technology and unconventional reservoir experiment analysis technology.

1.2.2. Permeability calculation

Although permeability does not directly participate in reserve calculation, it can play a key role in determining the lower limit of effective thickness and reserve class, calculating recovery factor, and designing development plans. Clearly, it is an indispensable parameter for reserve calculation.

Logging, especially nuclear magnetic resonance logging, can determine accurate formation permeability in continuous depth. However, for unconventional oil and gas reservoirs with an overburden permeability of less than 0.1×10-3 μm2, it is difficult to control the accuracy of calculation, and the accuracy of half an order of magnitude is considered satisfactory. Considering that the permeability of unconventional oil and gas reservoirs, especially shale oil and gas reservoirs, have strong anisotropy in permeability, the vertical and horizontal permeabilities need to be further calculated to evaluate the flow capability of vertical and horizontal wells respectively.

1.2.3. Saturation calculation

Generally, unconventional oil and gas reservoirs do not contain movable formation water. Therefore, as long as the irreducible water saturation is determined, the oil and gas saturation is:

Sh=1-Swr

There are many methods to calculate irreducible water saturation by logging data, such as resistivity rock-electricity model, nuclear magnetic resonance logging and empirical formula[6, 10]. When the reservoir contains movable formation water, the movable water saturation needs to be calculated. In this case, the oil and gas saturation is expressed as:

Sh=1- Swr-Swm

In shale oil reservoirs, movable oil and bound oil often coexist, but it is the movable oil content that determines the sweet spot location and production performance. For this reason, it is necessary to further calculate the movable oil saturation, and together with movable fluid porosity to calculate the movable oil content. For shale gas reservoir, the free gas saturation should be calculated in order to determine the free gas content.

In the current national reserve specifications, the absolute error of saturation calculation is required to be less than 5%. For unconventional oil and gas, it is very difficult to meet this requirement; therefore, it is necessary to develop new methods of saturation calculation by carrying out in-depth study of tight reservoir rock-electricity experiments and make full use of advanced non-resistivity logging technology. Unconventional oil and gas reservoir formations typically are drilled at faster speed and exposed to the fracturing fluid (often oil-based) for shorter time before logging, besides, the reservoir rocks are tight in nature, so the reservoirs are generally weak in fracturing fluid invasion, unless the reservoirs have rich natural fractures or shale bedding fractures, and greater flow capacity. When selecting a logging program for accurate calculation of saturation, it is not necessary to pay too much attention to the detection depth, but more attention to the vertical resolution of the instrument. It is suggested to prioritize research on saturation calculation methods based on nuclear magnetic resonance, dielectric permittivity and elemental spectrum.

1.2.4. Fluid identification

Different types of unconventional oil and gas reservoirs Note: [a] There is no movable water in typical tight and shale reservoirs, but if the oil and gas accumulation is insufficient, there may be some movable water; [b] means this fluid may exist, depending on the oil accumulation characteristics of the reservoir and the nature of the crude oil etc.; [c] means this fluid may exist, depending on the thermal evolution and gas accumulation characteristics of the shale gas reservoirs.

contain different types of fluids (Table 1), so identification of fluids in unconventional reservoirs is much more complicated than that in conventional oil and gas reservoirs. Therefore, the application of advanced and suitable logging information is preferred to establish interpretation charts for identifying different types of fluids. For shale oil reservoirs, it is necessary to identify various organic matters such as movable oil, bound oil, bitumen and kerogen, and calculate their corresponding volume contents, locate the oil and gas sweet spots, and correct the influence of bitumen and kerogen on porosity calculated from density log and resistivity log. For shale gas reservoirs, it is necessary to identify bitumen and kerogen and calculate their content, to obtain the accurate total organic carbon content, adsorbed gas content and organic porosity, and the effect of bitumen and kerogen on the porosity from density logging must be corrected.

Table 1 Fluid distribution of different types of unconventional oil and gas reservoirs.

| Oil and gas reservoir | Movable oil | Bound oil | Bound water | Movable water | Free gas | Adsorbed gas | Bitumen | Kerogen |

|---|---|---|---|---|---|---|---|---|

| Tight oil | √ | √ | √ | √[a] | √[b] | √[b] | ||

| Shale oil | √ | √ | √ | √[a] | √[b] | √ | √ | |

| Tight gas | √ | √[a] | ||||||

| Shale gas | √[c] | √[c] | √ | √ | √ | √ | √ |

1.2.5. Determination of effective thickness

Based on the above results of porosity, permeability and saturation calculations and fluid identification, oil testing and fracturing data are analyzed to select the sensitivity parameters which describe the characteristics of the reservoir (these parameters either comes from field acquisition or logging interpretation). Logging reservoir classification standard is established to determine the cutoff of effective thickness. Then the effective thickness of each well and each calculation unit is calculated one by one. In the determination of the effective thickness of unconventional oil and gas reservoirs, it is necessary to pay special attention to the following two aspects of research.

Firstly, one should consider the differences in oil and gas accumulation and select corresponding sensitivity parameters for specific types of unconventional oil and gas reservoirs. For shale gas reservoir, total organic carbon content (TOC) is one of the sensitivity parameters. For shale oil reservoir, this parameter may not be applicable, and the key sensitivity parameter should be movable oil content. For tight oil and gas reservoir, the oil and gas saturations are the key sensitivity parameters. What’s more, not only the sensitivity parameters of petrophysical properties and oil-bearing properties but also the static brittleness index describing the brittleness characteristics of the reservoir should be considered. These parameters should be combined to establish the effective thickness classification standard.

Secondly, shale oil and gas reservoirs (including some tight oil and gas ones) are basically thin interbedded, with single layer thickness smaller than the vertical resolution of most logging tools, so it is difficult to accurately classify a single reservoir. For this reason, the logging data with high vertical resolution should be made full use, and the inversion processing technology for thin interbedded reservoir should be studied.

1.3. Technical support for drilling and hydraulic fracturing

The technical support of logging technology for drilling and fracturing mainly lies in: (1) By carrying out multi-well evaluation and comprehensive analysis of well-seismic data, the spatial distribution characteristics of sweet spots can be figured out to support the deployment of horizontal wells. (2) Selecting sweet spots and target zones of the horizontal well. (3) The lateral connectivity of the reservoir, the horizontal in-situ stress direction, and the azimuth of natural fractures can be figured out to guide the design of horizontal well trajectory. (4) Optimizing the sensitive logging parameters of geosteering to guide the application of geosteering tools to improve the encountering rate of oil and gas zones. (5) The reservoir quality and engineering quality of the horizontal section, lithological barriers and stress barriers, and the configuration of reservoir sweet spots and engineering sweet spots can be worked out to guide the design of fracturing stages and clusters and improve the pertinence of hydraulic fracturing. (6) Horizontal well multiphase flow production profile logging and/or tracer logging can be used to figure out the fluid production of each stage or cluster, and horizontal well acoustic reflection logging can be used to evaluate the reservoir volume reached by hydraulic fractures, and assess fracturing effect quantitatively, improve the learning curve, supporting the optimization of later fracturing plans and improve the evaluation method of oil and gas sweet spots.

To sum up, in the era of unconventional oil and gas, logging for unconventional reservoirs should be developed, including logging technologies for data acquisition, data processing, interpretation and evaluation, and petrophysical analysis.

2. Key development points and technical requirements of logging technology

Unconventional oil and gas logging evaluation technology includes method and technology in three aspects, petrophysical research, logging data processing, and logging interpretation. Among them, logging interpretation is the purpose, and petrophysical research and logging data processing are the foundation. In view of technology requirements of logging evaluation and maturity of logging technology, petrophysical experiment and logging data processing methods which should be developed in priority are introduced first, then the logging evaluation technologies for shale oil reservoir with source-reservoir integration and deep shale gas reservoir are discussed.

2.1. Key technologies of petrophysical experiment

The petrophysical experiment is the basis for the research and development of logging acquisition technology and evaluation method. In view of the geological characteristics of unconventional oil and gas reservoirs, the following 3 key techniques of petrophysical experiment should be developed in priority.

2.1.1. Mobile full-diameter core two-dimensional NMR experiment

As mentioned above, although the two-dimensional NMR logging can identify movable oil, bound oil, movable water, bound water, natural gas, and bitumen and other fluid types, its specific identification model is closely related to lithology, pore structure, fluid properties and wettability of reservoir[11], Therefore, it is necessary to strengthen 2D NMR core experimental research and establish customized evaluation models, methods for parameter determination and standard chart for fluid type identification to eliminate the uncertainty of interpretation.

Nowadays, in most laboratories, conventional core plugs of 1.5 cm×2.5 cm are commonly used in two-dimensional NMR experiments, which is bound to bring about three problems. Firstly, it is very difficult to drill qualified plugs from shale cores, especially laminated shale cores. Secondly, the fluid distribution in the plug samples is often quite different from the fluid occurrence in the undisturbed formations, especially for cores containing gas and light crude oil. Thirdly, the sample is too small in size to fully describe the pore throat distribution and porosity and permeability of strong heterogeneous reservoirs, that is, the representativeness of the samples is questionable. To solve these problems, the mobile full-diameter core two-dimensional NMR experimental technology should be vigorously developed. It has technical functions below.

(1) It can finely describe pore throat characteristics of tight reservoirs with high signal-to-noise ratio (SNR) of data (greater than 50) and short echo spacing (0.1 ms or 0.2 ms, or even smaller). (2) With high vertical resolution (about 1 cm), it can evaluate thin interbeds. (3) Accurate identification of different types of fluids: as it can measure the longitudinal relaxation and transverse relaxation time at the same time, then T1-T2 charts of different types of oil and gas reservoirs can be established to work out the standards for identifying bound water, movable water, movable oil and bound oil. In addition, repeated measurements of core samples saturated with different fluids can be carried out to build systematic T1-T2 chart library. (4) With abundant measurement modes, flexible and adjustable measurement parameters, it can meet the requirements of measuring various types of reservoirs and fluid properties for different purposes. According to the macro-structure of the formation and logging acquisition speed, the core moving speed can be adjusted to obtain measured values at different resolutions. The time lapse measurements at different intervals can be carried out to study the characteristics of fluid volatility and dissipation to calculate crude oil viscosity and movable oil saturation. (5) Full-diameter core scanning measurement can be done at the wellsite as the tool can be safely and conveniently transported to the field to do measurement on fresh core samples in time on the wellsite. The scanning is done as the core sample moves at set speed in advance. In consideration of core incompleteness caused by factors such as coring recovery rate or core damage, a series of accurately calibrated rock samples with porosity of 3%-20% and permeability of (0.1-10.0)×10-3 μm2 need to be prepared in advance to ensure accurate measurement of incomplete core samples. (6) Natural gamma log should be measured at the same time to ensure the precise match of depths of the core sample and logging data.

2.1.2. Experiment technologies for shale acoustic and electrical anisotropies

Lamellar and thin interbedded shales all have strong anisotropy, so it is urgent to develop petrophysical experimental analysis techniques to study acoustic and electrical anisotropies. Conventional core plug samples can’t fully reflect the electrical and acoustic anisotropies of the formation. It is necessary to develop a complete set of experimental techniques for electrical anisotropy on large-scale square samples of 5 cm×5 cm and 7 cm×7 cm cut from drilling cores or even larger samples drilled from outcrops. With these technologies, we can do the following studies.

(1) The resistivity and rock electrical parameters in tri-axial directions, including acoustic properties such as the velocity, amplitude, and dispersion of compressional, shear, and Stoneley waves, as well as the permeability measured by pressure pulse decay method. The quality control during the experiment and data processing is important.

(2) The resistivity, rock electrical parameters, acoustic parameters and permeability of the original rock sample before oil cleaning and these parameters of the same sample with different water saturations after oil cleaning can be measured.

(3) Calculation models of porosity, saturation and permeability of heterogeneous reservoir and relevant parameter determination methods, and methods to define cutoffs of the electrical and petrophysical properties for effective thickness of formation based on logging data can be researched.

2.1.3. Physical modeling analysis with digital core

By measuring the macroscopic equivalent petrophysical properties of full-diameter cores or core plugs, conventional core experiments can not accurately characterize microscopic characteristics of unconventional oil and gas reservoirs with poor petrophysical properties, complex pore structure, and strong heterogeneity. Digital core experiment techniques such as multi-scale CT scanning, scanning electron microscopy, and quantitative mineral composition analysis can obtain large amounts of micro- and nano-resolution image data[12], and finely depict the characteristics of rock structure and pore structure (such as distribution pattern of organic matter, mineral content, grain size distribution, grain support structure, radius distribution of pores and throats and their connectivity and flow characteristics, etc.[13]), so they are very important means of unconventional oil and gas petrophysics research. In order to give full play to the excellent capability of digital core experiment to ensure the reliability and accuracy of its analysis results, and in view with the current situation of digital core analysis, three aspects of research should be enhanced. First, according to the complexity of the reservoir, the selection method and sampling quantity specification of different resolution scanning need to be studied to fully characterize the core microstructure to avoid sweeping generalization and data redundancy at the same time. Second, the technologies including micro-pore network modeling, two-phase seepage simulation and image coarsening and stitching processing with different resolutions and three-dimensional modeling should be developed to achieve fine analysis results that can match conventional core scales and even logging scales. Third, high precision nuclear magnetic resonance (echo spacing no more than 0.2 ms) and high-pressure mercury injection experiments for conventional cores should be carried out, and new calculation models of "seven-property" parameters and new "three-quality" logging evaluations need to be invented under the guidance of digital core research results.

2.2. Key technologies for logging data processing

The processing of borehole image logging and scanning of logging data is the important basis for logging interpretation and evaluation. Different from the "what you log is what you see" of conventional log curves, the raw data acquired by image logging and scanning of logging data must be processed by a series of inversion with appropriate models and parameters before used for further interpretation and evaluation. If any of the links is not done well, even if the quality of collected data is excellent, "false data" could come up to mislead logging interpretation and evaluation. Therefore, we should pay as much attention to log data processing as we do for seismic data processing. The geological complexity of unconventional oil and gas reservoir makes logging data of these reservoirs subject to influences of more factors and the processing more difficult. Hence, more attention should be paid to the research of processing methods, especially the processing methods for NMR and far detection acoustic log data of horizontal wells.

2.2.1. Fine inversion processing technology for tight reservoir NMR logging data

NMR logging is one of the main logging technologies for evaluating unconventional oil and gas reservoirs. But to make good use of this technology, the following three aspects are essential for data processing.

(1) Improving the SNR of the data. Compared with conventional reservoirs, unconventional oil and gas reservoirs have higher requirements on the accuracy of calculated total porosity, effective porosity and movable porosity, as well as the accuracy of pore structure evaluation. Using NMR logging data with high SNR is one of the effective countermeasures. However, the storage space of unconventional reservoirs is small, making it more difficult to obtain NMR logging data with high SNR. For this reason, after understanding the basics of the formations and types of noises (such as coherent noise and incoherent noise), the fit-for-purpose processing methods to improve the SNR need to be worked out. Unless conditions permit (such as thick reservoirs and high vertical resolution of the logging tool), it is not recommended to use the deep stacking method (stacking echo trains of adjacent depths) to improve the SNR, because this method is at the expense of sacrificing the vertical resolution, and if all data at different depths are low in signal-to-noise ratio, the processing result by this method is not good.

(2) Improving the resolution of micro pores capturing. In unconventional oil and gas reservoirs dominated by micro pores[14], the echo signals of NMR logging decay quickly, and most of them are in the short relaxation time period. At present, the commonly used T2 inversion method of uniform point distribution based on medium and high porosity and permeability reservoir can’t finely describe the pore structure of tight reservoir. Therefore, the T2 inversion method finely characterizing the variation of the short relaxation time spectrum should be studied to distinguish the differences in pore structure of tight reservoirs[15].

(3) Improving the recognition ability of different types of fluids. NMR logging is a very effective means to identify hydrocarbon in unconventional oil and gas reservoirs, but processing methods suitable for NMR logging need to be developed. In light of the characteristics of crude oil and reservoir pore structure, extraction technology of transverse relaxation information related to the bulk relaxation of crude oil and its sensitive parameters[16,17] need to be studied, and fluid identification method and chart need to be worked out[18]. The 2D NMR logging processing algorithm needs to be developed, for reservoirs with different pore structures and fluid properties, pertinent clustering processing methods based on T1-T2 spectrum and corresponding classification standards need to be studied to distinguish all kinds of fluids.

2.2.2. Processing technology for azimuthal ultra-distance detection acoustic logging of horizontal well

The current processing technology for far detection acoustic logging is developed for vertical well log data, and doesn’t fit the purpose of evaluating the hydraulic fracturing effect of horizontal well. On the basis of studying wave train propagation characteristics, extraction method and noise reduction method of acoustic field near horizontal wellbore and far detection acoustic field, the anisotropy and heterogeneity of fracture network, the acoustic field response characteristics of the interface between fracturing fluid and natural gas (or crude oil), and qualitative identification and quantitative description methods for the interface should be studied, and the corresponding evaluation criteria should be established.

2.3. Key logging interpretation and evaluation technologies

It is necessary to promote progressively the logging interpretation and evaluation technology for unconventional reservoirs, which includes the evaluation of “seven properties”, “three qualities” and sweet spot[4,6]. Among them, the evaluation technologies and methods for tight oil and gas and medium-shallow shale gas are basically mature and have been applied on a large scale with good results. The next paragraph in this paper only focuses on the technologies and methods that should be developed in priority for shale oil and deep shale gas reservoirs.

2.3.1. Technologies for shale oil “sweet spot” evaluation

Evaluation of shale oil sweet spot has many commonalities and particularities from evaluation of sweet spot. The commonalities are the calculation methods of TOC, contents of mineral components, porosity, pore structure and in-situ stress, while the particularities are the technical challenges caused by geological and reservoir characteristics of shale oil. Corresponding, the following sweet spot evaluation technologies for shale oil should be developed in priority.

Evaluation of shale oil sweet spot has many commonalities and particularities from evaluation of sweet spot. The commonalities are the calculation methods of TOC, contents of mineral components, porosity, pore structure and in-situ stress, while the particularities are the technical challenges caused by geological and reservoir characteristics of shale oil. Corresponding, the following sweet spot evaluation technologies for shale oil should be developed in priority.

2.3.1.1. Evaluation technologies for shale rock macro-texture

Due to differences in thermal evolution degree and original sedimentary environment, shale oil reservoirs have big differences in micron-millimeter scale laminar texture and bedding fracture, so they come in three types of macro-textures: massive, weak-laminated, laminated[19,20]. Laminated shale includes sandy laminar shale and shale with bedding fractures, and has horizontal permeability 12-78 times vertical permeability[21]. Although the large difference between horizontal permeability and vertical permeability may be attributed to the neglect of horizontal permeability increase caused by stress release of the core in the core testing, there is no doubt that the laminated shale has much stronger horizontal flow capacity[22,23]. Moreover, the sandy lamina and bedding fracture have more intergranular pores developed, and shale with beddings often has more organic pores[14]. Therefore, the laminated shale is a favorable reservoir for shale oil. In the evaluation of shale oil “sweet spot”, the first step is to identify macro-texture type of the shale, and the macro-texture is taken as the precondition of “sweet spot”.

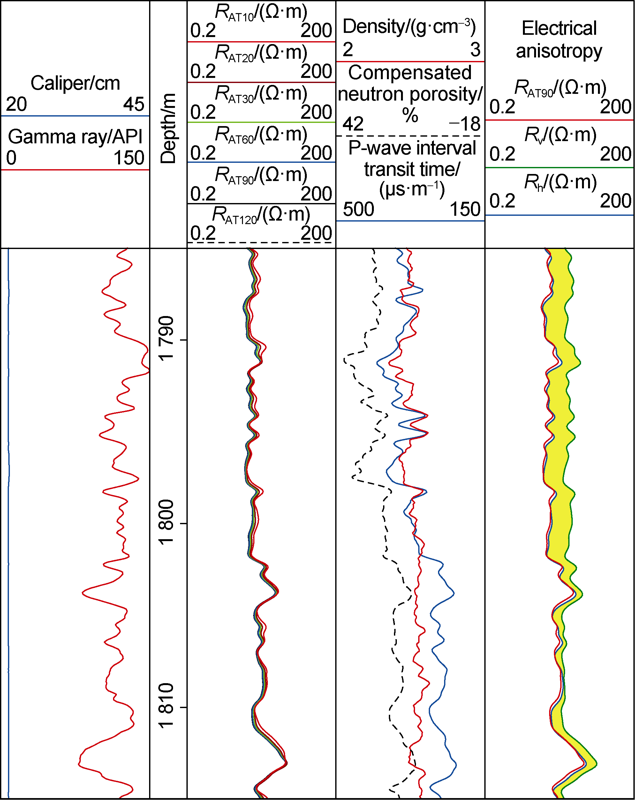

Electrical image logging has very high vertical resolution (up to 5 mm), and can clearly reflect millimeter scale laminae and bedding fractures distribution, so it is the most effective and powerful logging tool for shale macro-texture evaluation. But the relevant evaluation method has not been established. Therefore, the laminae and bedding fractures should be identified in electric imaging based on the anisotropy experimental analysis and core description, the typical image library of different types of shale oil reservoirs should be established as well, and then sensitive parameters (such as the number of laminae per unit thickness, connectivity, and thickness ratio, etc.) and evaluation methods to characterize the development of laminae and bedding fractures need to be studied. Based on this, the quantitative classification criterion of rock macro-texture can be established to distinguish three types of shale: laminated, weakly laminated and non-laminated, as shown in Fig. 1.

Fig. 1.

Fig. 1.

Evaluation of shale lamina and lamellation development by electrical imaging logging.

If there is no electrical imaging data, the electrical anisotropy data from three-component induction logging or full diameter core experiment can be analyzed to work out electrical anisotropy coefficient to evaluate the development degree of laminae and lamellation, and to establish the classification criterion of shale macro-texture as shown in Fig. 2. In the interval of 1785.2-1802.5 m, the vertical resistivity of the three-component induction logging is about 10 times of resistivity of array induction logging at 90 inches of detection depth (close to the horizontal resistivity), and the anisotropy coefficient is 3.2, indicating that the electrical anisotropy is strong, and the shale can be identified as laminated or layered shale. In the interval of 1802.5-1818.0 m, the vertical resistivity is basically equal to the horizontal one, and the anisotropy coefficient is about 1, indicating that the electrical anisotropy is weak, so this section of shale is identified as massive shale. In addition, the dispersion characteristic of cross dipole acoustic logging can be used to identify the acoustic anisotropy caused by laminae and bedding fractures and to establish the classification method and criterion of rock macro-texture.

Fig. 2.

Fig. 2.

Analysis of shale macro-texture by electrical anisotropy of three component induction logging.

2.3.1.2. Evaluation technologies of physical property

For fine evaluation of physical property of shale oil reservoirs, technologies in the following 4 aspects need to be developed:

(1) Shale oil is often accompanied by heavy hydrocarbons such as bitumen and bound oil, which seriously restrict the accuracy and reliability of effective porosity calculation. Therefore, the identification method of heavy hydrocarbon needs to be developed; Secondly, the determination method of its content needs to be developed to correct the calculated porosity from density logging and improve its calculation accuracy.

(2) As shale oil reservoir space basically contains no movable water, it can be regarded that its movable pore space only contains movable oil. On the basis of accurate calculation of total porosity and effective porosity, calculation method of movable porosity needs to be researched to support accurate calculation of movable oil content.

(3) Under the premise of high thermal evolution degree (with RO value of greater than 1.2%), organic pores (including micro fractures in organic matter) are relatively more developed in shale, sometimes accounting for 50% or more of the total porosity, making them an indispensable important part in petrophysical property evaluation. In the case with no organic pore collapse, the organic pore size is positively correlated with thermal evolution and TOC of the shale in general. If the TOC value from core experiment analysis or logging data calculation increases synchronously with the effective porosity, it can be concluded that the organic porosity is well-developed, and vice versa. Furthermore, the calculation method of organic porosity from logging data which has not yet been established needs to be invented.

(4) As shale oil reservoirs have strong permeability anisotropy, calculation methods for vertical permeability and horizontal permeability based on logging data need to be studied separately, to better analyze the flow characteristics of vertical and horizontal wells.

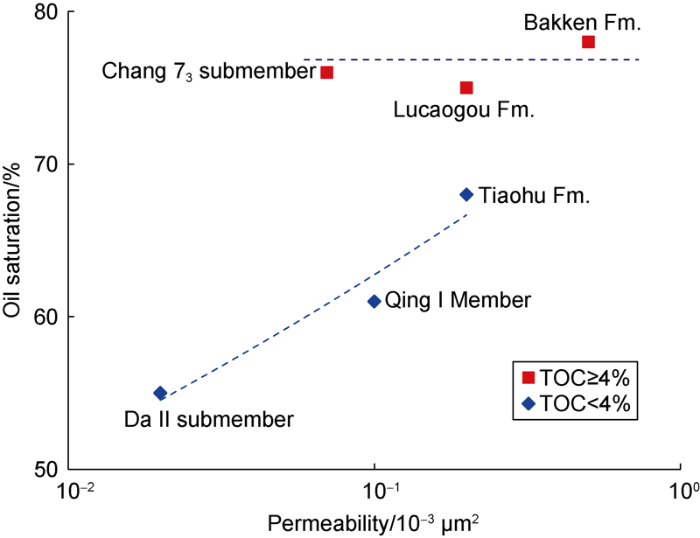

2.3.1.3. Quantitative evaluation technologies of saturation distribution

Oil saturation is comprehensive embodiment of reservoir accumulation and dynamic characteristics, and can quantitatively characterize the current oil-bearing characteristics of reservoir, so it is one of the four key parameters (saturation, porosity, effective thickness and oil-bearing area) for evaluation of shale oil sweet spot. Worldwide studies show that the higher the oil saturation, the better the quality of shale oil reservoir. For shale oil reservoirs with source-reservoir integration, the oil saturation is controlled by the quality of source rock and reservoir quality jointly. When the value of TOC is higher than 4%, the oil saturation is hardly affected by reservoir quality, as shown in Fig. 3. The reason is that when the value of TOC is high, the hydrocarbon diffusion pressure can overcome the high displacement pressure of poor-quality reservoir (with low permeability), resulting in high oil saturation in the reservoir. When the value of TOC is low, the hydrocarbon diffusion pressure is low and can only overcome the displacement pressure of good quality reservoir, so the oil saturation of a reservoir is closely related to the reservoir quality. That is, the better the quality, the higher the oil saturation of the reservoir will be.

Fig. 3.

Fig. 3.

Relationship between oil saturation and permeability of shale oil reservoir. Chang 73 submember—Chang 73 submember of Triassic Yanchang Formation in Ordos Basin; Lucaogou Fm.—Permian Lucaogou Formation in Jimusaer sag, Junggar basin; Bakken Fm.—Devonian Bakken Formation in Williston Basin, U.S.; Da II submember—The second sub-member of Da'anzhai member of Jurassic Ziliujing Formation in Central Sichuan Basin; Qing I Member—The first member of Cretaceous Qingshankou Formation in Songliao basin; Tiaohu Fm. —Permian Tiaohu Formation in Santanghu Basin.

It must be noted that the above understanding is based on the statistical analysis of specific well data, which belongs to qualitative description and analysis and cannot fully characterize the distribution pattern of saturation. Based on these qualitative descriptions, the inherent physical laws should be studied to establish the mathematical model to quantitatively characterize oil saturation distribution in shale, and then work out prediction method of saturation distribution to improve the accuracy of the sweet spot evaluation.

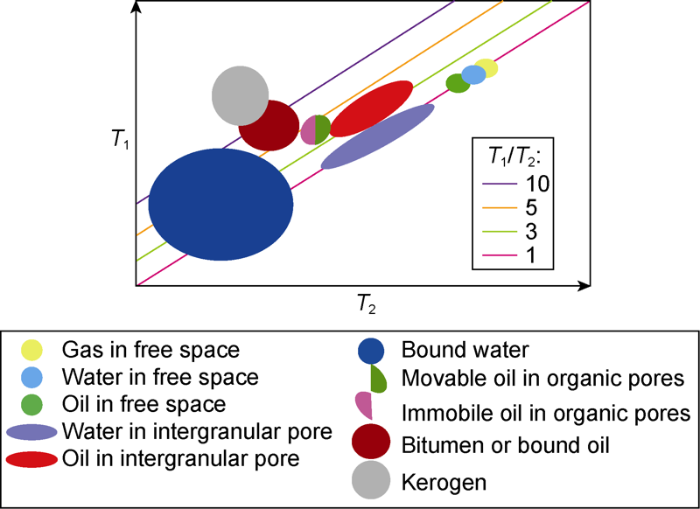

2.3.1.4. Calculation method of movable oil

Content and distribution of movable oil are key contents of medium and high maturity shale oil sweet spot evaluation. The calculation formula of movable oil content per unit area is as follows:

${{V}_{\text{om}}}=\phi h{{S}_{\text{om}}}$

In the above formula, porosity and effective thickness are easier to determine and controllable in calculation accuracy. The accuracy of movable oil content calculation mainly depends on the calculation accuracy of movable oil saturation. At present, only nuclear magnetic resonance logging can characterize and calculate the movable oil saturation. No matter one-dimensional or two-dimensional nuclear magnetic resonance logging is used, the essence of its movable oil saturation calculation method is T2 cut-off method or T1-T2 cross-plot classification method[24,25]. That is to say, the movable oil saturation is determined according to the T2 pore component greater than the cut-off or the cumulative pore volume of T1-T2 intersection points falling into the movable oil area (Fig. 4). The physical basis of the calculation method is that shale oil reservoir does not contain movable water and has oil-wet macropores and water-wet micropores. Hence, the macropore space is filled merely with crude oil flowable. In order to ensure the reliability of the method, the following three aspects need to be studied in priority.

Fig. 4.

Fig. 4.

Fluid type classification by T1-T2 of two-dimensional NMR (modified from reference [24]).

(1) Wettability analysis: To study the wettability differences of pores in different sizes to see whether they meet the prerequisite, that is whether the macropores are oil-wet and micropores are water-wet. (2) Cut off value determination: the T2 cut-off value of one-dimensional NMR logging and the movable oil distribution area of two-dimensional NMR logging are determined from the experimental data based on the reservoir pore structure and crude oil properties. (3) Evaluation of crude oil flowability: the crude oil flowability is evaluated based on the permeability and crude oil viscosity under reservoir conditions. Permeability can be calculated with logging data and then calibrated with core data. There are many methods for this, and the key is to improve the calculation accuracy (within half an order of magnitude). But there is still no mature logging calculation method for crude oil viscosity currently. Logging calculation method for crude oil viscosity by using 2D NMR logging data and core data calibration needs to be invented. The accuracy of viscosity calculation result can be validated by using modular formation test results of ultra-low permeability reservoir.

2.3.1.5. Calculation of static brittleness index

The calculation methods of brittleness index mainly include the acoustic elastic modulus method proposed by Rickman et al.[26] and the mineral composition method proposed by Jarvie et al.[27]. However, after these two methods were introduced into the oil and gas industry of China and widely used in tight reservoir and shale reservoir evaluation, it has been found that the brittleness indexes calculated have noticeable discrepancy from the actual experimental result. Further study reveals that the root causes of the problem may be the following factors.

(1) Acoustic elastic parameter method: This method calculates the dynamic brittleness index, which represents the brittleness property of rock under transient and micro-pressure. This situation is quite different from the long time and large static load on real subsurface rock, so this brittleness index can’t accurately characterize the brittleness characteristic of subsurface rock. On the other hand, this method does not consider the influence of rock texture and subsurface stress condition on brittleness and assumes that elastic modulus and Poisson's ratio have the same impact on brittleness, but in fact Poisson's ratio is more sensitive than elastic modulus to brittleness.

(2) Mineral composition method: This method only considers the content of brittle minerals but doesn’t take the effects of grain size and grain contact on brittleness into account, and this is more prominent for shale oil reservoir.

To overcome the above problems, a series of modified brittleness index formulas have been proposed[28,29], but these formulas all have a common deficiency, that is, they can’t calculate the static rock brittleness index in situ reservoir condition with logging data alone, so they haven’t really solved the bottleneck problem of static brittleness index calculation with logging data. In the past two years, based on the research on the damage effect of formation around the wellbore during drilling and the regularity of corresponding acoustic variation wave[30], the idea of predicting formation brittleness by radial variation profile of compressional wave velocity around the wellbore has been proposed. This idea aims to evaluate formation brittleness according to the actual damage situation of formation around the wellbore, so the brittleness obtained is deemed the static brittleness under formation in situ conditions, and more effort needs to be put in the research to work out suitable method. In the research of this method, the inversion algorithm of wave velocity around the wellbore on tomography, the quantitative characterization and normalization method of drilling cutting force, and the processing method of effects of natural fractures, drilling fluid invasion and formation heterogeneity on wave velocity need to be worked out, and the brittleness index classification criteria based on the radial profile of P-wave and S-wave velocity need to be established.

2.3.1.6. Calculation of pore pressure and evaluation of barrier

The parameters characterizing engineering quality include elastic modulus, Poisson's ratio, brittleness index, horizontal stress difference, pore pressure coefficient and barrier characteristics, etc. The calculation methods for the first 3 parameters are mature or relatively mature, and the calculation accuracy of horizontal stress difference can be basically guaranteed if the anisotropic geomechanics model is used to calculate the minimum horizontal principal stress and the maximum horizontal principal stress and the results are calibrated with fracturing pump stopping pressure and electrical imaging of wellbore. The main challenges are the calculation of the pore pressure coefficient and evaluation of barrier, as there aren’t mature methods available for these issues so far.

In conventional oil and gas reservoirs, the under compaction of mudstone will lead to changes of logging characteristics such as increase of acoustic time and decrease of resistivity. The pore pressure of reservoir can be estimated by using mudstone compaction trend line, which is the commonly used Eton method[31,32]. However, in unconventional oil and gas fields, it is difficult to find uncompacted mudstone layer and determine the compaction trend line of mudstone, so there aren’t application conditions for Eton method. In addition, in unconventional oil and gas reservoir, there is not only pressure anomaly caused by under compaction, but also pressure anomaly caused by continuous hydrocarbon charging nearby or in situ. Logging characterization methods of pore pressure need to be invented according to genetic mechanisms of different pressure anomalies, and new pore pressure prediction models need to be developed to calculate the pore pressure coefficient.

The barrier can seal off the flow of fracturing fluid gathering between different fracturing intervals, knowledge of barriers in the reservoir is the basis for the design of fracturing clusters and stages. The characteristics of barrier are related to reservoir quality and engineering quality and include the characteristics of lithologic barrier and stress barrier. The former is mainly related to lithological characteristics (including mineral composition and content, elastic modulus, Poisson's ratio and compressive strength), porosity and permeability characteristics and fracture characteristics (fracture density, occurrence, hydrodynamic width, filling degree and type of filling minerals, etc.), while the latter is mainly related to the difference between maximum and minimum horizontal stresses, minimum horizontal stress orientation, pore pressure and overburden stress. Calculation model quantitatively characterizing the barrier and criteria of fracturing stage and cluster division should be set up by integrating the characteristics of the lithologic and stress barriers, and considering parameters of cementing quality, fracturing scale and sand/liquid ratio jointly.

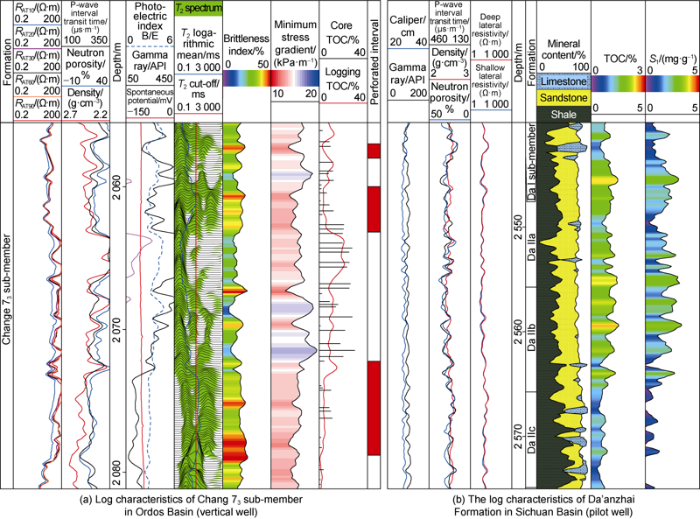

2.3.1.7. Evaluations and criterion for sweet spot

Current evaluation criteria for shale oil sweet spot are formed by inheriting the evaluation standards for shale gas sweet spot, and based on effective porosity, TOC, saturation and brittleness index. As mentioned above, TOC of shale oil reservoir comes from kerogen in source rock, as well as movable oil, bitumen and bound oil in storage space (including organic pore). But only TOC of movable oil is closely related to sweet spot. Obviously, it is not suitable to use the general TOC as the key parameter of sweet spot evaluation, and the evaluation result has big uncertainty in validity (Table 2). Movable oil content should be evaluated separately[23, 33-34] and taken as a key parameter for sweet spot evaluation. This is consistent with the conclusion that “it is more suitable to use free hydrocarbon rather than total organic carbon content to evaluate sweet spots in Songliao basin"[35]. Moreover, the fracturing results of quite a few vertical and horizontal shale oil wells have proved that the fractured intervals with large porosity, good pore structure, high brittleness index, small stress difference (the difference between the maximum horizontal stress and the minimum horizontal stress) and low TOC value have higher oil production. For example, the vertical well fracturing section (2073.5- 2078.0 m) in Fig. 5a had an oil production of 10.9 t per day. In contrast, the drilling interval with high TOC of horizontal well (2 554.5-2 562.5 m) shown in Fig. 5b had only a small amount of oil produced after fracturing.

Table 2 Effectiveness analysis of shale oil sweet spot evaluation with TOC and S1 from different origins.

| TOC from different origins | S1 from different origins | ||||

|---|---|---|---|---|---|

| Origin | Effectiveness of sweet spot evaluated by TOC | Effectiveness of sweet spot evaluated by S1/TOC | Origin | Effectiveness of sweet spot evaluated by S1 | Effectiveness of sweet spot evaluated by S1/TOC |

| Movable oil | Effective | Ineffective | Movable oil | Effective | Effective |

| Bound oil | Ineffective | Effective | Bound oil | Ineffective | Ineffective |

| Bitumen | Ineffective | Effective | Bitumen | Ineffective | Ineffective |

| Kerogen | Ineffective | Effective | Kerogen | Ineffective | Ineffective |

Fig. 5.

Fig. 5.

Comparison of fracturing results of different sweet spots.

In the past two years, based on the evaluation method of North American marine shale oil reservoirs, S1 or S1/TOC value were added as parameters for sweet spot evaluation. Like TOC, S1 can come from both movable oil in free hydrocarbon and retained hydrocarbon (immovable) of bitumen, bound oil, kerogen etc.[23, 36]. Obviously, sweet spot evaluation with S1 has big uncertainty (Table 2) too, and it will become more complicated if S1/TOC value is used as an evaluation parameter of sweet spot, the S1/TOC value is valid only when S1 comes from movable oil and TOC comes from immovable oil separately (Table 2). Moreover, when the TOC value is small, the ratio will be magnified multiple times, resulting in wrong interpretation of sweet spots, and thus overestimated number of sweet spots.

The evaluation method of shale oil sweet spot is still in the exploratory stage. The evaluation method of sweet spot with movable oil content as key parameter should be researched based on fine evaluation of petrophysical properties and crude oil properties. That is to say, the source rock quality should be evaluated by using distribution of organic matter, development degree of microfractures and organic pores as key parameters; reservoir quality should be evaluated by using porosity, permeability, porosity structure and movable oil content as key parameters; engineering quality should be evaluated by using static brittleness index, brittle mineral content and grain size, and grain support and contact relationship as key parameters. By comprehensively analyzing the correlation of the three qualities and source-reservoir matching relationship, the new shale oil evaluation criteria can be established, and the sweet spot intervals can be identified, and then the distribution area of sweet spots on the plane can be further defined by combining seismic data and logging data.

2.3.2. Evaluation technology for deep shale gas sweet spot

With the increase of depth and range of shale gas exploration and development, the shale gas reservoir more than 3500 m deep will become a new main type of target. As known to all, when the burial depth increases, and the temperature and pressure go up, the shale formation has the following characteristics: (1) The degree of thermal evolution increases, organic pores and lamination are more developed, and graphitization of shale may occur. (2) The content of free gas gets higher, and the adsorbed gas is mainly in state of multi-layer molecular adsorption. (3) The logging responses are more complex, and the anisotropy of electrical and petrophysical properties is stronger.

With these characteristics, deep shale gas reservoir can’t be evaluated by borrowing the evaluation method of medium and shallow shale gas reservoir. Specific evaluation methods and standards suitable for the characteristics of deep shale gas reservoir need to be invented on the basis of inheritance. Through high temperature and high pressure petrophysical experiments, the following researches on key properties of reservoir should be carried out: (1) organic pore distribution and resistivity response characteristics of shale rock in different thermal evolution degrees, especially the identification method and standard of graphitized shale; (2) calculation method of organic porosity and distribution pattern of organic pores; (3) features and calculation model of permeability anisotropy; (4) occurrence mechanism and content calculation method of adsorption gas.

Parameters for sweet spot evaluation include effective porosity (organic porosity included), TOC, total gas content (the sum content of free gas and adsorption gas) and graphitization degree. The first three parameters are almost the same as those of medium and shallow shale gas reservoir, while the fourth parameter is unique to deep shale gas reservoir. The parameters for deep shale gas engineering sweet spot evaluation consist of static brittleness index, horizontal stress difference and pore pressure. The deep shale gas sweet spot evaluation criteria can be established by combining features of reservoir sweet spot with engineering sweet spot.

2.3.3. Horizontal well formation modeling and evaluation technology

Horizontal well is the key technology to make the unconventional oil and gas development economic. The anisotropy of resistivity and acoustic logging is very strong in horizontal well, if combined with effect of thin interbedded surrounding rock, the logging responses are very complex, making the evaluation of "the seven properties" of unconventional oil and gas reservoir difficult. The following aspects in horizontal well logging processing and interpretation technology should be researched: (1) formation modeling based on the geometric relationship between borehole trajectory and formation; (2) data processing method for correcting surrounding rock and interface effect; (3) reservoir quality evaluation method with anisotropy considered; (4) evaluation methods of engineering quality integrating in-situ stress and brittleness; (5) identification method of sweet spot section of horizontal well combining reservoir quality and engineering quality and evaluation technology of formation fracability; (6) optimization method of fracturing staging and clustering scheme for horizontal well based on comprehensive evaluation of stress barrier and lithologic barrier; (7) processing and interpretation software for horizontal well logging data.

2.3.4. Big data intelligent sweet spot evaluation technology for unconventional oil and gas

The development era of unconventional oil and gas almost synchronizes with the digital development era of world oil and gas industry. The unexpected coincidence of the two spawns the intelligent logging technology for unconventional oil and gas evaluation. That involves establishment of logging processing, interpretation and evaluation methods, models and expert knowledge base for different types of unconventional oil and gas reservoirs based on multidisciplinary big data and professional knowledge related to unconventional oil and gas logging technology and technical standards, and creation of knowledge domain map based on "seven properties" relationship analysis of logging characteristics (including conventional logging, imaging logging and scanning logging), and research and development of intelligent algorithms for test interval recommendation, landing point optimization, and fracturing clustering and staging design for horizontal well based on "three quality" evaluation, and finally establish a set of logging intelligent technologies with data sharing and team collaboration driven by business workflow to comprehensively improve the quality, efficiency and safety of unconventional oil and gas logging. The set of logging technology includes logging program design, field data acquisition, logging supervision, logging data processing, interpretation and evaluation, and reserve parameter calculation etc. At present, large-scale unconventional oil and gas development blocks with good big data foundation, such as Sichuan-Chongqing shale gas, Chang 7 shale oil in Ordos Basin and Sulige tight gas, should be taken as breakthrough points to create replicable application scenarios of big data intelligent analysis for unconventional oil and gas logging as soon as possible, and progressively extend to the logging evaluation of different types of unconventional oil and gas reservoirs and study on remaining oil distribution pattern in old well blocks.

3. Conclusions

To meet the technical challenges in the era of unconventional oil and gas, the technical measures involving logging data processing, interpretation and evaluation, and petrophysics have been proposed in this paper, and the key points are summarized below:

· New petrophysical experimental methods represented by mobile full-diameter core 2D NMR and acoustic-electrical anisotropy measurement, as well as digital core analysis technology for unconventional reservoir characterization need to be developed in priority to guide the invention of new logging evaluation methods and new interpretation models.

· With hydrocarbon reservoir sweet spot evaluation as the core, the "seven properties” analysis technology and "three quality" evaluation method are improved to study the distribution pattern of fluid saturation in source rock controlled hydrocarbon reservoir, refined evaluation technique for barrier characterization considering both in-situ stress and lithologic characteristics, and data processing methods represented by 2D NMR and 3D ultra-distance detection acoustic logging in horizontal well need to be researched vigorously.

· Big data intelligent logging should be proactively developed. The unconventional oil and gas era coincides exactly with the digital era of big data intelligence in full swing. Naturally, we have come to the idea of integrating the big data of logging, mud log, core and fracturing data to establish the knowledge map, develop intelligent algorithms and intelligent analysis methods for the whole process of logging, from data acquisition to processing-evaluation and experiment, to continuously improve the effectiveness and quality of unconventional oil and gas formation evaluation with logging data.

Acknowledgements

The author is deeply grateful for Academician Zhao Wenzhi for his careful guidance and help during the writing of this paper.

Nomenclature

h—effective thickness, m;

RAT10, RAT20,RAT30, RAT60 and RAT90—array induction logging resistivity at detection depth of 25.4 cm (10 in), 50.8 cm (20 in), 76.2 cm (30 in), 152.4 cm (60 in) and 228.6 cm (90 in), Ω·m;

S1—soluble hydrocarbon obtained from pyrolysis per unit mass core or cuttings at temperatures of 90-300 °C, %;

Sh—hydrocarbon saturation, f;

Som—movable oil saturation, f;

Swir—irreducible water saturation, f;

Swm—movable water saturation, f;

T1—longitudinal relaxation time, ms;

T2—transverse relaxation time, ms;

TOC—total organic carbon content, %;

Vom—movable oil content, m3/m3;

ϕ—total porosity, f.

Reference

Types and resource potential of continental shale oil in China and its boundary with tight oil

DOI:10.1016/S1876-3804(20)60001-5 URL [Cited within: 2]

Development potential and technical strategy of continental shale oil in China

Progress, challenges and key issues of unconventional oil and gas developmentof CNPC

Logging characterization of macroscopic heterogeneity of tight oil reservoirs

Sweet spot classification method for tight oil reservoirs in Northern Songliao Basin

A comprehensive logging evaluation method of shale gas reservoir quality

Research on the log evaluation method of irreducible water saturation in Yinggehai Basin

NMR characterization of rock wettability and its preliminary experimental results

Review of 3D digital core modeling methods

Lithofacies characteristics of lacustrine shale oil and its optimization evaluation method: Chang 73 Member of Triassic Yanchang Formation in Ordos Basin

Micro- and nano-scale geological characteristics of the shale in the first Member of Lower Silurian Longmaxi Fm in SE Sichuan Basin

Quantitative evaluation method of pore structure of low permeability sandstone based on NMR logging: The Fourth Member of Shahejie Formation of South Slope in Dongying Sag

Nuclear magnetic resonance T2 spectrum multifractal characteristics and pore structure evaluation

DOI:10.1007/s11770-017-0614-0 URL [Cited within: 1]

Sensitive parameters of NMR T2 spectrum and their application to pore structure characterization and evaluation in logging profile: A case study from Chang 7 in the Yanchang Formation, Heshui area, Ordos Basin, NW China

DOI:10.1016/j.marpetgeo.2019.08.025 URL [Cited within: 1]

A method and device for online magnetic resonance multiphase flow detection

Laminae combination and shale oil enrichment patterns of Chang 73 sub-memberorganic-rich shales in the Triassic Yanchang Formation, Ordos Basin, NW China

Lower Es3 in Zhanhua Sag, Jiyang Depression: A case study for lithofacies classification in lacustrine mud shale

DOI:10.1007/s11770-018-0678-5 URL [Cited within: 1]

Progress and application of the experimental technologies for shale oil reservoirs: A case study on Gulong Area in Songliao Basin

Study on shale oil mobility and evaluation method of sweet spot

Research progress on shale oil mobility characterization

NMR Relaxometry in Shale and Implications for Logging

New generation NMR tool from Robust, continuous T1 and T2 measurements

Unconventional shale-gas systems: The Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale gas assessment

DOI:10.1306/12190606068 URL [Cited within: 1]

Micromechanical analysis and brittleness evaluation of heterogeneous tight reservoir

The influence of rock composition on dynamic and static elastic properties of longmaxi formation shales

Logging response characteristics and reservoir evaluation method of overpresure reservoir

On the problems of predicting pore pressure by equivalent depth method

Reservoir conditions and mechanism of shale oil flow

Oil-bearing potential, mobility evaluation and significance of shale oil in Chang 7 shale system in the Ordos Basin: A case study of well H317

Gulong shale oil in Songliao Basin

Advances in the basic study of lacustrine shale evolution and shale oil accumulation