Introduction

1. Drift flow closed relationship

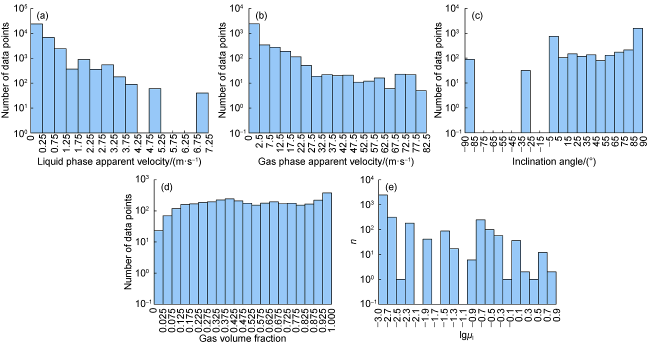

1.1. Multiphase flow experiment database

| Data sources | Number of data sets | Experimental fluid | Pipe Hydraulic diameter/m | Pipe inclination angle/(°) | Fluid viscosity/ (Pa·s) | Gas content |

|---|---|---|---|---|---|---|

| [14, 16, 19, 21-22, 24-28, 32, 34, 38, 40, 42, 44-46] | 1 794 | Air - water | 0.012 7-0.152 4 | -90-90 | 0.001 | 0.020 0-0.099 8 |

| [17] | 30 | Air - high viscosity oil | 0.050 8 | 0 | 0.187-0.587 | 0.102-0.660 |

| [18, 21] | 250 | Air - mineral oil | 0.050 8 | 28-90 | 0.185-0.213 | 0.149-0.777 |

| [23-24, 33, 35-36, 41, 43] | 954 | Air - kerosene | 0.030 4-0.051 0 | -90-90 | 0.001 3-0.002 0 | 0.006-0.991 |

| [37, 39, 47] | 227 | Air - oil | 0.038 1-0.050 8 | 0-90 | 0.123-0.568 | 0.08-0.89 |

| [26] | 54 | N2 - Luviskol | 0.054 5 | 90 | 0.980-6.880 | 0.08-0.69 |

| [21] | 24 | Air - paraffinic oil | 0.019 0 | 28-90 | 0.035 2 | 0.150-0.589 |

| [19] | 47 | Air - CMC | 0.076 0 | 90 | 0.010 | 0.688-0.963 |

| [20, 29-31] | 181 | Air - Silicone oil | 0.067 0 | 0-90 | 0.005 25 | 0.037-0.894 |

Fig. 1. Data distribution in the built database. |

1.2. Key parameters for drift flow closed relationship

Table 2. Correlation model of drift current relationship |

| References | Distribution coefficient | Gas drift velocity |

|---|---|---|

| [48] | ${{C}_{0}}=1.2$ | ${{v}_{\text{gm}}}=1.53{{\left( g\sigma \Delta \rho /\rho _{\text{l}}^{\text{2}} \right)}^{0.25}}$ |

| [7] | ${{C}_{0}}=1.15$ | ${{v}_{\text{gm}}}=1.53{{\left( g\sigma \Delta \rho /\rho _{\text{l}}^{\text{2}} \right)}^{0.25}}\sqrt{1-{{E}_{\text{g}}}}\sin \theta $ |

| [8] | Bubbly flow: ${{C}_{0}}=1.2-0.2\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;}\left[ 1-\exp \left( -18{{E}_{\text{g}}} \right) \right]\ \ $ Slug flow: ${{C}_{0}}=1.2-0.2\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;}\ $ Annular flow: ${{C}_{0}}=1+{\left( 1-{{E}_{\text{g}}} \right)}/{\left( {{E}_{\text{g}}}+4\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;} \right)\ \ }\;$ | Bubbly flow: ${{v}_{\text{gm}}}=1.41{{\left( g\sigma \Delta \rho /\rho _{\text{l}}^{\text{2}} \right)}^{0.25}}{{\left( 1-E_{\text{g}}^{{}} \right)}^{1.75}}$ Slug flow: ${{v}_{\text{gm}}}=0.35\sqrt{g{{D}_{\text{h}}}\Delta \rho /\rho _{\text{l}}^{{}}}$ Annular flow: ${{v}_{\text{gm}}}=\frac{1-E_{\text{g}}^{{}}}{E_{\text{g}}^{{}}+4\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;}}\left( {{v}_{\text{m}}}+\frac{\sqrt{g{{D}_{\text{h}}}\Delta \rho \left( 1-E_{\text{g}}^{{}} \right)}}{\sqrt{0.015{{\rho }_{\text{g}}}}} \right)$ |

| [9] | ${{C}_{0}}=\frac{A}{1+\left( A-1 \right)\min \left[ {{\left( \frac{\max \left( {{E}_{\text{g}}},\frac{{{E}_{\text{g}}}\left| {{v}_{\text{m}}} \right|}{{{v}_{\text{sgf}}}} \right)-B}{1-B} \right)}^{2}},1 \right]}$ | ${{v}_{\text{gm}}}=\frac{\left( 1-{{E}_{\text{g}}}{{C}_{0}} \right){{C}_{0}}K\left( {{E}_{\text{g}}} \right){{v}_{\text{c}}}}{{{E}_{\text{g}}}{{C}_{0}}\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;}+1-{{E}_{\text{g}}}{{C}_{0}}}$ $K\left( {{E}_{\text{g}}} \right)=\left\{ \begin{align} & 1.53/{{C}_{0}}\text{ }{{E}_{\text{g}}}\le 0.2 \\ & {{K}_{u}}\text{ }{{E}_{\text{g}}}\ge 0.4 \\ \end{align} \right.$ ${{v}_{c}}={{\left( g\sigma \Delta \rho /\rho _{\text{l}}^{\text{2}} \right)}^{0.25}}$ |

| [10] | ${{C}_{0}}=\frac{2}{1+{{\left( {R{{e}_{\text{m}}}}/{1000}\; \right)}^{2}}}+\frac{1.2-0.2\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;}\left( 1-\exp \left( -18{{E}_{\text{g}}} \right) \right)}{1+{{\left( {1000}/{R{{e}_{\text{m}}}}\; \right)}^{2}}}$ | ${{v}_{\text{gm}}}=0.024\,6\cos \theta +1.606{{v}_{\text{c}}}\sin \theta $ ${{v}_{\text{c}}}={{\left( g\sigma \Delta \rho /\rho _{\text{l}}^{\text{2}} \right)}^{0.25}}$ |

| [13] | ${{C}_{0}}=\frac{1.088}{1+0.088\min \left\{ {{{\left[ \max \left( {{E}_{\text{g}}},\frac{{{E}_{\text{g}}}\left| {{v}_{\text{m}}} \right|}{{{v}_{\text{sgf}}}} \right)-0.833 \right]}^{2}}}/{{{1.67}^{2}}}\;,1 \right\}}$ | ${{v}_{\text{gm}}}=\left\{ 1.017{{v}_{\text{v}}}\sin \theta +\left[ 1-\frac{2}{1+{{\text{e}}^{50\sin \left( \theta +2.303{{v}_{\text{m}}} \right)}}} \right]{{v}_{\text{h}}}\cos \theta \right\}\left( 1+\frac{1000}{R{{e}_{\text{m}}}+1000} \right)$ ${{v}_{\text{v}}}=\frac{\left( 1-{{E}_{\text{g}}}{{C}_{0}} \right){{C}_{0}}K\left( {{E}_{\text{g}}} \right){{v}_{c}}}{{{E}_{\text{g}}}{{C}_{0}}\sqrt{{{{\rho }_{\text{g}}}}/{{{\rho }_{\text{l}}}}\;}+1-{{E}_{\text{g}}}{{C}_{0}}}$ ${{v}_{\text{h}}}={{E}_{\text{g}}}\left( 1-{{E}_{\text{g}}} \right)\sqrt{g{{D}_{\text{h}}}}\left( 1.981-1.759\frac{{{N}_{\mu }}^{0.477}}{{{N}_{\text{Eö}}}^{0.574}} \right)$ |

| [12] | ${{C}_{0}}=\frac{2-1.07E_{\text{g}}^{\text{1}\text{.3}}}{1+{{\left( {R{{e}_{\text{m}}}}/{1\text{ }000}\; \right)}^{2}}}+\frac{1.2-0.205E_{\text{g}}^{\text{5}\text{.8}}}{1+{{\left( {1\text{ }000}/{R{{e}_{\text{m}}}}\; \right)}^{2}}}$ | ${{v}_{\text{gm}}}=\left( 0.45\cos \theta +0.35\sin \theta \right)\sqrt{g{{D}_{\text{h}}}}{{\left( 1-{{E}_{\text{g}}} \right)}^{0.75}}$ |

1.3. Drift flow closed relationship construction

1.3.1. Gas drift velocity model

1.3.1.1. Influence of pipe inclination

1.3.1.2. Effect of liquid viscosity

1.3.1.3. Influence of interference between gas groups

1.3.1.4. Influence of pipe diameter and surface tension

1.3.2. Distribution coefficient model

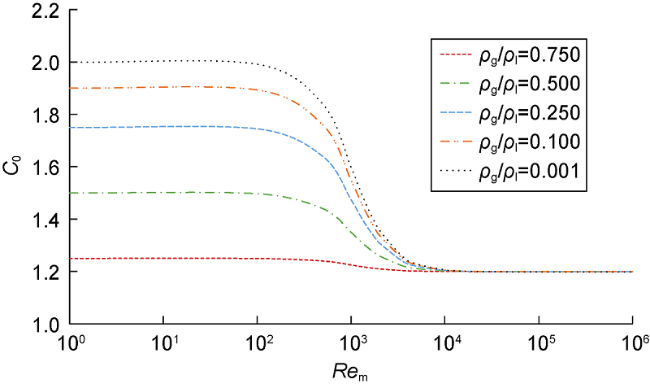

1.3.2.1. Influence of viscosity

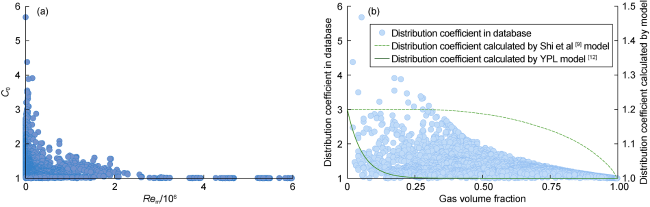

Fig. 2. Correlation analysis of distribution coefficient. |

1.3.2.2. Influence of pipe inclination

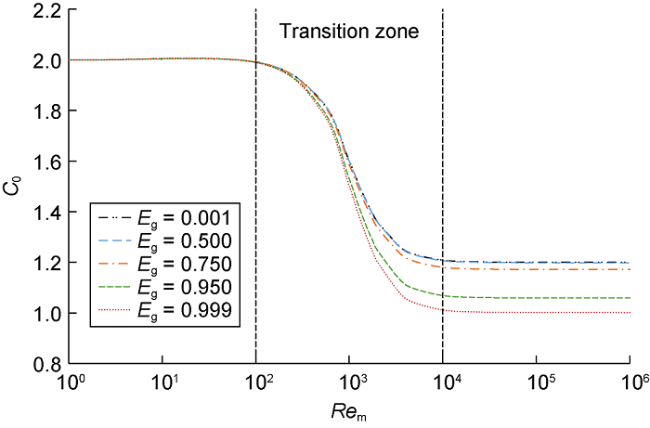

1.3.2.3. Influence of gas content

1.3.3. Model performance

Fig. 3. Influence of gas content on distribution coefficient. |

Fig. 4. Influence of density ratio on distribution coefficient. |

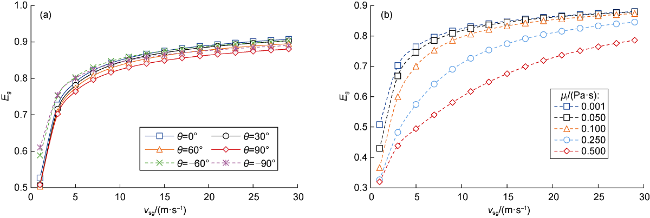

Fig. 5. Influence of pipeline inclination and fluid viscosity on predicted gas content. |

2. Model validation and application

2.1. Drift flow model verification

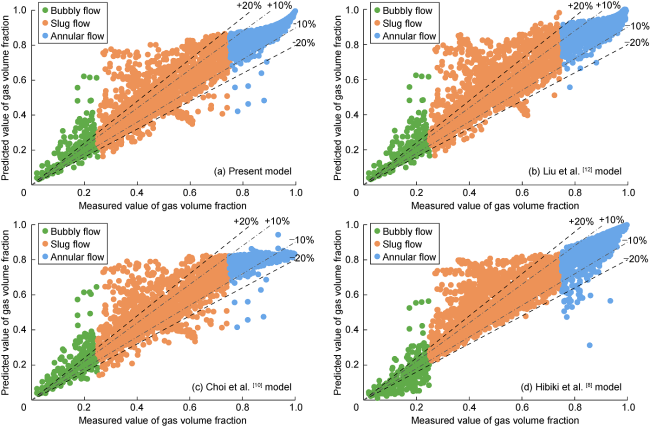

Fig. 6. Comparison between predicted and measured values of gas content with different models. |

Table 3. Prediction results of different drift current relationships |

| Models | Proportion of data points within ± 20% error range | Proportion of data points within ± 10% error range | ε1 | ε2 | ε3 |

|---|---|---|---|---|---|

| Present model | 80.86% | 62.63% | 0.057 8 | 0.132 9 | 0.065 2 |

| Liu et al. model[12] | 76.36% | 57.49% | 0.069 1 | 0.154 5 | 0.083 3 |

| Choi et al. model[10] | 80.00% | 43.56% | 0.081 7 | 0.164 0 | 0.076 1 |

| Hibiki et al. model[8] | 75.56% | 57.92% | 0.066 2 | 0.155 7 | 0.083 9 |

2.2. Application of drift flow relationship in wellbore multiphase flow

2.2.1. Transient drift flow model solution

2.2.2. Bullheading killing simulation

Table 4. Relevant parameters of a well in Tarim |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Casing inner diameter | 200.0 mm | Drilling fluid density | 1.2 g/cm3 |

| Casing running depth | 6 384 m | Drilling fluid viscosity | 30 mPa·s |

| Drill pipe od above 2480 m | 114.3 mm | Kill fluid density | 1.94 g/cm3 |

| Outer diameter of drill pipe deeper than 2480 m | 88.9 mm | Kill fluid viscosity | 25 mPa·s |

| overflow quantity | 6.4 m3 | Well depth | 7 241.4 m |

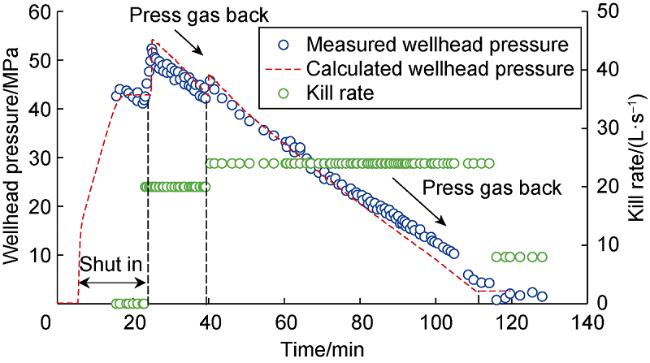

Fig. 7. Wellhead pressure change during well killing by back pressure method. |

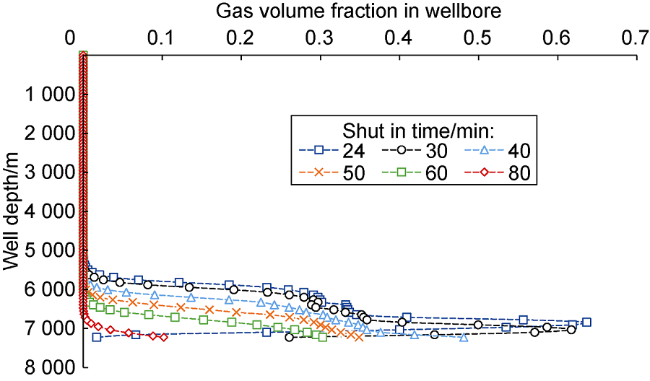

Fig. 8. Variation of wellbore gas content at different times during backpressure. |