restricted, and the overall geometry is uncertain

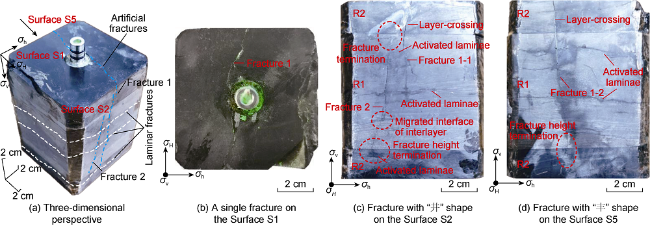

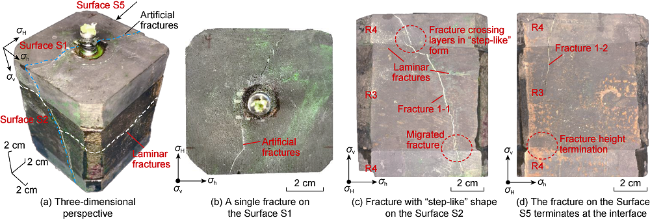

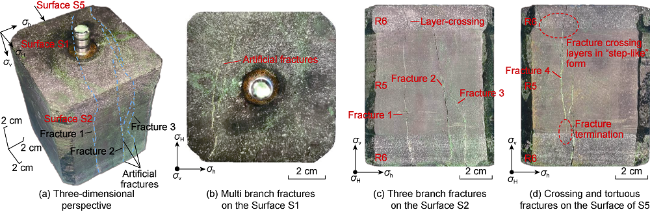

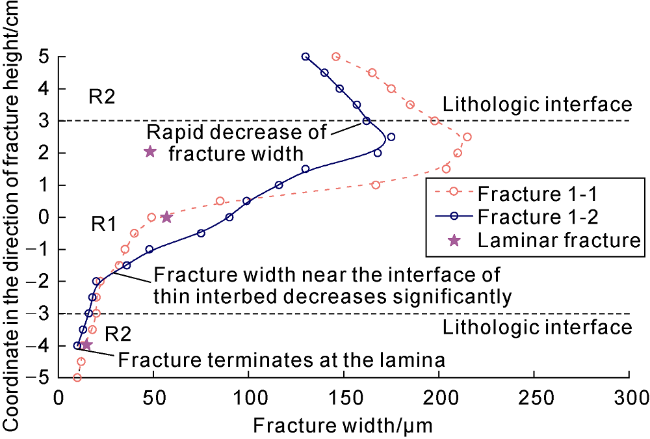

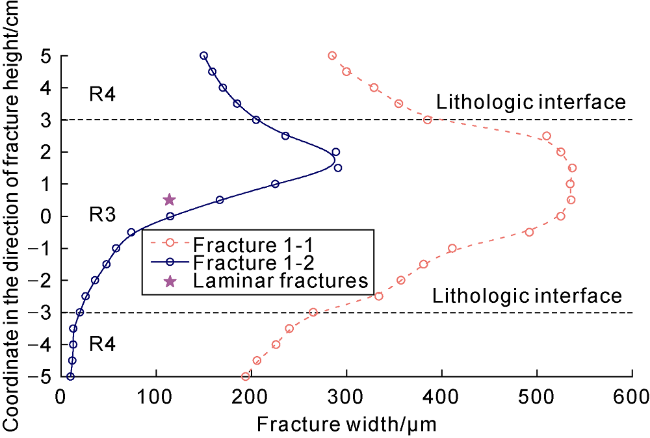

[5⇓⇓-8]. In general, simple fractures are easy to form in vertical homogeneous rocks, while complex fractures are easy to form in thin interbeds, which are controlled by the difference of mechanical properties between layers, stress difference between layers and interface properties

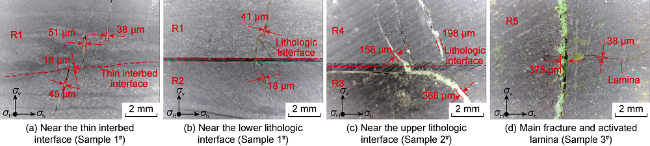

[9⇓-11]. When stratified shale (or sandstone) has laminae (or beddings), it usually has significant mechanical anisotropy and is prone to fracture under the action of high pressure fluid or induced stress. The influence of laminae (or beddings) on fracture height and overall fracture geometry is very significant

[12-13]. However, the current research on artificial fracture propagation mechanism of continental shale oil reservoirs in China is relatively insufficient

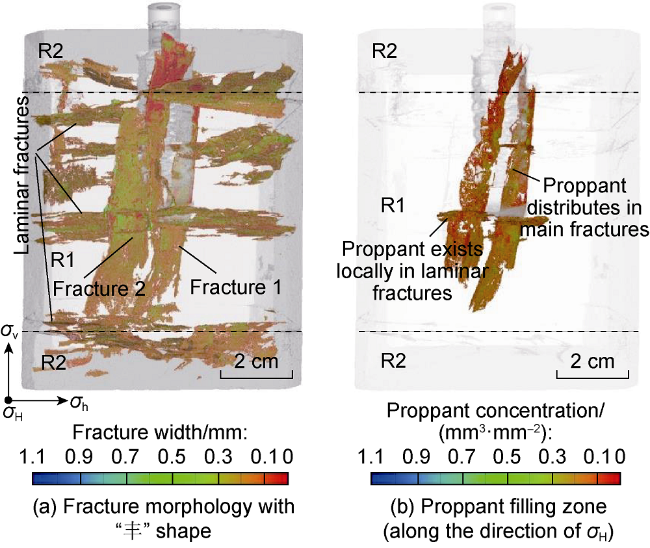

[14], which restricts the optimization of fracturing parameter design. Compared with conventional single fracture, fracturing fluid flow field in complex fracture system is more complex, and proppant distribution directly determines the effectiveness of post-fracture

[15-16]. Laboratory simulation of proppant migration in fractures mainly adopts the method of pre-set constant fracture size and geometry, which cannot consider the influence of real-time changes of reservoir fracture geometry on proppant distribution

[17-18]. However, proppant is usually not added in laboratory fracturing experiments, and the distribution mechanism of proppant and the effectiveness of fracture are unknown under in-situ stress conditions

[19⇓⇓-22]. Therefore, it is necessary to further study the dynamic migration and distribution of proppant during fracturing.