In recent years, with the advancement in nanotechnology and realization of its potential capabilities, researchers have conducted studies on the use of nanoparticles to enhance oil production

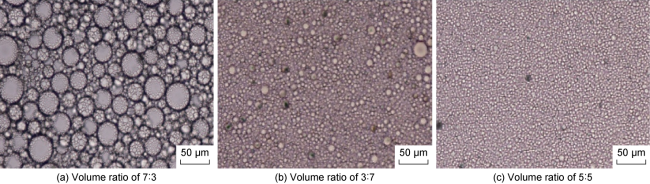

[4-5]. Pickering emulsion has been proposed as a new method of C-EOR where the stability of the emulsion is improved by employing solid particles

[6⇓⇓-9]. Silica and titanium are the most studied metallic nanoparticles for which it is confirmed that the synthesis conditions, functionalizing, and other factors can greatly impact their performance. Qin et al.

[10] proposed a novel method to in-situ synthesize silica nanoparticles in microemulsions with less tendency to agglomeration and a better Pickering formation activity and therefore the better performance in EOR. Yoon et al.

[11] stabilized the Pickering emulsion by using a colloidal layer that was composed of silica nanoparticles, dodecyl trimethyl ammonium bromide (DTAB) and poly (4-styrenesulfonic acid-co-maleic acid) sodium salt (PSS-co-MA). They observed that the colloidal dispersion raised the oil recovery factor by 4 percentage points in comparison to that of water flooding. In another work, Jia et al.

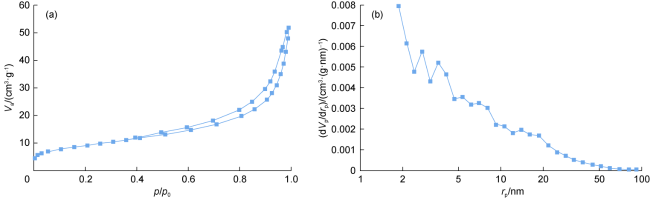

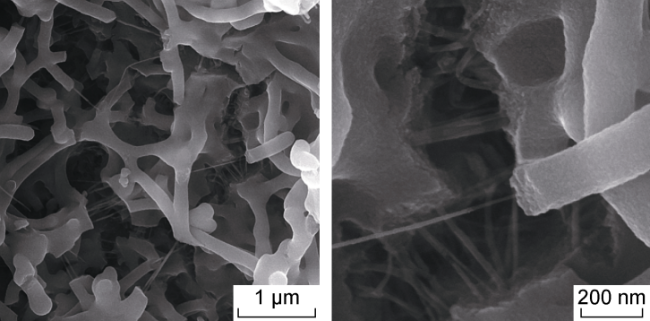

[12] stabilized the Pickering emulsions by dendritic silica nanoparticles and hybrids of dendritic mesoporous silica and titanium. In other attempts, Junus-SiO

2 nanoparticles

[13], AlO(OH) nanoparticles on sodium dodecyl benzene sulfonate

[14], mixed AlO(OH)/SiO

2 aqueous dispersions

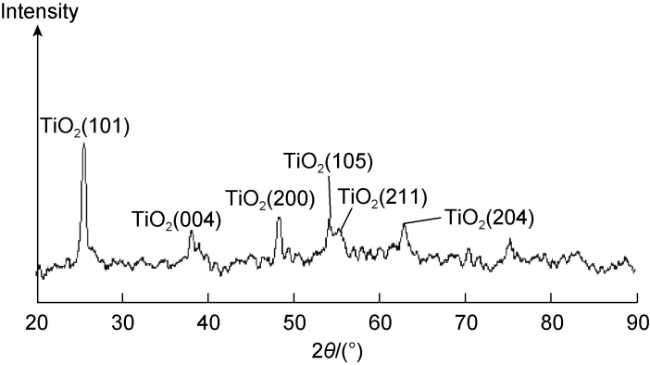

[15], and silica nanoparticles/nonionic surfactant have been examined in stabilizing the Pickering emulsion and the EOR investigation. TiO

2 has also been a fascinating choice for EOR

[16-17]; however, TiO

2 has not been assessed in stabilizing the Pickering emulsions.