With the in-depth development of oilfields, the contradiction between layers increases, so it is necessary to increase the measurement & adjustment period to ensure the qualified rate of water injection. In order to shorten the field test time and reduce the workload effectively, the separated zone water injection process with "cable supporting bridge eccentric water injection string and bridge concentric water injection string" as the core was developed and applied by scale in the 1990s

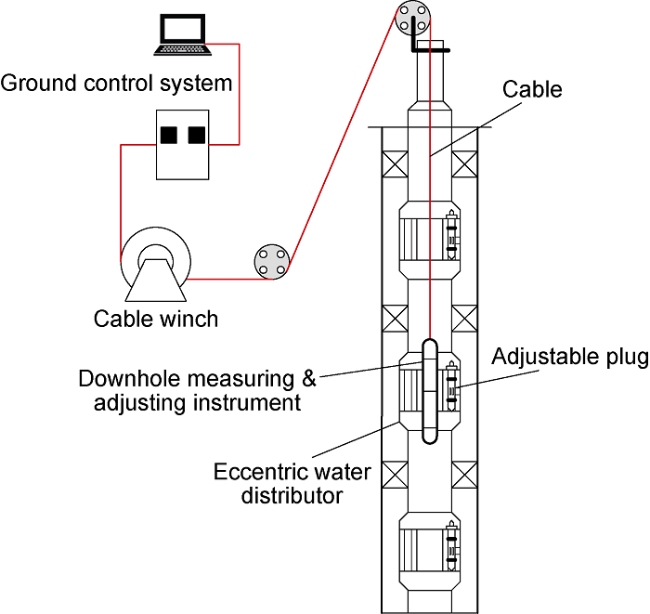

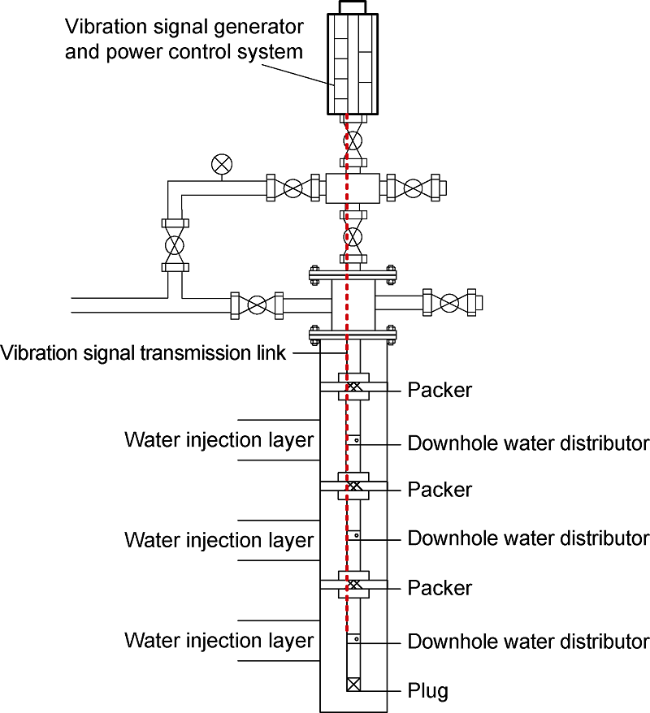

[1]. The core is to replace steel wire with cable, and carry downhole electric measuring and adjusting instrument for operation. The system composition is shown in

Fig. 2. The system consists of three parts: electric measuring & adjusting instrument, cable winch and ground control system. The downhole electric measuring & adjusting instrument is connected with the plug of the bridge eccentric water distributor to realize the automatic adjustment of the flow rate without fishing the plug by manual adjustment. At the same time, the online real-time acquisition of downhole flow, pressure, temperature and other signals greatly improves the measurement and adjustment efficiency of water injection wells. The downhole electric measuring and adjusting instrument is connected to the ground control system through the cable winch. The ground control system mainly completes the power supply control, communication, collection and processing of upload signal, which can realize the real-time monitoring of the water injection volume of each layer, the monitoring of the adjustment process, the drawing of the result curves and the water-absorption index curves and so on. In addition, it can realize the signal transmission between the ground control system and the downhole measuring & adjusting instruments by DC carrier wave modulating. That is, with the help of the capacitance and resistance characteristics of the cable itself, the capacitance charge and discharge, and the equivalent relationship with the resistance is used to achieve the effect of voltage modulation, to load the measurement and control signal in the power supply system for high-speed time-sharing transmission. At the same time, through program optimization, the loaded measurement and control signal is directly modulated onto the baseband to achieve the amplitude and frequency of the carrier wave. In addition, the principle of suppression function is used to make the measurement and control signal always near the baseband to overcome the signal attenuation and distortion caused by the cable length, improving the reliability and stability of measurement and control signal transmission. Therefore, the signal transmission distance can reach more than 4 km.