Introduction

1. Development history of CCUS-EOR technology

1.1. Research and exploration stage (1965-2004)

1.2. Field test stage (2005-2020)

1.3. Industrial application stage (2021 to present)

2. New understandings on mechanisms of CO2 flooding in continental reservoirs and field tests

2.1. Mechanisms of CO2 flooding in continental reservoirs

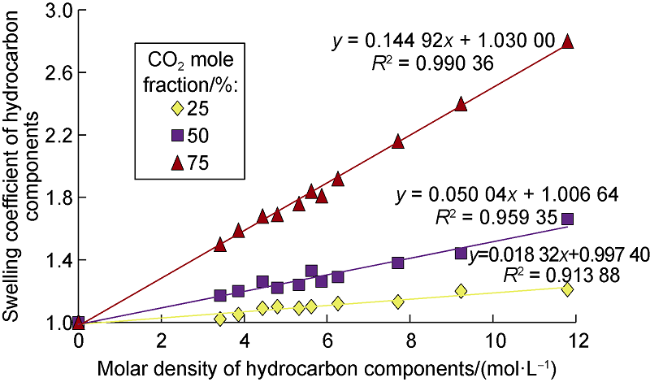

Fig. 1. Swelling coefficient vs. molar density of hydrocarbon components at 50 °C and 30 MPa. |

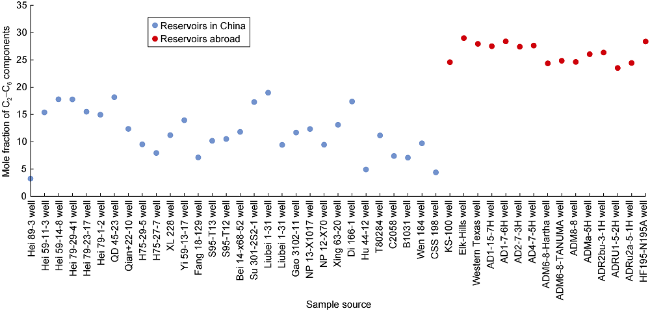

Fig. 2. Content of C2-C6 components in reservoirs in China and abroad. |

2.2. Field tests

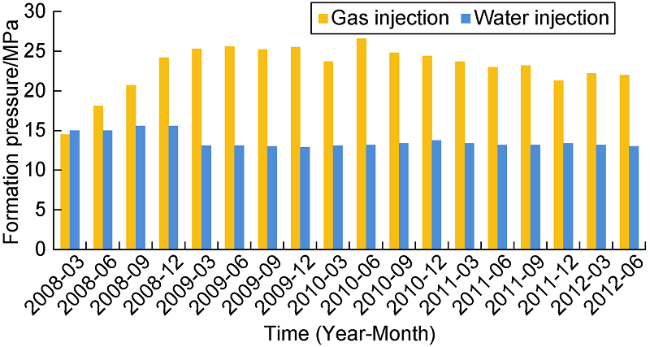

Fig. 3. Histogram of formation pressure in Hei 59 and analog blocks. |

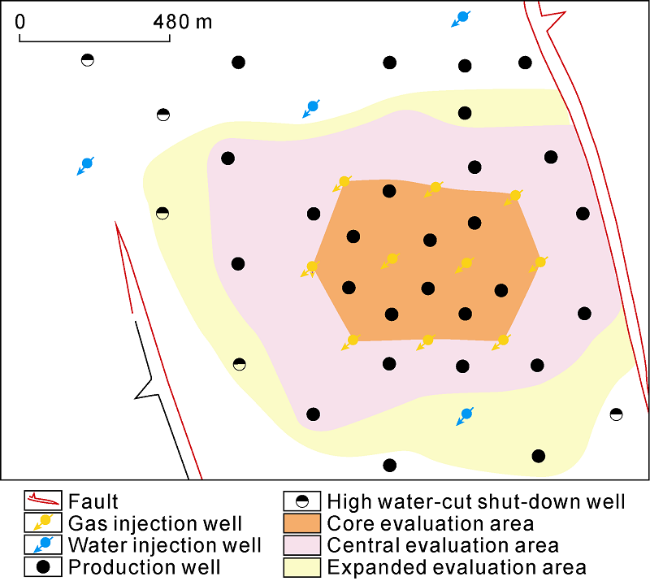

Fig. 4. Well pattern with small well spacing for CO2 miscible flooding in Hei 79-north block. |

Fig. 5. Test curves of CO2 miscible flooding with small well spacing in core evaluation area of Hei 79-north block. |

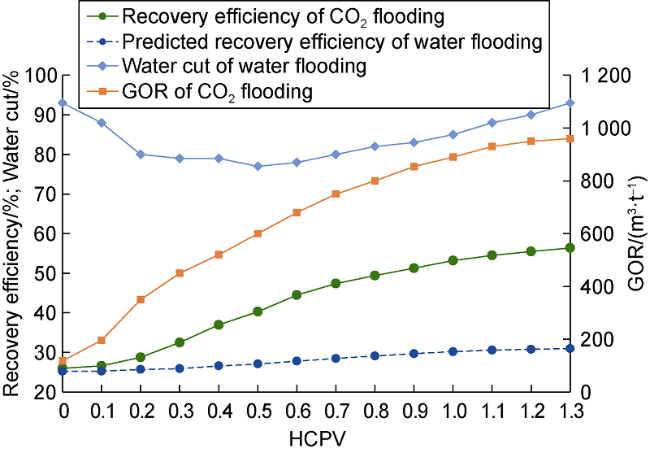

Table 1. Four-stage CO2 flooding process |

| Stage of CO2 flooding | CO2 injected/HCPV | Performance |

|---|---|---|

| Water flooding continuation and formation energy recovery (I) | 0-0.05 | Formation pressure rises and the response of water flooding continues. After gas flooding is implemented, for production wells with low water cut, the liquid production and oil production increase significantly, and the water cut decreases; for production wells with medium to high water cut, the liquid production increases, the oil production changes little, the water cut increases, the gas breaks through locally, and the GOR is less than 50 m3/t. |

| Successive response and production increase (II) | 0.05-0.30 | Miscible oil bank induced by CO2 flooding reaches the production wells successively, the total water cut begins to drop, the liquid production and oil production gradually increase, and the GOR gradually rises to 200 m3/t. |

| Overall response and stable production (III) | 0.30-0.65 | Miscible oil bank induced by CO2 flooding reaches all production wells, the water cut drops significantly, the liquid production and oil production rise to a plateau, and the GOR rises steadily to 500 m3/t. |

| Comprehensive breakthrough and high GOR (IV) | >0.65 | Breakthrough is realized in all production wells, gas channeling occurs in many production wells, the GOR is high (greater than 500 m3/t), and the liquid production and oil production decrease gradually. |

3. Technologies for optimizing CCUS-EOR reservoir engineering design

3.1. Reservoir numerical simulation for CO2 flooding

3.2. Design of reservoir engineering parameters for CCUS-EOR

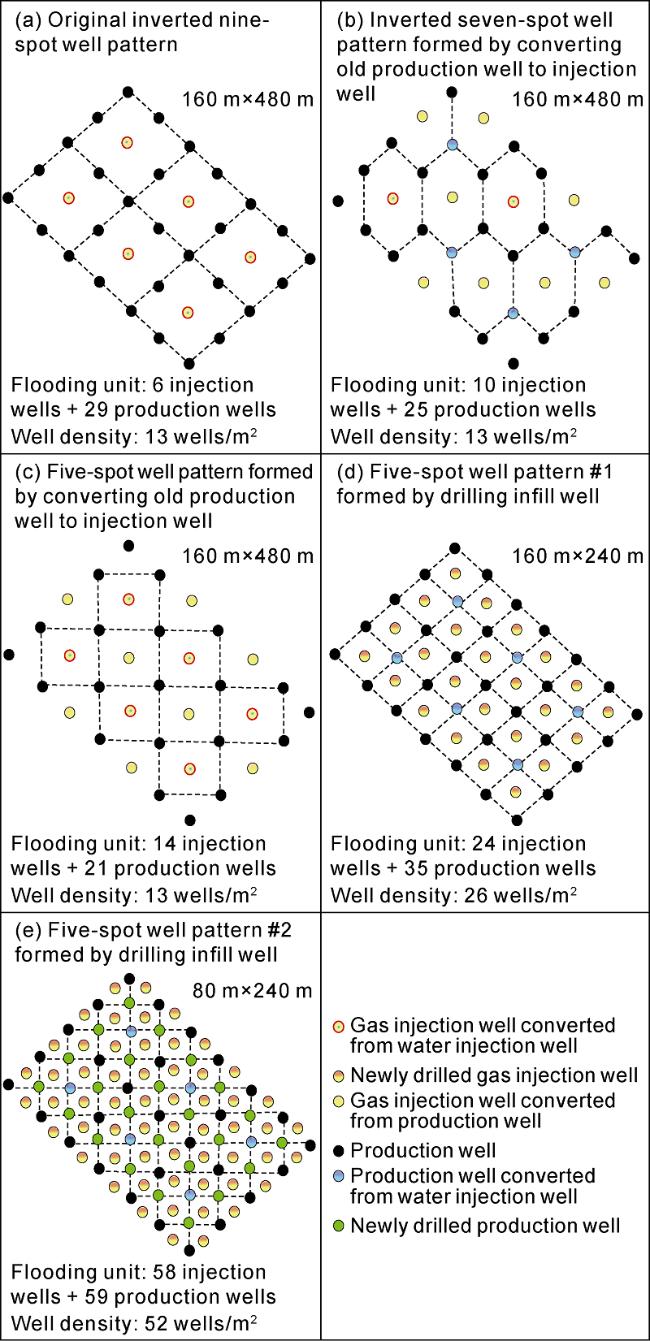

3.3. Optimization of well pattern/spacing for CCUS-EOR

Fig. 6. Adjustment of well patterns in Daqingzijing Oilfield. |

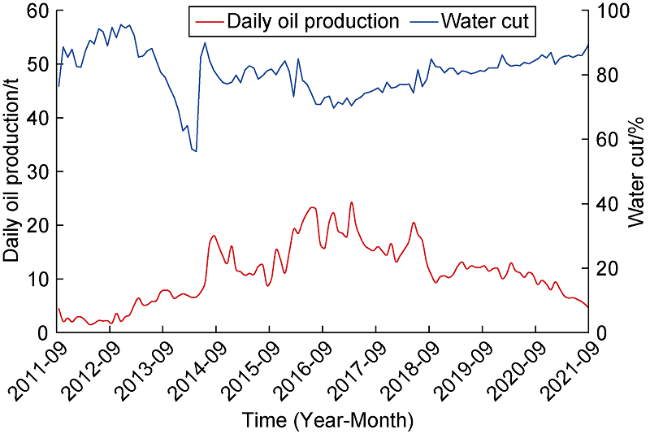

Fig. 7. Production profile of the core evaluation area in CO2 miscible flooding test with small well spacing in Hei 79-north block. |

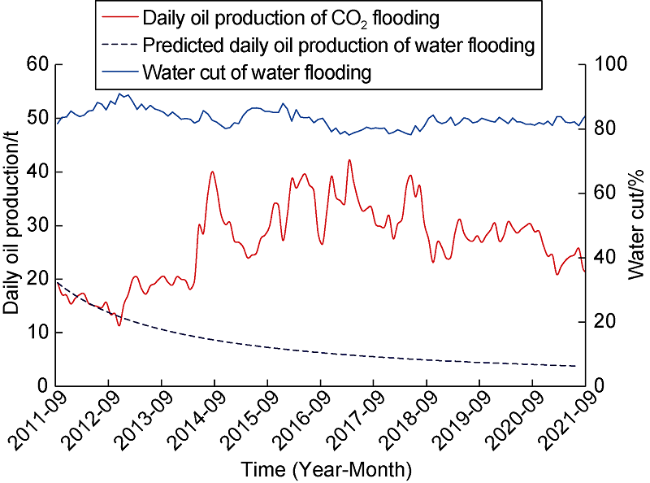

Fig. 8. Production profile of the central evaluation area in CO2 miscible flooding test with small well spacing in Hei 79-north block. |

4. Engineering supporting technologies for CCUS-EOR

4.1. CO2 capture technologies

4.2. CO2 injection-production technologies

4.3. Whole process equipment

4.4. System-wide anti-corrosion technologies

4.5. CO2 monitoring technologies

Table 2. Methods for safety monitoring on CO2 storage |

| Item | Monitoring stage | Monitoring point | Monitoring requirements | Monitoring interval | Monitoring equipment |

|---|---|---|---|---|---|

| Atmospheric CO2 concentration | During gas injection | Select about 10 gas injection wells and production wells in the test area, and take samples within 20 m around each well | Measure CO2 concentration | Quarterly, or more frequently in case of abnormality | Pump suction CO2 detector |

| Soil gas concentration | During gas injection | Select about 10 gas injection wells and production wells in the test area, and take samples within 20 m around each well | When the CO2 concentration is higher than the normal value and the predicted value, then carry out the concentration test on O2, N2, CH4, C2H6, C3H8 and other gases, so as to analyze the source of CO2 | Quarterly, or more frequently in case of abnormality | DIK-5220 soil gas sampler |

| After gas injection | Annually after the injection, in 5 years | Gas chromatograph | |||

| pH and CO32-, HCO3- and CO2 concen- trations of surface water and lake water | Before gas injection | Drill two shallow formation water wells in the production well site in Hei 59 test area, and set up two sampling points; set up eight sampling points in the surface water source wells in the eight metering rooms in the south Hei 79 block; set up two sampling points in nearby villages | Measure the pH value and CO32-, HCO3-, and CO2 concentrations of original surface water samples | Once | Portable multiparameter water quality analyzer |

| During gas injection | Measure the pH value and CO32-, HCO3-, and CO2 concentrations of shallow surface water | Quarterly, or more frequently in case of abnormality |

5. CCUS-EOR prospects

5.1. CO2 flooding and storage

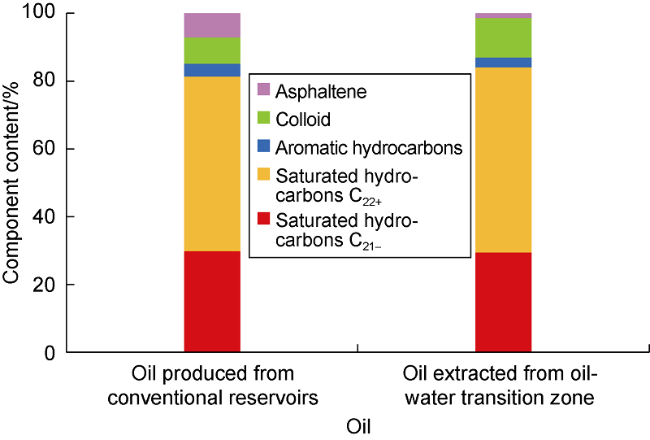

Fig. 9. Components of oil from Daqingzijing Oilfield. |

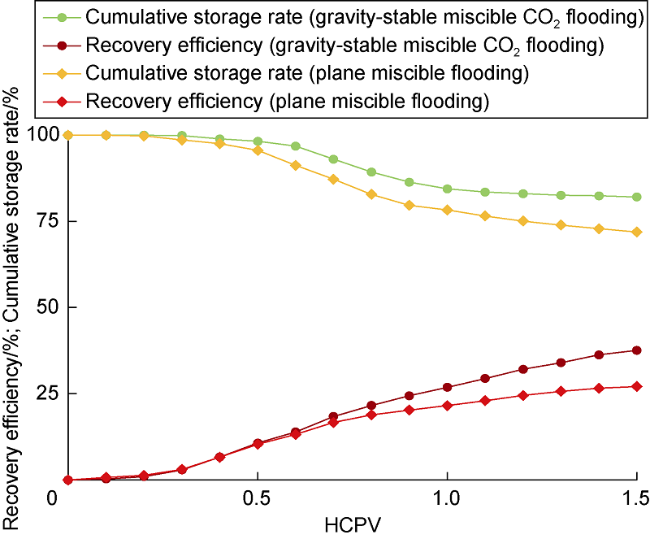

Fig. 10. Recovery efficiency and cumulative storage rate of oil-water transition zone under different CO2 flooding techniques. |

5.2. CO2 storage and utilization

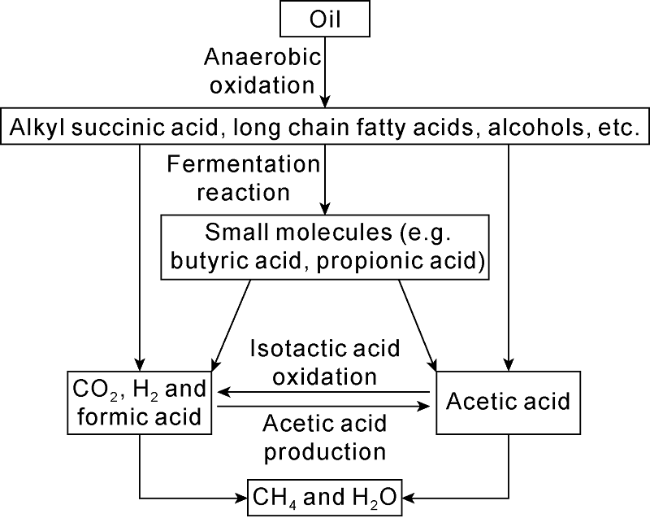

Fig. 11. Process of anaerobic microorganisms to produce methane by using oil and CO2. |