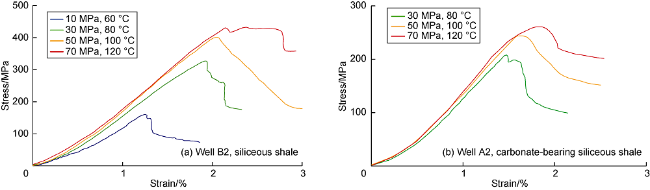

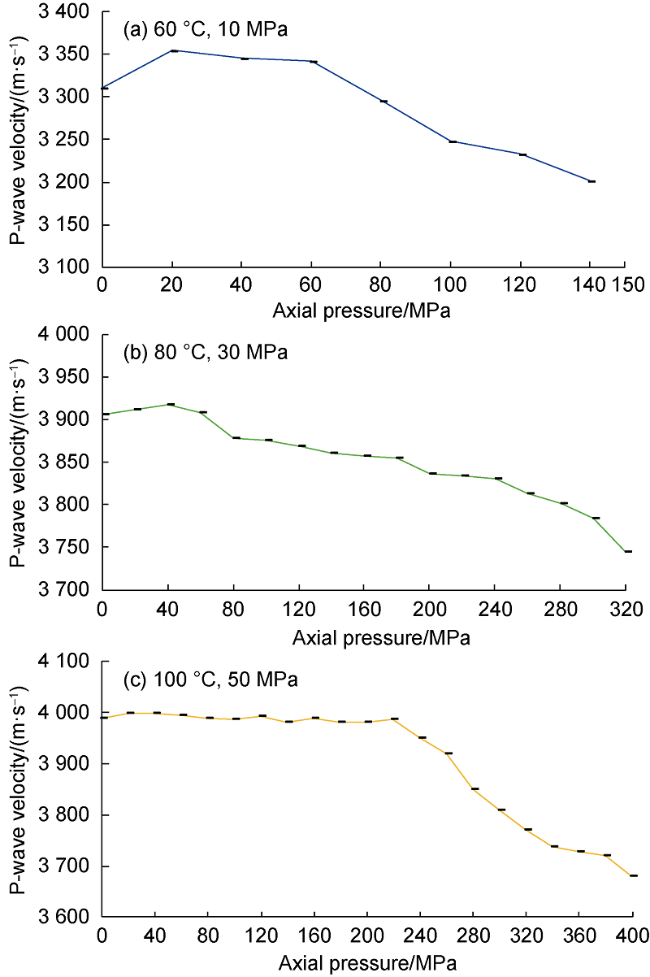

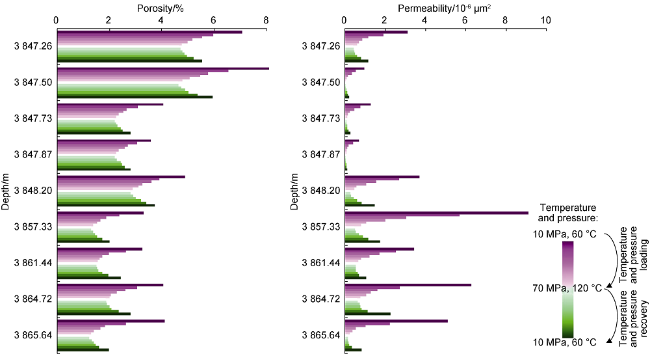

The rock deformation and failure is essentially the break of the microstructure. The change of shale microscopic porosity and permeability caused by high temperature and high pressure has a constraint on rock deformation, which is mainly reflected in three aspects. (1) The constraint on the formation of main fracture. As the wave velocity is more sensitive to the changes of microfractures and pores in the rock, the triaxial compression experiment at high temperature and high pressure integrated with the monitoring of P-wave velocity was conducted, for the first time, in this study, to dynamically reflect the control of microstructure on rock deformation fracture. Taking 3 samples of Well B2 as an example, when the temperature gradually rises from room temperature (25 °C) to the designed value, given no confining pressure, the porosity and permeability increase, the shale expands freely, and the P-wave velocity decreases. When the confining pressure is set to the designed value, because the cutting direction of the sample is parallel to the bedding, the microfractures show an obvious closing trend under the confining pressure, and the P-wave velocity recovers. When the axial pressure is loaded, for the shale samples with low temperature and low pressure, the internal microfractures of the rock are opened and grow faster, and the P-wave velocity starts to drop when the axial pressure is slightly higher than the confining pressure (

Fig. 5a, 5b); for the shale samples with high temperature and high pressure, the opening and expansion of microfractures are restrained, and the P-wave velocity tends to maintain at a high value (

Fig. 5c). When the axial pressure is increased to a certain critical value, the number of microfractures increases sharply, and the volume expands, forming a main fracture through the rock mass

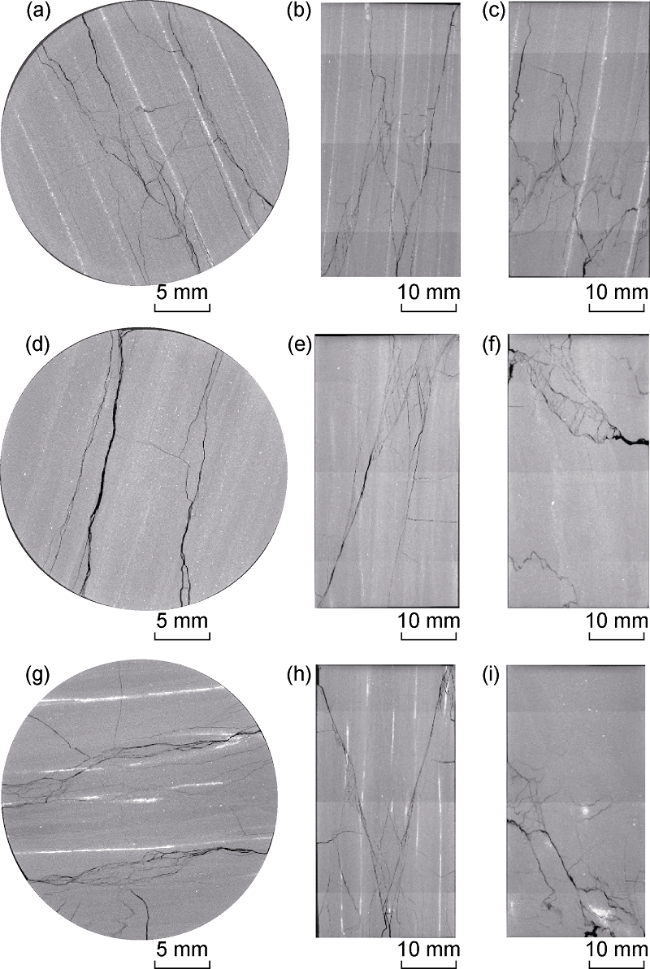

[24], and the P-wave velocity decreases rapidly. (2) The constraint on the macro-fracture type of rock. According to the CT scanning image after compression, the rock undergoes tensile fracture (

Fig. 6a-6c and

Fig. 7a-7c) and shear fracture (

Fig. 6d-6i and

Fig. 7d-7i) under low and high temperature and pressure conditions respectively. The final macro-fracture of rock is formed by the evolution of microfractures and pore expansion in the rock, that is, the tensile fracture of microfractures causes macroscopic tensile fracture, and the shear fracture of microfractures determines macroscopic shear fracture

[24]. (3) The constraint on fracture propagation pattern. With the increase of temperature and pressure, the angle between the fracture plane and the bedding surface tends to increase greatly, and the development of fractures becomes worse and less complex. When the confining pressure is low, the internal cracks of the rock under the axial stress experience tensile fracture. Because the cracks in shale are mainly developed in the mechanical weak surface (bedding surface) with high mud content, the angle between the fracture plane and the bedding surface is small. In this case, the surface friction of the microfractures is small, and they are easy to expand, forming the most cracks (

Fig. 6a-6c and

Fig. 7a-7c). When the confining pressure is high, the resultant direction of confining pressure and axial stress forms an angle with the bedding plane. The microfractures with a certain angle with the bedding plane form shear expansion, leading to an increased angle between the fracture plane and the bedding plane. By contrast, the microfractures parallel to or with a small angle with the bedding plane are mostly difficult to close or expand, the crack development is poor, and the complexity of the macro-fracture is reduced (

Fig. 6d-6i and

Fig. 7d-7i).