Introduction

1. Temporary plugging experiment

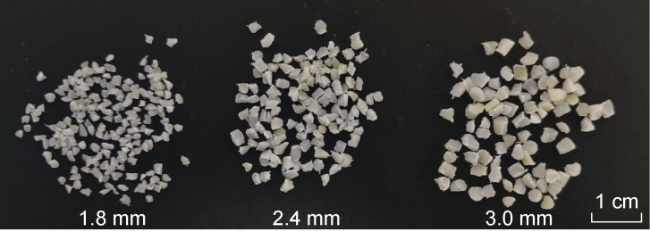

1.1. Temporary plugging particles

Fig. 1. Experimental samples. |

Table 1. Density and shape characteristics of temporary plugging particles |

| Diameter/mm | True density/(g·cm−3) | Aspect ratio | Roundness |

|---|---|---|---|

| 1.8 | 1.12 | 1.38 | 0.78 |

| 2.4 | 1.41 | 0.78 | |

| 3.0 | 1.41 | 0.75 |

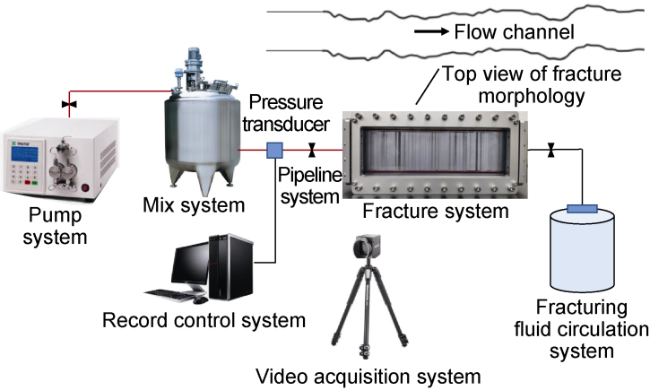

1.2. Experimental device

Fig. 2. Schematic diagram of experimental device. |

1.3. Experimental design

Table 2. Parameter combination of experiment scheme |

| Fracture width/mm | Temporary plugging particle size/mm | Ratio of particle size to fracture width | Temporary plugging particle mass concentration/(kg•m−3) | Carrier fluid viscosity/ (mPa•s) | Carrier fluid displacement/ (L•min−1) | Group of experiment |

|---|---|---|---|---|---|---|

| 4 | 1.8 | 0.45 | 10.0 | 3 | 0.7 | 1 |

| 15.0 | 3 | 0.7 | 1 | |||

| 20.0 | 1, 3, 6 | 0.7, 1.3, 1.6 | 9 | |||

| 40.0 | 1, 3, 6 | 0.7, 1.3, 1.6 | 9 | |||

| 2.4 | 0.60 | 5.0 | 3 | 0.7 | 1 | |

| 10.0 | 1, 3, 6 | 0.7, 1.3, 1.6 | 9 | |||

| 20.0 | 1, 3, 6 | 0.7, 1.3, 1.6 | 9 | |||

| 3.0 | 0.75 | 2.5 | 3 | 0.7 | 1 | |

| 5.0 | 1, 3, 6 | 0.7, 1.3, 1.6 | 9 | |||

| 10.0 | 1, 3, 6 | 0.7, 1.3, 1.6 | 9 |

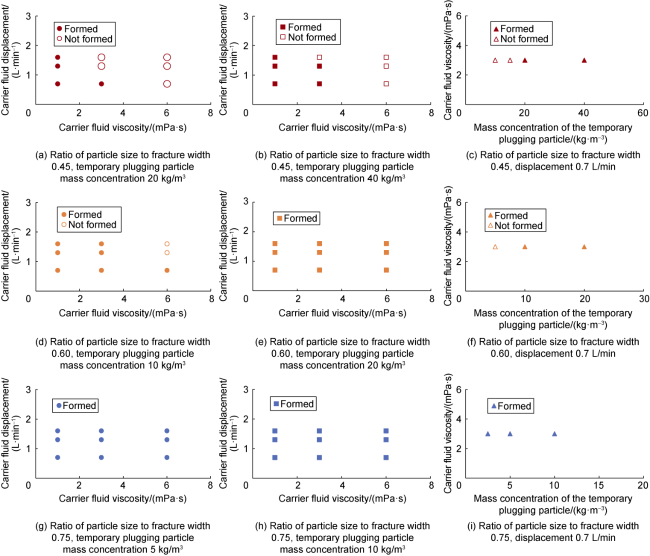

2. Plugging layer formation conditions

Fig. 3. Parameter combination for forming plugging layer by temporary plugging particles in hydraulic fracture. |

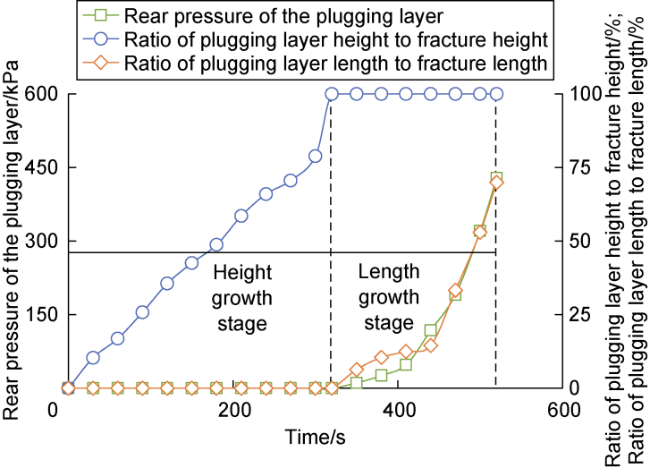

3. Plugging layer formation process

3.1. Formation stages

Fig. 4. The relationship of length, height and pressure of plugging layer with time. |

3.2. Formation modes

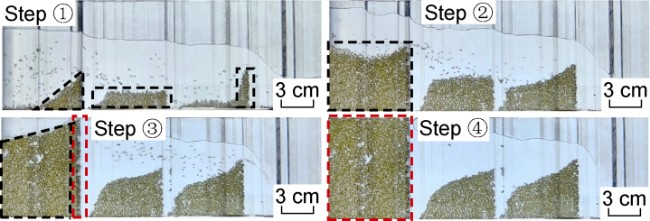

Fig. 5. Temporary plugging particle distribution during the formation of plugging layer (Mode I). |

Table 3. Parameter combination of Mode I |

| Ratio of particle size to fracture width | Carrier fluid viscosity/ (mPa·s) | Carrier fluid displacement/ (L·min−1) | Temporary plugging particle mass concentration/(kg·m−3) |

|---|---|---|---|

| 0.45 | 1 | 0.7, 1.3, 1.6 | 20, 40 |

| 0.60 | 1 | 0.7, 1.3, 1.6 | 10, 20 |

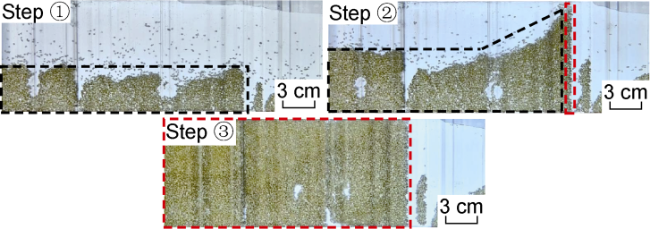

Fig. 6. Temporary plugging particle distribution during the formation of plugging layer (Mode II). |

Table 4. Parameter combination of Mode II |

| Ratio of particle size to fracture width | Carrier fluid viscosity/(mPa·s) | Carrier fluid displacement/(L·min−1) | Temporary plugging particle concentration/(kg·m−3) |

|---|---|---|---|

| 0.45 | 3 | 0.7, 1.3 | 20, 40 |

| 0.60 | 3, 6 | 0.7 | 10, 20 |

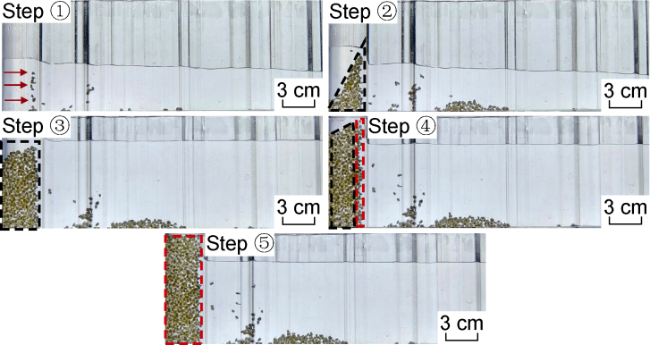

Fig. 7. Temporary plugging particle distribution during the formation of plugging layer (Mode III). |

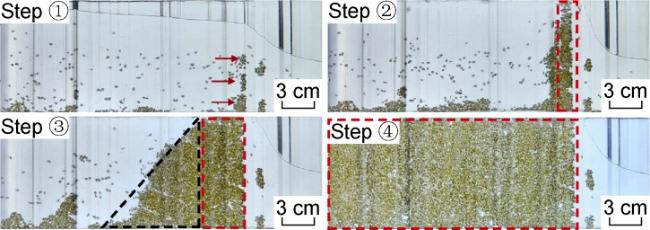

Fig. 8. Temporary plugging particle distribution during the formation of plugging layer (Mode IV). |

Table 5. Parameter combination of Mode IV |

| Ratio of particle size to fracture width | Carrier fluid viscosity/ (mPa·s) | Carrier fluid displacement/ (L·min−1) | Temporary plugging particle mass concentration/(kg·m−3) |

|---|---|---|---|

| 0.60 | 3, 6 | 1.3, 1.6 | 10, 20 |

| 0.75 | 3, 6 | 0.7, 1.3, 1.6 | 5, 10 |

4. Field verification of construction parameters

Table 6. ITPDF effect of wells Wei204H51-6 and Wei204H51-7 |

| Well | Fracture network length/m | Fracture network width/m | Number of micro-seismic events | Average pressure/ MPa |

|---|---|---|---|---|

| Wei204H51-6 | 370 | 125 | 58.7 | 3.8 |

| Wei204H51-67 | 378 | 85 | 30.8 |