The occurrence states of shale oil are mainly free and adsorbed (or mutually soluble)

[19-20]. The free oil is commonly estimated by the rock pyrolysis

S1 quantification method

[20]. The adsorbed oil is evaluated by the difference in rock pyrolysis

S2 before and after organic solvent extraction. Previous studies have shown that the difference in rock pyrolysis

S2 before and after chloroform extraction of the Gulong shale is essentially the same as the difference between chloroform bitumen "A" and S

1. Therefore, the adsorbed oil can also be analyzed quantitatively

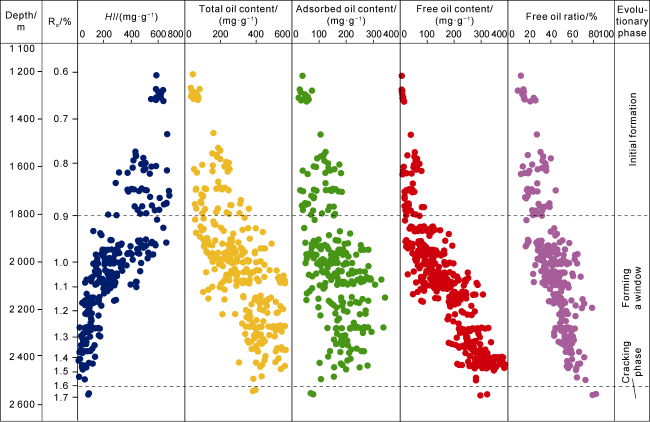

[21]. This study decomposed the retained oil in the hydrocarbon generation thermal simulation experiment. The peak value of free oil generation comes to at R

o of 1.3%, and the peak value of adsorbed oil generation comes to at R

o of 1.1%, indicating that the peak of free oil generation lags behind that of adsorbed oil. Based on the material balancing principle in hydrocarbon generation, most of the free oil was formed by the cracking and conversion of adsorbed oil. However, a small amount of hydrocarbon was also generated by kerogen cracking. Based on a large amount of measured

S1 data and chloroform bitumen "A" data from the Gulong shale, integrated with the oil content measurement results of the pressure-preserved cores for light hydrocarbon correction, we established the oil occurrence and evolution model of the Gulong shale

[22] (

Fig. 3). The model shows three stages of evolution: (1) The initial generation stage. R

o value is less than 0.9%, and the oil is mainly produced by the kerogen. The free oil accounts for 20%-40% of the retained oil. Therefore, the occurrence state is mainly adsorbed oil. (2) The oil generation stage. The R

o value at this stage is 0.9%-1.6%, and the adsorbed oil is converted to free oil in large quantities. The free oil accounts for 40%-80% of the retained oil. (3) The cracking stage. The value of R

o in the cracking stage is greater than 1.60%,and the shale oil starts to crack into gas. By quantifying the free oil and adsorbed oil in the kerogen and mineral matrix and pores and fractures

[6] respectively, applying a R

o cutoff value of 1.0%, it is found that two transformation processes of the Gulong shale oil occurrence state occur: (1) in the middle and low evolutionary stage, the shale oil transforms from mainly in the kerogen to mainly in the rock and organic pores (organic clay composite pores

[11]). (2) In the middle and high evolutionary stage, the shale oil transforms from the adsorbed state to the free state.