Introduction

1. Main types and basic characteristics of lacustrine shale oil in China

Fig. 1. Shale oil production curve and chromatographic analysis results of different sampling points in the GY 5-1-2L well of the Cangdong Sag [24]. |

Fig. 2. Movable hydrocarbons vs. cumulative productivity index of shale oil in Gulong Sag. |

2. Enrichment factors of movable hydrocarbons in shale oil

Table 1. Enrichment factors and evaluation indexes of movable hydrocarbons in lacustrine shale oil, and parameters of shale oil in Gulong Sag, Songliao Basin |

| Type | Material basis | Hydrocarbon mobility | Engineering-related factors | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TOC and organic matter type | S1/(mg·g-1) | OSI/(mg·g-1) | Porosity/% | Ro/% | GOR/ (m3·m-3) | Crude oil density/ (g·cm-3) | Hydrocarbon component | Storage conditions | Formation energy | Brittleness | Laminated structure | Shale lithofacies | |

| Enrichment zone | TOC>2%, preferably 3%-4%; Type I-II1 | >2, preferably 4-6 | >100, preferably >150 | >3%, preferably >6% | Saline lacustrine basin: >0.6%; fresh lacustrine basin: >0.9%; resource sweet spot zone: >1.2% | >80, preferably 150-300 | Pure: <0.85; Transitional: <0.9 | If Ro>0.9%, saturated hydrocarbons greater than 80% and C1-14/C15+ >0.8; if Ro=0.6%-0.9%, saturated hydrocarbons greater than 55% and C1-21/C22+ >1.0 | Caprock thickness >2-5 m, and breakthrough pressure >10 MPa | Pressure coefficient greater than 1.2 | Middle diagenesis Stage B, brittleness index greater than 50%, and clay content less than 40% | Laminated structure and high peelability | Felsic shale and biosparite carbonate shale |

| Light oil belt of the Gulong Sag | TOC of 1%-6% generally, and >2% on average; Type I | 4-15 | >200 | >4% | Mostly greater than 1.2%, locally greater than 1.4% | Mostly greater than 200 | 0.78-0.85 | Average content of saturated hydrocarbons = 90% and C1-14/C15+ = 1.0-1.5 | Average roof breakthrough pressure = 12.6 MPa | Pressure coefficient >1.4 | Middle diagenesis Stage B-late diagenesis, and average brittleness index = 60% | Laminated structure and high peelability | Laminar felsic shale |

2.1. Material basis

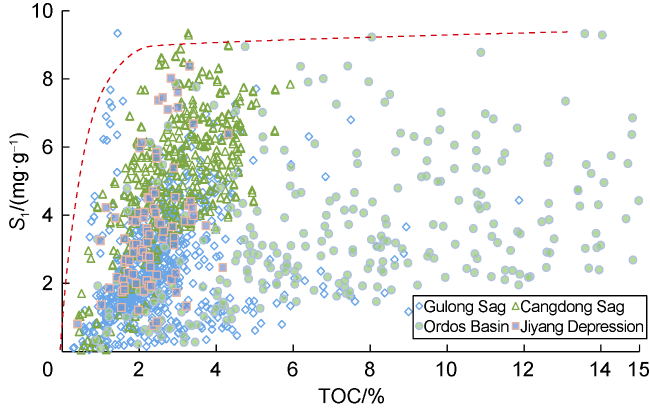

Fig. 3. Correlation of TOC with S1 of major continental shales in China. |

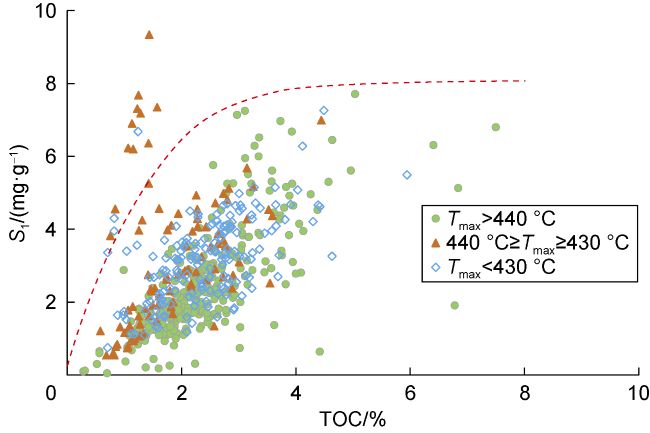

Fig. 4. Correlation of TOC with S1 of major continental shale oil zones with different maturities in China. |

Fig. 5. Correlation of TOC with cumulative oil production per well at the Kongdian Formation shale in Dagang oilfield. |

2.2. Mobility of retained hydrocarbons

2.2.1. Thermal maturity (Ro)

Fig. 6. Correlation of the content of movable hydrocarbons with the maturity of shale oil in the Qingshankou Formation in the Gulong Sag, Songliao Basin. The amount of adsorbed hydrocarbon was estimated using the formula y= 88.76x−1.128 (where x means Ro) in Reference [31]. The amount of movable hydrocarbons is the difference between retained hydrocarbons and adsorbed hydrocarbons. |

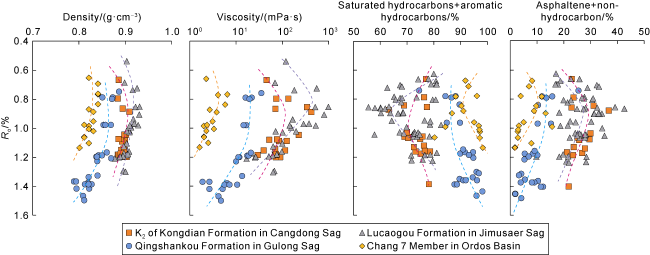

Fig. 7. Changes in the physical properties of shale oil in different liquid windows. |

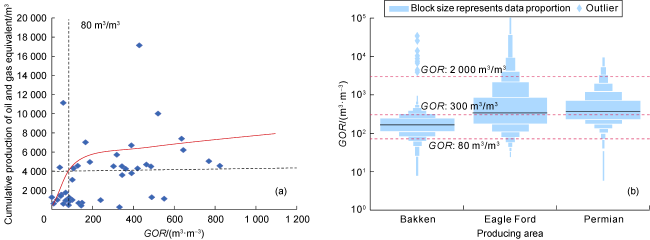

2.2.2. Gas oil ratio

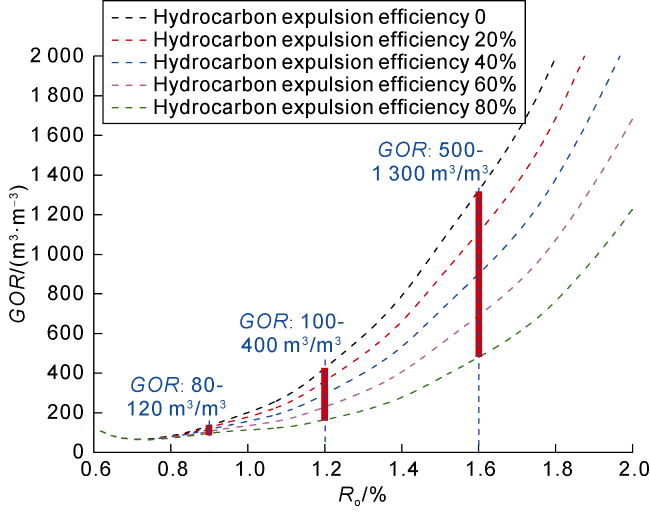

Fig. 8. Correlation between GOR and Ro for hydrocarbon production of shale in the Qingshankou Formation of the Songliao Basin (based on simulation experiments and hydrocarbon-producing kinetics). |

Fig. 9. Correlation between GOR and oil production in (a) Gulong Sag and (b) important shale oil production areas in the United States. |

2.2.3. Density of crude oil

2.2.4. Hydrocarbon composition

Fig. 10. Correlation between density and hydrocarbon composition of shale oil in the Lucaogou Formation in Jimusaer Sag and the second member of the Kongdian Formation in Cangdong Sag. |

2.2.5. Storage conditions and formation energy

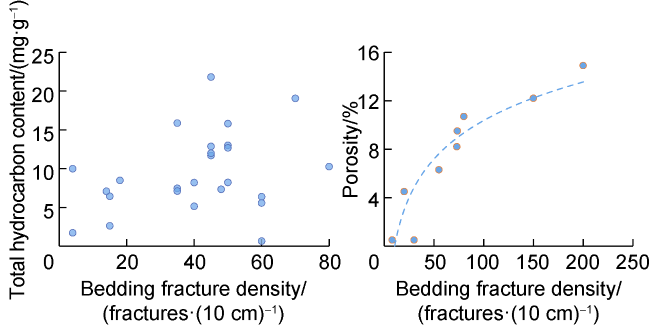

2.3. Engineering-related factors

Fig. 11. Correlation between bedding fracture density and the content of retained hydrocarbon and porosity of the Qingshankou Formation shale in the Gulong Sag, Songliao Basin. |

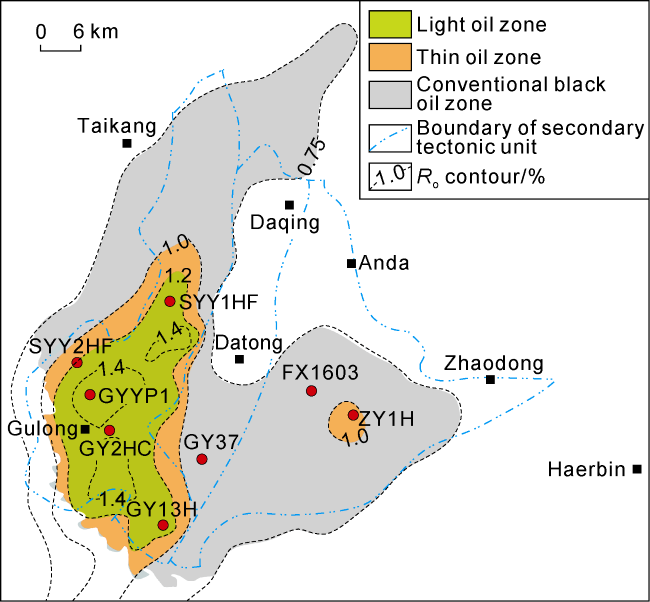

3. Enrichment features of movable hydrocarbon and exploration value of shale oil in Gulong Sag

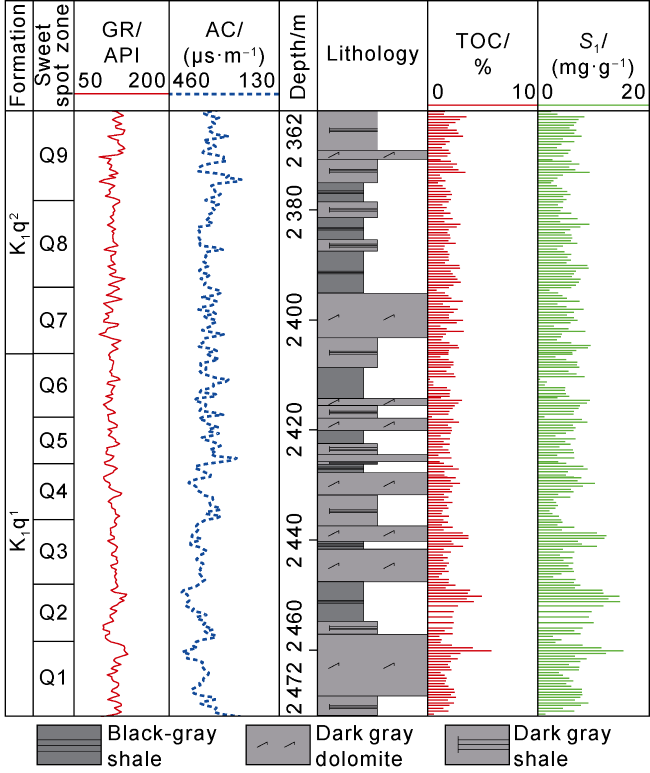

Fig. 12. Lithology and geochemical features of the Qingshankou Formation in Well 8HC in Gulong Sag, Songliao Basin. |

3.1. Enrichment features of movable hydrocarbon

3.2. Exploration potential

Fig. 13. Zones of shale oil types in the Qingshankou Formation in the Songliao Basin. |