Gulong shale oil reservoirs in the Songliao Basin are dominated by shale with particles less than 0.003 9 mm, in which the cumulative thickness of other lithology such as siltstone and carbonate rock is very small. The shale oil is typical continental pure shale oil. The structural evolution of the Gulong shale oil pay zone is complex, the sedimentary environment is diverse, and the heterogeneity of the reservoir and space is strong, making the development of shale oil difficult

[1]. Based on the theory of continental oil generation, and with the transformation of exploration concepts and technological progress, significant strategic breakthroughs have been made to the exploration of Gulong shale oil

[10]. Key exploration wells such as GYH 1, YY 1H, and GY 2HC have delivered high production and relatively stable oil flow, confirming that Gulong shale oil has good exploration and development potentials

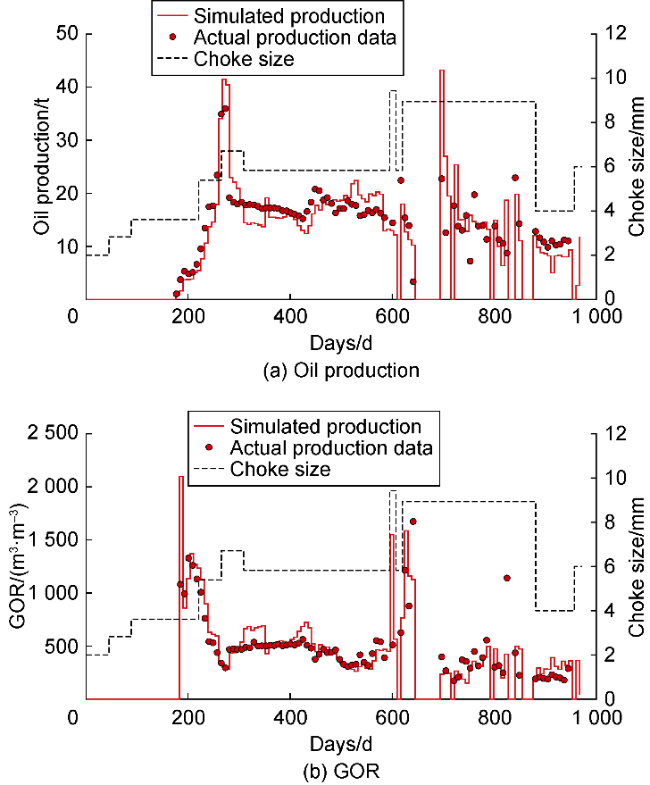

[2-3]. The horizontal section of Well GYH 1 is 1562 m long. It has been producing for 850 d, and the cumulative oil and gas equivalent has been nearly 14 000 t

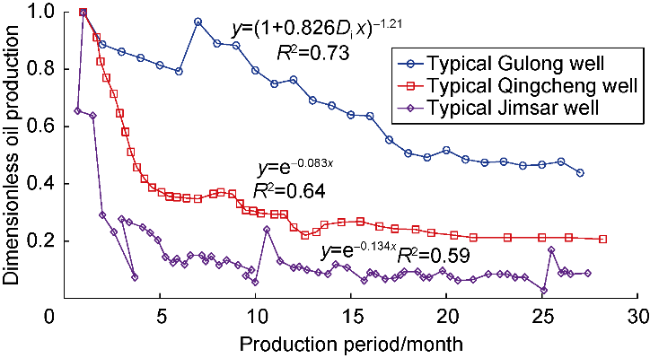

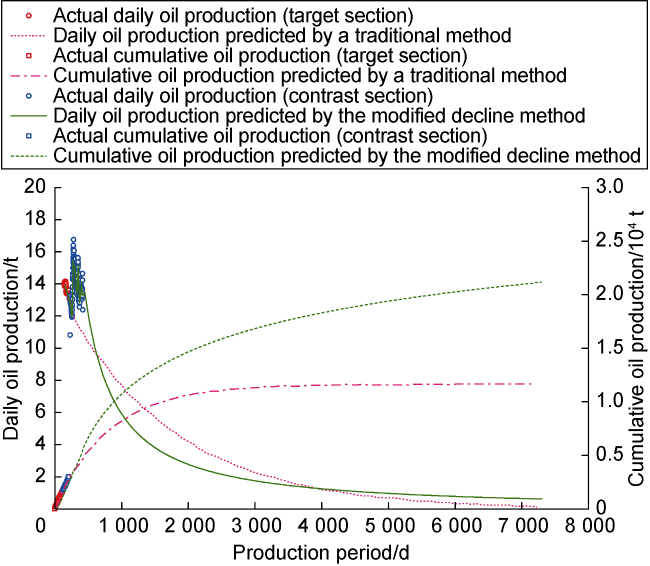

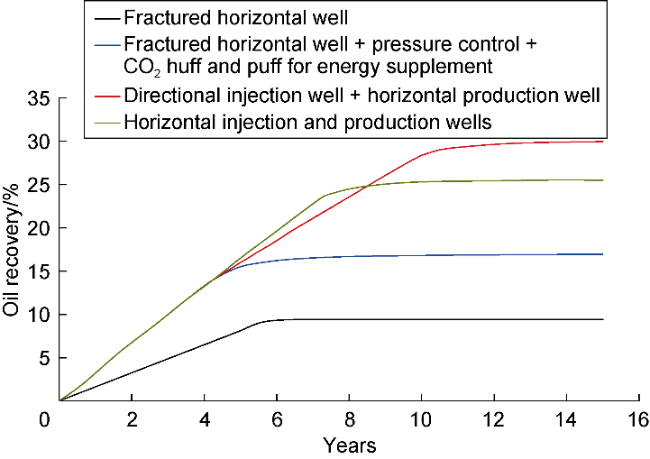

[1]. Compared to the exponential decline characteristics of shale oil in North America, and Qingcheng in Changqing Oilfield and Jimsar in Xinjiang in China, oil and gas produce together from Gulong shale oil wells, exhibiting a special feature as hyperbolic decline (

Fig. 1). For example, 11 trial production wells such as GYH 1 show a low hyperbolic decline

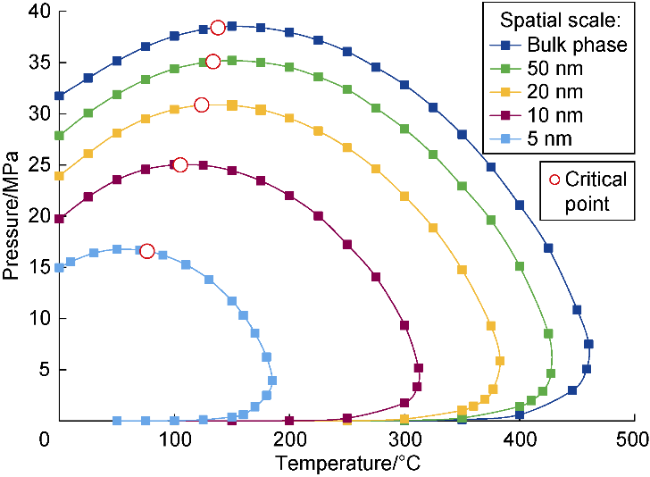

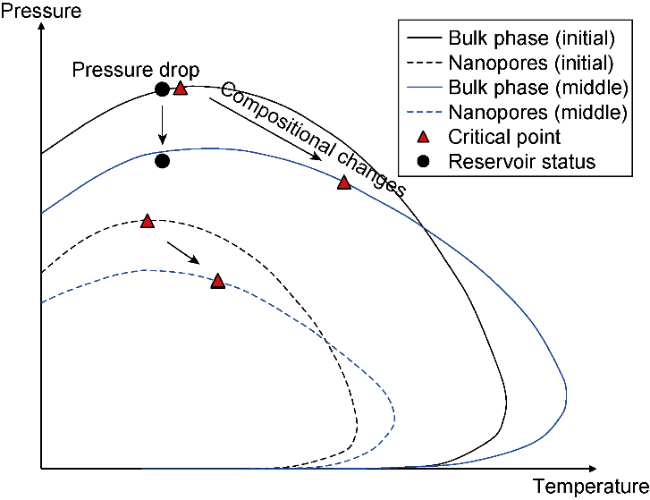

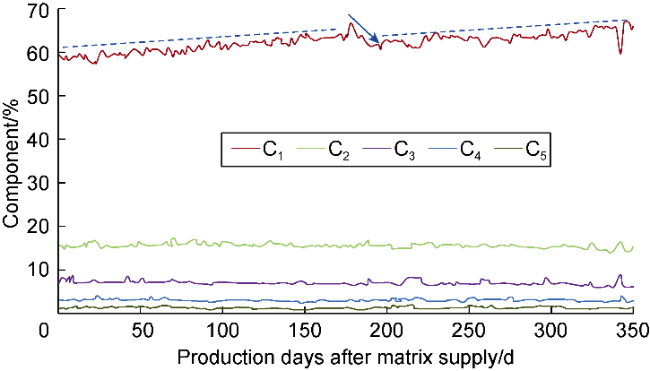

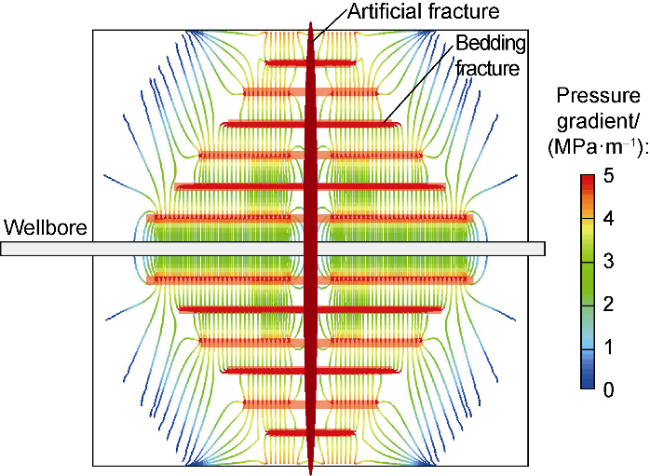

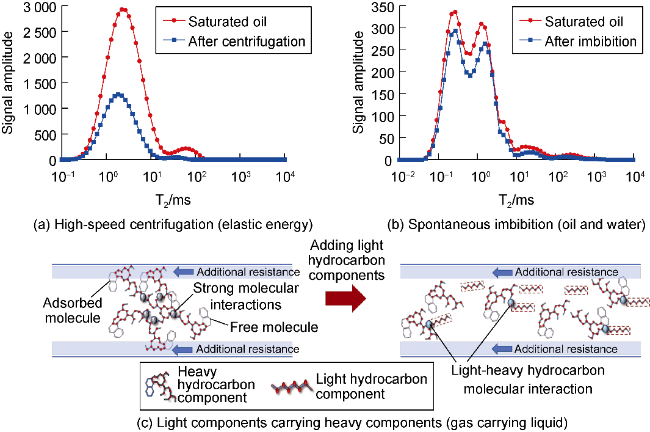

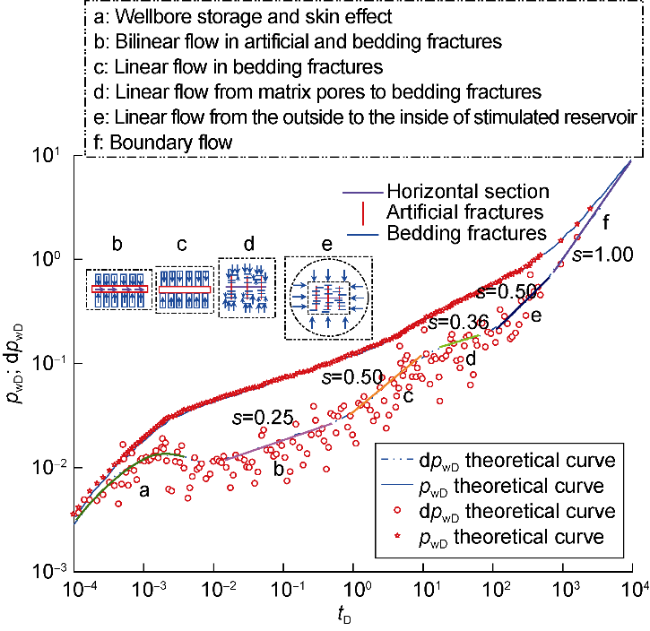

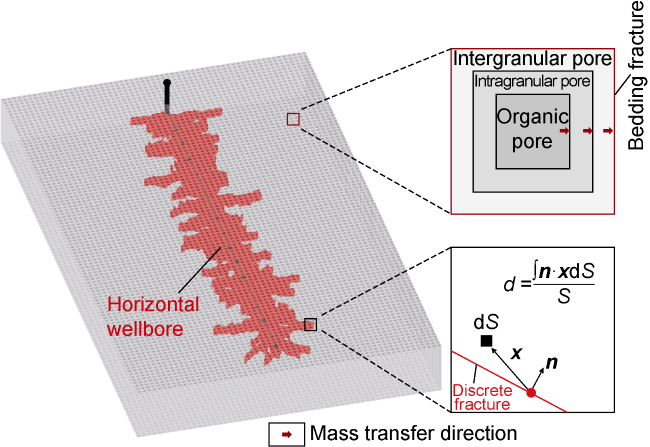

[11], with an initial annual decline rate of only 14.5%. Numerical simulation carried out by using an organic-inorganic dual porosity medium model and average pore diameter as 20 nm exactly simulated the production performance of Well GYH 1 and realized the strong coupling of rock mechanics-flow mechanics-thermodynamics, organic-inorganic dual porosity media, and nanometer pores.