The northern Songliao Basin mainly develops two sets of shale oil reservoirs, and the Gulong shale oil mostly occurs in the second-order structural units of the Central Depression, such as the Qijia-Gulong Sag, Daqing Placanticline and Sanzhao Sag

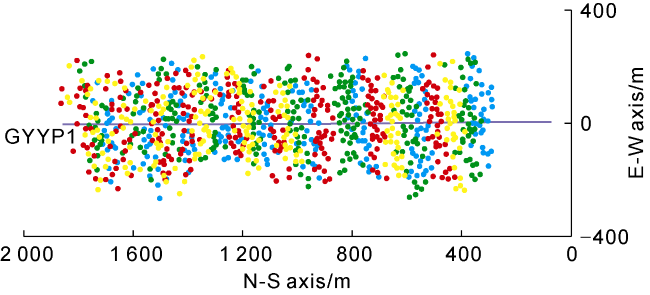

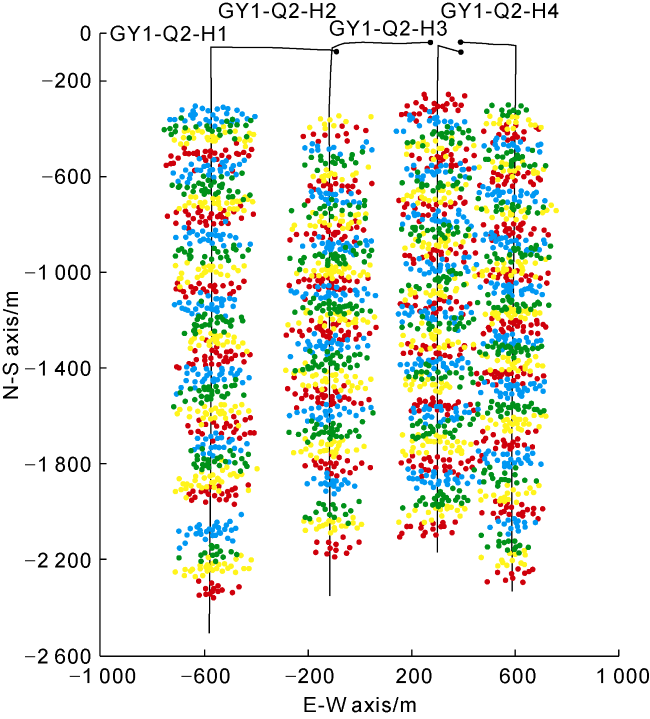

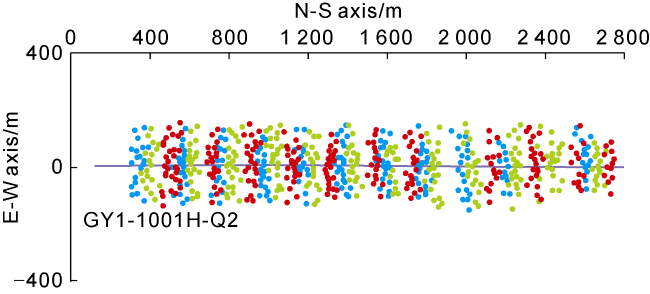

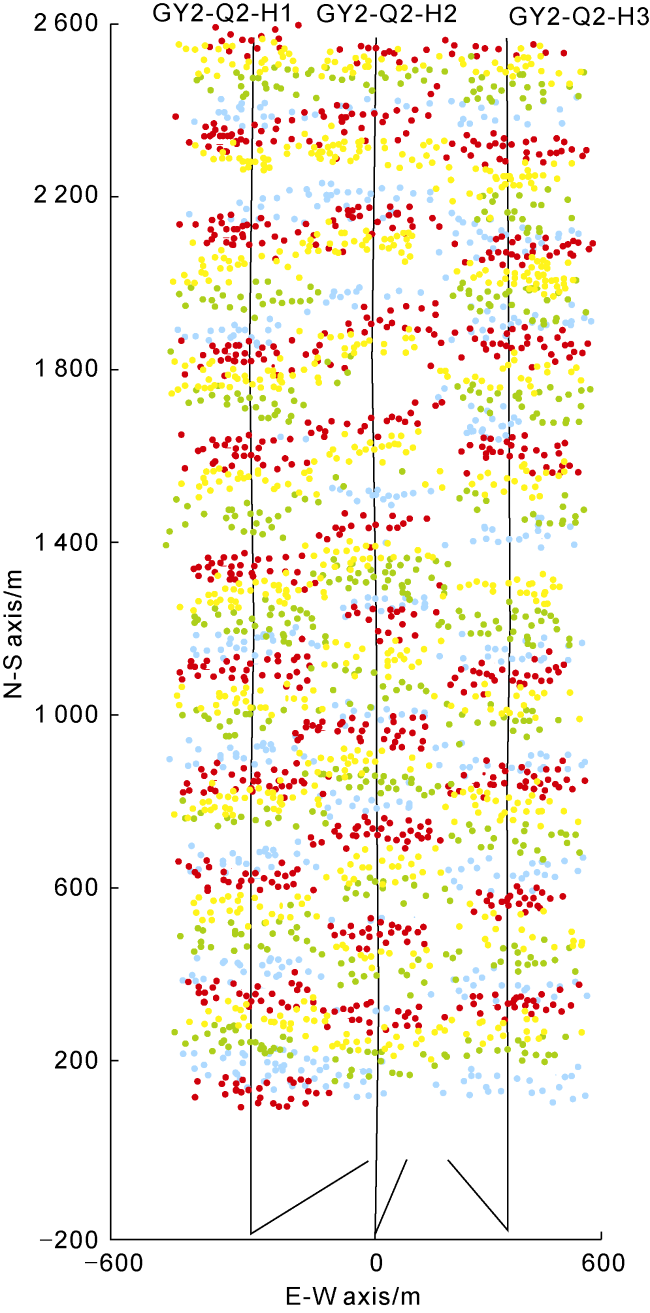

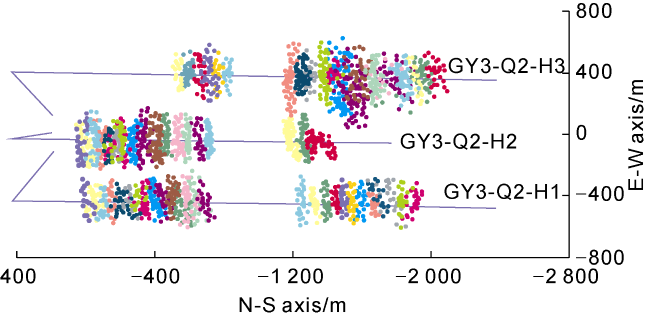

[21⇓-23]. By the maturity and hydrocarbon composition of shale oil, the Gulong shale oil can be grouped into light oil and thin oil zones. The shale oil of Qingshankou Formation mainly occurs in the first and second members of Qingshankou Formation (Qing-1 and 2 members), which is divided into 9 oil layers (Q1-Q9) from bottom to top. The Qingshankou shale oil, medium-highly mature, is now the main target for exploration and development. Forty-two wells are drilled for exploration and appraisal, including 25 vertical wells and 17 horizontal wells. Five pilot testing well groups, consisting of 58 wells, are deployed for horizontal well development. By far, all 58 wells have been completely drilled; specifically, 49 wells have been fractured, and 48 wells have been brought into production. Well GY-YP-1, a representative well, targets Q2 and Q3, and has a horizontal section of 1562 m. It yielded high-rate industrial hydrocarbon streams - the flowing oil production of 30.5 t/d and the flowing gas production of 1.30×10

4 m

3/d - during the production test after fracturing with 82 314 m

3 fluids. During the 905-d post-breakthrough production, Well GY-YP-1 contributed a cumulative production of 1.44×10

4 t of oil equivalent, including 1.02×10

4 t oil and 542×10

4 m

3 gas, recording a major breakthrough in shale oil production. In addition, Well GY-9HC, targeting Q9, achieved flowing production after reservoir stimulation, and produced 6670 t oil or 1.09×10

4 t oil equivalent in the first year.