Introduction

1. Radial borehole fracturing fracture propagation model

1.1. Model assumptions

1.2. Model governing equation

1.2.1. Solid-phase control equations

1.2.2. Fluid control equations

1.2.3. Fracture propagation criteria

1.3. Model parameters

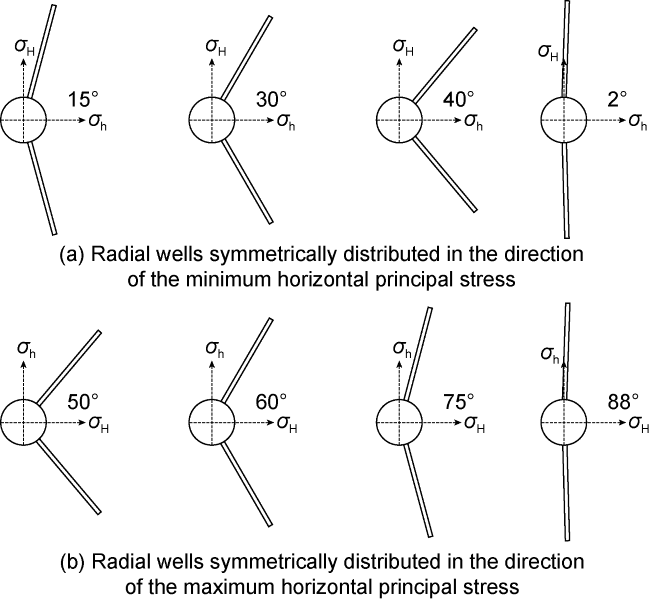

Fig. 1. Schematic diagram of the layout of two radial boreholes radial boreholes on the same floor. |

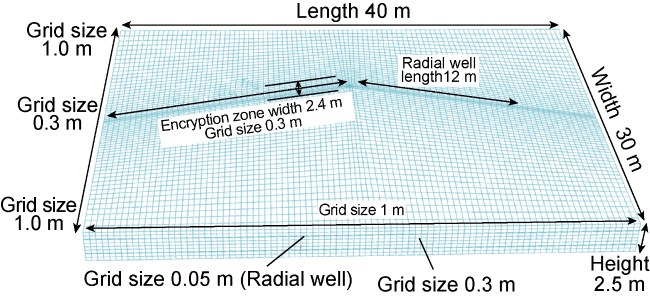

Fig. 2. Schematic diagram of model size and mesh size. |

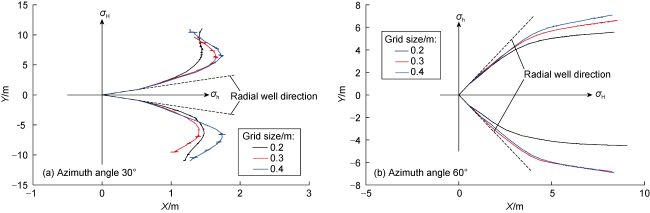

Fig. 3. Two-dimensional fracture geometries under different mesh sizes. |

1.4. Model validation

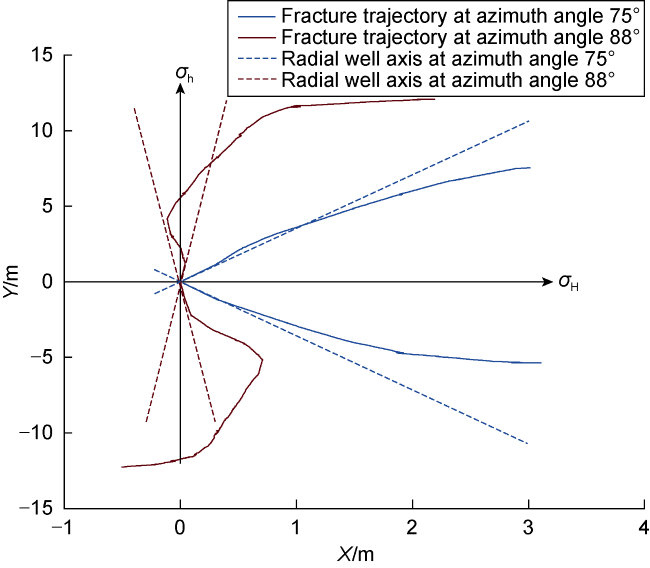

Fig. 4. Local magnification of fracture geometries at azimuths of 75° and 88°. |

2. Deviation distance and radial borehole-to- well extrusion

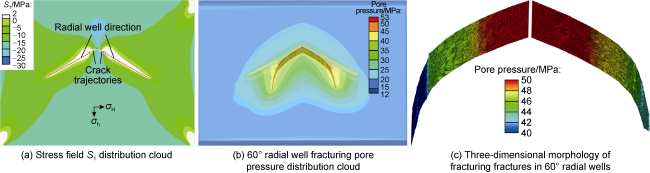

Fig. 5. Model stress field S1 distribution cloud, 60° radial borehole fracturing pore pressure distribution cloud and radial borehole fracture geometries. |

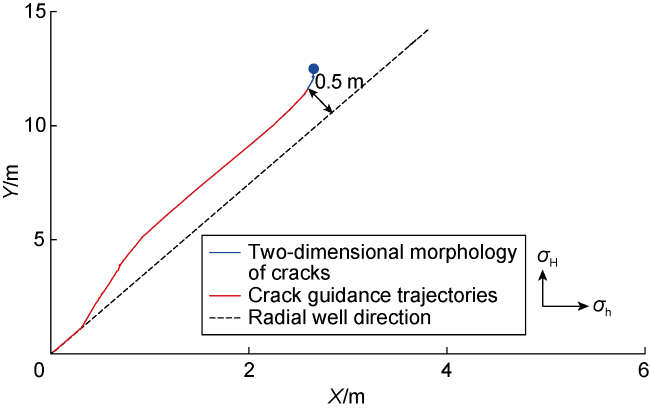

2.1. Deviation distance

Fig. 6. Schematic diagram of deviation distances. |

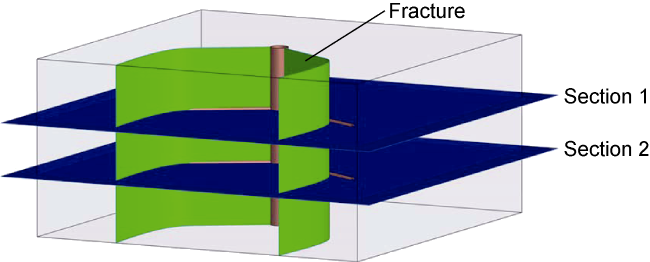

Fig. 7. Schematic diagram of fracture data extraction profile. |

2.2. Radial inter-well extrusion

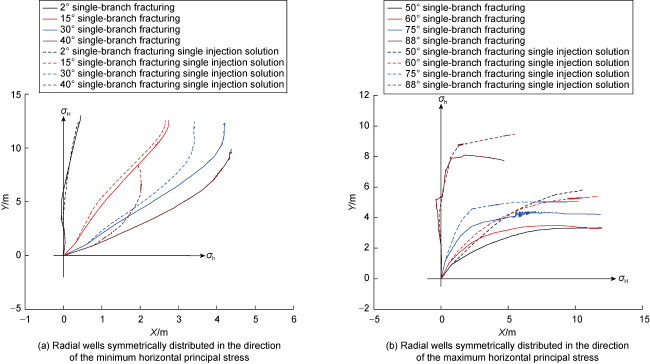

Fig. 8. Morphology comparison of two radial boreholes fracturing and one single radial borehole fracturing fractures. |

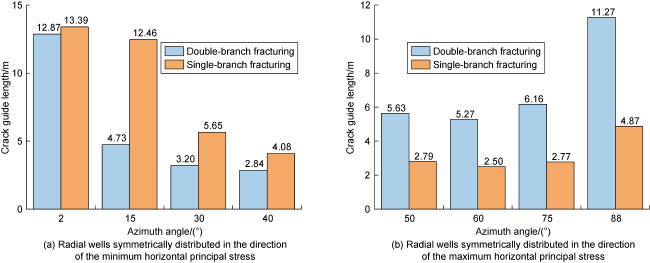

Fig. 9. Comparison of guide lengths of two radial boreholes fracturing and one single radial borehole fracturing fractures. |

Fig. 10. Comparison of one single radial borehole fracturing and one single radial borehole fracturing one single radial borehole injection fracture geometries. |

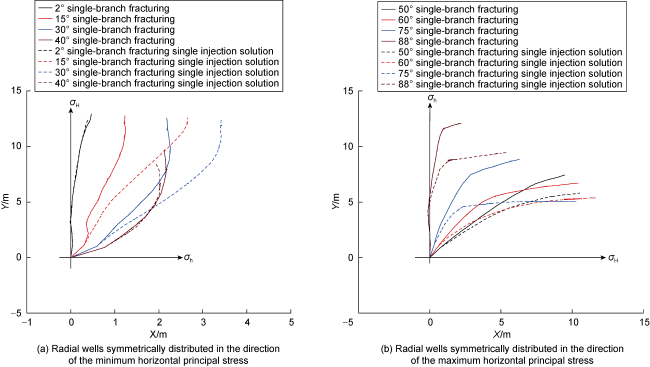

Fig. 11. Comparison of fracture geometries of two radial boreholes fracturing and one single radial borehole fracturing one single radial borehole injection solution. |

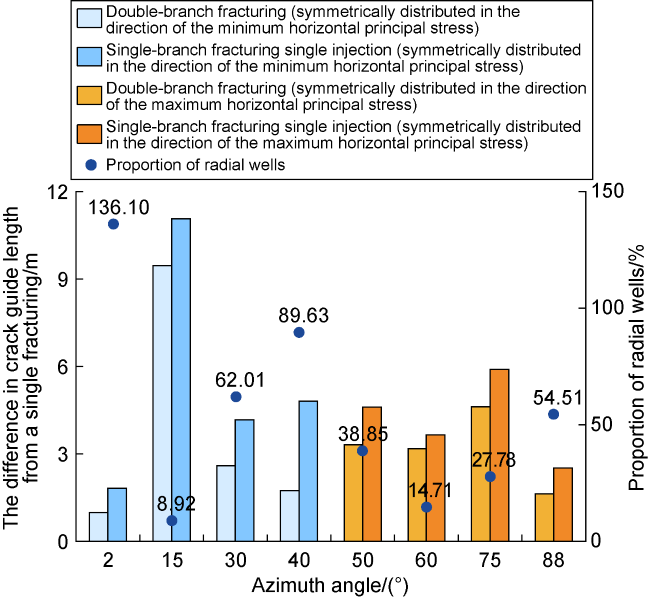

Fig. 12. The difference between the deviation distances and the proportion of radial boreholes in double fracturing, single fracturing, single fracturing and single fracturing. |

3. Influence law of fracture geometries

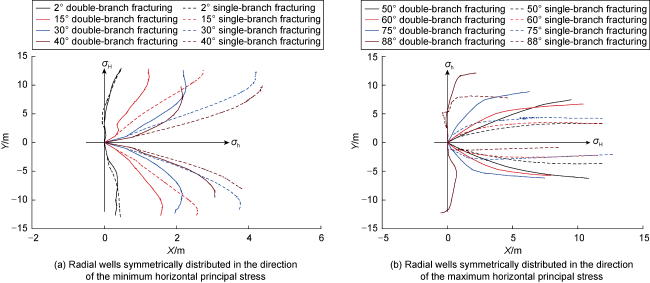

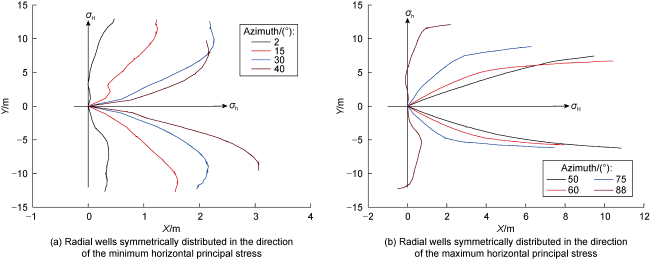

3.1. Effect of azimuth on deviation distances

Fig. 13. Fracture geometries at different azimuths. |

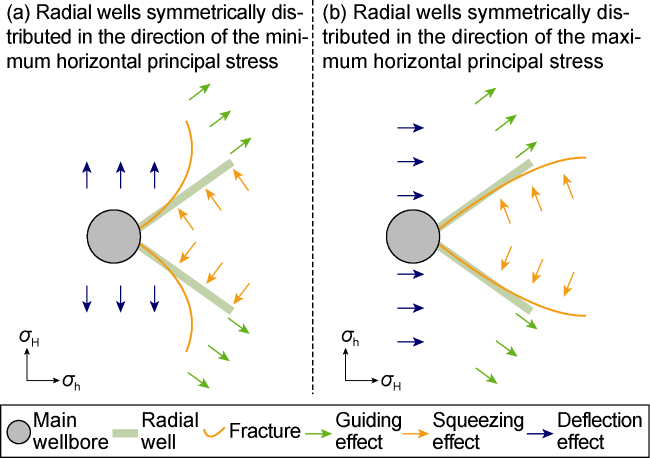

Fig. 14. Schematic diagram of three functions to jointly control fracture propagation. |

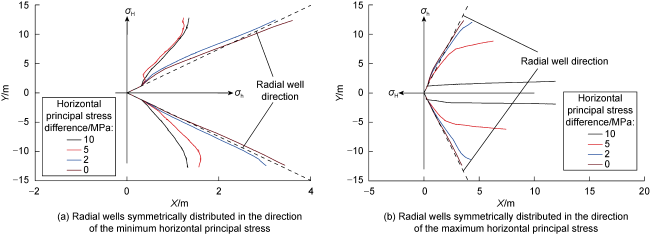

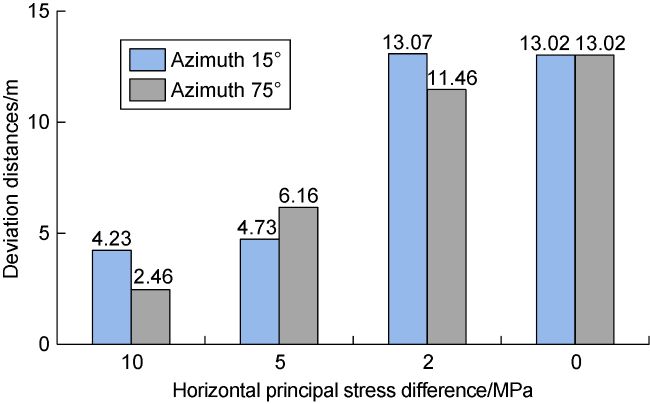

3.2. Effect of horizontal main pressure difference on deviation distances

Fig. 15. Fracture geometries under principal stress difference at different levels. |

Fig. 16. Deviation distances under principal stress difference at different levels. |

3.3. Effect of rock matrix permeability on deviation distance

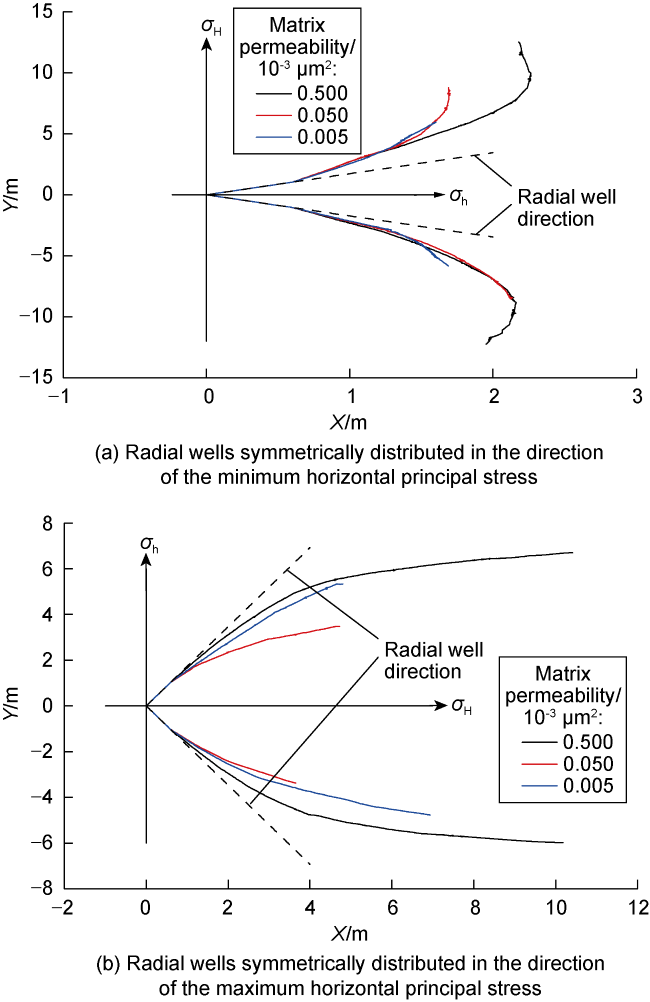

Fig. 17. Fracture geometries under different rock matrix permeability. |

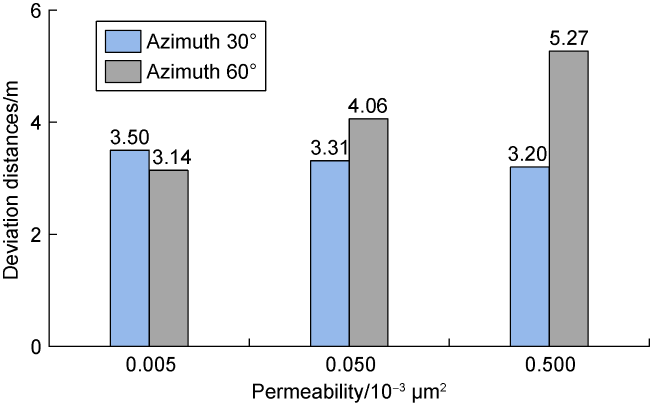

Fig. 18. Deviation distances under different rock matrix permeability. |