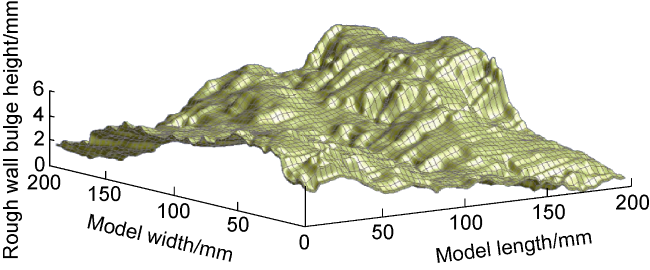

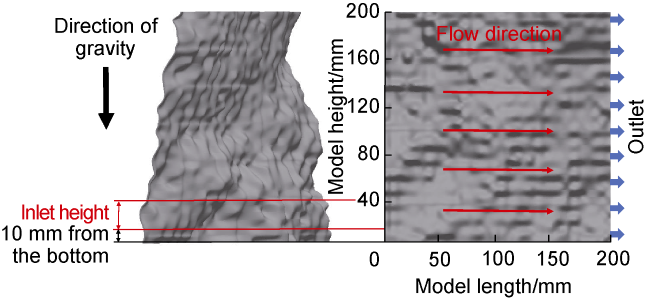

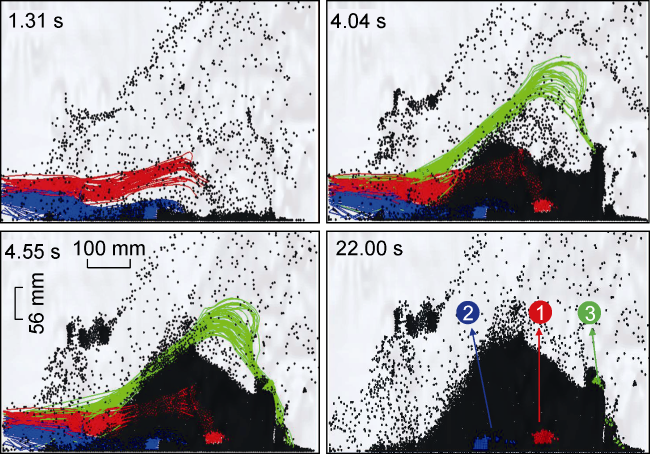

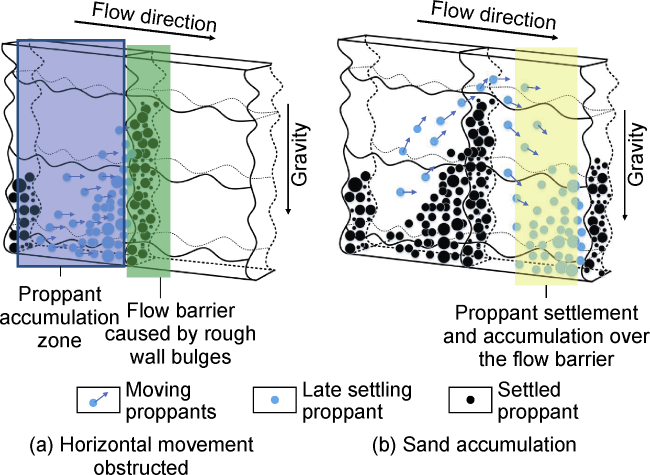

The proppant accumulation process in the vertical rough fracture is illustrated in

Fig. 14. The flow of fluid carrying proppant particles through narrow and rough channels is decomposed into horizontal and vertical movement. The former is controlled by injection pressure and flow resistance, and the latter is controlled by gravity, buoyancy and resistance to subsidence. When the particles move to the position with a larger roughness (shaded in green), the horizontal movement is affected by the fracture wall and slows down. Then, particles settle and are accumulated under the action of gravity and form the sand mass. Once the sand mass is formed, the flow field near the bottom sand mass is seriously affected, which hinders the horizontal movement of particles. A large amount of proppants settle down between the inlet and the accumulated sand mass. As more particles settle down, the sand plugging occurs ultimately. The larger the roughness is, the more likely to cause vertical proppant accumulation at the inlet until proppants fill the entire inlet. The green area of the rough fracture is much rougher than the blue and yellow areas, it's most possible for particles to impact on the fracture wall, and the possibility of proppant settlement is also highest

[4]. Therefore, sand plugging is likely to occur in the green area. Moreover, in this process, the sand mass diverts part of the sand-carrying fluid upward, making a certain amount of particles skip over the sand mass, and settle down and accumulate on the back of the sand mass under the action of gravity. The higher the fracture roughness is, the faster the proppant settlement near the fracture inlet, the shorter the horizontal migration, and the more possible to accumulate near the fracture inlet. Finally, sand plugging may occur in the fracture in a short time.