Introduction

1. Model data

1.1. CO2 capture

1.2. CO2 storage

1.3. CO2 utilization

1.4. CO2 transportation

2. Model construction

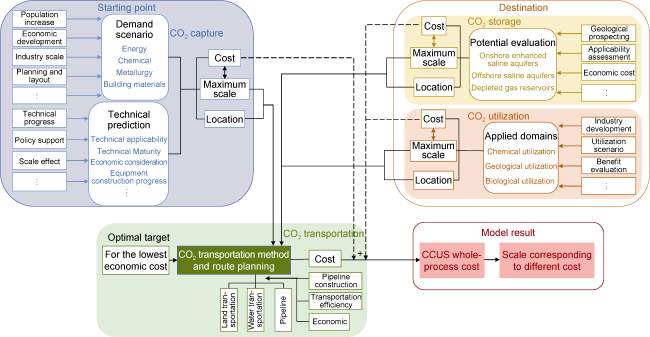

2.1. General thought

Fig. 1. The general thought of CCUS cost-scale model. |

2.2. Construction steps

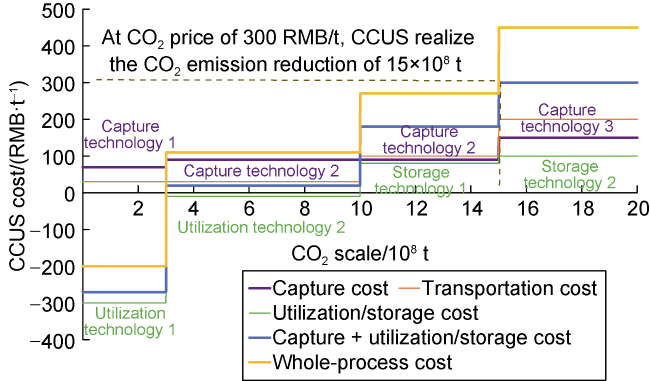

Fig. 2. Schematic diagram of CCUS cost-scale curve. |

2.2.1. Capture link curve

2.2.2. Transportation + utilization/storage link curve

2.2.3. Whole-process curve

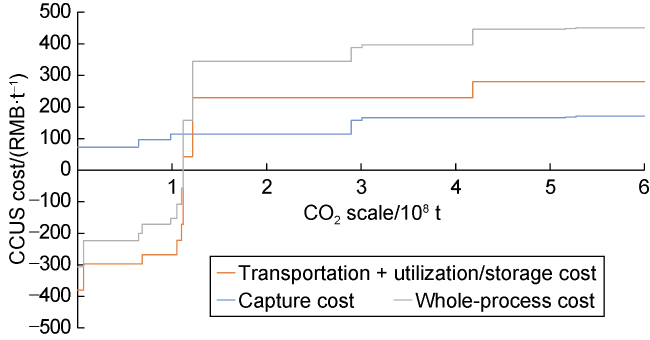

2.2.4. Regional model example

Table 1. CO2 capture demand in East China |

| CO2 capture classification | CO2 capture cost/ (RMB•t-1) | Capacity/ 108 t | Cumulative capacity/ 108 t |

|---|---|---|---|

| Petrochemical: exhaust gas capture from chemical plants | 73.15 | 0.64 | 0.64 |

| Petrochemical: heating boilers | 96.51 | 0.34 | 0.98 |

| Thermal power: post-combustion | 114.65 | 1.92 | 2.90 |

| Thermal power: pre-combustion | 158.15 | 0.11 | 3.01 |

| Steel industry | 166.51 | 2.15 | 5.16 |

| Thermal power: oxygen- enriched combustion | 168.15 | 0.11 | 5.27 |

| Cement industry | 170.94 | 0.96 | 6.24 |

Fig. 3. The CCUS cost-scale curve of East China in 2060. |

Table 2. The transportation + utilization/storage potential East China |

| Utilization/ Storage | Utilization/ Storage cost/ (RMB•t-1) | Capacity/ 104 t | Destination | Distance/ km | Transportation cost/ (RMB•t-1•km-1) | Transportation cost/ (RMB•t-1) | Two links' cost/ (RMB•t-1) | Cumulative capacity/ 104 t |

|---|---|---|---|---|---|---|---|---|

| Gas fertilizer | -455 | 635 | Local | 50 | 1.5 | 75 | -380 | 635 |

| Ethylene | -347 | 6222 | Local | 50 | 1.0 | 50 | -297 | 6857 |

| Traditional raw materials | -343 | 3648 | Local | 50 | 1.5 | 75 | -268 | 10 505 |

| Urea | -298 | 496 | Local | 50 | 1.5 | 75 | -223 | 11 001 |

| Methane | -247 | 178 | Local | 50 | 1.5 | 75 | -172 | 11 179 |

| Aromatic hydrocarbons | -7 | 1004 | Local | 50 | 1.0 | 50 | 43 | 12 183 |

| Saline aquifer storage | 80 | 29 655 | Jianghan Basin | 500 | 0.3 | 150 | 230 | 41 838 |

| Saline aquifer storage | 80 | 130 710 | North Jiangsu-South Yellow Sea Basin | 400 | 0.5 | 200 | 280 | 172 548 |

| Ocean storage | 100 | 32 220 | East China Sea | 300 | 1.0 | 300 | 400 | 204 768 |

2.2.5. Integrated analysis

2.3. Result application

2.4. Scheme comparison

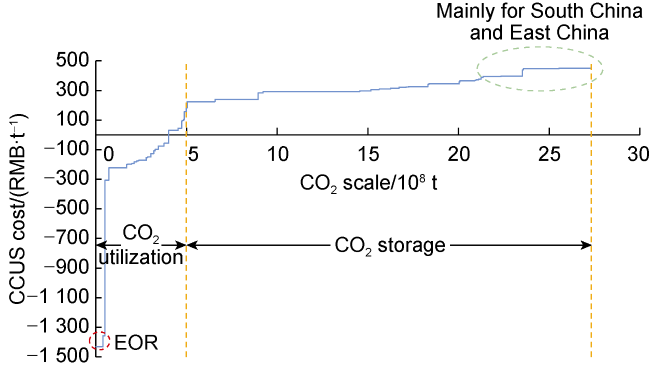

3. Calculation results

3.1. Long-distance off-site storage scheme

Table 3. Predicted data calculated by long-distance off-site storage scheme |

| Regions | Reduction demand*/ 108 t | Reduction scale/108 t | Reduction percentage/% | Highest cost/ (RMB·t−1) | Average cost/ (RMB·t−1) | Off-site transportation | Average distance/ km | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CO2 price 100RMB/t | CO2 price 200RMB/t | CO2 price 300RMB/t | CO2 price 100RMB/t | CO2 price 200RMB/t | CO2 price 300RMB/t | ||||||

| North | 8.34 | 0.93 | 0.99 | 1.30 | 11.15 | 11.87 | 15.54 | 620.94 | 455.48 | No | 736.02 |

| Northeast | 2.04 | 0.46 | 0.50 | 0.50 | 22.49 | 24.50 | 24.50 | 420.94 | 199.00 | No | 341.36 |

| East | 6.24 | 0.61 | 1.22 | 1.22 | 9.86 | 19.54 | 19.54 | 670.94 | 495.75 | Yes | 1 136.23 |

| Central | 3.16 | 0.27 | 0.27 | 0.27 | 8.53 | 8.53 | 8.53 | 460.94 | 387.66 | Yes | 736.02 |

| South | 3.19 | 0.31 | 0.31 | 0.31 | 9.75 | 9.75 | 9.75 | 490.94 | 473.31 | Yes | 726.90 |

| Southwest | 1.65 | 0.54 | 0.54 | 0.77 | 32.57 | 32.57 | 46.49 | 310.94 | 198.04 | No | 264.87 |

| Northwest | 2.71 | 0.72 | 1.22 | 1.84 | 26.71 | 45.04 | 67.96 | 370.94 | 91.05 | No | 248.90 |

| Country | 27.33 | 3.84 | 5.05 | 6.21 | 14.07 | 18.47 | 22.71 | 670.94 | 388.07 | 720.05 | |

*“Reduction demand” is the statistical data. The rest is calculated from the model. |

3.2. Local on-site storage scheme

Table 4. Predicted data calculated by local on-site storage scheme |

| Regions | Reduction demand*/ 108 t | Reduction scale/108 t | Reduction percentage/% | Highest cost/ (RMB·t−1) | Average cost/ (RMB·t−1) | Off-site transportation | Average distance/ km | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CO2 price 100RMB/t | CO2 price 200RMB/t | CO2 price 300RMB/t | CO2 price 100RMB/t | CO2 price 200RMB/t | CO2 price 300RMB/t | ||||||

| North | 8.34 | 0.90 | 0.96 | 5.87 | 10.79 | 11.52 | 70.31 | 325.94 | 232.05 | No | 141.47 |

| Northeast | 2.04 | 0.46 | 0.50 | 0.50 | 22.49 | 24.50 | 24.50 | 370.94 | 157.38 | No | 258.11 |

| East | 6.24 | 1.12 | 1.22 | 1.22 | 17.93 | 19.54 | 19.54 | 450.94 | 312.32 | No | 170.69 |

| Central | 3.16 | 0.27 | 0.27 | 2.65 | 8.53 | 8.53 | 83.77 | 325.94 | 240.51 | No | 141.47 |

| South | 3.19 | 0.31 | 0.31 | 0.31 | 9.75 | 9.75 | 9.75 | 570.94 | 474.93 | No | 185.38 |

| Southwest | 1.65 | 0.54 | 0.54 | 0.54 | 32.57 | 32.57 | 32.57 | 340.94 | 200.82 | No | 264.87 |

| Northwest | 2.71 | 1.22 | 1.22 | 2.71 | 45.04 | 45.04 | 100.00 | 295.94 | 31.38 | No | 129.56 |

| Country | 27.33 | 4.82 | 5.02 | 13.80 | 17.62 | 18.36 | 50.47 | 570.94 | 252.31 | 168.22 | |

Note: *“Reduction demand” is the statistical data. The rest is calculated from the model. |

3.3. On-site and off-site combined storage scheme

Table 5. Predicted data calculated by on-site and off-site combined storage scheme |

| Regions | Reduction demand*/ 108 t | Reduction scale/108 t | Reduction percentage/% | Highest cost/ (RMB·t−1) | Average cost/ (RMB·t−1) | Off-site transportation | Average distance/ km | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CO2 price 100RMB/t | CO2 price 200RMB/t | CO2 price 300RMB/t | CO2 price 100RMB/t | CO2 price 200RMB/t | CO2 price 300RMB/t | ||||||

| North | 8.34 | 0.93 | 0.99 | 6.2 | 11.15 | 11.87 | 74.33 | 325.94 | 201.17 | No | 141.47 |

| Northeast | 2.04 | 0.46 | 0.5 | 0.5 | 22.49 | 24.5 | 24.5 | 370.94 | 157.38 | No | 258.11 |

| East | 6.24 | 1.12 | 1.22 | 1.22 | 17.93 | 19.54 | 19.54 | 450.94 | 288.54 | Yes | 379.17 |

| Central | 3.16 | 0.27 | 0.27 | 2.65 | 8.53 | 8.53 | 83.77 | 325.94 | 240.51 | No | 141.47 |

| South | 3.19 | 0.31 | 0.31 | 0.31 | 9.75 | 9.75 | 9.75 | 450.94 | 366.63 | Yes | 546.39 |

| Southwest | 1.65 | 0.54 | 0.54 | 0.44 | 32.57 | 32.57 | 26.49 | 340.94 | 200.82 | No | 264.87 |

| Northwest | 2.71 | 1.22 | 1.22 | 2.71 | 45.04 | 45.04 | 100 | 295.94 | 31.38 | No | 111.23 |

| Country | 27.33 | 4.85 | 5.05 | 14.03 | 17.73 | 18.47 | 51.33 | 450.94 | 224.82 | 256.09 | |

*“Reduction demand” is the statistical data. The rest is calculated from the model. |

3.4. Result comparison and analysis

Fig. 4. Cost-scale curve of CO2 emission reduction by CCUS in China in 2060. |