a—acceleration of fluid microelement motion, m/s2;

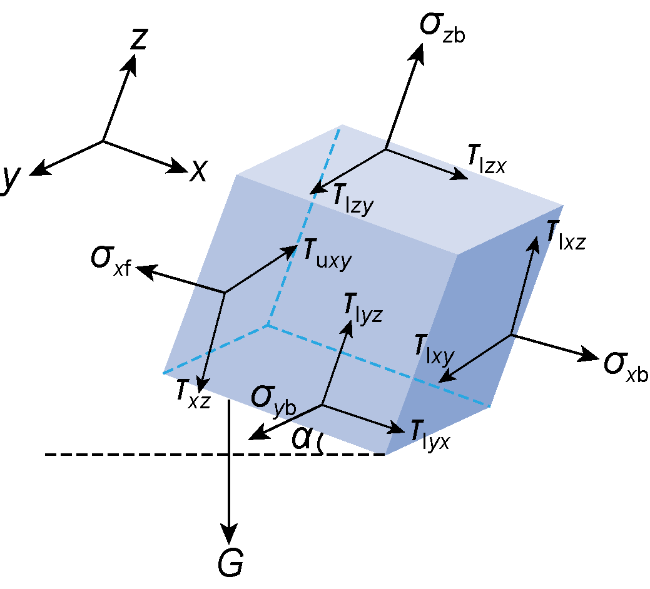

a—acceleration matrix of a hexahedron microelement, m/s2;

a0—coefficient of normal stress term on fluid microelement, dimensionless;

b0—coefficient of constitutive relationship term for fluid microelement, dimensionless;

A—cross-sectional area of tubing, m2;

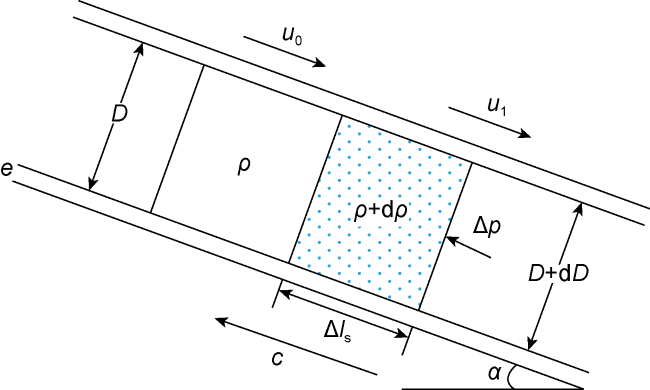

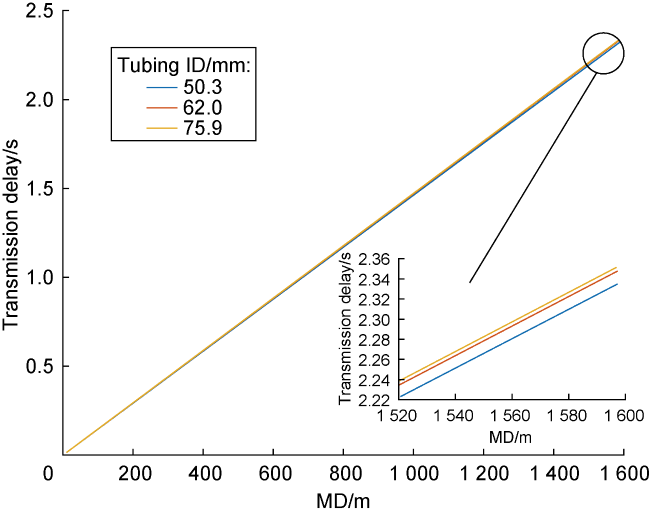

c—fluid wave propagation velocity, m/s;

e—thickness of tubing wall, m;

eσ—normal stress matrix of a moving fluid microelement, Pa;

$\overline{{{e}_{\sigma }}}$—normal stress matrix of a static fluid microelement, Pa;

eτ—constitutive tangential stress matrix of a fluid microelement, Pa;

eστ—resultant stress on a fluid microelement, Pa;

E—elastic modulus of fluid, Pa;

E0—elastic modulus of tubing, Pa;

f—fluid wave frequency, Hz;

F—resultant force on a fluid microelement, N;

g—gravitational acceleration, m/s2;

G—gravity matrix of a fluid microelement, N;

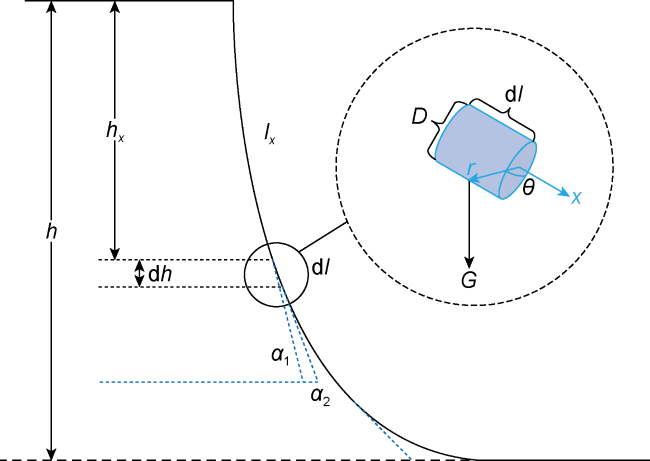

h—vertical depth of a whole well, m;

hx—vertical depth at a point in a wellbore, m;

k—formation water absorption index, m3/(s•Pa);

kε—material coefficient, dimensionless;

l—measured depth of a whole well, m;

lx—measured depth at a point in a wellbore, m;

Δls—length of the flow section with water hammer effect, m;

pb—formation opening pressure, Pa;

ph—bottom hole pressure, Pa;

px—pressure at lx from the wellhead, Pa;

p0—wellhead pressure, Pa;

p1—inlet pressure of the micro-section, Pa;

p2—outlet pressure of the micro-section, Pa;

qv—volume flow rate, m3/s;

Δp—pressure difference, Pa;

Δpe—fluid pressure drop per unit length of wellbore, Pa/m;

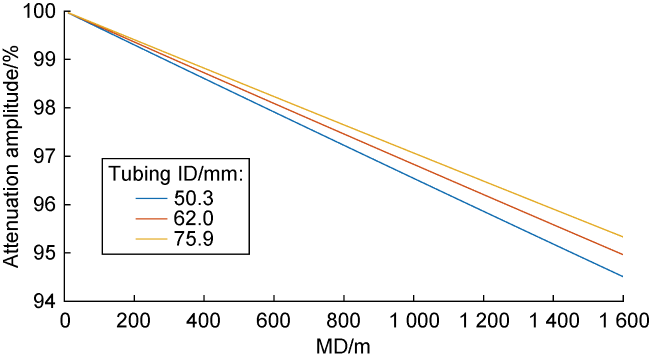

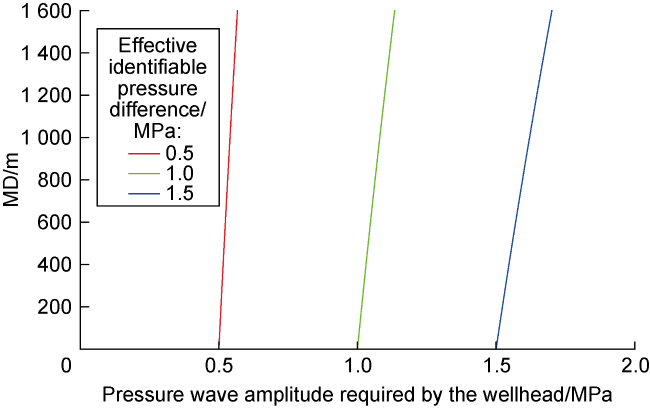

Δpx—pressure wave amplitude at lx, Pa;

Δpl—pressure amplitude at the throttling element, Pa;

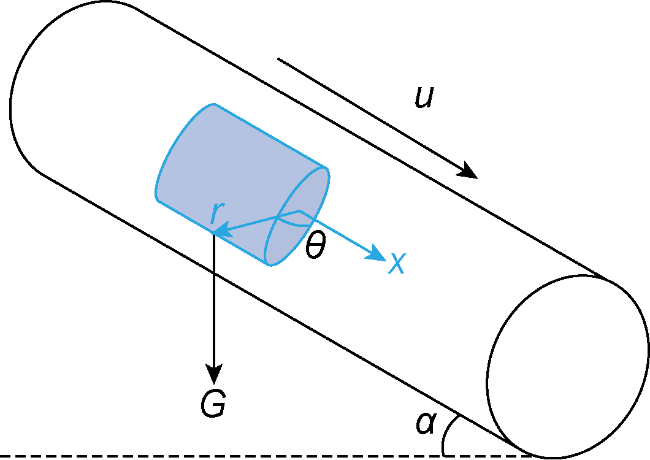

r—radial distance in a cylindrical coordinate system, m;

Re—Reynolds number, dimensionless;

T—period of pulse signal, s;

u—fluid rate matrix of a hexahedron microelement, m/s;

$\bar{u}$—average flow rate, m/s;

u0, u1—flow rate before and after fluid compression, m/s;

ΔV—volume of the flow section, m3;

x, y, z—Cartesian coordinate system, m;

Z—practical conductivity coefficient, m4/(s•Pa);

Z0—conductivity coefficient of continuous tubing, m4/(s•Pa);

α—angle between fluid microelement and horizontal direction, (°);

α1—angle between the tangent line at the inlet of the well section and the horizontal line, (°);

α2—angle between the tangent line at the outlet of the well section and the horizontal direction, (°);

δx—signal attenuation coefficient, dimensionless;

θ—polar angle in cylindrical coordinate system, (°);

σ—normal stress on a fluid microelement, Pa;

σp—normal stress matrix on a fluid microelement, Pa;

σp—normal stress on the stress surface of a static fluid microelement, Pa;

σxb, σyb, σzb—normal stresses perpendicular to the stress surface of the microelement generated by the back microelement at x, y, z axis, Pa;

σxf, σyf, σzf—normal stresses perpendicular to the stress surface of the microelement generated by the front microelement at x, y, z axis, Pa;

τ—tangential stress on a fluid microelement, Pa;

τq—tangential stress matrix on a fluid microelement, Pa;

τxy, τxz—tangential stresses generated by deformation in x direction on y and z directions, Pa;

τyx, τyz—tangential stresses generated by deformation in y direction on x and z directions, Pa;

τzx, τzy—tangential stresses generated by deformation in z direction on x and y directions, Pa;

ϕ—angle between a well section and the horizontal line, which is a function of well MD and VD, (°).

u, l—top and bottom surfaces of a microelement perpendicular to the axis;