Introduction

1. Global CCUS industry

1.1. Development history

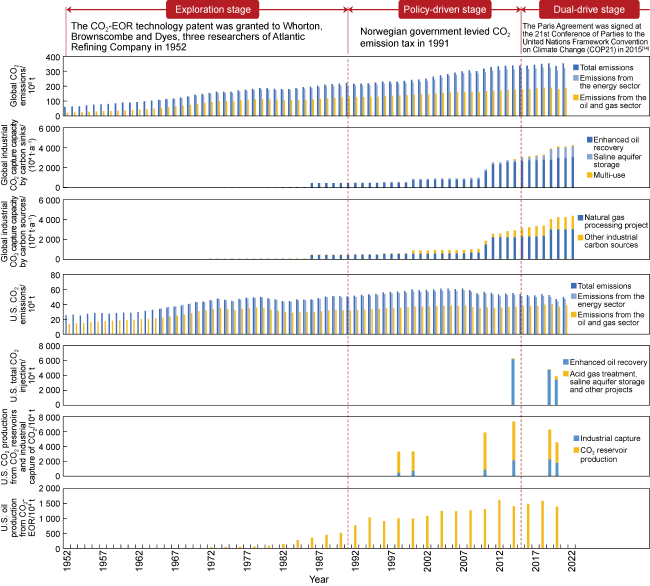

Fig. 1. Process of global CCUS development. Data on global CO2 emissions and U.S. CO2 emissions are sourced from References [15⇓-17]. Data on global industrial CO2 capture capacity by carbon sinks and global industrial CO2 capture capacity by carbon sources are sourced from Reference [5]. Data on total CO2 injection, as well as CO2 production from CO2 reservoirs and industrial capture of CO2 in the United States are sourced from Reference [19], while data in other years were not obtained. Data on oil production from CO2-EOR in the United States are sourced from Reference [7]. |

Table 1. International agreements, policies and regulations, and typical cases at different stages of global CCUS development |

| Stage | International agreements [11] | Policies and regulations [11] | Typical cases | ||

|---|---|---|---|---|---|

| Carbon source: high- concentration natural CO2 reservoirs | Carbon source: natural gas processing plants | Carbon sources: other industrial carbon sources | |||

| Exploration stage (1952-1990) | Declaration of United Nations Conference on Human Environment, 1972 | Energy Policy, Europe, 1986; Single European Act, Europe, 1987; American Clean Energy and Security, National Energy Conservation Policy Act, Federal Energy Administration Act, and Climate Change Action Plan, the United States, 1989-1993 | ① CO2-EOR project in SACROC Block, the first commercial CO2-EOR project [4,18,20 -21]: carbon sink - SACROC block; carbon source - McElmo Dome high-concentration natural CO2 reservoir and Val Verde natural gas processing plant ② EOR project in Wasson (ODC Unit) oilfield [18,20,27]: Carbon sink - Wasson (ODC Unit) oilfield; carbon source - Bravo Dome high-concentration natural CO2 reservoir, Sheep Mountain high-concentration natural CO2 reservoir | Shute Creek natural gas processing project [28⇓⇓-31] (in operation to date): carbon sink - Rangely Weber Oilfield Salt Creek Oilfield; carbon source - Shute Creek (LaBarge) natural gas processing plant; trading model - the carbon sink operator buys CO2 from the carbon source operator | |

| Policy-driven stage (1991-2014) | United Nations Framework Convention on Climate Change, 1992; Kyoto Protocol, Japan, 1997; Copenhagen Accord, Denmark, 2009 | The European Climate Change Program, and the G20 Energy Efficiency Action Plan, Europe, 2000; 2020 Climate And Energy Package, Europe, 2007; American Clean Energy and Security, the United States, 2009; Roadmap for moving to a competitive low- carbon economy in 2050, Europe, 2011; Clean Energy Standard Act, the United States, 2012; The President’s Climate Action Plan, the United States, 2013 | ① Sleipner Saline Aquifer Storage Project, the first commercial saline aquifer storage project [24⇓-26] (in operation to date): carbon sink - Utsira saline aquifer; carbon source - natural gas processing plant ② Century Plant project [20,23] (in operation to date): carbon sink - oil fields in the Permian Basin of the United States; carbon source - Century Plant natural gas processing plant | ① Great Plain synthetic fuel plant and Weyburn-Midale project [32-33] (in operation to date): carbon sink - Weyburn Oilfield; carbon source - Great Plain synthetic fuel plant: trading model - carbon sink operator buys CO2 from carbon source operator ② Air Products steam methane reforming project [34-35] (in operation to date): carbon sink - West Hastings Oilfield; carbon source - Air Products steam methane reforming furnace | |

| Dual-drive stage (Since 2015) | Paris Agreement, 2015; Glasgow Climate Pact, the UK, 2021 | China-U.S. Joint Statement on Climate Change, China and the United States, 2015; European Green Deal, Europe, 2019; Clean Future Act, the United States, 2021 | Gorgon CO2 injection project, a project in operation with the largest capture capacity and with saline aquifer as carbon sink [5,36]: Carbon sink - Dupuy saline aquifer; carbon source - natural gas processing plant | Alberta Carbon Trunk Line [37]: carbon sink - oil fields near Clive, Alberta, Canada; carbon source - fertilizer plant and North West Redwater Sturgeon refinery | |

1.1.1. Exploration stage (1952-1990)

1.1.2. Policy-driven stage (1991-2014)

1.1.3. Dual-drive stage (Since 2015)

1.2. CCUS projects, technologies and policies

1.2.1. Projects

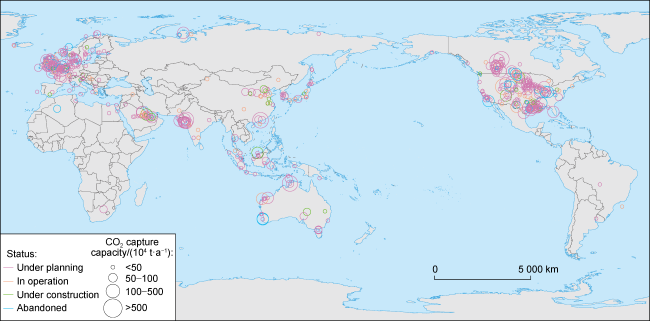

Fig. 2. Distribution of CCUS projects worldwide (data from Reference [38]). |

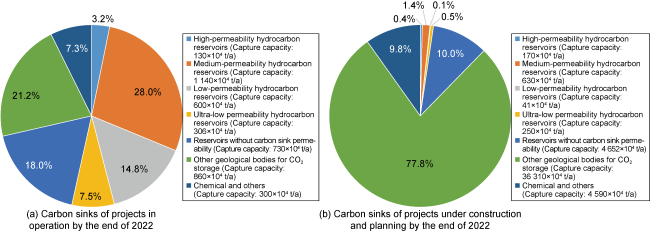

Fig. 3. Carbon sinks and capture capacity of global projects in operation, under construction and planning by the end of 2022 (Data from Reference [38]). |

1.2.2. Clusters

1.2.3. Technologies

Table 2. Carbon sources, capture methods, capture capacity and pipeline transportation distances of eight large CCUS projects in operation in North America |

| Project | Carbon source | Capture method | Capture capacity/ (104 t·a-1) | Pipeline transportation distance/km |

|---|---|---|---|---|

| Shute Creek natural gas processing project, U.S. | Natural gas processing plant [31] | Solvent-based physical absorption (polyethylene glycol dimethyl ether) [31] | 700 [5] | About 460.0 [31] |

| Century Plant, U.S. | Natural gas processing plant [45] | Solvent-based physical absorption (polyethylene glycol dimethyl ether) [45] | 500 [5] | >255.0 [45] |

| Great Plains synthetic fuel plant and Weyburn-Midale project, Canada | Synthetic fuel plant [46] | Solvent-based physical absorption (usually methanol) [46] | 300 [5] | 328.0 [46] |

| Alberta Carbon Trunk Line, Canada | Fertilizer plant and oil refinery [37] | Various types of carbon sources and different capture methods [37] | 190 by design [5] | 240.0 [37] |

| Air Products Steam Methane Reformer, U.S. | Hydrogen production [47] | Adsorption [47] | 100 [5] | About 500.0 [47] |

| Boundary Dam carbon capture and storage project, Canada | Power plant [48] | Solvent absorption [48] | 100 [5] | |

| Quest project, Canada | Hydrogen production [5] | PSA- chemical absorption [49] | 130 [5] | About 80.0 [49] |

| Industrial carbon capture and storage project in Illinois, U.S. | Ethanol plant [5] | Physical separation method (dehydration) [50] | 100 [5] | 1.5 [50] |

Table 3. Typical large saline aquifer storage projects in operation globally and their monitoring technologies |

| Project | Geological body for storage | Monitoring technology |

|---|---|---|

| Gorgon CO2 injection project, Australia | 2500 m in depth Dupuy sandstone stratum [36,54] | Seismic monitoring, monitoring wells [55] |

| Quest project, Canada | 2100 m in depth sandstone saline aquifer [49] | Underground monitoring, surface monitoring [49] |

| Sleipner saline aquifer storage project, Norway | 800-1000 m in depth sandstone saline aquifer [25] | Seismic monitoring, gravity field monitoring [56] |

| Industrial carbon capture and storage project in Illinois, the United States | 2100 m in depth Mt. Simon sandstone saline aquifer [57] | Time-lapse seismic monitoring, thermobaric monitoring wells, etc. [58] |

1.2.4. Policies

1.3. Outlook

2. CCUS industry in China

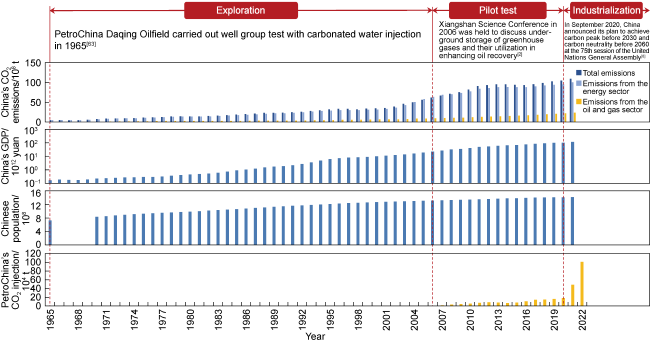

2.1. Development history

Table 4. Development stages of CCUS in China and typical cases |

| Stage | Typical cases | ||

|---|---|---|---|

| PetroChina [10,63,66⇓ -68] | Sinopec [66,69] | Yanchang Petroleum [70] | |

| Exploration (1965-2005) | Well group test with carbonated water injection by Daqing Oilfield, multi-well group CO2 huff and puff test by Jilin Oilfield, and CO2 flooding test by Jilin Oilfield | CO2 flooding tests by Shengli, Huadong, Jiangsu and Caoshe oilfields | |

| Pilot test (2006-2019) | Pilot test in Hei-59 well area by Jilin Oilfield, pilot test in Hei-79 South well area and expansion test in Hei-79 North small well spacing area by Jilin Oilfield, and expansion test in Hei-46 block by Jilin Oilfield | First CO2 flooding test well in Chuankou Oilfield, Jingbian- Wuqi pilot test of 5×104 t/a CO2 flooding and storage, and 10× 104 t/a CO2 flooding and storage demonstration project in Ansai | |

| Industrialization Since 2020) | National CCUS-EOR pilot test in ultra-low permeability reservoirs by Jilin Oilfield, national CCUS-EOR pilot test in low permeability reservoirs by Daqing Oilfield, national CCUS-EOR pilot test in ultra-low permeability reservoirs by Changqing Oilfield, national CCUS-EOR pilot test in conglomerate reservoirs by Xinjiang Oilfield | Qilu Petrochemical-Shengli Oilfield million-ton CCUS-EOR project | 26×104 t/a CCUS injection project under construction |