When massive fracturing fluid is injected into reservoirs and retained in the fracture system, the fluid will interact with the reservoir rocks and further impact the physical and mechanical properties of shale. The main mechanism of water-shale interaction is the hydration expansion of water-sensitive clay minerals like montmorillonite and illite/smectite mixed layer. Sui et al.

[11] and Xue et al.

[12] investigated the micro-pore structure, hydration-induced fractures, and porosity and permeability of shale after hydration. Zeng et al.

[13-14] analyzed the influence of various clay minerals and inorganic cations on the hydration characteristics of shale. Liu et al.

[15] and Yang et al.

[16] studied the deterioration behavior of mechanical parameters of different types of shales induced by hydration through triaxial mechanical experiments. The interaction mechanism between CO

2 and shale includes adsorption expansion, chemical dissolution, extraction of dissolved organic matter, etc. Supercritical CO

2 with strong adsorption capacity tends to adsorb on the surface of mineral particles such as organic matter and tiny clay, in turn reducing the surface free energy and leading to the expansion and deformation of shale

[8,17]. Ao et al.

[18] tested the deformation characteristics of shale induced by CO

2 adsorption under different pressures. Jiang et al.

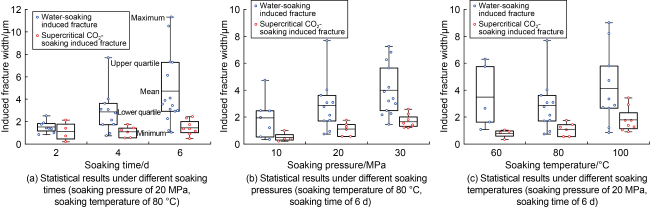

[19] found that the specific surface area and porosity of shale were increased after the CO

2-soaking, which is affected by soaking time, temperature, and pressure. Ozotta et al.

[20] quantitatively characterized the changes in pore structure and connectivity of organic-rich shale after supercritical CO

2-soaking. Tang et al.

[17] and Ni et al.

[21] studied the changes in the mechanical strength of shale under different CO

2-soaking conditions through rock mechanics experiments. In addition, Zhang et al.

[22] and Zhou et al.

[23-24] respectively compared the softening degree of shale soaked by different types of fluids.