Introduction

1. Status quo of coalbed methane industry

1.1. Status quo outside China

1.2. Status quo in China

1.2.1. Development history

1.2.2. Resources volume

1.2.3. Completion status of National Five Year Plan

Table 1. Completion status of coalbed methane planning goals from the 11th Five Year Plan to the 13th Five Year Plan |

| Development indicators | Newly added proven geological reserves/ 108 m3 | Output/ 108 m3 | Commodity/ 108 m3 | |

|---|---|---|---|---|

| 11th Five Year Plan Period | Planned goal | 3000 | 50 | 50 |

| Completion status | 1980 | 15 | 12 | |

| 12th Five Year Plan Period | Planned goal | 10 000 | 160 | 160 |

| Completion status | 3504 | 44 | 38 | |

| 13th Five Year Plan Period | Planned goal | 200 | 100 | >90 |

| Completion status | 1839 | 67 | 62 | |

1.2.4. Practical benefits of coalbed methane development

1.3. Key technology progress of national coalbed methane industry base

1.3.1. The eastern edge of the Ordos Basin

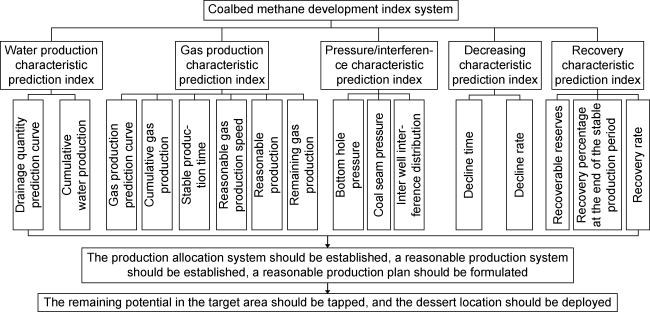

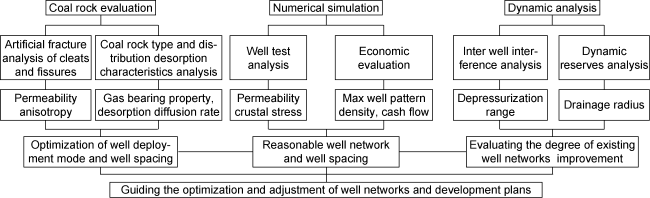

1.3.1.1. Gas reservoir dynamic analysis and development index prediction technology

Table 2. Fine description index system, technical process, and result types for coalbed methane reservoirs [11-12] |

| Indicator System | Technical Process | Achievements | ||||

|---|---|---|---|---|---|---|

| 9 static variables | 9 dynamic variables | 7 steps | 3 tables | 9 figures | 3 models | |

| Structure | Reservoir pressure | Static feature description | Reservoir features statistic table | Structural map of coal seam top surface | Structure- terrain model | |

| Coal seam thickness | Desorption pressure | Dynamic feature description | Coal seam burial depth map | |||

| Coal rock types and coal body structure structure | Sleeve pressure and flow pressure | Division of development units | Coal seam gas content map | |||

| Gas content and isothermal adsorption constant | Pressure drop radius | Geological model establishment | Recovery output statistic table | Coal seam thickness map | Reservoir properties model | |

| Reservoir physical properties | Desorption radius | Development unit evaluation | Coal seam storage ratio diagram | |||

| Top and bottom plate characteristics | Unit pressure drop gas production | Evaluation of remaining reserves | Hydrological unit division diagram | |||

| Hydrographic features | Gas production | Development adjustment suggestions | Remaining reservoir statistic table | Macro distribution map of coal and rock types | Remaining reserve distribution model | |

| Burial depth and crustal stress | Water yield | Pressure drop distribution diagram | ||||

| Rock mechanics | Remaining recoverable reserves | Dynamic permeability change chart | ||||

Table 3. Evaluation index system and analysis method for coalbed methane production capacity [11-12] |

| Affecting factors | Analysis index | Evaluation base | Productivity evaluation method |

|---|---|---|---|

| Resource conditions | Equivalent resource per unit area | Static material foundation | Parameter fitting method |

| Preservation conditions | Equivalent height of local structural height difference | ||

| Mineralization value | |||

| Emission and recovery characteristics | Critical desorption press/initial reservoir pressure ratio | ||

| Historical highest water yield | |||

| Accumulated water production before casing pressure | |||

| Bottom hole pressure | Dynamic development capability | Curve analogy method | |

| Unit pressure drop gas production | Actual production performance | Dynamic analysis method |

1.3.1.2. Optimal and fast drilling technology for coalbed methane

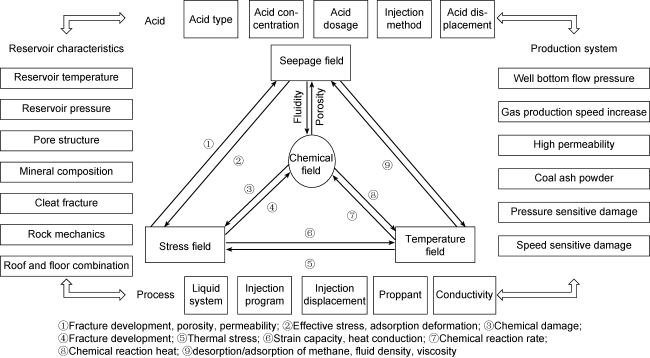

1.3.1.3. Fracturing modification

Fig. 3. Volume acidized fracturing process technology system diagram. |

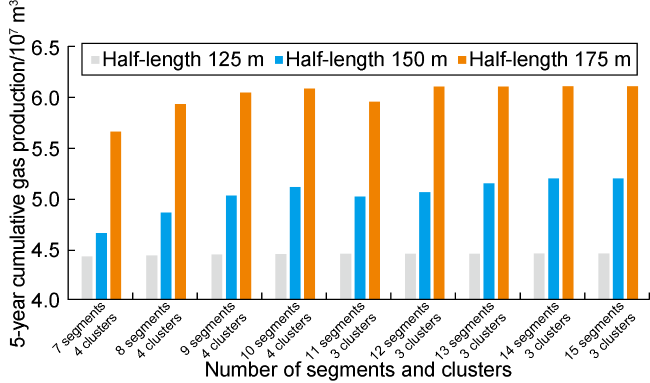

Fig. 4. Comparison of 5-year cumulative gas production under different segmented conditions. |

1.3.1.4. Key technologies for coalbed methane recovery

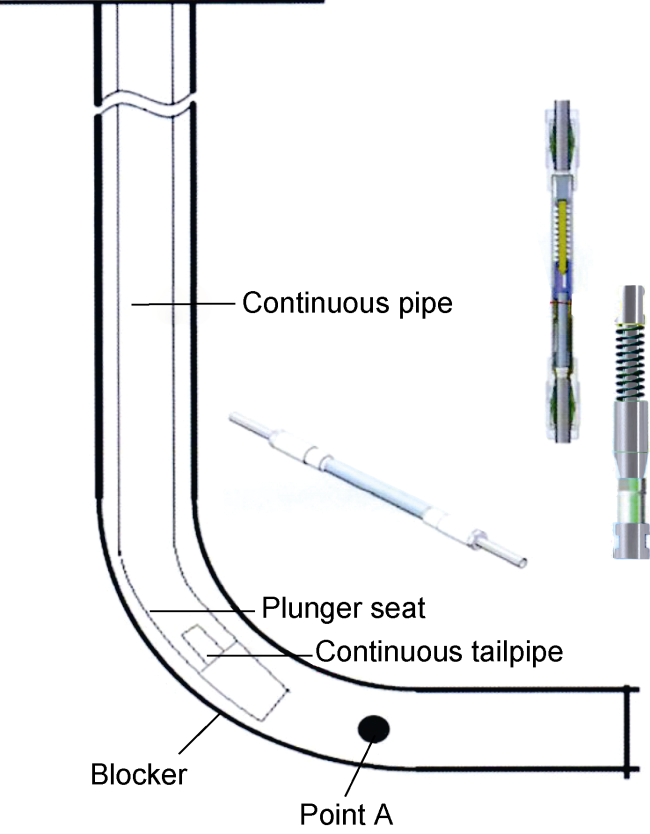

Fig. 5. Full life cycle wellbore process design diagram. |

1.3.2. Qinshui basin

1.3.2.1. Stress release gas production technology for large diameter horizontal wells

1.3.2.2. Nitrogen injection displacement technology under controllable temperature for production increase

1.3.2.3. Low-cost development technology for thin coal seam and multi-layer combined mining

1.3.2.4. Ground development technology of coalbed methane in goaf of coal mines

1.4. Exploration and development results of deep (layer) coalbed methane

2. Problems in the development of coalbed methane industry

2.1. Low level of exploration

2.2. Low technical adaptability

2.2.1. Complex geological conditions

2.2.2. Mature technology cannot be copied

2.2.3. Insufficient precision in research on middle-shallow (layer) resource conditions

2.2.4. Deep (layer) coalbed methane exploration and development is in its early stages and the technology is not mature

2.3. Low return on investment

2.4. Small development scale

2.5. Management is not implemented

3. Development strategy of coalbed methane under the background of carbon peaking and carbon neutrality

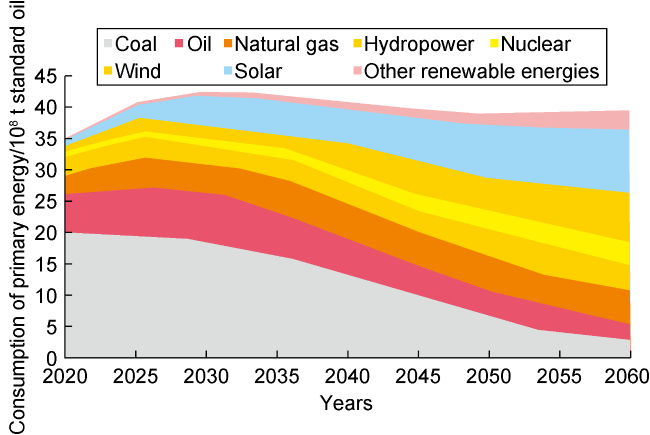

3.1. Energy structure under the goal of carbon peaking and carbon neutrality

Fig. 6. Trend of the primary energy consumption structure of China [25]. |

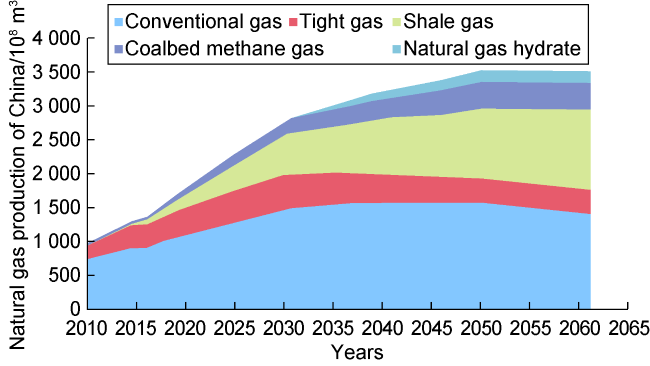

3.2. The development of natural gas (coalbed methane) meets the goal of “dual carbon”

Fig. 7. The natural gas production structure of China [25]. |