Introduction

1. Overview of shale oil in Jiyang Depression

1.1. Geology

Table 1. Characteristics of shale oil in Jiyang Depression and other areas in China |

| Area | Horizon | Basin type | Shale lithofacies | Stratigraphic thickness/m | Burial depth/m | Ro /% | Crude oil density/ (g•cm-3) | |

|---|---|---|---|---|---|---|---|---|

| Range | Producing or test | |||||||

| Jiyang Depression | The Eocene Shahejie Formation | Saline to semi-saline lacustrine basin | Muddy limestone, limy mudstone | 300-1 500 | 3 000-5 500 | 0.5-1.5 | 0.7-0.9 | 0.82-0.89 |

| Cangdong Sag | The 2nd member of Paleogene Kongdian Formation | Semi-saline to freshwater lacustrine basin | Dolomitic and felsic shales | 50-200 | 2 800-4 200 | 0.5-1.1 | 0.86-0.89 | |

| Songliao Basin | The Cretaceous | Freshwater lacustrine basin | Felsic shale | 106-149 | 1 600-2 700 | 0.5-1.7 | 1.0-1.4 | 0.78-0.87 |

| Ordos Basin | The 7th member of Triassic Yanchang Formation | Freshwater lacustrine basin | Siltstone, fine sandstone | 10-40 | 1 600-2 900 | 0.7-1.2 | 0.80-0.86 | |

| Junggar Basin | The Permian Lucaogou Formation | Saline lacustrine basin | Dolomitic siltstone, muddy dolomite | 20-70 | 2 500-4 800 | 0.6-1.1 | 0.88-0.92 | |

| Santanghu Basin | The Permian | Saline lacustrine basin | Muddy limestone, limy dolomite | 15-100 | 2 000-2 800 | 0.6-1.3 | 0.85-0.90 | |

1.2. Development

1.3. Challenges

2. The ternary-element storage and flow concept for shale oil in Jiyang Depression

2.1. The “storage element” provides the material basis for the shale oil enrichment

2.1.1. Pore-fracture development characteristics govern the shale oil storage space

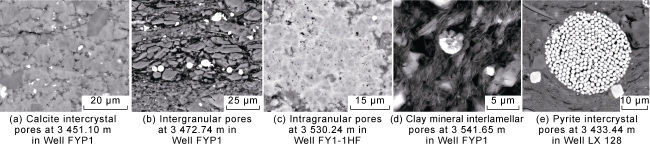

Fig. 1. Pore types and pore size distribution of shales in the Jiyang Depression. |

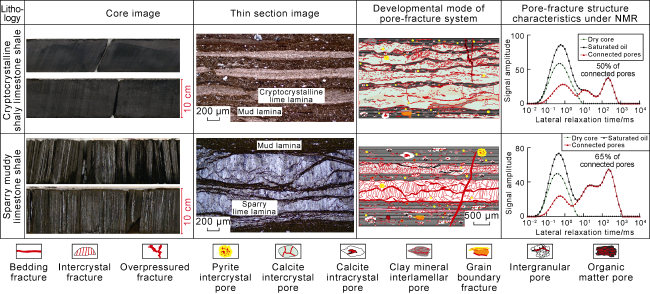

2.1.2. Pore-fracture combination modes govern the shale oil storage capacity

Fig. 2. Characteristics of laminated lime-mud texture for shale oil development in Jiyang Depression. |

2.1.3. The hydrocarbon generation capacity and free hydrocarbon content determine the shale oil enrichment

2.2. The “fracture element” provides flow pathways for shale oil

2.2.1. Natural fractures control the shale oil migration and accumulation

2.2.2. Hydraulic fractures promote the high production of shale oil

2.3. The “pressure element” provides sufficient energy for the shale oil migration, accumulation and production

2.3.1. Primitive high pressures promote the shale oil migration and accumulation

2.3.2. Artificial high pressures increase the elastic energy

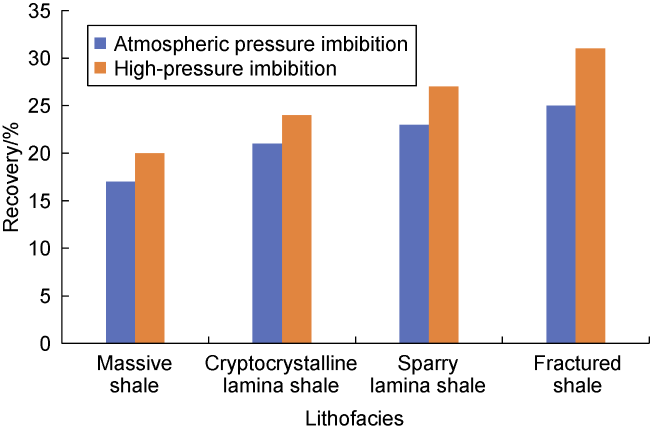

2.3.3. Artificial high pressures improve the imbibition capacity

Fig. 3. Imbibition recoveries in different lithofacies and at different pressures. |

2.3.4. Reasonable pressure control ensures long-term stable production of wells

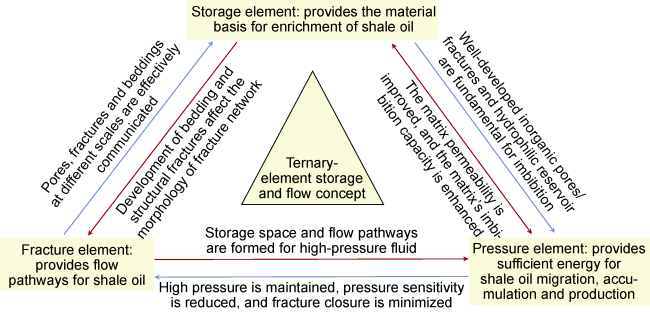

2.4. Three elements jointly control shale oil the enrichment and high production

2.4.1. The synergy of three elements controls the high and stable production of shale oil

Fig. 4. Triangle of ternary-element storage and flow concept for shale oil in Jiyang Depression. |

2.4.2. Development based on the ternary-element storage and flow concept

3. Techniques for 3D development of shale oil in Jiyang Depression

3.1. 3D well pattern optimization

3.1.1. Sweet spot evaluation and prediction

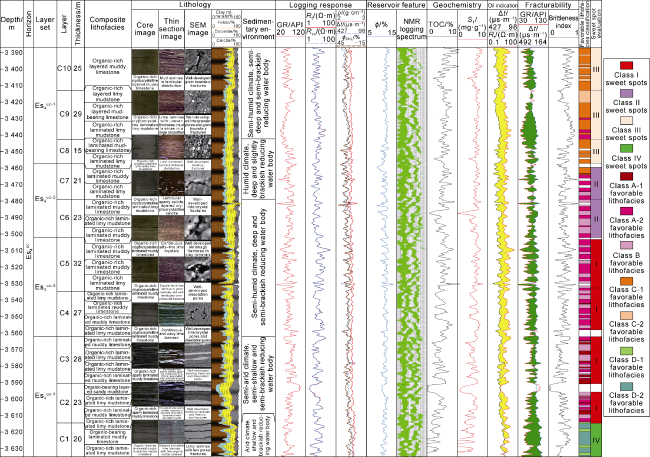

Fig. 5. Composite column for shale oil in Jiyang Depression. GR—Gammy ray; Rt—Formation resistivity; Rxo—Flushed zone formation resistivity; S1—Free hydrocarbon content; TOC—Total organic carbon content; ρ—Formation density; Δt—Acoustic time; ϕ—Formation porosity; ϕCNL—Neutron porosity. |

3.1.2. Layer set division

3.1.3. Optimization of 3D well pattern and well spacing

3.1.4. 3D well spacing pattern

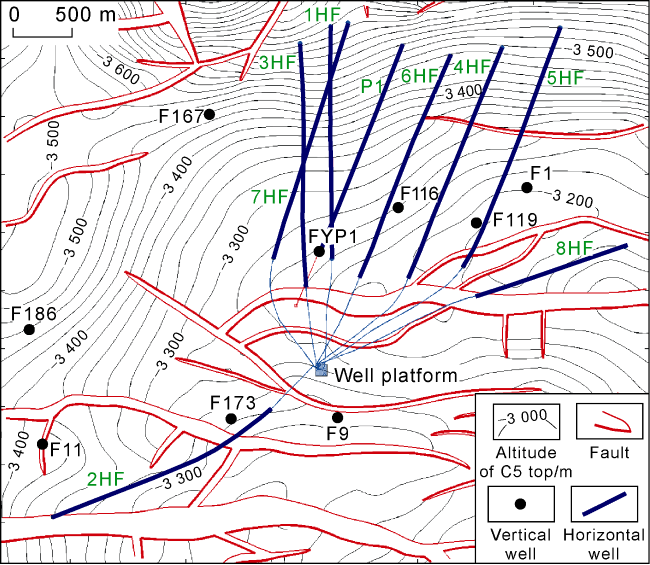

Fig. 6. Schemes of horizontal well deployment in Well FYP1 area. |

3.2. 3D balanced fracturing

3.2.1. Fracturing design

3.2.2. Optimization of parameters

3.3. Lifecycle optimization and control

3.3.1. Soaking time optimization

3.3.2. Backflow pressure drawdown optimization

3.3.3. Production pressure drawdown optimization

4. Application of ternary-element storage and flow concept in development

Fig. 7. Well pattern in Well FYP1 area. |