Displacement pressure is a key factor in the dynamic imbibition process. Foreign studies have shown that the displacement is considered unstable when the displacement pressure is greater than the critical value, leading to a low recovery, and it is stable when the displacement pressure is less than the critical value, corresponding to a high recovery

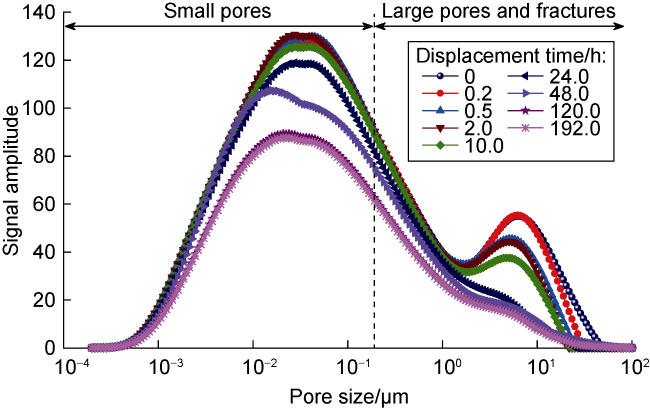

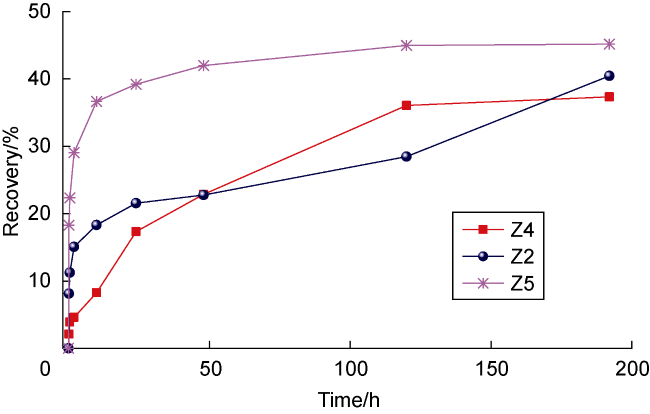

[26]. Z1, Z2, and Z3 samples in

Table 1 were selected for dynamic imbibition experiments at different displacement pressures. As shown in

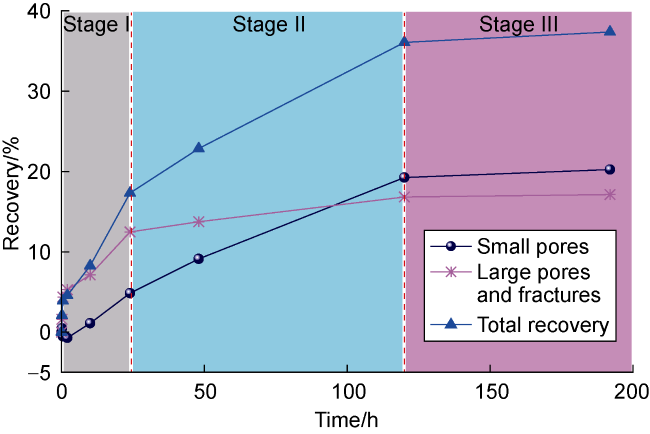

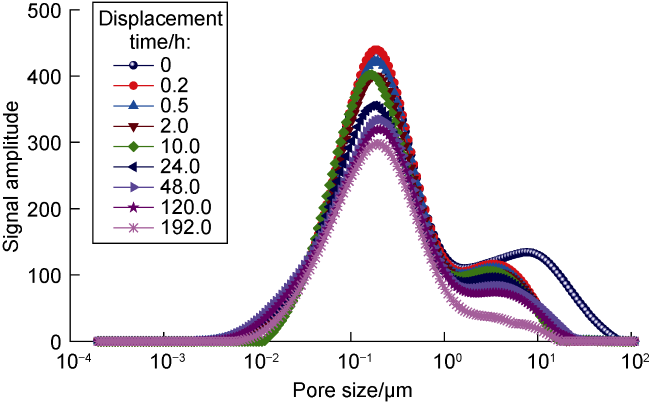

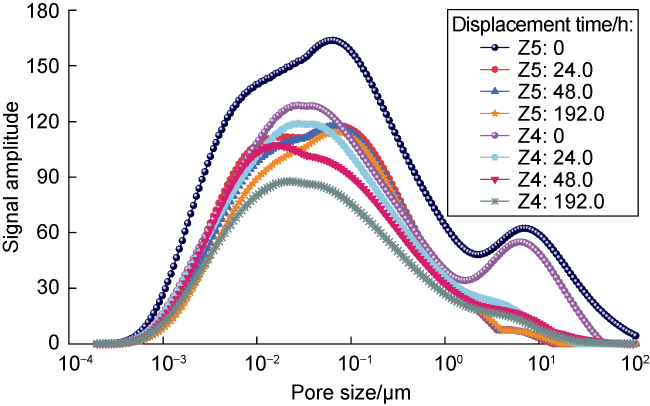

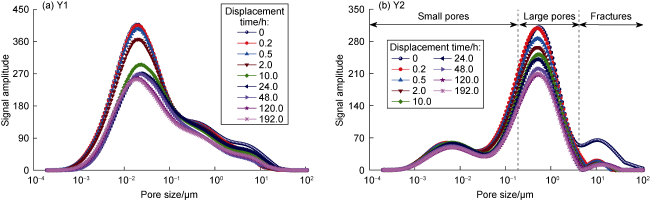

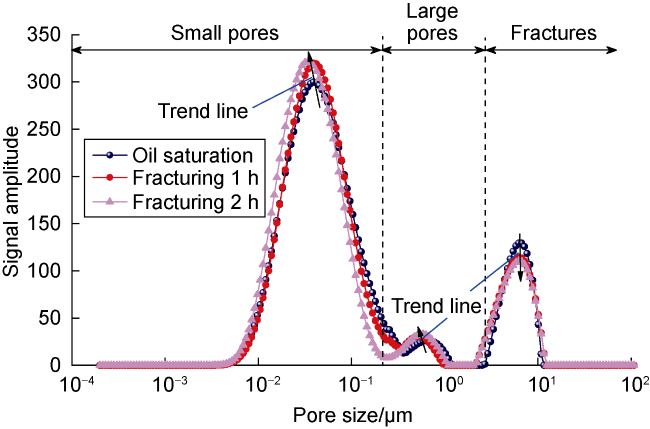

Fig. 7, the

T2 spectrum peak decreases with the displacement time, indicating that the crude oil in the core can be effectively produced under a certain pressure difference. The permeability levels of Z1, Z2, and Z3 samples are basically the same. The recovery of Z1 at 3 MPa, Z2 at 10 MPa, and Z3 at 15 MPa is 34.68%, 40.47%, and 36.35%, respectively (

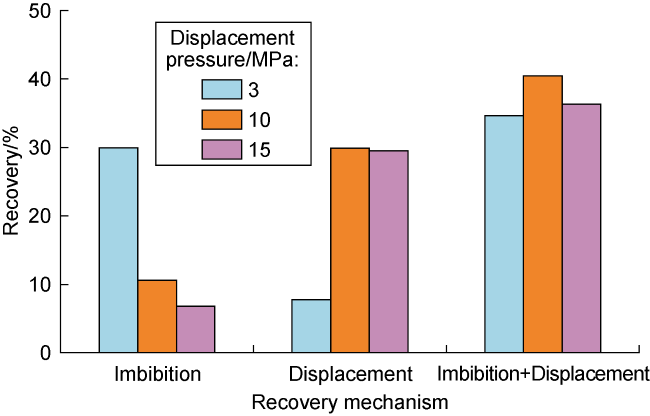

Table 3). With the increase of the displacement pressure, the recovery increases and then decreases, indicating that a higher displacement pressure is not certainly better in the dynamic imbibition experiment, and there is an optimal value range. It can be seen from

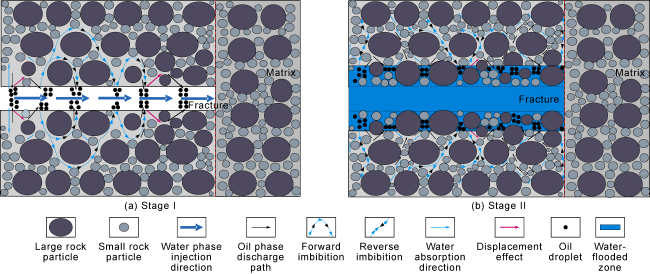

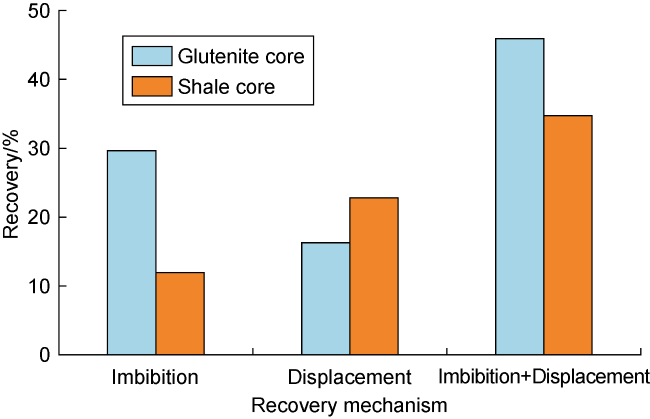

Fig. 8 that the imbibition recovery decreases from 29.92% to 6.82% with the increase of the displacement pressure, while the displacement recovery increases and then decreases slowly with the increase of the displacement pressure. When the displacement pressure is small, the viscous force is small, the core imbibition process is close to a spontaneous imbibition, and the water can slowly spread to the small pores in the matrix. The imbibition process occurs in the area with balanced capillary pressure and viscous force. In this period, the main oil drainage mechanism is the imbibition at capillary pressure in small pores. However, the low pressure makes the viscous force difficult to overcome the capillary pressure of most small pore throats, leading to an invalid displacement. Moreover, the volume of water injected in the same time period is limited, which cannot guarantee the high efficiency of imbibition, resulting in a lower total recovery. When the displacement pressure rises to 10 MPa, the viscous force increases with the rising displacement pressure. Under the action of imbibition at capillary pressure and displacement at viscous force, the crude oil imbibed into large pores or fractures can be quickly displaced by the viscous force, thus resulting in a high total recovery. When the displacement pressure further rises to 15 MPa, the viscous force becomes dominant in oil drainage. However, the water in the fracture is discharged before it undergoes imbibition and exchange with the crude oil in the matrix. The matrix imbibition is limited and the imbibition effect is poor. Meanwhile, the displacement pressure is high and the viscous force is large. When the viscous force is greater than the capillary pressure, a fingering phenomenon occurs, the breakthrough time reduces sharply, and the oil-water front becomes unstable, which may cause serious water channeling, resulting in a low recovery at high injection pressure.