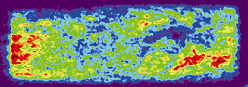

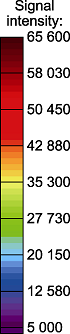

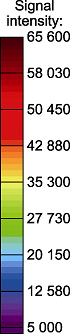

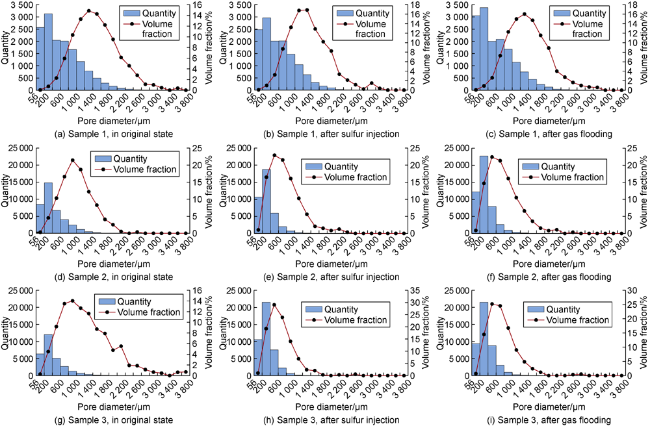

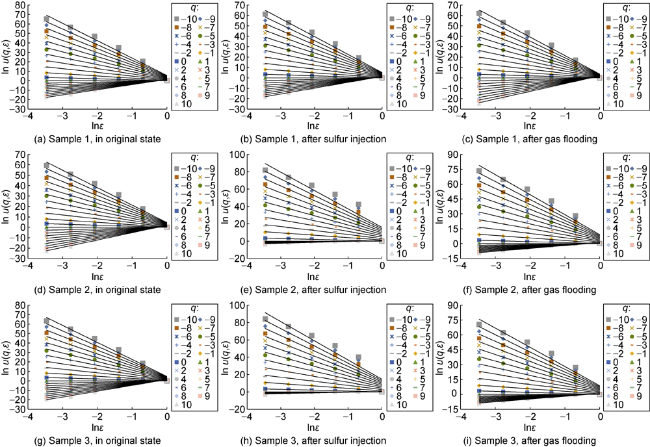

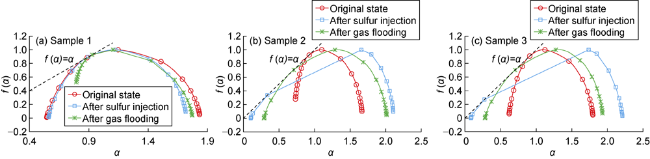

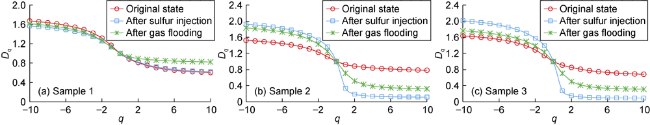

Fig. 10 shows the generalized fractal dimension spectrum

q-

Dq for samples in different states, which exhibits a reverse “S” shape with monotonic decrease, confirming the multifractal characteristics of pore size distribution in the samples

[27].

Table 3 lists several parameters of the generalized fractal dimension spectrum. Among them, the

D0 values are all 1, indicating the presence of pores in each box, corresponding to the Euclidean dimension of one-dimensional distribution

[28].

D10− to

D10+ reflects the heterogeneity degree of pore size distribution across the entire interval, with higher values indicating stronger heterogeneity. Its trend for the three samples is similar to that of Δ

α. It is noteworthy that the values of

D10− to

D10+ after gas flooding for Sample 1 are significantly lower than those for samples 2 and 3, indicating weaker heterogeneity of the former, which suggests a greater impact of liquid sulfur deposition on the heterogeneity of samples with poorer pore structures. Although gas flooding can carry away some liquid sulfur, it still cannot eliminate the negative impact of liquid sulfur deposition on the complexity of spatial structure as a whole. Additionally, the spectra of all three samples exhibit more pronounced changes on the right side compared to the left side (

Fig. 10), indicating information about two variables. The left (

q<0) and right (

q>0) regions represent low and high values of pore size distribution, respectively, indicating that the heterogeneity of pore structure in larger pores changes more significantly during sulfur injection-gas flooding, while the change in smaller pores is less significant. This suggests that liquid sulfur is easily transported during gas flooding. It is less likely to deposit and adsorb in larger pores, but probably in smaller pores. In other words, once blocked, it is difficult to be carried by gas; hence, the pore size changes just slightly. This finding is consistent with the previous analysis. Furthermore, the value of

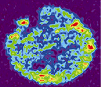

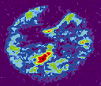

H can indicate the characteristics of spatial connectivity changes in the samples. For Sample 1,

H changes slightly, indicating no significant changes in connectivity during sulfur injection-gas flooding. This phenomenon is consistent with the results of NMR imaging, that is, for Sample 1 with relatively good physical properties, liquid sulfur deposition and adsorption mainly affect small pores, with little impact on the main gas flow channels and virtually no effect on overall connectivity. The situations of samples 2 and 3 are similar: after sulfur injection-gas flooding,

H significantly decreases, indicating that compared to the original state, there is still a considerable amount of liquid sulfur adsorption and deposition, leading to blockage in the rock cores and deterioration in connectivity.