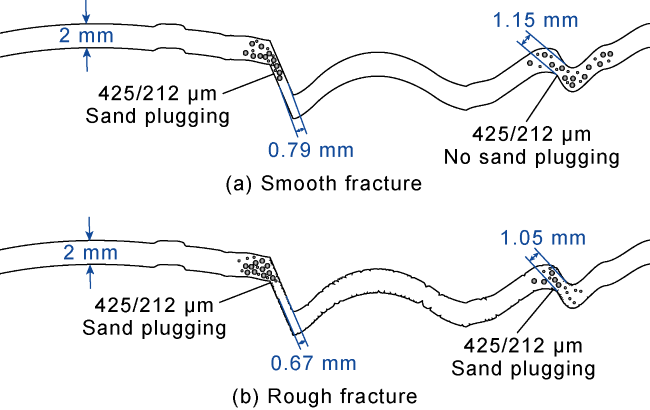

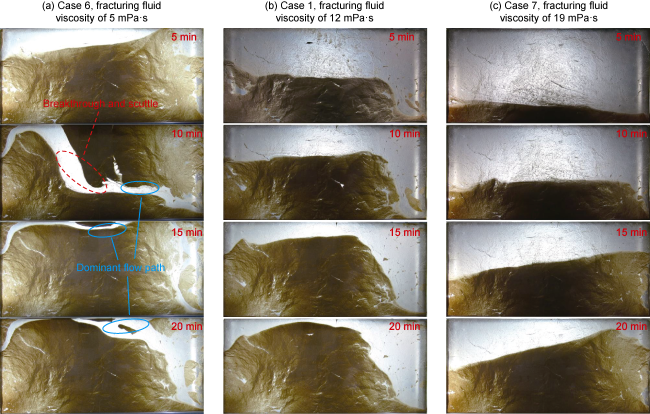

Observation of the experimental images shows that the occurrence of bridging and the formation of unfilled zones when the proppant is transported in a rough fracture is the most obvious feature that distinguishes it from its transport and placement behaviors in a straight smooth fracture. The roughness of the fracture surface has the most direct impact on the geometry of the flow channel

[30]. Taking the fracture with an average width of 2 mm in the experiment as an example, a schematic diagram of the fracture width variation is provided in

Fig. 6. For a smooth fracture, local width reduction occurs at the location where the flow channel becomes tortuous, with a greater reduction at a location with increased tortuosity, which causes bridging of the proppant (

Fig. 6a). Given the same channel shape, the effective width of the rough fracture at the tortuous position is smaller than that of the smooth fracture (

Fig. 6b), increasing the possibility of bridging during the proppant transport. Due to the effect of roughness, the hydraulic aperture of the fracture is usually lower than the mechanical aperture

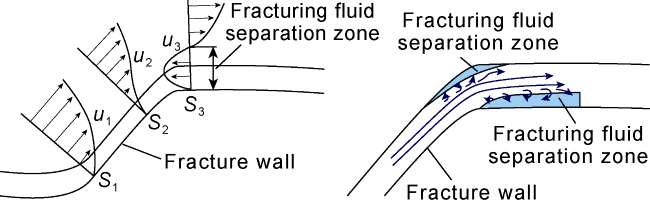

[31]. According to the boundary layer theory, it is known that when the sand-carrying fluid flows through the turning of the flow channel, as shown in

Fig. 7, there is a favorable pressure gradient at the point

S1, and the pressure force acting on the fluid particle is in the same direction as the flow direction. After the fluid passes through the point

S2, the pressure gradient is positive, and the pressure force acting on the fluid particle is opposite to the flow direction. Under the dual effect of the reverse pressure gradient and viscous resistance, fracturing fluid separation begins to occur at the point

S3, thus causing flow loss, which is not conducive to the transport of proppant. Therefore, the proppant is more prone to generate bridging and buildup at the tortuous location in the rough fracture.