The use of horizontal wells is now an important procedure in the petroleum industry. Although the production of horizontal wellbore is larger than that of vertical wellbore, the cost of horizontal drilling is expensive compared to vertical drilling. The increase in production in the horizontal wellbore is affected by many factors such as the flow patterns that occurred due to the difference in the flow rate of multiphase inside the horizontal wellbore, which induce pressure drop in the wellbore and thereby affect the production. Doan et al.

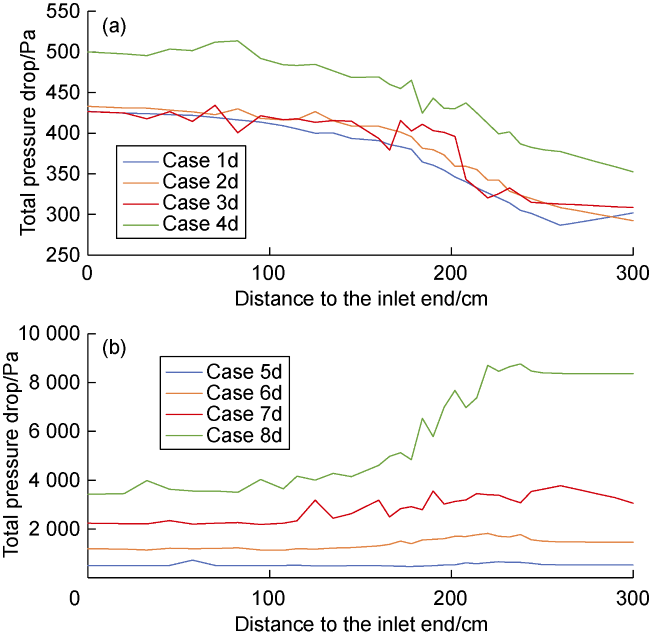

[1] indicated that the casing perforation affects the oil production because it causes pressure drop. Marett et al.

[2] investigated the friction through perforations by using Darcy law and friction flow that occurs in the horizontal wellbore. It was elaborated that the production was affected by friction pressure drop, which occurred along the perforated horizontal wellbore. The friction may cause an increase in the fluid that enters through the downstream region. However, the fluid flow may be reduced by passing it from downstream to the upstream region at the end of the horizontal wellbore and perhaps induce the reverse flow. Brekke et al.

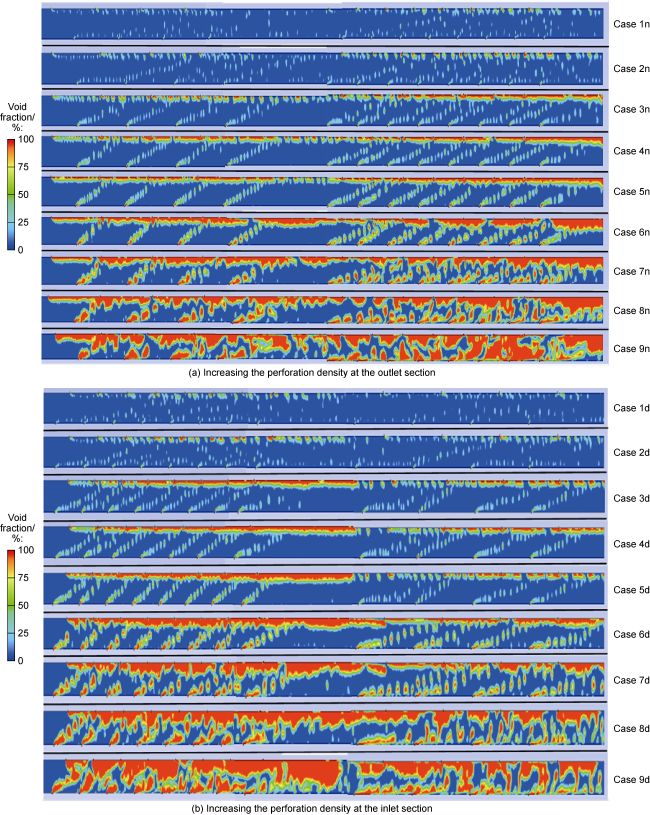

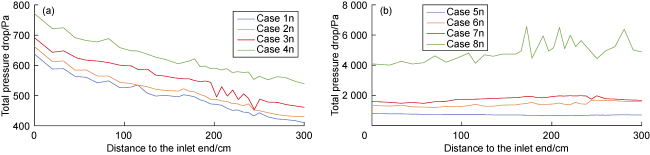

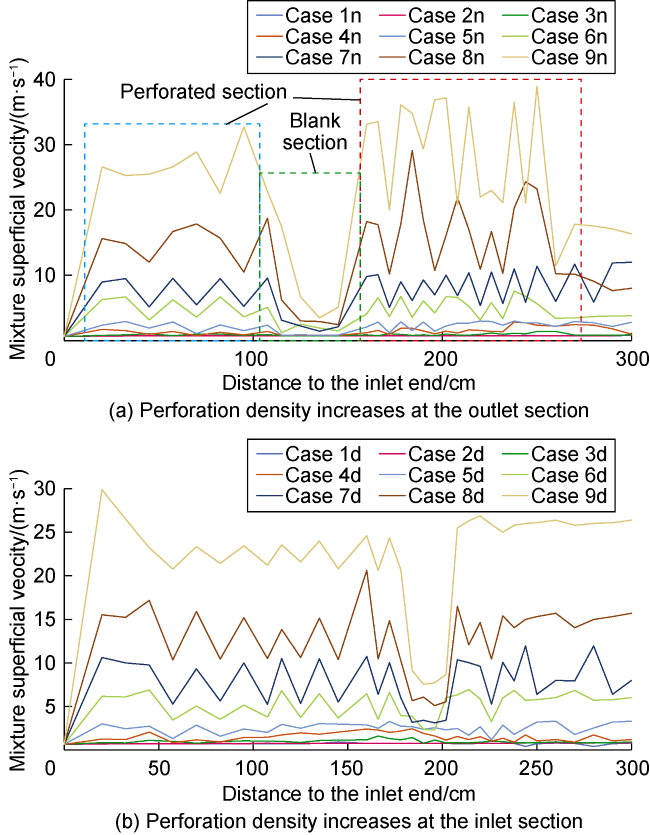

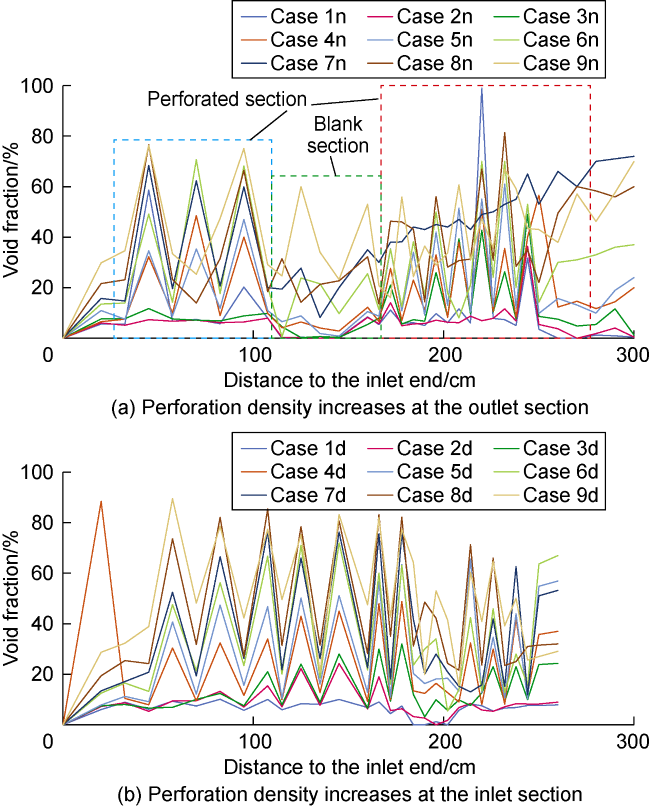

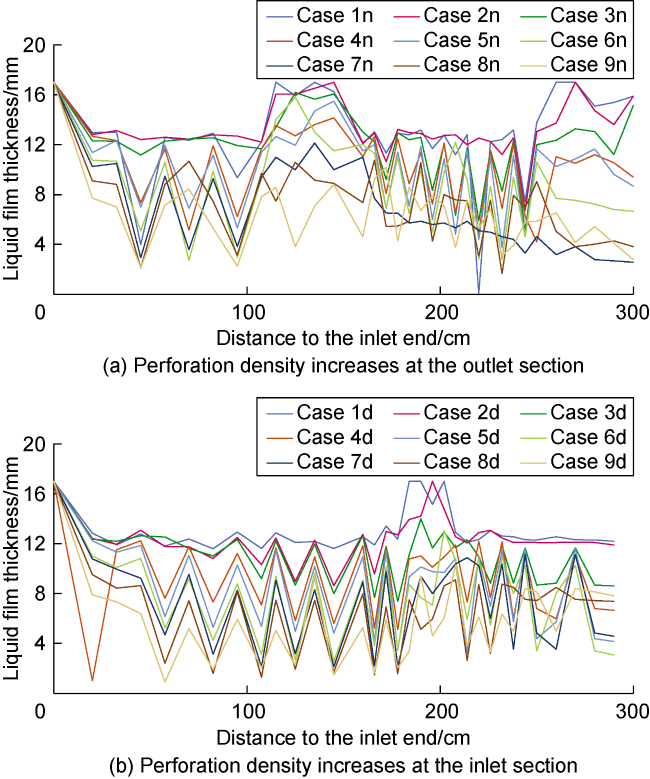

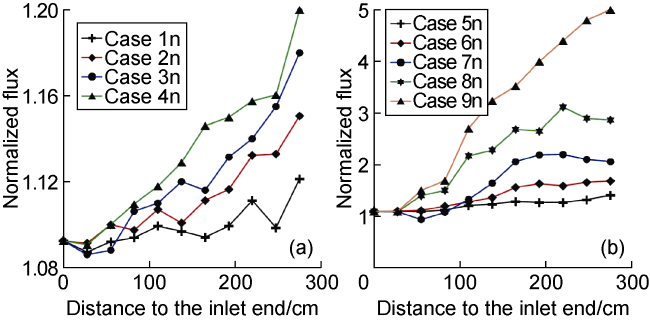

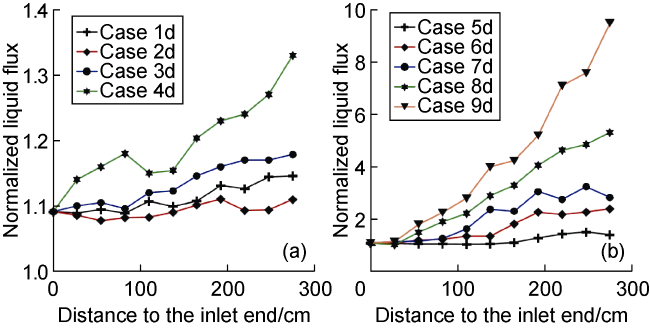

[3⇓⇓⇓⇓⇓⇓-10] illustrated that when incrementing the density of the perforations, the friction factor increased too. It has been observed that the friction factor was increased with the turbulent flow and drag effect. Olson et al.

[11⇓⇓-14] investigated the relation between friction pressure drop and flow through perforations (radial flow) in a perforated horizontal pipe, and illustrated that the friction pressure drop increases with the roughness or perforation density. Arshad et al.

[15] utilized pipes with different diameters to study the pressure drop and production through the horizontal wellbore. It was observed that the pressure drop was almost constant along the wellbore through the large-diameter pipe, and this can be attributed to the low flow velocity inside the wellbore. Moreover, it was noted that the friction factor was found to be insignificant in production when different diameters of pipes were used. Novy

[16] remarked that an increase in the diameter of the wellbore might reduce the friction and hence increase the production. Liu et al.

[17-18] studied the production in horizontal wells and observed found that the production depended on the thickness of the reservoir and wellbore pressure. They applied a new method to the four adjusting wells in the Bohai B oil field, and the errors were little enough to be used in determining the production in the offshore oil field. King et al.

[19⇓⇓⇓⇓⇓⇓⇓-27] investigated productivity through the horizontal wellbore, and observed that the production was dependent on the length of the wellbore, reservoir anisotropy and perforation density. The production was found to increase with the increasing of these parameters. Tang et al.

[28] and Du et al.

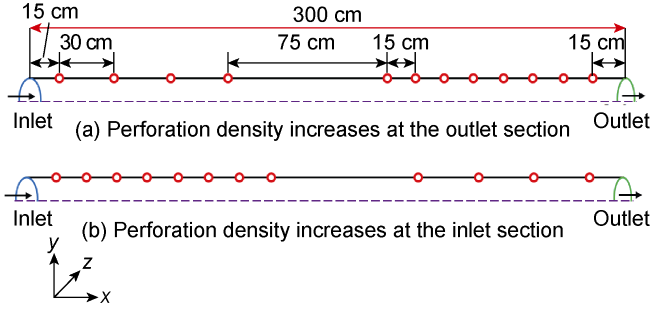

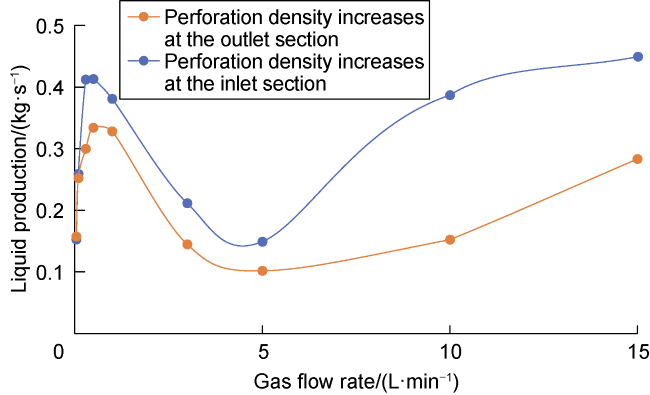

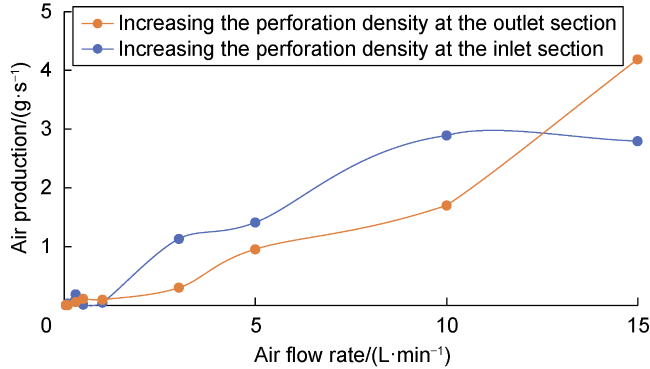

[29] studied the production and flow efficiency through horizontal wellbores using slotted-lines or perforations, and they observed that the perforation depth and perforation phase angle have a lower influence on the pressure than perforation density, and the effect of the slotted-line was less important compared to the perforations. Moreover, the production increased when the density of the perforations near the heel region (perforations at the outlet section) of the horizontal wellbore increased. Dankwa et al.

[30] investigated the production through the horizontal and vertical wellbores. It was observed that the production increased with the wellbore length in the horizontal wellbore while vertical productivity is unaffected by the wellbore length. The production was increased by increasing the thickness of the reservoir through the horizontal and vertical wellbore.